boosted300

Members-

Posts

302 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by boosted300

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

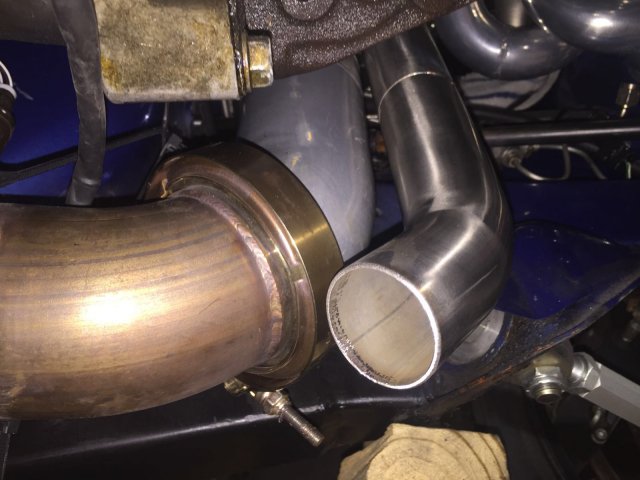

The exhaust housing uncovered was so nice, it was a shame to have to cover it up...but the ceramic coating alone wouldn't be enough to contain the heat from the turbine... One last look...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

With all the modification to the manifold, the original mounting point for the throttle cable was removed. So Doug fab'd a very sweet bracket to solve the problem...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Mostly just finishing touches from this point... Bolted all the goodies in place and then test fitting the intake...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

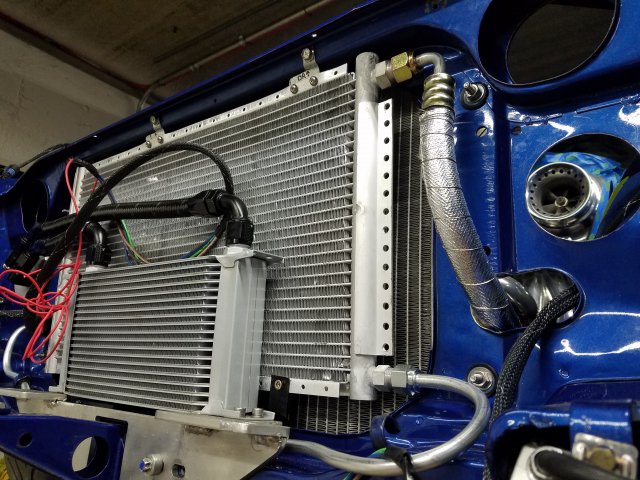

Prior to my concoction, there was continuity from the battery to the radiator...and after, there was none. Hopefully that will help keep electrolysis at bay.

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

I decided to try and defend the beautiful radiator against electrolysis as much as possible by trying to isolate the radiator from the frame, so I took a trip to Ace Hardware and experimented in the fittings and fasteners aisle. I started with a piece of rubber vacuum hose, added the components from Ace, and came up with this...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

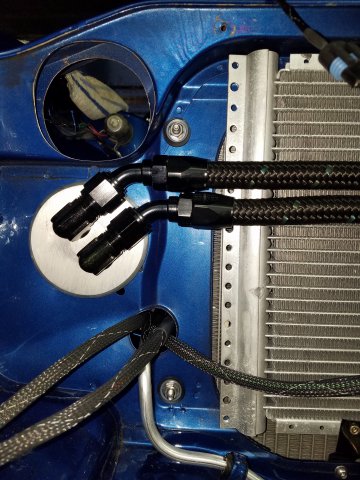

Uh...yeah...what he said! Thanks ZHoob, I'll be honest...AC is one thing I've never really been much of an expert at. I understand the basics but that's about it. I bought the kit which came with everything needed, but with very basic parts that weren't designed for aesthetic appeal but, rather, to simply get the job done, ie cheap rubber hoses and fittings, flat black dryer, etc. I decided to upgrade a bit with some dressier components, like the hard lines, from Vintage Air.

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

I'm in Miami.

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

After taking measurements, I had the lines cut and pressed onto the fittings, and Doug finished them all off with a nice heat wrap job...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Back to the drawing board...I got another set of factory lines and decided to weld some Schrader valves directly to them, along with male barbs for new lines to be crimped to...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

So I cut the lines and used the factory base to make a male base and then some vintage air parts to make functional charging ports...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Back to the AC system... The factory compressor I had, came with lines that were cut from the car, and as such had no Schrader valves for charging the system...

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

After all the mocking up, time to actually do some installing. Starting with the exhaust manifold, which should be easy enough...right?

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

Finally found a little time so I thought I continue on with the story Some mocking up of the wastegate and dump tube

- 199 replies

-

- rb25det 240z

- rota rb-r

-

(and 2 more)

Tagged with:

-

I'm really enjoying your build...love the details!

- 47 replies

-

- engine swap

- 280z

-

(and 5 more)

Tagged with:

-

A musician's therapist (The $300 Z)

boosted300 replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Never...but then again, would you want it to?