-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

I'll agree for a street driven car. However, using PWM on the track did not work for me. I was at a very warm track day and the car would intermittently lose power for a few seconds towards the end of the session in the afternoon. The logs showed going full lean. After eliminating spark as a possible culprit, I hypothesized that the injector drivers were overheating. Of course, there was no practical or safe way to recreate this away from the track, so I added the resistors and have never had the issue happen again. It may just be a combination of issues unique to my car and injectors, but using the resistors is simple, cheap and reliable. And given the cost of a track day, I didn't want to spoil any more sessions.

-

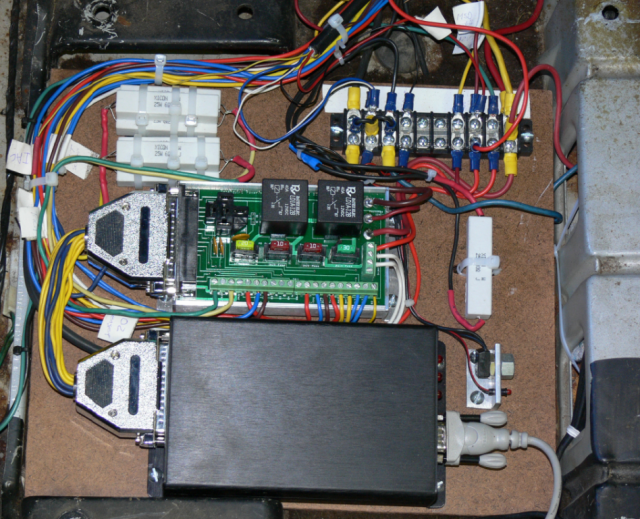

This is how I did it. 3 x 10W 6 ohm resistors in parallel for each bank. I forget which online electronics parts store I bought them from, but they're cheap. The conductors are solid so not forgiving of flexing over time. So mount them solidly and tie the wires down and you'll be fine. These have been in for 8 years now.

-

1990 Maxima. Autolite #14661. I initially purchased a rebuilt from my local parts store and it failed within 2 years. The warranty replacement is now making noise with higher electrical loads, so I wouldn't recommend Autolight...

-

Chassis Setup (corner weights)

Zmanco replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

What have we learned in the last 10 years that caused the thinking to switch to stiffer springs in front, even when there's still a rearward weight bias? And is the "new thinking" only for track cars with stiffer springs and smaller bars as opposed to the more traditional street setup with relatively softer springs and stiffer bars? -

Tony, I was using Corky Bell's definition from his book, "Maximum Boost". From the glossary on page 235: Boost Threshold or Boost Point: This is the lowest engine rpm at which boost from the turbocharger will increase power over the engine's atmospheric equivalent. More simply, the lowest rpm at which noticeable boost (usually 1-2 psi) can be achieved.

-

You probably don't want to hear this, but you could switch to crank trigger pretty easily

-

How did you wire it? Did you use shielded wire? At which end is it grounded? FYI, I know my setup is different than yours (using EDIS with trigger off of crank), but I used shielded wire grounded at MS and have no issues with tach sync. Try to avoid routing it near the injector wires too - but you probably already knew that.

-

I ran the same setup as you with a 4.11 and turned 3100 rpm at 75 mph. There is so much other noise in my 73 that the extra revs don't make a big difference. I recently swapped to a T5 with 3.54 that keeps the same ratio in 1 and 2, but lowers in 3-5 and now turn 2800 rpm at 75 mph. There's no doubt that the car is a little more "relaxed" cruising, but the difference is small. I think the bigger issue is going to be running out of revs and having to shift more with a 4.36. On the road course I frequent, I was constantly bumping up against the rev limit in third before, but the extra 10 mph in that gear now let me focus more on driving and less on shifting.

-

I wouldn't be too concerned yet about the low compression readings as you could probably increase them by doing the test warm, holding the throttle open, adding a little oil to the cylinders, etc. What's the MAP reading at idle? Mine is typically between 45 and 48 at 750 rpm at 6200 ft elevation. As for hesitating and misfires, your new best friend is datalogging. Look at the misfire events to see what's going on. One simple cause could be not enough Accel Enrichment. There's really no good way to tune this except trial and error, although I think I saw an article on the DIY Autotune site that was the best approach I've seen yet. Most people use too much AE initially as it's an easy way to solve hesitation issues due to improperly tuned VE tables. I have learned that as I improve the VE table, I find I can use less and less AE. So either use it sparingly to start, or don't forget to come back and reduce it later.

