-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

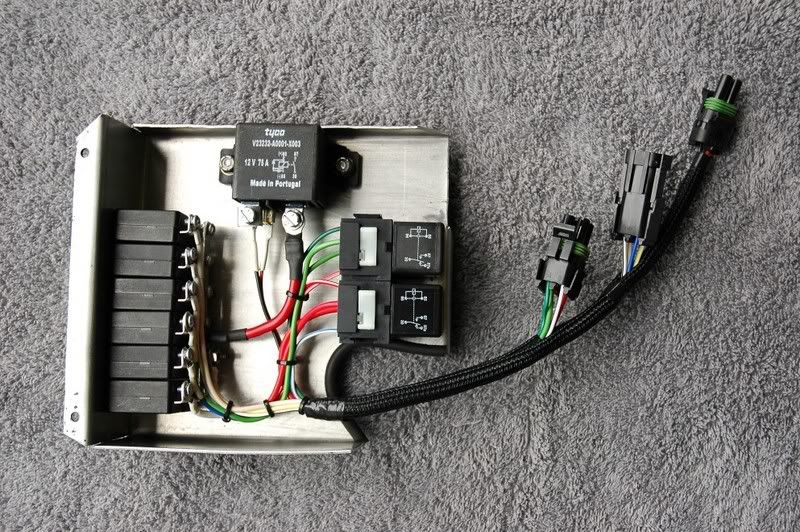

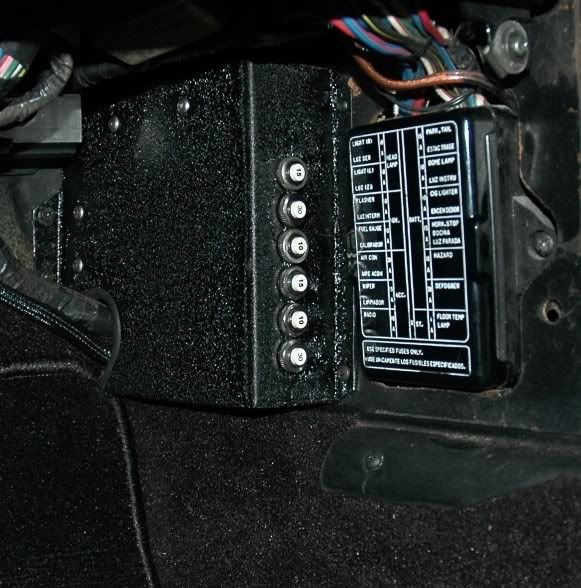

I'm trying something a little different on this next Wolf installation. I wanted to avoid the fuse box route and opted to use aircraft circuit breakers instead.

The housing itself is mounted in the passenger footwell, adjacent the OE fuse box.

I need to label the circuit breakers and I'm interested in your thoughts/experiences/opinions on the most suitable method(s)?

Pictures of the installation....

.

.

.

.

.

.

-

Anybody have any opinion on this

Sure, I've got opinions...

The effects of oversized injectors partly hinges on the resolution of the EMS. For example, MS's resolution is .1 ms. If you are running slightly lean at 1.2 ms, the next step is 1.3 ms. If injector dead time is 1ms, you just increased fuel volume by 50% (actual 'on' time went from .2ms to .3ms). If, however, you ran an EMS with resolution of say .003ms, you can now make a 1% adjustment.

The general rule of thumb for injector placement is close to the valve for idle quality, fuel economy, response, and emissions, while further from the valve generally promotes more HP. Running a staged system, even if done with equal sized injectors, could give you both worlds.

Sequentially fired injectors can deliver slightly more HP for their size due to the fact that there is only one dead time instead of two.

I don't agree with generalizing that batch is for performance while sequential is for emissions/economy. Sequential will typically produce more power at low RPM and may have a slight advantage through the midrange. At high RPM, there usually isn't enough time to get all the fuel in before the valve shuts (unless you're running monster injectors), so its tit for tat.

Another advantage of sequential that is often overlooked is that it requires that there be a dedicated channel for each injector. This in turn means (if your EMS is capable) you can trim fuel on an individual cylinder basis. No engine process's the same volume of air in every cylinder. This means, with batch fire, some cylinders may run rich, while others run lean.

-

and I hate wires.

Wires can be 'hidden'?!?!?!

.

.

-

Ron, how did you hang that plate off that supports the coils?

Bo,

There are two bosses in the block that originally hung (or is that hanged?) your heater hose. I re-routed the heater hose along the frame rail and used those bosses to support the bracket, per this picture...

As a side note, my preference is to use the truck coils in this aplication due to the low voltage terminals originating from the 'bottom'.

Pete, I have unconfirmed data that suggests the truck coils are electrically identical... if I send you one, would you care to test it?

P.S. I like where Pete is going with this thread and would hate to jack it, so any further questions/comments about this specific arrangement would best be posted here... http://forums.hybridz.org/showthread.php?t=119783

-

Nice work!

What voltage are you supplying the ignitors with?

It would be nice to see similar testing with low voltages, say around 10v, to simulate starting conditions.

