boosted300

Members-

Posts

302 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by boosted300

-

I imagine you must still spin those 315 NT05R's no?

-

Interested in the two piece door panels as well!

-

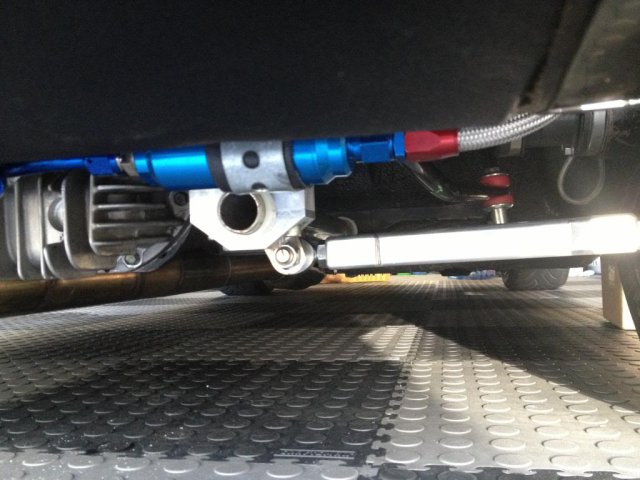

So madkaw/RebekahZ: regarding the cost of widening...ironically enough, with these wheels, it was more than the wheel itself. It was $215/each. Blu: RebekahZ reminded me of something important to note before you make any decisions. When I originally got the 17x8.5 +4, it was based on research I had done on here and in speaking to members on this board who had Rotas that I felt had perfect fitment on non-flared S30's. When I got the Rotas, for some reason they actually sat too far outside the wheel well. I came to the conclusion that it was due to the fact that all of the members on here that I had asked for their wheel size, likely had stock suspension whereas I have AZC LCAs and coil overs. In any case, since the wheels had already been purchased, I had to go through a rather arduous process of getting them to fit underneath the wheel well...kind of a backward way of doing things unfortunately. Because AZC LCAs are adjustable, I moved them inward as much as possible but it still wasn't enough, and I was limited by the length of the halfshafts which wouldn't allow me to move the arms any further inwards. I ended up getting some custom shortened half shafts from Driveshaft shop, which allowed me to move the arms in farther as you can see here: For those unfamiliar, the AZC LCA comes default at parallel to the ground, here you can see I rotated the arm's tube downward, which pulled the whole arm inward. Then I had to drill through it and insert a retaining bolt to prevent it from rotating back outward (which happened several times to disasterous effect throughout this whole process!). I did a mini write up in the Drivetrain forum, I'll look for the link. The whole process was such an ordeal, I guess I tried to block it from my mind! But nonetheless, it is important for anyone to know if they decide to try this.

