-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

I had a 2002 Corvette Z06...which comes with an LS2.

You meant LS6, right?

-

What he said

-

I remember a time, shortly after finishing the LT1 240Z, that my wife, with me shotgun, was 'done with 3rd and reaching for 4th'... on our RESIDENTIAL street. Needless to say, I had to stop THAT. The point remains, however.... yeah, she likes cars.

-

I took the original post for what it's worth as it was presented. To me it was just to provoke a thought process that just because 'everyone' thinks something is true you should still validate it for yourself.

Nailed it.

Thank You.

-

He said to do the standard racer trick of using bearings under the spring to reduce friction and that's about the best you could hope for.

Cary

Cary,

I was just thinking about this a couple weeks ago. You're talking about running needle thrust bearings between the spring and perch right? Have you tried this? How much benefit are we talking about? Would they normally go top and bottom (of spring) or is one bearing per spring typical?

-

Guy's,

This was never intended to be precise. I kept hearing rumors of 75lbs, 60lbs, 90lbs, etc. I had reasons to believe otherwise. We did what we did to see if there was a SIGNIFICANT difference. We didn't find it in the short block. Yeah, there are a few small parts missing but not 50Lbs of them. Yes, the LS1 is lighter. *If* its 55 lbs lighter, it not in the shortblock.

-

You can't pile a bunch of parts ontop of either motor and weigh them like that and consider it myth busting... Don't get me wrong guys, YOU'RE ON TO SOMETHING... Now follow thru with it.

Do the parts weigh more installed then they do on top?

-

The big thing with a V8 is gas consumption. I still have to be able to drive this car 350 miles and not not be broke at the end of the day. With a performance V8 I am guessing I could get maybe 12mpg or upto 15 with an LSx motor.

Not true. Plenty V8Z's get over 20. My LT1/T56 240z got 28+ on the highway.

If you make big power you WILL burn fuel, regardless of engine, period.

-

Well let's just let the thread roll on. I keep reading it and I keep reading that he's being sarcastic and saying that the two idiots in their garage with some bathroom scales are wrong and that GM wouldn't have spent billions of dollars in vain.

Jon,

Don't sweat it. We knew full well it would be controversial. People can believe what they want... my Rice Crispies will still be crispy

-

This thread prompts some questions. Let's assume for argument sake that the LS1 and L98 short blocks are similar in weight. Is the major advantage in the more modern EFI and head design? The LSx series engines and especially the LS7 have such a superbly flat powerband for the power they make. Could you get close with a L98 or LT1 with aluminum heads?

Kurzahls,

One thing I hope this thread does NOT turn into is a debate about which motor is superior. For what its worth, both Paul and I feel that the LSx series is better in almost every way... you'll get no debate from us.

Glad you're back!

-

For some reason I didn't open this thread initially... glad I did. Congrats to all of you.

At 21 I married the coolest woman on the planet (aside from yours

)... 15 years next month.

)... 15 years next month. -

Any opinions or other ideas?

Flying lessons?

-

Ron Tyler: Actually if you go to Z***.com you will get that.

...and I thought I was on to something.

-

I'm not crazy about convertible S30's... but if I was, I'd like yours

-

Olderthanyou,

There is no right or wrong answer.

If there's something that tickles you, use it.

If you want to get into the nitty-gritty of each, search.

Another way to look at it... In about 5 years I'm going to start a forum called "NonHybridZ". 8 people will subscribe.

-

Cary,

In your linked pictures, the rear (outboard, toe link) pivot is not substantially supported vertically. Jon doesn't seem terribly comfortable with the extra side loads this would impart on the strut. If I read you correctly, not only have you driven the car in that configuration, but you're also doing it again on the revised car?

What are your thoughts on the increased side loads?

Thanks,

-

Jon,

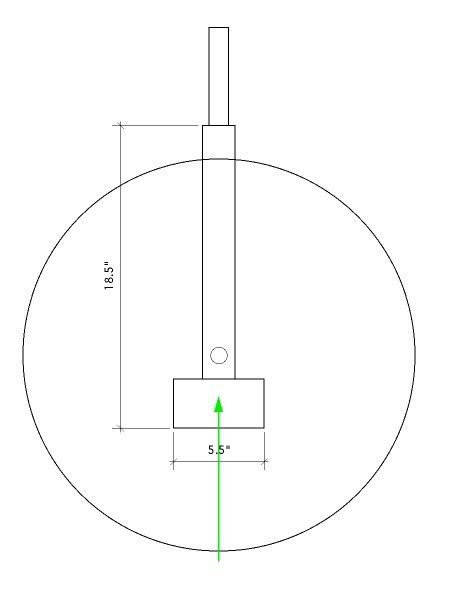

Something was bugging me about my numbers... I went back and found an error. 189LBS should be more accurate. I edited the previous picture to reflect that.

Sorry.

-

-

The spindle is in front of the strut.

Opps

I made an effort to calculate this out. I don't expect it to be exactly accurate, but I think its close enough for the purpose, just as 3g's is probably close enough... I come up with 189 LBS.

-

Jon,

The thing that I struggle with the most, with the track that you are on, and I think we've discussed it in PM, is that if you succeeded in making all the suspension components absolutely rigid (to reduce the longitudinal stiction) then all the mounts in the car have to be PERFECTLY aligned. If you succedded in that, then there can be NO flex in the chassis. If there is, then something else has to flex.

-

It'll still get wet and read inaccurately.

-

Jon,

I started drawing this (instead of studying like I’m supposed to be) and quickly came to realize that it doesn't matter (at least with the perameters you gave). *IF* the spindle is in the center, then the loads are the same on each side. The only way they’ll be different is if there is an imbalance. So what imbalance are you concerned about? Friction, braking, accell, the pot-hole? I might be able to figure it out with more info.

-

From the jist I'm getting is that I need to put the IAT right before the fuel injection point which is acctually really easy for me so I'll probably put it there.

I think you're in an unusual position to do what I described. There is one flaw that I see though... If its too close to the injector, you could easily get fuel on the IAT sensor due to reversion. Not good.

-

I think I'm in the process of building a car serious enough...

Can't someone with some math skill (this precludes me) figure out what the actual loading would be?

I *might* be able to figure that out but I think its more complicated than that... wouldn't the spring and shock rate be a factor? (its the reaction force right?).

someone PLEASE convince me to stay L6!!!

in Non Tech Board

Posted

Listen to Pop.