boosted300

Members-

Posts

302 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by boosted300

-

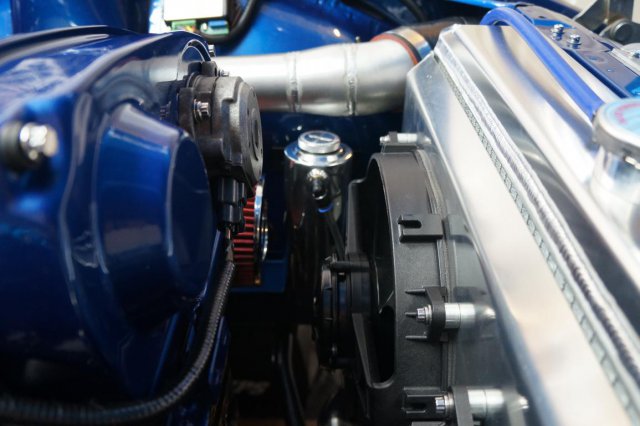

As this (RE)build was snowballing...I decided to pick and choose my battles. Although the turbo was dated and there are obviously more modern units that would deliver much higher and more efficient power, I opted to maximize this unit for the time being... New .82 A/R turbine housing...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Some random pics from the shop, just because.... Wouldn't it be nice if I could pair these two together? These look familiar...except they're for a GTR!

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

On to the fun stuff.... The turbo system! The car was using a stock RB25DET exhaust manifold and an aged GT35 with a .63 A/R and an ATP Ultimate internal wastegate. It was a simple, and easy to package, setup. Boost response was good but it obviously restricted the power ceiling. As I mentioned, the snowball was in full effect...needing to fabricate new plumbing anyway, I figured might as well get a tubular manifold for top mount and upgrade to a bigger turbine housing and external wastegate. Out with the old... And in with the new...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

I have an OCD like phobia of cutting anything on this car, but we had backed ourselves into a bit of a corner now so I acquiesced knowing that Doug would make the cut very nicely and leave it looking factory. We decided on a location just above and slightly to the left of the original hole...then marked it off carefully... Doug then cut a perfect hole in just the right location for the harness to pass through to the engine bay... Then we finished it off with a nice grommet...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Once we mounted the evaporator inside, we noticed after the fact that we had covered up the firewall opening for the wiring harness to pass through...ugh

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

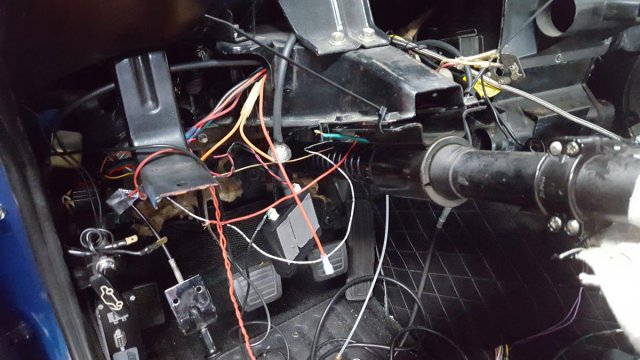

So of course the new Greddy oil filter adapter/thermostat led to a re-examination of the rest of the oil cooler assembly… We decided that the lines from the adapter to the cooler could stand some improvement…not to mention the mess of wires that surrounded it... First step is ...remove the mess of wires

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Thank you sir...gotta admit I had to look up the meaning of that saying, never heard that one but I love it!

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Pausing here for the night...much more to come.

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

So while in the engine bay moving everything around and cleaning everything up… why not get rid of cumbersome, unsightly factory oil cooler adapter and replace with a shiny, new Greddy unit with thermostat?

