-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

So are you saying I can run distributorless ignition with a modified/capped off dizzy??

In a nut shell, yes. Obviously it requires an EMS that's suitable. I'm not even going to pretend to guess at all of them that do or do not support this type of trigger.

Hmm... but isn't one of the problems is play in the dizzy drive shaft that can cause bad timing/signal in the first place??

For what its worth, I did some preliminary testing a while back. I ran magnetic sensors on both the crank and distributor drive. Long story short, I found that most of the scatter associated with a common distributor was in the 'plate'... the mechanisms for mechanical and vacuum advance were significant contributors. A dual channel O' scope, on both mag. sensors, minus the advance mechanisms, showed an average of plus/minus 1 deg. scatter. Not F1 territory, but certainly satisfactory for most of us earthbound folk.

-

You're modified ZX disty now provides cam position information to the ECU?

Yes.

Can you describe the output waveform?

7 pulses per revolution, square, 12 volts.

Leading edges 120 (crank) degrees apart, trailing edges variable (depending on disc). Used in this manner, rising edge is the ONLY option. I'm running this sensor at 12v with a pull-up resistor. In retrospect, I'm reasonably confident that it will work just as well on 5 volts (more chance of signal noise, though).

Is there one wider pulse that indicates TDC on piston 1 during the compression stroke?

No. Two quick pulses, hence the additional drilled hole. See above picture (red arrow). Wolf looks for the sync pulse to fall within a specified 'window'. It ignores anything outside of that window (as a sync.).

How many pulses follow before the next TDC pulse?

One pulse per cylinder, plus one sync pulse. Total... 7.

You can fire two igniters with one ignition output of the wolf. You can also do the same with MS.

Yes, but that prevents you from individually timing independent cylinders. V500 allows complex timing and fueling on a cylinder-per-cylinder basis.

What size injectors are you using

19lb., 15 deg. Ford's

and how is the idle quality?

Quite good!

The V4.0 units improved this greatly.

Yup, .003ms resolution is some of the best in the business. V500 carries on this tradition (this particular system is V4+, BTW). We've gotten an E30 BMW M3 with 750cc p&h injectors to idle better than OE.

I have not seen a V500 unit, and was wondering how it faired.

V500, is an ENORMOUS step up in power. And frankly, both of these pages combined barley whisper the advancements made to V500...

V500 Specs....

http://www.wolfems.com/component/option,com_docman/task,doc_download/gid,25/Itemid,48/mode,view/

V500 Highlight sheet....

-

I always viewed him as harmless... guess I was mistaken.

-

But one of the problems with the stock 280ZXT distributor is that it does not have a reference mark for #1 position.

So... you want me to give away ALL my tricks?...LOL

I drill a .100" hole about .040" after cylinder one slot, as below...

This provides the 'sync' pulse for cylinder one.

Note: The above disc is a Z32 CAS I modified for the same purpose. It is slightly different in that all 6 slots are differently sized. The 280zxt's slots are all the same width. Its irrelevant, as long as you configure the trigger to rising edge.

That is why people keep telling me that I would have to use a 36-1 crank sensor.

And if you use that 36-1 crank sensor solo, you'll be stuck with batch fire & wasted spark. Gotta have a cam sync. if you want sequential injection/sequential ignition.

-

With the head work and the Wolf EFI, what are you estimating the hp level?

I'm going to save actual numbers for the dyno

"A Nissan optical cam sensor provides the trigger"

"A Nissan optical cam sensor provides the trigger"i was wondering if you had a pic of this.

I don't have any close-ups. You'll have to settle for this...

I was wondering the same about the optical sensor providing the signal to the COP system.

I was wondering the same about the optical sensor providing the signal to the COP system.The CAS is not directly linked to the coils. The job of the CAS is to tell Wolf the exact position of the engine. With that information, Wolf knows precisely when to fire each ignition channel & each injector channel.

I used an Infiniti M30 distributor in this case, due to convenience. It only required minimal modification to adapt to an L-series. A better solution is to use the distributor from a late 280zxt as it already fits 'the hole'. Just chuck the cap & rotor in the round bin and machine a new aluminum cap, per the picture

-

So coils from any 2000 or later GM Vortec V8 have the igniters built in.

I've seen a number of variations of Denso coils. If they are 4 wire, they should have dumb ignitors built-in.

-

so would that mean then that a centrifugal S/C would be geared toward the higher RPMS as a turbo is?

As Pete mentioned, a turbo is not mechanically connected. In theory at least, a turbo can make peak boost at a low RPM, and then bleed off excess at higher RPM's. That is the function of the wastegate. At higher RPM, the wastegate reduces the exhaust volume getting to the turbine by bypassing the appropriate amount for the circumstances.

