-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

Interesting post Pascal. Its good to see some diversity from the other side of the pond. However, I'm compelled to stand in defense of your miss-information regarding Wolf...

I think it would be unreasonable to blanket all generations of Wolf systems (or any brand for that matter) into one lump. I make this assumption due in part to your seemingly inaccurate claim of a singular map. As of version 4, multi-mapping has been an option through an external plug-in. V500 has it built-in. This leads me to believe that you are making claims based on an older Wolf generation. Admittedly, the older versions had limited individual cylinder tuning and, if compared to a far more expensive system at the time, could easily explain the power discrepancy. However, If you were intimate with Wolf these day's, you'd know that this is no longer the case. You'd find that Wolf has addressed this deficiency head on. In this case, it seems that old data is worse than no data.

There are a few more flaws in your portrayal of Wolf. Please allow me to clarify a few things. You mentioned that Wolf is "missing shitload of stuff" and implied that these features is what sets Motec apart... for a mere $2400 AUD. I spent a little time shopping for a Motec today. The LEAST expensive M600 I found was $3170 AUD. And, interesting enough, the majority of these cool features that Motec 'has' are not included. They are *EXTRA*. Things like Data Logging, Anti-Lag, Dual Wideband, Staged injection, Variable Cam timing, Drive-by-wire, etc. Opting for just 3 of these... Data logging ($350 AUD), Drive by wire ($700 AUD), and Anti-Lag ($350 AUD) added another $1400 AUD. I'm not gonna split hairs with you... I'll take your word for it that you can buy an M600 for less than I quoted, in the limited time I spent 'shopping'. Nonetheless, I'm not seeing this "WRC" or "Formula 3" level system coming anywhere NEAR the prices you quoted... the add-on's alone can cost more than an entire Wolf system.

Further, Wolf will do nearly ALL of these things INCLUDED in the box for around $1900 AUD (approx. $1600 US). For example, Wolf has 13 auxiliary inputs and 22 auxiliary outputs (6 of which are PWM)... how many Wide-bands would you like? Data logging built-in. With multi-mapping, Anti-lag is implied. Continuously variable cam timing is built-in. Drive-by-wire could be arranged... if you're savvy. M600 has 6 ignition & 6 injector channels. Wolf V500 has 8 of each. Granted, this is a 6 cylinder thread. But, Wolf allows you to put those 4 unused channels to work as independent auxiliary outputs. A Motec M800 (with 8 of each) costs another $350 AUD. Motec's individual cylinder trim tables (fuel and spark) have 210 points. Wolf has 2048... nearly 10 times the resolution. Boost control is the same on both accounts... 210 vs. 2048.

Forgive me for wondering about the "shitload of stuff" missing from Motec. They are BOTH formidable systems. Each with their own strengths.

Don't get me wrong. I have plenty of respect for Motec. It truly is a nice system. I can appreciate your attraction to it. For a lot of us, its price is what holds it back. For me, its simple... in my opinion, its performance is not proportionate to its price.

-

First I'd say that Haltec may in fact be 'better' than MS.

All EMS's have limitations. Do yourself a favor and take your time researching the pro's and con's of the systems that fall into your budget.

This thread may or may not help... http://forums.hybridz.org/showthread.php?t=119404

-

Several people offered advice for fixing the warped plenum (thanks!). A close friend of mine had an unusual solution... dry ice.

The warp is caused primarily from the expansion of the material with no place to go. Dry ice contracts the metal considerably, and nearly instantly, I found.

A video illustrating the rough idea... http://www.youtube.com/watch?v=4rIKo6241vg

To aid the process I capped and pressurized the manifold to 10 PSI to help the 'valleys' come up. This seemed to help a little but probably wasn't entirely necessary (air was off for the 'peaks')

The larger 'dents' towards the center came out very readily. The wrinkles at or near the welds took substantially more effort and I wasn't able to get them out completely. I did find though, through a tip from Roostmonkey, that a large portion of the stress is in the weld itself and, oddly enough, using ice on the weld helped a surprising amount.

Although not perfect, here are results...

Before...

After...

Although I wouldn't do this on a painted surface, I would recommend giving it a try. Pretty slick.