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

The AC system is by no means "bolt on"... So brackets had to be fabricated to hold everything in place...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

The AC unit that I received with the car happened to be the unit that is sold by the Nissan dealer as a retrofit kit. It's a draw-through system that is designed to bolt up to the air inlet of the factory blower. As such it mounts under the glove compartment. While not the easiest system to install, you dance with the girl you brung...so I went full steam ahead with it. Here is the draw-through evaporator unit test fitted...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

I also decided to improve the firewall a little by adding some Dynamat, followed by a replica firewall from the Z store, and then dressed the whole thing up with some fancy fasteners just because. Before After

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

A little research on HybridZ on AC systems revealed a blower fan upgrade utilizing a blower from a KIA. I followed the write up step by step…thanks to all who contributed to that and made my life easier. I scribed the housing, and ground it out to size. I had to slot out the bolt holes on the fan to get it to line up right. I then improvised a little and used a foam gasket from a speaker to seal the blower to the diverter assembly, it fit perfectly.

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Further inspection revealed that the melted harness extended into the engine bay…I decided not to drive it anymore and had it trailered once again to Doug’s shop. We came to the conclusion that the dash would have to be removed and we would have to re-do the harness. Since the dash had to come out anyway…I figured this might as well be the time to install the AC system. Removal of the dash revealed a rat’s nest of wiring, nothing wrapped, nothing secured, nothing organized, electrical tape and butt connectors everywhere. It was a very sloppy job to say the least…it was clear this would be another challenging project.

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

That project worked out perfectly and I’m really happy with the results. But of course, as luck would have it, I was only able to enjoy it for one measly day. On my very first drive with the new setup, after about an hour or two of driving around town, I began to smell something acrid. Next thing you know, I see smoke starting to emanate from my glovebox/dash area. I pulled over immediately, panicked that the car was about to catch fire. But as soon as I turned the car off, the smoke stopped. I inspected around the source of the smoke and discovered that the wiring harness that runs behind the dash had almost melted through. I traced the melted wire to the factory fuel and amp gauge which had been poorly placed in the glove compartment as the factory location was occupied by an Autometer oil temp gauge. The gauge had shifted around in the glove box and it appeared it was grounding out on some metal towards the back. I carefully moved the gauge into a position that appeared not to be touching anything and attempted to start the car… It fired right up and luckily drove fine. It appeared no critical components were affected by the melted wires. I gingerly drove it home. Not exactly the best luck with the car to that point! But in retrospect...what I came to realize is that "bad luck" was really a direct byproduct of poor work...this was just another step in the arduous process of working out the kinks and fixing all the mistakes...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

The actual project of installing the AC system was a hefty task to say the least, including removal of the dash, so I decided to put that off for a while so I could actually enjoy the car. With everything in place and running well, I was able to enjoy the car as much as I could for a bit, but after a while I craved really putting all of the power to use. That spawned my next project…getting the power to the ground. I did a separate write up on that here: http://forums.hybridz.org/topic/122385-275s-in-240z-factory-well-mission-accomplished/?do=findComment&comment=1144553

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

The end result was very satisfying, both functionally as well as aesthetically. The setup looks fantastic, the fans are very quiet, and the radiator cools so well that, depending on the ambient temperature, the water temp on the highway hovers around 150-160 degrees…meaning the fans never even have to kick on as they are set to come on at 180 and shut off at 170.

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

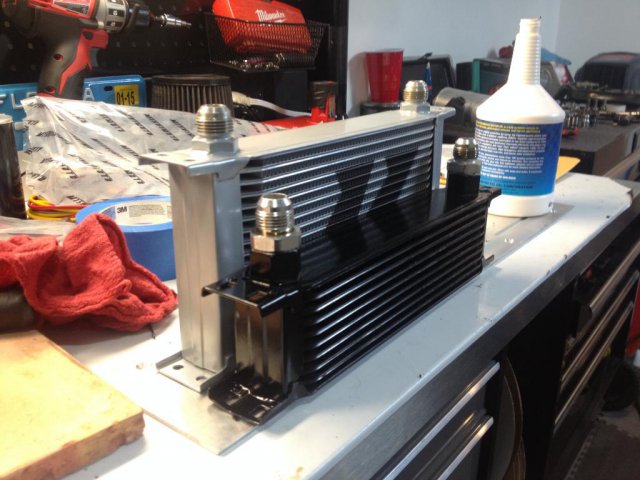

When I pulled the McKinney out, I discovered the oil cooler then car came with... Naturally while I was in there already and the radiator was out of the car, might as well upgrade the oil cooler of course. I went with a larger Mishimoto unit...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with: