-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

since you're still designing, why not add a second set of injectors?

On paper, this is a great idea... small primaries, coupled with large secondaries up stream. Keep in mind the costs and complexity go up significantly... double the injectors, double the fuel rails, double the mounts/bosses, potential accessibility issues with the secondry set, blah, blah, blah.

like sequential.... one for better atomization one for direct fuel

Actually, what you're referring to is 'staged' injection. Sequential refers to the injectors being timed with the valves, opening once every other revolution. As opposed to batch-fired, opening every revolution with disregard of valve timing.

-

i love the intake design.. how can i get one for my 76 n42head???

At this time, the key word is... patience

-

Paul do you think the gain in atomization by moving the injectors back on the runner will be worth while?

My feeling is that you'd have to move them farther than you have to make it worth while, say inside the plenum, directed straight down the runners throat. Anything less than that isn't worth the extra expense and complication (don't forget the mounts for the rail). IMO, flange mounted injectors are an elegant overall compromise.

-

So you guys are going to be making fuel rails that go with it too ?

I think its fair to say as many fuel rails will be available as there are manifolds.

-

photos of this electromotive setup?

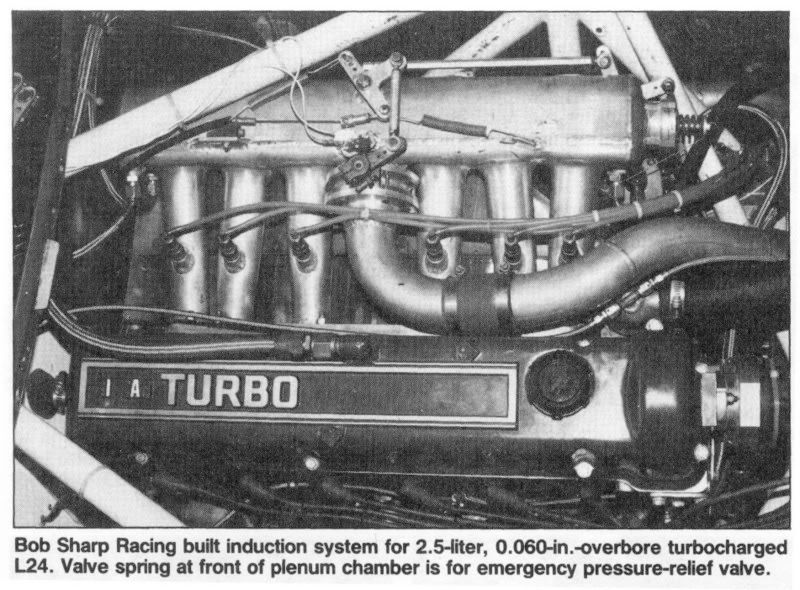

I initially thought Tony was referring to this manifold... but I see it doesn't quite match his description, save for the central mouted TB facing the head.

I'm sure Tony would like to comment on this one

-

LoL.. ya a pilot Ron?!

Roger that.

Im workn on my instrument rating right now .. commercial by the end of the summer =)

Very good!... how far along in your IR training?

I'm 'finished' with my IR so to speak... passed the written (most difficult test I've ever taken) and fulfilled all curriculum requirements. I just need to take the practical. I'm slowly plinking away at a CFI position. Probably get stretched out over years, as instructing would be primarily for the enjoyment of it.

I expect a ping when you get your IR and Commercial.

Best of luck!

-

Density altitude during the day was around 8000 feet.. so with heat soak in the cylinders and warm engine.. the density altitude in the cylinders was probably around 9000-10000 feet.

Only pilots talk that way

-

Doc, that's right up there with pooping in the tank of their toilet at a party...every time they flush, they'd be like WTF?!?!?!?!

Ohh my!

-

Sandy, Oregon.

Braap, it seems we live in the same town, do I know you?

-

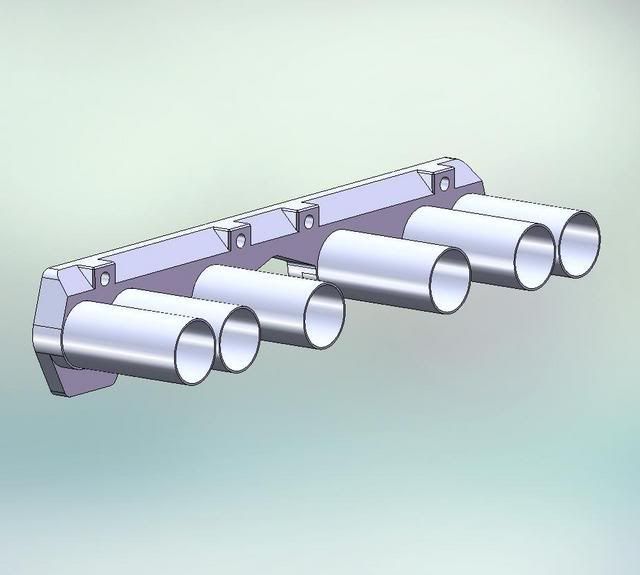

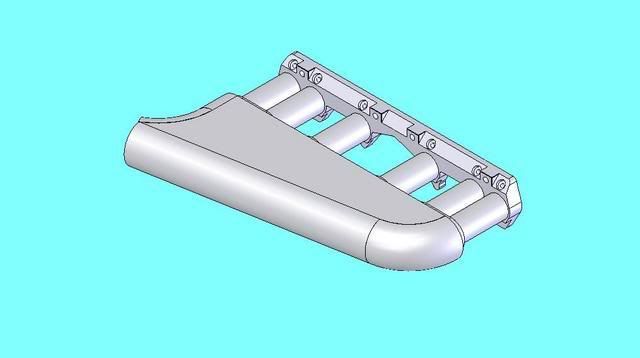

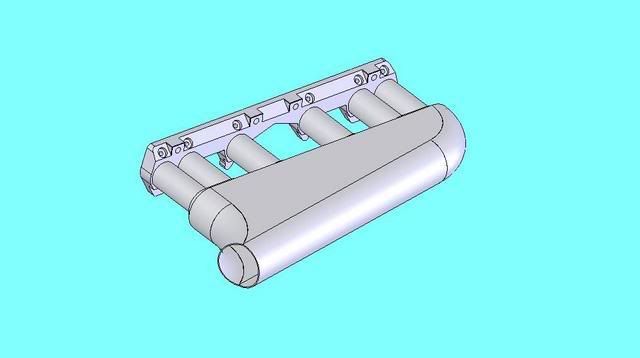

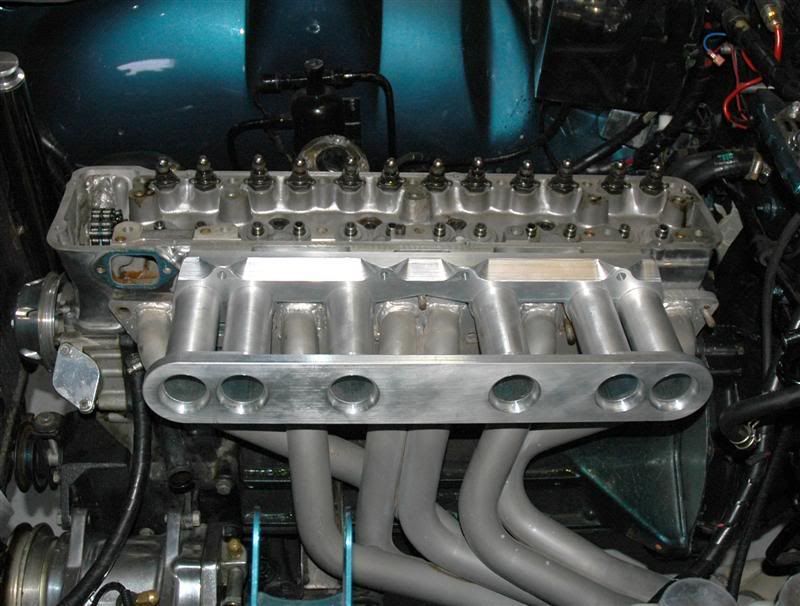

Justin Olson has been doing a pretty nice job of modeling the manifold in Solid Works...

.

.

.

.

.

.

-

Davy beat me to it... very professional welds.

Pardon my ignorance, what is the purpose of the larger upper tube size?

-

Hartley 2.8 liter V8, weighs 200lbs, develops 400 HP at 10,000 RPM, and 'sounds right'... http://www.h1v8.com/page/page/1562068.htm

-

-

Not sure what you mean. I thought the 240s and early 260s had the doors with no reinforcement, and the 280s had the reinforcement.

I believe its correct to associate the latch change with the door reinforcement... that happend circa '77, near as I can tell.

-

You could always destroke a SBC 350 to 327 and put forged high compression pistons it it with forged rods and crank. Get a high lift and long duration cam and top the engine off with individual throttle bodies

Damn it sounds easy, doesnt it?

Damn it sounds easy, doesnt it?

Don't forget the single-plane crank!

-

-

rontyler I'll be happy to test your manifold.

Thanks.

DXF is 'in the mail'.

-

ive looked at that manifold for years. thought to myself why are they all doing that instead of a "engineered" race setup!

You make it sound as if that information is readily available and, somehow, a "race setup" is appropriate for a street engine. Am I reading you wrong?

-

Maybe you two should get a room

-

It seems even a thermal barrier coated plastic intake would be a good idea. And coat the runners inside as well...

For what its worth, Finish Line Coatings refuses to ceramic coat the interior of an intake manifold... ingestion risk should any of it 'depart', they claim.

-

Looking good Justin.

I have a couple comments, if I may...

I added slight cutouts(0.050") to center the runners to the flange. Also, I added material to make the runners easier to weld up.I wouldn't (and didn't) do that. Considering the weight of the plenum, over the years, the pounding could work at the welds. None of my welds at the tubes carry any weight. I ran my tubes the full 1" depth (into the flange), beveled them, and welded them on the mating surface (fly cut afterwards). This way the flange carries the weight and the welds only 'keep it together'.

In other words, at the time of this picture, there wasn't a single weld, but you could stand on the outboard flange...

I also had this idea for the top bolt holes. Let me know what you guys think. I'm not a machinist, so I'm not sure which design is more efficient (cheaper) to machine.

I also had this idea for the top bolt holes. Let me know what you guys think. I'm not a machinist, so I'm not sure which design is more efficient (cheaper) to machine.

The above picture is what my original drawings reflected (regarding the bolt bosses). While it is more attractive, I feel that method would allow more deformity to develop in the gasket. I'm of the opinion you'll get a more consistent seal with your original, 'flush' bosses.

-

I like my women to eat meat and shave their legs, but to each his own...

-

Im pretty sure that goes to the canister on the passenger side radiator support/fender.

'tis a fact.

-

Pop,

I *thought* I saw them for sale at a nearby dealership about a month ago. I could be wrong, but I'm not sure how I could mistake identifying a car of its... um... high profile

L28 custom intake flange

in Nissan L6 Forum

Posted

Justin,

They're offset .150" from the centerline of each runner. Drawings should pretty clearly indicate which direction, per cylnder. If you need me to work on that aspect of the drawings just shout.