-

Is that on the street or the track? I don't mean to argue with you, it's just hard to imagine an S30 with its poor aerodynamics making 400+ whp and not exceeding 195 on a road course. What else have you done to improve cooling?

-

I'm running the aluminum AFCO from MSA with my turbo L28 ~300 whp and see 235F water temps (and 250F oil with 25 row Earl's cooler) within 15 minutes on 85F days at the track (at which point I usually back off). This is at ~5k feet elevation which doesn't help either. I don't think this a radiator issue as much as it's an airflow to the radiator issue. See Proxlamus' thread about blocking off the inlet to the radiator to see how managing flow into the rad will affect cooling. I have not gone that route as I don't want to change the look of the car, so have accepted that I just have to live with it.

-

The shaft hole measures 11.9 mm across.

-

-

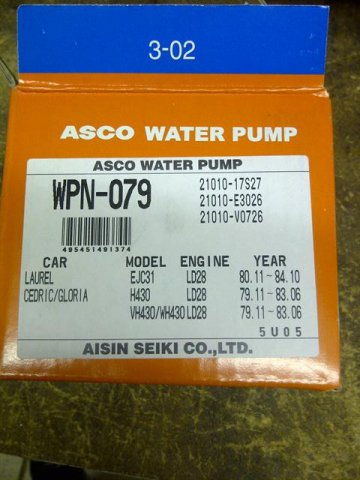

Rockauto lists a separate part number for the Maxima diesel AISIN Part #WPN079 and I've ordered one. Should be in by the time I'm back home on the weekend. We'll see if it really is the diesel one...

-

L28ET - Suddenly 0 oil pressure (Not a faulty gauge!) *SOLVED*

Zmanco replied to tyson's topic in Nissan L6 Forum

What you say is true, but the problem with the air in a tire analogy is that you are using a compressible fluid (air in this case) and oil is essentially uncompressable. So the amount of oil in a given volume at 0 psi is essentially the same as at 35 psi. So my question remains: all else being equal, in our L engines, does using a lower viscosity oil result in more or less VOLUME of oil being delivered to the lubricating surfaces? -

Welcome to Hybridz! The assumption in these forums is that you'll do some homework (searching) to see if your question has already been answered before asking it again. In this case, this has been discussed in detail many times over, so spend a little time searching first. That said, either approach is fine - especially if you're only going to do a build to 250-300 whp. There are some subtle pros/cons to each, and the direction you go could just as easily be determined by what you already have.

-

L28ET - Suddenly 0 oil pressure (Not a faulty gauge!) *SOLVED*

Zmanco replied to tyson's topic in Nissan L6 Forum

I realize we're diverging from the original topic now, but as OP's issue has been resolved, seems like it's ok to explore... Aren't we missing the bigger picture here? Isn't what matters here that an adequate VOLUME of oil gets to all the lubricated surfaces?. Given that it's difficult and expensive to measure volume, didn't the designers instead choose to measure PRESSURE and assume that as long as the pressure is adequate, the volume will be too? That would seem to work as long as the viscosity of the oil is within the range for which the system is calibrated. Assuming that is correct, then can we also assume that if the pressure is low, that the volume must be low? I think this is where we need more information. I've often wondered if there is any data that shows that by using a thicker oil which results in higher measured pressure, if any more oil actually reaches the surfaces? (I'm deliberately ignoring having adequate pressure to pump up valve lifters as our older Zs don't have them). Alternatively, if the oil is very thin (say 0 weight) we expect the pressure to be lower than with a thicker oil, but how do we know that this means there isn't perhaps MORE oil making it the surfaces? As the saying goes, inquiring minds want to know ... -

P79 and P90 have the same combustion chambers. Difference is that the P79 has round exhaust ports and exhaust liners. While I haven't seen anyone replace a P90 with a P79, don't see why you couldn't. The ports won't match up the best to the exhaust manifold, but if it's that or leave the engine in pieces, I'd go for it. I don't know how the liners would hold up on a turbo motor - maybe someone can speak to that from experience. That said, people post P90 heads for sale here pretty often, so unless you're in a rush, you might want to source a P90, especially if you're going to pour some money into rebuilding it.

