-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

The stub axles are what connects the wheel to the half shafts. You don't want to change those unless you have to - not a fun project. The diff I pulled was open, and I suspect they all will be - remember this is coming off the front of the pickup. Probably not a bad idea to pull the cover and check things out inside. You should also check the side bearings before you install it. I didn't bother and found out that they were shot once I drove it - nothing like pulling it back out the very next day

-

That's how I sourced the diff for my 73. Yes, but you have to swap the flanges. Do you mean stub axles or flanges? I swapped the stock half shaft and drive shaft flanges to the new diff before installing. No, but you can swap from your existing diff. It's a lot easier if you have an impact gun.

-

I agree with ozconnection on this. As a point of reference, we have 2 turbo volvos as daily drivers. One has the smaller low pressure turbo and the other their larger "high pressure turbo". Off the line the low pressure turbo has lots of torque IMMEDIATELY. If you didn't know it was a turbo, you wouldn't guess. On the other hand, the high pressure is a dog below 3k and then surges to redline. In the real world the low pressure turbo is by far the faster and more satisfying car. And in case you're not familiar with volvo engines, these are 5 cylinder engines (2.3l for the HP turbo, and 2.4l for the low pressure) moving a 3500 lb vehicle. I suspect a stock T3 turbo on your engine along with some experimenting with cam timing with the stock cam would yield a lot of low end torque, and still give you some reasonable high rpm power.

-

In my case the rust was really just on the surface. They still measured 0.160" after cleaning with 0000 steel wool. In hind sight I was probably more concerned when I started this thread than I needed to be. But I had ordered some a year before from Nismo and they were in perfect condition so thought something was wrong this time.

-

Those are the same cam - MSA resells Schneider cams. But in your first post you said you were concerned with low end torque, not high rpm power. Why would you go with a cam with more valve overlap? The stock NA cams all have a pretty flat torque curve at low revs and fall off pretty fast after 4500 or so. From what you've said you want, why not stay with the stock cam?

-

It was shaved .080" yielding 45.5 cc chambers. LEngine predicted a CR of 10.3:1 so I was detonation limited. FYI, Paul, before I built that engine you had warned about the tradeoffs of higher CR forcing less timing advance and that the opposite was the better way to go. I am now a convert! Of course, I've since gone to the turbo dark side ... BTW, Paul, what was the CR of that race motor?

-

Ok, after discussing with some of the locals including slownrusty, I decided to shim the spring. 3 washers totaling 0.185" seems to have done it, although I'll have to wait until the snow melts and I can get some temp beyond idling in the garage.

-

Wilwood versus 4x4 vented .. pro's vs con's

Zmanco replied to proxlamus©'s topic in Brakes, Wheels, Suspension and Chassis

bjhines and ktm, did either of you use those pads on the street? I'm wondering how they were when cold? -

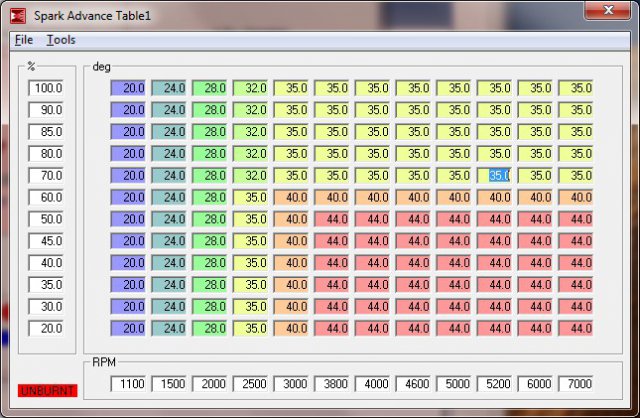

I wouldn't worry too much about the shape of the advance curve below 3k. Similar to what cygnusx1 said, I'd be all in with the advance by 3.5k. When I ran NA I was able to go as far as 35 degrees total advance, and although I don't remember where I read it, that seems to be the generally accepted max advance for our NA engines. I never dyno tuned, but I've read others say that after 30 - 35 advance there is no more power to be gained. Of course, this all assumes that you can run that much without detonation. Above you said you can run 87 octane, but you didn't say at what advance. In any event, with a stock cam you can run between 12 and 20 degrees of advance at idle. I found that with a larger cam it liked more advance, and the closer to stock with the cam profile the less advance I needed. Here's the last advance curve I ran with my NA (flat top pistons, shaved P90, moderate cam, megasquirt, etc.).