And if the last sentence is true, then it's only reason for it being called a S/C would be because it's driven by a pulley,

Not entirely. They are ALL "superchargers". Super, in this case, means 'more than'. 'More than' meaning... more air is processed than would be without the 'device'. The term "turbo" implies that the supercharger is driven by a turbine.

-

Thanks Guys.

THE Z LOOKS FANTASTIC!!!Im currently building a coil set up similar to yours, do you have any pics of how you ran the water pump inlet/ head return line with that set up?

Tommy,

I'm afraid I didn't take any pictures of that (and the car is no longer here). However, I think a description will suffice. I welded up a tee and inserted into the lower radiator hose, angled it towards the frame-rail a bit, and ran a 5/8" hose along the frame-rail. Fastened with Adell clamps.

Which coils did you decide on?

What vehicle can I get those coils from, and do they have the igniters built in?

What mods were done to the engine (CR, pistons, cam, etc.)? Been on the dyno yet?

Pete,

The coils are 2000 Chev. Suburban. Electrically the same as LS1 coils, just re-oriented low voltage connector. Ignitors are integral... Wolf drives them directly. Fully saturated in 5.6-5.8 ms. Paired up with Magnecor wires.

The engine has a Braap massaged P79 head running flat-tops. CR is 9.0:1, with a stock cam (for now). Header is 6-1, exhaust 2 1/2". Aluminum flywheel. The car is anxiously awaiting a dyno session.

-

Wow ^^^. I was gonna say E30 with a latter M3 motor...

You mean like Andreas's car...

.

.

With 950hp...

Last I knew, he was at 963hp. Run's 10.4's at the strip.

To clarify, its not a later M3 six. Its a 3.8 (M50 I believe) out of a 5-series coupled to a T-56.

-

I'll start with one...

I think a car built similar to this E30 BMW would be a hoot... under 2200lbs, and about 450hp...

.

.

.

There are a few things I'd do differently. But the concept is pretty close.

Of course a 'must have' would be an LS7.... perfect... sub 2200lbs with 550 easy HP.

-

I'm with wheelman... Too many people try to attach morals to cars. In the 'BIG' picture, it just doesn't work.

-

Years ago, I used a 2D system, when 3D was less popular. These day's I don't see the point. Its kind of like inventing a black & white Plasma screen TV... nice, but ultimately 'not it'.

Don't discount the value in proper ignition control, particularly on a modified engine. If you use the factory curve, you WILL sacrafice power. Power, response, and reliability are just as influenced by proper timing, as proper AFR.

Its a small step in effort, but potentially a huge leap in performance.

-

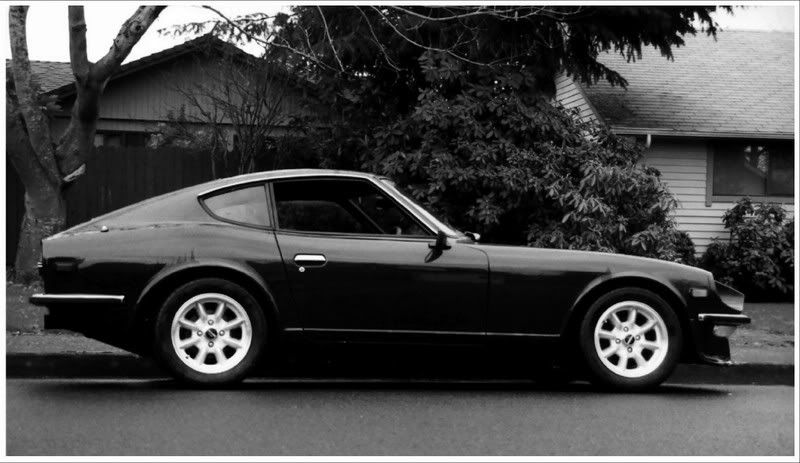

The daily driver...

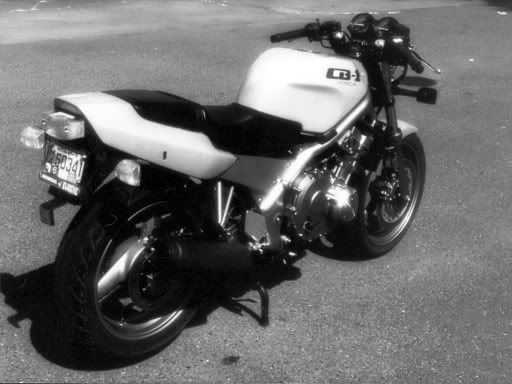

The "Other Woman"...

.

Some of my favorite past rides...

http://forums.hybridz.org/showthread.php?t=118147

.

.

.

.

.

.

-

Mike and Terry Hintz took delivery of thier newly Wolf’d 280zx today.

Nearly two years ago, their immaculate silver ZX was involved in an accident...

Being beyond reasonable repair (racked the entire chassis, head to toe), they decided to find a donor chassis for thier drivetrain/suspension/interior.

This is the car they agree’d upon...

.

.... and thus began the pursuit.

Mike and Terry decided they wanted their classic car... essentially new.

In 22 short months, Mike turned water into wine...

.

.

His diligence is inspiring!

Eventually, He asked me to spend a 'little' time under the hood. We opted for a Wolf3D EMS system with a couple bells and whistles.

Arriving at our shop...

.

A Nissan optical cam sensor provides the trigger, with 6 coils (Denso) and semi-sequential injectors. A Rusch Motorsports head, intake manifold, fuel rail, and 14mm injector conversion, ceramic coated intake and exhuast manifolds, 2.5” exhuast, 60mm TB, fresh 5-speed, coupled with an immaculate interior.

.

.

.

.

.

Of course a fully rebuilt suspension including ball-joints, bushings, springs, bars, and dampers have been added to 'top-it-off'.

Mike had this to say...

"Terry and I took possesion of our born again ZX this evening. After spending the past 22 months strippng the old zx down and rebuilding the the new one it is a great feeling to have it road worthy again. Quite a bit has taken place during this entire ordeal.

I owe a great deal too several people. Both Ron Tyler of Prime Engine Management, and Paul Rushman of Rushmotorsports, both located in Sandy, Oregon are the main contributors. Without their help this project would never have come too pass.

The car is totaly awsome! It has been transformed from the respectable silver sports car is was to a fire breathin rip snortin heart stopper.

Mike Hintz"

-

so can i set up a secondary control circuit in another little box stashed somewhere... and tell wolf3D that if the temp of the intake is within temp range (A) it will send out a shot of water... and if the temp jumps into range (

, the output on the wolf dedicated to this function will change the voltage signal to a higher number, so that the control box i've made can read that higher incoming voltage and adjust its own signal that it sends to the wolf input, and the wolf computer will tell either a second or third output to activate, based on what the control box has fed into the wolf?

, the output on the wolf dedicated to this function will change the voltage signal to a higher number, so that the control box i've made can read that higher incoming voltage and adjust its own signal that it sends to the wolf input, and the wolf computer will tell either a second or third output to activate, based on what the control box has fed into the wolf?What you’ve asked seems more complex than what I imagine would be needed. For clarification, the primary auxiliary “out’s†will only pull to ground (whereas the inputs are voltage influenced). The PWM outputs will do just that (modulate pulse width). Depending on your “controllerâ€, this can give the perception (or 'average') of a specific voltage.

If you're trying to set-up a two stage IC cooler (based on two separate, increasing thresholds, triggering two separate cooling systems), I would use two auxiliaries for this purpose. I understand you’re thinking ‘outside the box’ so I apologize if I have missed your point. Keep in mind that there are many ways to get the same job done. If you have something specific you’d like to accomplish, let me know and I’ll have a go at it.

-

-

Methanol attacks aluminum.

Methanol attacks aluminum.

-

Or... you could go aftermarket EMS and ditch the MAF altogether. Just thinking aloud

-

-

Paul tossed me the key's a couple nights ago. Being the gentleman that I am, I graciously accepted

. So, I took my wife for a short drive and I can report... that Z is a Sweetheart!

. So, I took my wife for a short drive and I can report... that Z is a Sweetheart! -

I don't think you can do it in an NA Z32. Not even the mighty BRAAP could pull this one off...

I agree, I don't think he's got what it takes

-

Hey Ron, I recently got the plug in wolf V500 for the RB25DET but have had the worst time finding someone to give me help with it.

Chris,

This is unfortunate. Wolf works very hard at preventing this. Some people seem to slip through the cracks, though. Lets get this taken care of... you've been PM'd

-

Here she be.. ’93 N/A coupe,…. We are quite happy…

:trippen:

:trippen: -

are you basing what you've said on the WOLF unit? because that sounds quite elaborate compared to say... SDS EFi, which i think has 1/4 of the aux in /out that you mentioned

Yes.

you mention all these aux inputs and such, but im sure each of the mentioned ECU's has that.