4ms charge time, it has not hit coil saturation point.[/Quote]

I undertstand saturation with those coils hits around 5.6 to 5.8ms. I'd like to see that confirmed/denied.

This is where no additional output current is created when the peak input charge current continues to increase.[/Quote]

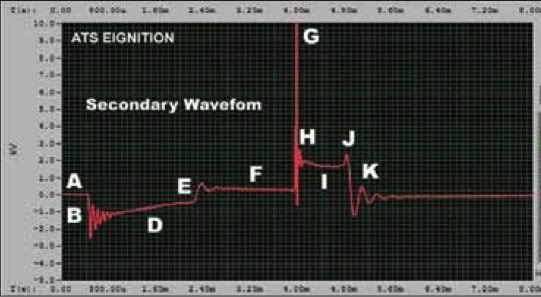

Another way to say it... where the ringing stops and the curve flattens, per this diagram, area D, yes?

This is when things will start to get hot! I will take more measurements at 5, 6 and 7ms to see what the effects are.[/Quote]

I believe you'll find these coils to protect themselves somewhere around 8ms... they dump their charge irrespective of the requested timing.

These are the coils that Ron Tyler has used on L6s with a Wolf ECU as the trigger source. [/Quote]Pete's referring to these...

.

.

-

Should the motor be straight up and down, or should the motor have a slight lean to it?

It should lean 12.5 degrees... judging by your picture, I'd say you've got it.

-

What scares me about the AEM is that I'm not an experienced tuner"YET".

The Wolf appears to be a bit more intuitive than the AEM.

The only system that I've ever used that was easier to tune than Wolf is SDS. Wolf is very intuitive. Drivability is also top-shelf... The belching and bucking stories I've seen and heard about some systems isn't 'included' with Wolf

Does Wolf have a support forum like AEM?

The short answer is no, not exactly.

Wolf systems have been very trouble free overall. This limits most of the tech support to configuration and understanding how the system works. Most of the time, the complexity of the system revolves around the configuration process. Since Wolf can interface with almost any sensor, trigger, ignition, etc, the number of choices in the config. menu can be a little daunting to the first time user. If you buy a Plug N Play, the config. will already be done. If you buy a universal fit, your dealer should help you with, or provide you with, the correct configuration. Wolf relies heavily on their dealers to provide the necessary support. You should feel free to contact him/her with your tech questions.

I don't have every answer. No one does. If I can't answer a question, I have my own 'support group', be it Wolf themselves, other dealers, etc.

Additionally any Wolf customer can contact Wolf directly via email or phone.

Of course, If enough of you buy systems, maybe *I'll* start a support forum

-

Somehow, beyond my recollection, I bumped into Ross Corrigan many years ago when HybridZ was still young. He introduced me to HZ. Shortly after, again forgetting the details, Pete Paraska 'poked' me... resistance eventually became futility.

-

The answers to all your questions can be found here. http://aempower.com/ViewCategory.aspx?CategoryID=62

I have read many spec. sheets and brochures, including the one you linked. What I was looking for is what tickles YOU. What floats YOUR boat is the goal, regardless of what's important to Careless, Braap, myself... or a brochure.

The Wolf 5 looks like a nice system as well. It seems as if thw Wolf and AEM are the most similiar. But the AEM is still "Plug & Play"

Wolf *is* "Plug N Play" for various engines, including the RB. V500 recently superseded V4 and the maps are somewhat lagging. Although, I'm expecting Wolf to be caught up in a few weeks... the transition into a vastly new product almost always incur's some teething.

-

I'm surprised that no one has mentioned the AEM ECU yet. Out of all the other systems that I've looked into, this one has the most flexability.

In your opinion, what are its stand-out features?

But if look at the fact that it is also a boost controler...Is it a flat boost controller or does it allow boost trims based on RPM, vehicle speed, air temp, water temp, throttle position, various auxiliary inputs, valet mode, others? Does it allow a potentiometer, switch (or switches) to be used to adjust boost on the fly? Overboost protection?

If you don't know the answers to these types of questions, you're not done 'shopping'

-

I plan on installing the new firmware this week.

We expect a full report

-

I don't know ANYONE who has EVER gotten a ticket for tailgating. EVER. Anyone heard of someone getting a tailgating ticket lately?

My wife was issued a warning for it... does that count

-

The main thing that is "wrong" with the stock battery location is that it is too high.

I would agree with Jon on this. Depending on the cars intended purpose, dropping the battery might be the 'right' solution. I've done this a couple of times myself...

-

My question is this: Is it acceptable to run the O2 sensor on only one bank of the engine?

Mid to late '80's Vette's ran an O2 on one bank only. I suspect most, if not all, V6/V8 GM's in that time period did (I can also vouch for 2.8L V6 Celebrities in that period). Later, with the release of the LT1, GM ran one on EACH bank... BUT, the ECM had the power to individually trim on a bank-to-bank basis.

-

I have had my drive gear pinned with a 3mm dowel.

Great advice Tony. Thanks

-

A bit more progress...

.

.

.

.

.

.