-

Today I remembered that the fuel pressure gauge I have installed on the engine has the same NPT fitting as the mechanical gauge so I temporarily connected it. I didn't test at all the rpm points, but above 4k rpm it peaked at 52 psi which is pretty close to the mechanical gauge. Next I went through the 82 280zx FSM trying to find the factory spec for oil pressure, but if it's in there, I can't find it. I know the rule of thumb is 10 psi per 1k rpm, but at the same time, remember a recent thread on oil where the real issue is getting enough volume of oil throughout the engine, and the actual pressure isn't so important. As I'm currently running 5w30 synthetic, I'm wondering if there really is anything I need to be concerned about? Also, the pressure levels off after 4k, which leads me to believe that limit to pressure is from the relief valve/spring, not a worn oil pump. Someone please check my reasoning here: if the pump was worn and the relief valve wasn't limiting the pressure, wouldn't it continue to rise with revs? And I've tried this with 2 valve springs and obtained the same readings, so figure it's not due to a worn spring. So what do the experts think? Should I put a washer under the spring to increase the pressure? Or do I just buy a new pump from MSA? Or do I accept that the 10 psi/1k rpm rule is just a guideline and not worry about it? Lastly, does anyone know the factory spec for oil pressure?

-

I checked around and wasn't able to find any small tubing at the local shops so reconnected the mechanical gauge using the plastic hose and ferrules. I cut the old ends off and paid close attention to make sure that nothing was crimped or blocked. When cold, I was able to get a max pressure of 55 psi on the gauge, and when warm it was still 50-52 once above 4k rpm. So I'm confused now based on the following information: - This pump has less than 2k miles on it and came from a stock 280zx turbo. - I get the same max pressure when I use the spring from the pump from my old engine. - Ignoring for the moment that the stock gauge can't be read literally, it still read somewhat higher pressures with this engine than it did with the old engine. That one I put almost 30k miles on, including many track days where revs were mostly between 4k - 7k. My assumption is that I didn't have an oil pressure problem with that engine, and this one reads slightly higher pressure using the same sending unit and gauge. - The mechanical gauge I bought from Summit is an el cheapo: http://www.summitracing.com/parts/SUM-G2924/ How accurate are these? Could it be off by 15 - 20 psi? - I've got almost 3k miles on this engine all street driven, but haven't been shy about taking it to 7k rpm often. If it really was only seeing 50 psi, albeit with 5w30 synthetic and an oil cooler, should I expect to begin to see issues with wear and hence oil consumption or smoke? Right now there is no smoke nor is it burning any oil. So I'm not sure what to do next. 1. I suppose I could buy a higher quality gauge, but hate to spend the $$$ for something I'll not use again. Maybe I have to look at it as insurance? 2. I could put my old non-turbo oil pump in and see if that changes the readings. But if it reads low as well, can I safely conclude it's the cheap gauge? 3. I could just buy a new turbo oil pump. They're $74 at MSA. Maybe look at this as insurance? I'm leaning towards #3, but would appreciate any other ideas. And of course, none of this addresses the original issue of the oil seepage/leak. Ugh.

-

Wilwood versus 4x4 vented .. pro's vs con's

Zmanco replied to proxlamus©'s topic in Brakes, Wheels, Suspension and Chassis

Like you, I evolved into my present vented toyota with 240sx in the rears and with a better (higher friction) pad in the rear, it works very well on the street and track. But if I was to do it again, I'd wait until I could go with the wilwoods all at once. The main reason is that the vented toyota / 240sx setup inherently has too much front bias. From what I've read here, the wilwood system is far more balanced even without dual master cylinders and it appears that people can run the same pads front/rear and still adjust the prop valve to get optimum balance. That's not possible with the vented 4x4 approach, at least not on my my 73 S30. -

Readings are: RPM Pressure 750 ~5 psi 1000 10 1500 18 2000 28 2500 38 3000 45 3500 47 4000 50 >4000 50 This is with relatively new 5w30 Mobil 1 synthetic after driving for about 15 minutes to get some heat in it. But I do have an oil cooler and it was about 45 F ambient. The pump came from the donor turbo engine which had less than 100 miles on it. I did swap the spring with another pump and it didn't make any difference. I'm thinking/hoping the gauge was reading low. I guess I'll find some copper tubing and try again. But the ferrels are slightly compressed at the thinnest part so it may be hard to slide them over the new tubing. I'll have to look more closely tonight to see if they're closed up too much. That would appear to explain the low readings - if that's what happened.