Some clean-up work and its off to be ceramic coated.

-

Idk though I'm becoming very disallusioned since my gf got a 95 325ic.

I hear ya. I own an '88 M3... It has been mostly trouble free. Some of my friends and family have various models and ages of BMW's with mixed levels of reliability... from impressive to disturbing. However, engine issues have been nearly nonexistent... I wouldn't hesitate to use a BMW powerplant.

-

That v8 sounds nice though if there is a manual tranny for it.

Its an M... a manual trans is a pre-requisite

-

I measure the S30 2+2 at around 33 1/4" and the coupe at about 29 1/4".

-

The new BMW M3 has been announced... 4.0 liter all aluminum V8, 420 HP at 8300 RPM, 295 ft/lbs at 3900... 85% of which is available at 2,000 rpm. According to BMW, it weighs 445 lbs, 33 lbs less than the base 3-Series' inline-six.

These vid's are a little lame but there are some nice sounds and 'visual information'...

http://www.bmwarchiv.de/video/bmw-m3-coupe-2007.html

-

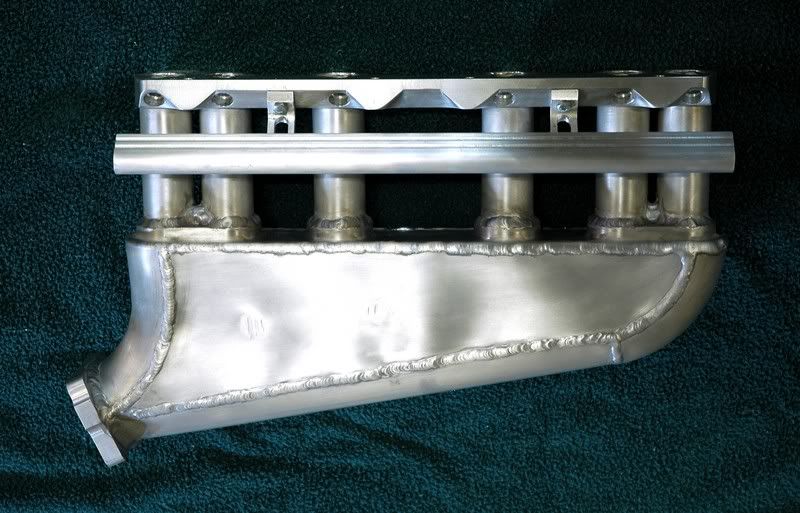

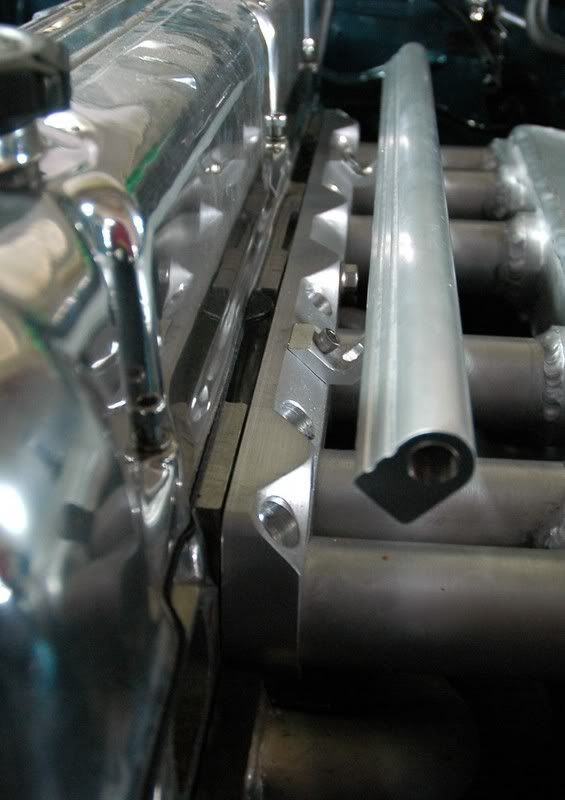

At a members request, pictures of the rail, mounts, and injector bosses...

-

-

The good news is that the manifold is fully welded and fits pretty well.

The bad news is that the plenum warped a bit. Next plenum will be of a heavier gauge... lesson learned.