-

I’m sure this has been done before but I thought I’d share my experience anyway. I found myself in dire need of traction, but apprehensive about going the ZG flare route. I agonized over this for a loooong time because, although my S30 is a resto-mod, I really had a hard time imagining carving up the panels. I absolutely love the ZG flare look…but for some reason just couldn’t bring myself to do it. I love the look so much that my goal is to eventually get another S30 and go the flare/tail/fender mirror route. Obviously not going the flare route limits options due to the size of the factory wheel wells. I also was dead set on staying with Rota RBR’s which further complicated things due to the limited size and offset options. I had 17 x 8.5 +4 which I found to be the size that best fits the factory wheel well. The look was exactly what I wanted. However in second gear, it was like driving on ice. I tried to compensate for the lack of tire width a bit by going with soft compound tires: 235/45/17 Yokohama Advan A048 – treadwear 60…but it didn’t help at all. I’d read that some had gotten away with 245’s but some also mentioned that they rubbed…in either case, I didn’t feel 245’ would be enough. I decided to get the desired results I would need to go with 275 drag radials…which, near as I had researched, would be a challenge without flares. So I had two challenges here…getting a 275 tire to fit…and staying with Rota RBR’s in a width/offset combination that was not available because 275’s on an 8.5 inch wheel was not a practical option. I didn’t want to roll the fenders for fear of cracking the paint…but I knew I had to compromise somewhere. While there was no room to go outward, I examined the inner side of the wheel and determined I could get approximately 3/4 inch of wheel width towards the inside…still not quite enough. I decided to trim the inner lip of the fender. That, combined with ¾ inch on the inside, would net me about 1 more inch in total width. So I decided to trim the fender lip, rather than roll it, and have my Rota’s professionally widened by 1”. Not being a big fan of downtime, and thanks to the fact that Rota’s are so economically priced, I decided to order another pair of Hyperblack 17 x 8.5 +4 RBRs and had them drop shipped directly to Weldcraft Wheels to have them widened 1” to the inside. Meanwhile, I ordered a pair of Nitto NT05R 275/40/17. A few weeks later, the wheels arrived to me. Now I had a custom set of 17 x 9.5 + 29 (?) One little thing I noticed though almost as soon as I opened the box…the rim seemed darker than the ones I currently had on the car. I verified the color on the box as Hyperblack…but they were definitely a shade darker. An email to Racing Lab explaining the issue got me a quick response…Rota changed the shade of their Hyperblack to slightly darker about 3 years ago…my current Rotas were about 4 years old…Just my luck! Now I was faced with different colored rims in the front and the back of the car…sigh…I ordered two more of the “new” Hyperblack for the fronts so I could match all the way around. After mounting the tires, I compared them to my current setup. Then I did a quick test fit…(no modifications made yet) The wheel and the tire both touched the coil over, as anticipated. Using some old 3mm spacers, I played with combinations and determined that, for some reason, I would need 6mm on the passenger side, and 10mm on the driver side. And, as a result, I would also need longer wheel studs. I ordered some Kics spacers, and a set of 12x1.25 60mm studs. Surprisingly, it was not all that easy finding the longer wheel studs in the factory 12x1.25 thread. Most of the research I had done on here resulted in suggestions of going with ARP 12x1.5 studs. But I really wanted to stay with the factory pitch. Then it was time to trim the fender lips. The last step was to tighten up the coil overs just a tad to minimize squat that would cause the tires to rub. The finished product… You can see the slight shade difference from the rear wheel to the front. But the most important thing is…it works perfectly. The car sticks now on full throttle and there is zero rubbing. I have launched from 1st, floored it in 2nd, and taken some high speed highway cruises over dips and bumps that would definitely cause rubbing if there were an issue…but there is none. This setup works like a charm! I'm very pleased.

-

My 1974 260z-rb . The neverending project.

boosted300 replied to mtnickel's topic in Nissan RB Forum

Lookin good. -

Glad to see you back in action and glad you didn't give up and stuck with it. Congrats.

-

I thought about another re-balance...I may have to send it away.

-

I honestly haven't had those checked but mainly because I feel that if it was a driveline angle issue, it would be a constant vibration, not just when going on or off throttle.

-

Sorry for another thread on the subject, but I didn't want to threadjack the other thread. I am also experiencing a high speed driveline vibration that has me confounded. I have RB25/RB25 Transmission. Over 80mph there is a progressively severe driveline vibration that is also audible, but it doesn't happen under load. It happens when I get on/off throttle. And it is most severe if I accelerate to say 100mph...and then pull it out of gear and coast in neutral...it vibrates pretty severely and makes an awful vibrating noise. As soon as I put it back into gear, it goes away. If I am in gear over 80mph and I let off the gas, you hear/feel it for a split second. When I get back on throttle, again you feel/hear it for a split second. My initial impression is that the driveshaft is rubbing against something. That is what is really sounds like, but after getting under the car and inspecting, I cannot find any signs of damage or rubbing that you would expect to be easy to see if the driveshaft is rubbing against something. Driveshaft has just over 1,000 miles on it and was balanced before initial install, then rebalanced in attempt to solve this problem...which it did not. Double checked driveshaft bolts which are tight. Stubaxles are new and custom made from DriveshaftShop. Trans-mount and diff mounts are also new and do not appear to have any play. Overall the whole build has just over 1,000 miles on it. Thanks in advance for any thoughts/advice.