-

Yes, new gasket. I scraped all the old gasket off and cleaned all the surfaces with brake cleaner. As for the FSM, no, didn't realize there was supposed to be sealer used for the timing cover. The first time I assembled an L engine I followed the FSM, but don't remember any reference to it. Since then I've put timing covers on at least half a dozen times. Every time I did it dry going from memory, so not sure why this time was different. But I'll pull the old FSM out and see what it says.

-

I used an inexpensive mechanical oil pressure gauge and an NPT to BPT adapter from Summit. MAG58, is that what you're referring to?

-

It did have a brass ferrule and plastic tubing. The gauge response was a little sluggish, but I thought that was due to the trapped air in the line acting as a spring as the pressure changed. There wasn't much to installing the ferrule - it's cone-shaped and can only fit one way. When I pulled it off it looked fine - no weird dents or distortions, although I wasn't specifically looking for anything in particular. How would installing it incorrectly affect the readings? Are you saying that it could perhaps pinch the tubing and affect it that way? Wouldn't holding a sustained rpm cause the pressure to eventually equalize and become accurate, albeit it might take a few seconds?

-

Update: the oil is still seeping, but much less than with the original install. Last night I put a mechanical gauge on and the max pressure is 50 psi. It hits that by 4k rpm and never goes higher. So clearly it's not an excessive pressure situation. Side note: the notoriously inaccurate oil pressure gauge is just that - inaccurate. It's reading around 75 psi when in fact it's only 50 (assuming the mechanical gauge was accurate of course). I'm still confused why this is happening as the block surface was clean (scraped with razor and cleaned with brake cleaner) as were both timing covers. I suppose there's no harm in just driving it and wiping the area down regularly, but it's frustrating to have an oil leak on this otherwise very clean engine. Anyone else had this happen before?

-

Not a bad sound right now, although I suspect my computer speakers are adding some bass to it. Slightly off topic if you don't mind - what steering wheel is that? Is it leather wrapped? Blends in nicely with the interior.

-

I have a similar setup to yours except with 240sx calipers in the rear and could only get a good balance by going to a pad in the rear with a higher coefficient of friction. I believe the 240sx calipers and 300zx rotors have a slightly larger diameter than the Maxima setup so I suspect you will have the same issue as well, perhaps a little more so.

-

Jon, take a look at 29 seconds - is that what you're referring to?

-

I shaved my P90 (as well as unshrouded the valves and port matched the intake) and learned nearly everything I needed by searching.

-

His foot work is amazing. I also noticed that there were times where he was just briefly tapping the brakes with his left foot. I suspect that if he only used his right foot, he might not move it over for those little taps. Not sure how to quantify it, but I suspect the overall benefit of left foot braking is BOTH the reduced reaction time (to move from throttle to brake and back) AS WELL AS that you are more likely to use the brakes for small adjustments that you might not otherwise make.

-

This has been asked and answered dozens of times - do keep searching. I think you'll find that there is no definitive answer. The P90 will be reliable and resist detonation allowing you to run full advance on pump gas. Plus it has larger valves so should flow better. The E31 has a reputation mostly left over from those who were restricted by rules (such as SCCA) as to which heads they could use. It needs some work to flow as well as a P90 (new valves and seats). It would have a higher CR, but it's doubtful you could run full advance with pump gas so would probably "give back" more than you gained. Go with the P90. And search!

-

I was out on a deserted section of I25 in the northern part of New Mexico and used MLV to test a 4th gear pull. I downshifted into 4th at about 80 mph and went to WOT until redline. Using MLV afterwards I was able to see that I went from 85 mph to 125 (redline in 4th) in 9.4 seconds. I was pretty happy with that given the only aero mods i have are a spook up front on my 73 which we all know has the aero of a brick.

-

I spent a little time tonight with the toyota canister and I think it can work fine. The purge line is a one way valve and blowing on it to simulate boost causes it to close completely. I'm going to run with it for a while and see how it does. If it fails, then I guess I'll source a 280zx turbo one.