Aside from having to fix my screw-up, its well on its way to being tested...

-

Measuring the dynamic current is the most accurate way (and easiest) to measure opening time. How else would you do it?

I guess I made the poor assumption that you could run the scope in series to take a current reading directly.

Will you ever forgive me?

-

Burnouts/Foggy's are so immature.

Heres a couple of mine

...

...Budget V8 280Z

http://forums.hybridz.org/showthread.php?t=118146

.

.

.

'88 M3

.

-

Hear are some measurements I made on various injectors I have kicking around.

Great work Pete!

This might prove useful for establishing battery voltage compensation tables more empirically.

Question... what is the reasoning for measuring inductively rather than directly?

-

Does fuel requirement of 15.4 sound correct for stock injectors on a L28 N/A?

Care to re-phrase that?

-

He used bathroom scales

-

The vh45de is around 100Lbs lighter than the vg30dett.

Have anything to back that up?

-

... or buy stainless. that won't cause any galvanic corrosion issues either.

I've done this on a number of occasions and probably will continue to do so in some instances BUT... according to this chart, some alloy's of aluminum don't play well with some alloy's of stainless.

The farther apart the metals are (on the chart) the less compatible they are...

The Galvanic Table

Active (Anodic)

Magnesium

Mg alloy AZ-31B

Mg alloy HK-31A

Zinc (hot-dip, die cast, or plated)

Beryllium (hot pressed)

Al 7072 clad on 7075

Al 2014-T3

Al 1160-H14

Al 7079-T6

Cadmium (plated)

Uranium

Al 218 (die cast)

Al 5052-0

Al 5052-H12

Al 5456-0, H353

Al 5052-H32

Al 1100-0

Al 3003-H25

Al 6061-T6

Al A360 (die cast)

Al 7075-T6

Al 6061-0

Indium

Al 2014-0

Al 2024-T4

Al 5052-H16

Tin (plated)

Stainless steel 430 (active)

Lead

Steel 1010

Iron (cast)

Stainless steel 410 (active)

Copper (plated, cast, or wrought)

Nickel (plated)

Chromium (Plated)

Tantalum

AM350 (active)

Stainless steel 310 (active)

Stainless steel 301 (active)

Stainless steel 304 (active)

Stainless steel 430 (active)

Stainless steel 410 (active)

Stainless steel 17-7PH (active)

Tungsten

Niobium (columbium) 1% Zr

Brass, Yellow, 268

Uranium 8% Mo.

Brass, Naval, 464

Yellow Brass

Muntz Metal 280

Brass (plated)

Nickel-silver (18% Ni)

Stainless steel 316L (active)

Bronze 220

Copper 110

Red Brass

Stainless steel 347 (active)

Molybdenum, Commercial pure

Copper-nickel 715

Admiralty brass

Stainless steel 202 (active)

Bronze, Phosphor 534 (B-1)

Monel 400

Stainless steel 201 (active)

Carpenter 20 (active)

Stainless steel 321 (active)

Stainless steel 316 (active)

Stainless steel 309 (active)

Stainless steel 17-7PH (passive)

Silicone Bronze 655

Stainless steel 304 (passive)

Stainless steel 301 (passive)

Stainless steel 321 (passive)

Stainless steel 201 (passive)

Stainless steel 286 (passive)

Stainless steel 316L (passive)

AM355 (active)

Stainless steel 202 (passive)

Carpenter 20 (passive)

AM355 (passive)

A286 (passive)

Titanium 5A1, 2.5 Sn

Titanium 13V, 11Cr, 3Al (annealed)

Titanium 6Al, 4V (solution treated and aged)

Titanium 6Al, 4V (anneal)

Titanium 8Mn

Titanium 13V, 11Cr 3Al (solution heat treated and aged)

Titanium 75A

AM350 (passive)

Silver

Gold

Graphite

Noble (Less Active, Cathodic)

-

Talk about deja vu...

.

.

.

..

...http://forums.hybridz.org/showthread.php?t=117607

-

Does anyone have any info on the ArizonaZ car 4bbl conversion.

I have a Bob Sharp manifold with Holley 390 mounted atop. I haven't put any real miles on the car so I couldn't say how 'good' the carb is. Make me an offer.

-

So Ron, are we going to again this year? It's still in Portland right?

Possibly... its Spetember 22nd and 23rd, same location, Kliever Armory in Portland.

GEARS Website... http://216.197.127.227/index.html

-

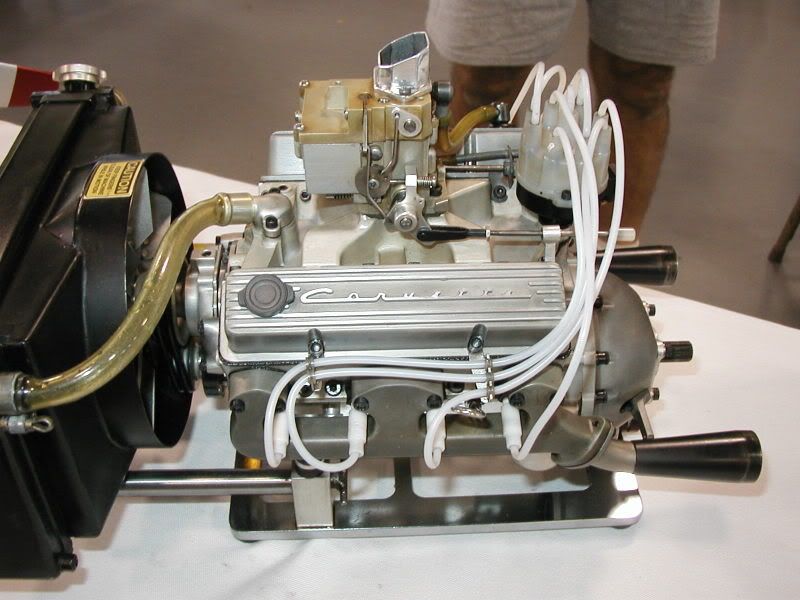

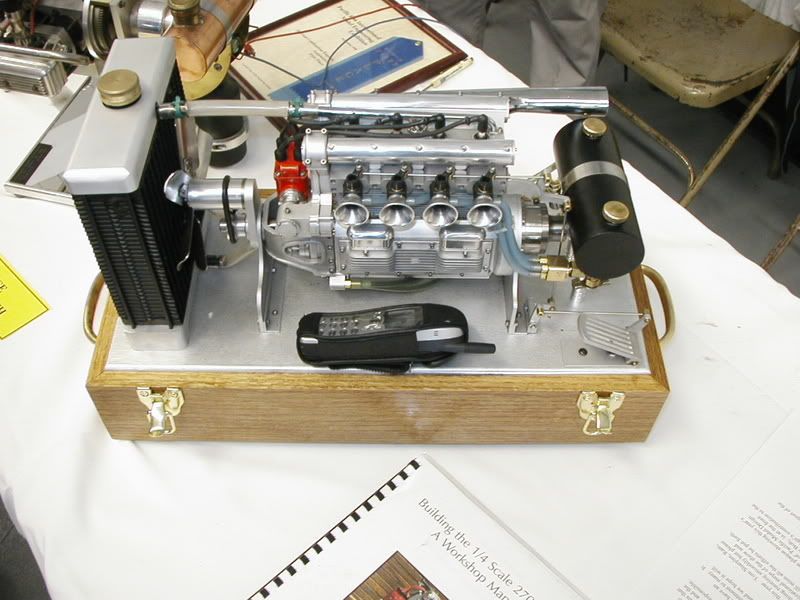

Very cool!

Not the smallest, though.

This is the smallest that I know of at 1/16th scale...

.

.

.

.

Those pictures were taken 6 years ago. The last I heard it was up and running.

A couple of my favorite MICE (Miniature Internal Combustion Engine)...

Corvette...

Offy....

.

.

I have a full set of blueprints for the Offy. One of these day's I'd like to get around to making some chips.

Braap and I have a slew of pictures from shows we've attended. If anyone is interested, I'll dig up some more.

-

To those that have used the LS1 coil packs in their L28, what did you do with the mounting bracket on the coil?

I don't know of anyone that has yet completed an L28 with LS1 coils. I believe both "Z-Ya" and "Chemicalblue" are both working on it... Pete triggering them with MS and Tommy triggering them with Haltec.

I'm using Wolf3D to drive cousin coils from a truck (part#12558693). I prefer these due to the slightly more compact packaging and the low voltage ports originating from the 'bottom' of the coil. Allegedly, they are electrically identical. I'll be shipping one to "Z-Ya" shortly for confirmation, per this great thread by Pete... http://forums.hybridz.org/showthread.php?t=120533

No modifications to the coils are necessary with the bracket pictured below...

.

.

.

Its a snug fit to be sure, but the outcome is fairly clean...

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Mount's are circled in red...

The heater hose is mounted to the top of the block with two clamps. Re-routing the hose frees up a secure place for the coil bracket. Long machine screws with .460" spacers behind the bracket stand it off nicely.

Custom length Magnecor wires top it off.

For more information about the above installation...http://forums.hybridz.org/showthread.php?t=119783

-

200 WHP would tickle me pink; I currently have modest goals.

My opinion is that 200-215 crank HP is going to be about 'it' on an OE manifold. There may be a few that that find more, but I fully expect that a small gain in peak HP will cost a large amount of average HP.

Has anyone ever spent a decent amount of effort and time, putting together an NA motor, FI, standalone engine management, and given themselves a good intake manifold?

As Braap mentioned... I'm working on it

I honestly believe that I may have a good chance at getting beyond the 170-200 HP bottleneck of the NA motor, by doing something along the lines of a dual stock TB setup on some SU manifolds, or something of that nature. the "su manifold" idea is one that came up last night, and I haven't even looked at the manifold to know if the TB would even come CLOSE to fitting, but I should be able to get a flange welded on if I need to. For the purposes of this post, lets assume the term "SU Manifold" simply means a good manifold for one TB to 3 cylinders.

I think you're on the right track. An N42 manifold's runner's are about 53% of valve area. Assuming appropriate headwork and cam, I believe the valve could flow nearly 80% of its area... choking it with a 53% runner over 7" long doesn't seem 'useful'.

I figure in the long run I WILL want to turbo this car; so the idea of dumping money into a manifold setup for my NA motor, to me, is identical to "dumping money" into a MS setup for my NA motor. To turbo it in the future, i can just replace it with an uncut P90 or dished pistons, or whatever..

This is where I might disagree with you. If you're looking for 'exceptional' performance with a boosted motor then I believe that a proper intake manifold is just as important turbo as it is NA.

Has anyone proven me wrong already? Has the NA setup been tried with a good intake manifold?

There are a couple of folks that appear to be giving a good shout on the Lonewolf manifold. It might warrant further investigation.

-

Stranger things have happened. I've seen a few people use Megasquirt for ignition control with carbed engines.

Why yes, I've done this myself

In all seriousness though, If a guy is already carb'd, relatively new to injection, and wants to make the transistion into EFI, I think its a viable consideration to start with ignition. Its *usually* more forgiving, less potential down time (or at least breaking it into smaller bites) and a real eye opener for the first time user.

-

well, since the housing is aluminum you could take it to a local trophy shop or engraving shop and have some nice labeling engraved in the cover.

I think that would be a classy solution if it had a normal finish. I coated it in VHT wrinkle finish as its tough and inexpensive. I'm afraid it would be to thick for engraving.

is there a good (affordable) online source for those?

Thermal circuit breakers come in a huge variety of prices (and quality). These particular models are fairly inexpensive.... under $10 each. They are what you find in the typical '80's Cessna. Aircraft Spruce is one of the more popular vendors.... http://aircraftspruce.com/menus/el/circuitbreakers.html

Take a look at P-touch machinesAn acquaintance of mine has one of those machines. It does work pretty well, hmmmm....

.

.

Which ECU Should I go with (FAQ)

in Nissan RB Forum

Posted

No need to apologize! EMS's have evolved so much in the last few years that its virtually impossible to keep track of who's doing what.

For what its worth, I can find something to like about nearly all of the available systems, irrespective of price. Personally, I think there are enough brands to go around for everyone

Todays 'suggested retail price' for V500 is $1895 AUD (around $1600 US). Some dealers offer club discounts, group buy's, and so on.