-

Smaller Cold Air Intake vs. Larger Intake with hot air

boosted300 replied to boosted300's topic in Nissan RB Forum

Unfortunately I don't have IAT sensors so I really don't have any way of taking readings while driving. That would certainly give me a definitive answer to my question though! I agree that ducting is very helpful, however in this case, with the filter in such proximity to some fairly high flowing fans, I would think any ambient air entering through the ducting would easily be overcome/overpowered by the hot air from the fans. With everyone's greatly appreciated input, I have a two different set-ups I'm thinking of testing out. The consensus seems to be that a 3" inlet would be sufficient for what I'm trying to achieve. 500hp in a sub 3000lb car is fine for me. I'm not trying to be the fastest guy in town...I never could be in this town anyway! However, before I go that route (which would actually most likely be the simplest route) I have one other setup I may want to experiment with first because, as I mentioned before, if at all possible I'd like to avoid any cutting of the radiator support. -

In my test fit with a stock RB25 compressor, the pulley on the mounting bracket touched the sway bar. It may be as simple as moving the bracket up and using a shorter belt, but I haven't gotten that far yet. If you don't mind, let me know if you experience the same thing and, if so, how you address it.

-

http://forums.hybridz.org/topic/91330-240z-chassis-prep-reinforcements/

-

Smaller Cold Air Intake vs. Larger Intake with hot air

boosted300 replied to boosted300's topic in Nissan RB Forum

Thanks John. Since I'm so reluctant to cut, I would not go the wheel well route. Yes I would agree, due to the turbo in my car and a lack of any modifications to evacuate the hot air, there's probably a greater than 20 degree temperature differential. Regarding your race Z, what modifications did you make to get air out of the compartment? Due to the fact that I have the stock, non-vented hood, once the fans kick on there's 2600 cfm of hot air being pumped into the engine bay, pressurizing it to a certain extent and it's unknown what effect the open bottom has on evacuating that hot air, ie does it suck it out, does it recirculate, etc. In either case, once they are on it doubtful that the filter would be able to access any of the outside air that rushes by underneath the car as the hot air from the fans will most likely be displacing any external air imo. -

Smaller Cold Air Intake vs. Larger Intake with hot air

boosted300 replied to boosted300's topic in Nissan RB Forum

Good info, thank you. If I do give in and decide to cut, I think that 3" to possibly 3.5" is the largest diameter I can get away with anyway as I believe that might be all the spacing between the radiator and the wheel well will allow. So it would still require a transition from 4" to 3" at the very least. As a result, if I go the tapering route, the best I may be able to get away with due to space constraints would be 4" to 3" down to 2.5" on the engine side, then back to 3" to 4" in front of the radiator support. It will be a tight space in front for such a dramatic flare which will likely result in needing to go with a fairly compact filter. So in a nutshell, in that specific example, do you feel that the gains from the colder air will offset the loss from the reduction in tubing size? -

Smaller Cold Air Intake vs. Larger Intake with hot air

boosted300 replied to boosted300's topic in Nissan RB Forum

I respectfully disagree John. To a certain extent, the use of an intercooler makes the temps at the filter irrelevant. However, in my opinion, if you just look at the picture of my engine bay, it seems apparent that the heat extracted by the intercooler, gets plumbed right back into the intake. This is exacerbated by the fact that there is not one, but two heat exchangers that are having heat extracted from them. Once I put the AC system in, it will be heat from three heat exchangers being extracted and pumped right into the intake. It's like a vicious circle that seriously decreases the efficiency of the intercooler. I tried to illustrate what I mean in the following pic. It's not a great illustration as I lack a good photo editor, but I think you get the gist of what I mean. The yellow line shows the flow of heat from the intercooler/radiator, into the turbo, back into the intercooler, where it gets extracted and pumped back into the intake, etc. etc. This can't possibly not affect the efficiency of the intercooler. Also, while I agree that, with fans off, underhood temps with car sitting still might be meaningless compared to the underhood temps while the car is moving...with the unvented hood closed, even with the car moving, once the fans kick on, hot air is being extracted from the heat exchanger and being pumped directly into the intake before it has any chance to escape the engine bay downward. While the difference may not be 200 degrees to 100 degrees...it may still be 180 degrees to 100 degrees...which is still a significant difference. Even if the 10 degrees = 1% rule is inaccurate, I live in South Florida where temps are typically mid to upper 80's... When the temps drop to the 50's turbo cars feel like they are on nitrous. That's only a 30 degree difference. I can't help but believe that an 80 degree reduction in intake temps would make a decent difference in HP. Could you lend your opinion as to the effect the reduction in intake diameter might have? -