-

i was just wondering if you got rid of all the junk and the passenger side fender (carbon canister, vacuum pump, cruise control)

The carbon canister was relocated to inner right front fender well.

To my knowledge, 280zx's never came with a smog pump.

Cruise control was deleted.

is this a return-less fuel system?Affirmative.

Out of curiousity what kind of money is tied up in the car?One MEEEEEELLLLIIIIIOON Dollars!

But seriously, I wouldn't be at liberty to say even if I did know the answer.

-

IT SHOWS THAT THE FUEL PSI DROPS ALONG WITH THE INJ PULSE,

First, some respectable people are trying to help you and you are talking 'at' them. Chill, my friend.

Second, I'd like to see the log's that show the fuel pressure dropping?

-

I general, I don't sympathize with the current 'bigger is better' craze.

However, when properly engineered, there may in fact be some advantages...

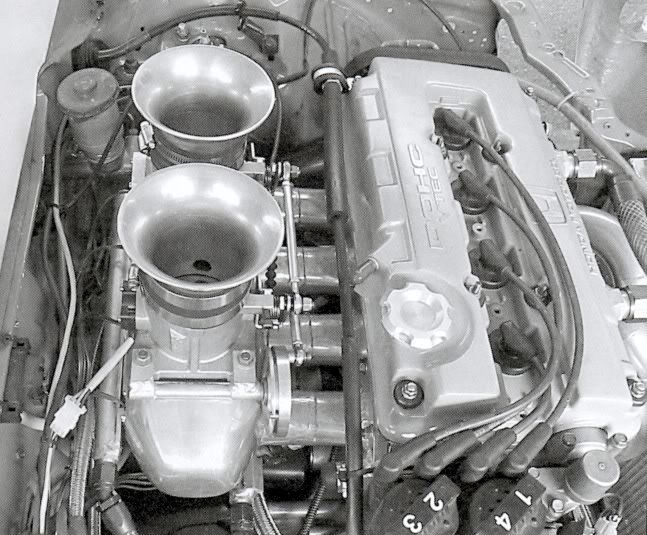

Fueling the fire....

Courtesy Mike Kokima, "Honda/Acura engine performance"

Courtesy Mike Kokima, "Honda/Acura engine performance"

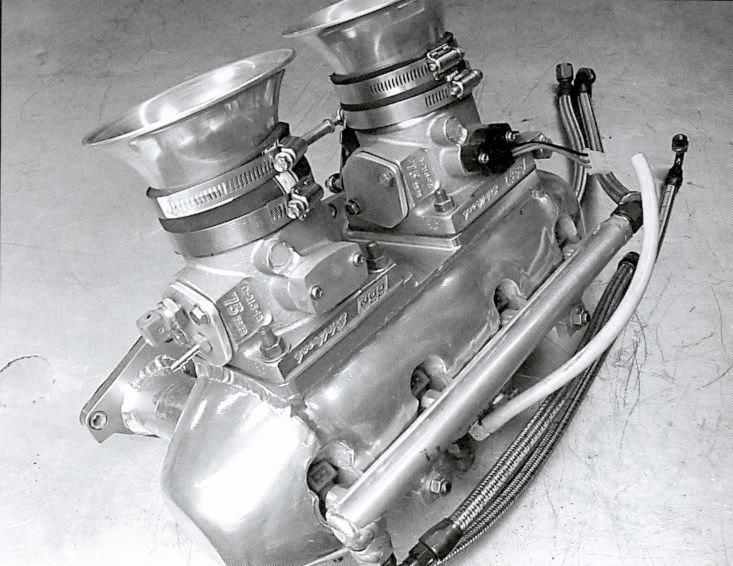

These monstrous B&K TB's are mounted to a 2.1 liter Honda that does 10.95's at 125mph... all motor. 260HP@9000rpm to the wheel's, 166 ft'lbs at 7200.

Mike Kojima... "Although they are too big for this engine when calculated, their placement helps ensure equal air distribution through the manifold and helps keep the plenum non-resonant".

-

Racetronix lists pretty competitive prices on injectors. I was thinking about giving them a whirl. Anybody have any experience with this company, and specifically, their injectors?

-

It will change a dual plane manifold into poor single plane by allowing each cylinder to have 'access' to all barrels instead of half.

-

You can say were going to make intake for car XXX and get lots of please do responses then when you publish a price,,,, even a very reasonable price all you will here is crickets.

Bullseye

-

-

Is it out on video?

Yup.

Good movie

if you were building it

in Gen I & II Chevy V8 Tech Board

Posted

Why single? You can route two exhaust systems, or you can route two intake systems. I would much prefer the later. Different strokes, I guess.

He hasn't mentioned budget, although I'm sure he has one. I say build as much displacement you can afford. All things being equal, a 383 will produce the same HP/torque on less boost AND be more responsive for its respective power.

This is the best advice you've given so far, although it still hinges on a budget that he hasn't yet established.

Why? The TPI manifold is FAR more restictive than its TB.

Massive tourqe on a boosted TPI is nearly a given. However, you might have trouble reaching that HP goal. Any efforts I've seen to push airflow through a TPI have been futile.