-

Unless there is something wrong with the current diff so that you have to replace it, an R180 will easily handle the power of modified L28. I would spend the money on suspension, tires (and wheels if you still have the 14" rims) and maybe a track day or two to learn how to drive the car better before I upgraded to an R200 (assuming you don't already have one).

-

One more thing I just though of: make sure you have Incorporate AFR Target set to "include" as that's how I tuned. This enables changing AFR targets later without having to retune VE. FYI, the VE values will be different with this turned on so you can't switch back and forth without retuning. Lastly, I've changed my strategy for timing and AFR a little so here's my latest set of tables if you want to start from these. I've pulled some timing under boost near the torque peak to reduce detonation, and also reduced advance under light throttle at low rpm to improve driveability. I also went to richer AFR targets there as I was getting mild surging. tables.zip

-

Well, that's good news and bad news - good news that you probably have found the problem, bad news that you have to r&r the timing cover. FYI, you'll likely need to replace the timing cover gasket. I have a spare set if you can't get one in time, although I know Castle Rock isn't all that close to you. Also, I'd suggest using some form a gasket on the timing cover gasket - for some reason I had coolant leaks on my turbo motor when I installed the gaskets dry that I finally cured with this. Get it running and come out to the track and we'll help you get it tuned. Maybe we can convince Roy to let you go out in multiple sessions in the morning so you can get it sorted faster. BTW, run VE Analyzer from Tuner Studio on the drive out and vary your engine speed and load a lot and you'll be surprise how much progress you'll make even before you get on the track. Lastly, for VEAL to work well, you need to set the Lambda Delay. Attached is what I've found to work well. In my case, the O2 sensor is mounted on the underside of the down tube about 1 foot from the exit of the turbo. If yours is farther than that that, these times may be too short. Lambda_delay_2012-09-06_09.36.40.table.zip

-

I don't see anything obvious that would prevent it from starting. That said, I would suggest you change Incorporate AFR Target to "include" as that means that in the future, if you change the AFR table, you won't have to retune the VE table. Also, I'd suggest bumping Cranking RPM up to 300 rpm so MS doesn't think the engine has started when it's still cranking. But neither of those should prevent the engine from starting. If you haven't done this already, use a timing light to measure timing while cranking. It should be somewhere around 10 deg advanced (note: confirm what you have this set to on MS). That will confirm two important things: 1) the coil is firing and 2) it's firing at the right time.

-

I'm running MS2/extra which only supports integer values for the VE table hence the need to double the VE values and halve req fuel to get more range for tuning idle. I believe MS3 supports decimal values for VE? Then you could go back to the "proper" req fuel and halve the VE table. Just last week I had the head milled to clean up the surface and after reassembling it, it would not start unless I floored the throttle to go into flood mode. Turned out I had moved the cam to remove the followers and when I put the cam gear back on (also not running on the #1 position) I failed to verify that I wasn't a tooth off. The engine exhibed the same symptoms as you describe. Turns out it was 2 teeth retarded. To be sure, put the cam gear on in #1 postion and verify that the wedge on the cam gear lines up with the mark on the cam tower. Then move the cam a few deg to put it on the hole you want. If you didn't already verify that, I'd suggest doing it just to be sure. Alternatively, take it for a quick drive - if there is less torque than before you started this project, that's another clue

-

Sounds like you've slain another dragon and now need to fight the next one Have you double checked the cam timing? Both symptoms (can't get enough air to idle and much too rich) sound like the cam is retarded. As for being out of range with the distributor, if you're using the distributor only as the tach trigger, then yes, you can just add some more advance in MS. But if it's also distributing spark, then you may run out of range of overlap between the rotor and the nodes in the cap. I think you're going to have to drop the oil pump and move the shaft one tooth. Sounds like you are getting close - slay these last dragons and bring her out to the track on Saturday - great chance to do some tuning

-

Glad you found the culprit (we hope)! Do come out on Saturday - so far the weather is forecast to be relatively mild so should help keeping the cars (and drivers) cool.