Apologies if already discussed, I searched cold air intake and air filters and wasn’t successful in locating what I was looking for. I did review the Show your RB thread to look at the engine bay layouts of others with RB motors and for the most part, it appears most people have their air filters within the engine bay in some configuration or the other. Currently I do as well The obvious reason, as I’m sure is the case for most, is convenience/simplicity combined with an aversion to start cutting things in the engine bay: There’s really no room to route a 4” intake pipe anywhere unless you want to start cutting holes in the radiator support. The obvious issue is the detrimental effect of the hot air from the fans pumping right into the intake. For lack of an air temperature gauge I tried my best to measure the difference. I used an infrared laser temp gun to take some temp readings. With the engine at operating temp, I waited for the to turn fans on, and watched as the temperature of the surface of the air filter rose to approximately 215 degrees. I then put a dummy filter in the area in front of the radiator support, just below the intercooler piping on the driver side, right in front of the lower 2.5” hole of the support. Everything else being equal, the temp of the surface of this air filter was approx. 100 degrees. Assuming the rule of thumb that every 10 degrees of temperature (colder) equates to a 1% increase in HP is accurate, the assumption could be make that there is approx. 40-50 HP to be gained from a cold air intake. However, I personally have a strong aversion to cutting a larger hole in the radiator support if it can at all be avoided. What’s the alternative? I’ve looked at all angles of the engine bay and don’t see any realistic, efficient, and aesthetically appealing (yes this is important to me!) method of plumbing a 4” cold air intake. That being the case, the thought occurred to me of using a reducer to plumb from the 4” turbo inlet down to the 2.5” existing hole in the radiator support, knowing that this obviously would create a significant restriction to air flow. Taking volume, air speed, turbo efficiency etc. out of the equation (because I’m no M.E. and couldn’t figure it out anyway!), a simple area calculation shows a 61% reduction in area available for air flow. Would this equate to a 61% reduction in power? I highly doubt it. But would it result in a greater HP reduction than HP increase provided by the colder air? I also considered fabricating a sort of collector with a 4” inlet to two 2.5” pipes running to each of the holes on either side of the radiator support. Even this would result in a 22% reduction in area available for airflow, and also would be a bit unsightly. So, finally, here is my question: Which would result in a greater HP net result? Or perhaps I say, which is the lesser of two evils? A 4” unrestricted inlet with 200+ degree air temps. A 2.5” restricted inlet with ~100 degree air temps. I know there’s some really technical guys on here so please share your opinions with if you don’t mind. Thanks in advance.

-

Glad to hear personally. I know 2J's are the rage and with good reason...but I guess I'm just a Nissan purist, I find putting anything other than a Nissan motor in these beautiful cars sacrilegious. (no offense to those that do... to each his own!)

-

Yes, I learned this the hard (and actually kinda scary) way. To try and accommodate the wheels I had purchased, I moved LCA's all the way inward and shortened my half-shafts, which were 280ZX tripod and sleeves. Under the first heavy acceleration, the LCA rotated outward, and because the half shafts were shorter than stock, they pulled apart and came completely out of the sleeve. The sensation was like hitting a slick patch of cement and the car got a little squirly....luckily I didn't lose control. Afterwards, looking at the damage underneath, I was surprised at myself for not seeing how obvious the flaw was. The plastic bushings are completely smooth, as are the tubes for the LCA...there's very little other than the torque pressure of the bolts keeping them from rotating. If they were at least ribbed it would probably not be a problem. Long story short, I had some new, really nice half shafts made by the DriveShaftShop, and put a setting bolt in the LCA's...problem solved. (I actually planned to do a whole write up as this is the abridged version of what was an arduous process from beginning to end!)

-

Here's hoping you stay Nissan all the way!