Not necessarily. Some don't have any. Some only have a few. Last time I used SDS it didn't include any and their site doesn't currently list any. Further, some have only remedial control over their aux.'s. Wolf has multidimensional control, i.e, you may choose multiple criteria to be met in order for 'action' too take place (based on virtually any parameter... RPM, air temp, water temp, boost, MAP, TPS, etc, etc.)

but which one has better features to take advantage of those is what I'm asking.

*That* is the sticky part...

First, trying to empirically and indisputably declare which system has the *better* feature set is impossible. For example, I can appreciate individual cylinder tuning. It has value to me. The higher the specific output of an engine and the closer to the ragged edge you run it, the more important this feature is, for both power and, more importantly, reliability. Another example is voltage compensation, not all systems allow you control over this curve. I refuse to own a system that doesn't. Its part of what leads to consistency. Consistency leads to power WITH reliability . If you're trying to squeeze every last drop, these items are important. BUT, If you don't have the means or desire to take advantage of these features, its a waste. Every feature, as Bernardd suggested, falls into this trap. If it doesn't blow your skirt up, its meaningless. I currently have two L28 powered Z's in the shop receiving Wolf transplants. They are both being installed/configured differently, each one ignoring different features, while taking advantage of others. Why? because each owner has a different priority set.

Second, 90% of everything you hear about EMS's is opinion based. I have tried to avoid opinion as much as possible throughout this thread. Since your backing me into a corner, I'm going to give you some opinion... Wolf3D is one of the most full featured, flexible, and capable systems available. Money aside, it is a good system. If you factor in cost, I'll pit it against ANY system in its price range. V500 spec's out very well. Its also a delight to tune. It is not without flaws... no system is. However, of all the systems I've jumped in bed with, it has the highest ratio of right-to-wrong I've yet seen. Thats my opinion. You can trust it or discount it, your choice. Of course, the average person will say, "But Ron, its in your best interest to say such things... you stand in a biased position". My response to this is simply, I fell in love with Wolf... and THEN became a dealer.

If you force me into giving you a "Black and White" answer... I'll tell you that all the features you need, and more, come in Wolf3D

how recent is this book?

That is a very good book.

And after looking at the Haltech E6X, It looks like the Wolf3D is a much more robust unit, by comparing the feature sheets.

I agree

Wolf'd '79 280zx

in Nissan L6 Forum

Posted

There is a possibility that I may. I'm currently booked solid for the next 4-5 months. After which, I would consider building a few. However, its child's play, even for a newly employed apprentice machinist. If you're looking to get one made, just take you distributor to a couple shops an ask what they'd charge.

There are a number of ways to address this...

In post #7,8 and 9, Pete and I glossed over this. These particular coils have 'dumb' ignitors built in. Nothing else is needed.

However, if there is a coil that tickles your fancy, that has no ignitor, there are options. I sell 2,3 and 4 channel, Bosch type ignitors that have proven to work well. These will drive most common coils. While its not been tested (to my knowledge), I suspect a bank of VB921's would also work.

I also sell J&S Safeguard. For use with/or without ignitors. The Safeguard interfaces with Wolf seamlessly. This unit will independently listen to and retard individual cylinders on an as-needed basis, resulting in a quasi-custom timing map for each cylinder. Using a single knock sensor with a 'smart' processor, it can hold EACH cylinder just below its knock threshold, on the fly.

http://www.jandssafeguard.com/

http://www.jandssafeguard.com/safeguard.html

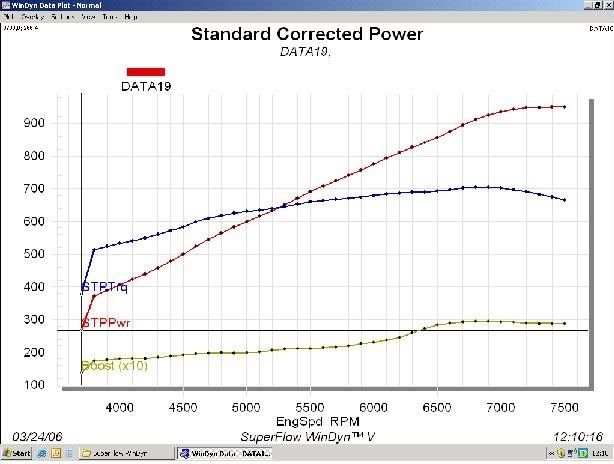

Here's a nice graph to drool over... peak power is only slightly improved but the average power gain is impressive...

This graph demonstrates the advantage's using high octane fuels, but it also implies that a bump in compression ratio, on pump gas, will have a similar effect.

The Z currently in the shop is receiving a J&S transplant... we'll see how a high compression L6 responds.