docjim

Members-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by docjim

-

Gauge Guidance Needed! 260z w/ 350/th350

docjim replied to nolant178's topic in Gen I & II Chevy V8 Tech Board

After trying different gauges, etc. I bought a speedhut gps speedometer for the same reason. My speedometer read 60 with the autometer gauge while the TomTom gps said I was going 45. -

1970 SBC 350 Transmission Questions

docjim replied to Revenant's topic in Gen I & II Chevy V8 Tech Board

The "t5 guy" otherwise known as Richard Lopez in Phoenix sells a shifter for the camaro t5 that eliminates the offset. Just search the Phoenix az craigslist. He advertises there.- 26 replies

-

- Transmission

- t-5

- (and 4 more)

-

Zinpieces, what brand of system is shown. I really like the fittings and braided hoses. Jim

-

Advise on suspension needed

docjim replied to docjim's topic in Brakes, Wheels, Suspension and Chassis

-

Advise on suspension needed

docjim replied to docjim's topic in Brakes, Wheels, Suspension and Chassis

Wow! Your questions have shown me how naive I am about suspensions. However I will try to answer them. Ride height: I didn't know where to measure since there is an aero fiberglass piece as a side molding and the frame has added metal on the bottom, so I measured using the only original sheet metal I could find--The piece of sheet metal that contains the jacking points for the trunk jack. It measures 6" at the front and 6 1/2" at the back from the ground to the bottom of that piece. The engine in a 1975 code block with steel Edelbrock heads and intake manifold. It's pretty heavy. The tires are Yokahams that Discount tire said has decent traction and good ride. I had the alignment done at a Nissan dealer (which may or may not have been the best choice) and they said the caster out of spec bu more than 1 degree. I'll try to add pictures in a separate post. From what I'm gathering, the best quick fix is to leave the springs as is and get better shocks? Jim -

Note: Richard Lopez, "the t5 guy" in Phoenix sells a shifter for camaro t5's that allows the transmission to be mounted at the camaro angle. It works fine and only costs about $60. Search the phoenix craig's list auto parts ads and you'll find him.

-

My 1975 vintage 350 ended up with an 1985 corvette clutch and 1985 camaro t5 transmission. Good luck.

-

What I've learned: * Buy the engine/transmission as a unit--that will solve a lot of what goes with what problems. * do the frame reinforcement before you do anything else. don't scrimp on this part. * I ripped out the entire wiring system (it had too many hacks that were iffy) and replaced it with an aftermarket set. * DEFINITELY drive/repair the brakes, fuel system, suspension, etc. before the transplant. * READ THE BOOKS AND FORUMS! Before you rip up anything. I hate the "Oh, that's what I should have done" moments. * And, remember, "Projects take twice as long and cost 3 times as much as you estimate." Quote from a car mag. Jim

-

Doesn't anyone use a remote filter? Jim

-

Advise on suspension needed

docjim replied to docjim's topic in Brakes, Wheels, Suspension and Chassis

Thanks for the input. This is just a cruiser--I can't afford to race it (plus at my age, my reactions are way too slow). If I can help it I would prefer to just change to brand new springs. I've replaced the springs with used ones (260Z) twice and both sets sag. I know coil overs are probably the best solution, but that's a lot of work that I'm not sure I can do (I don't weld). The problem is I would like to put on springs that will give a decent ride without bouncing on every road imperfection. Plus, with the heavier v8 up front, I don't know what spring/coilover will give me what I want. PS I'm happy with the stock ride height. Jim -

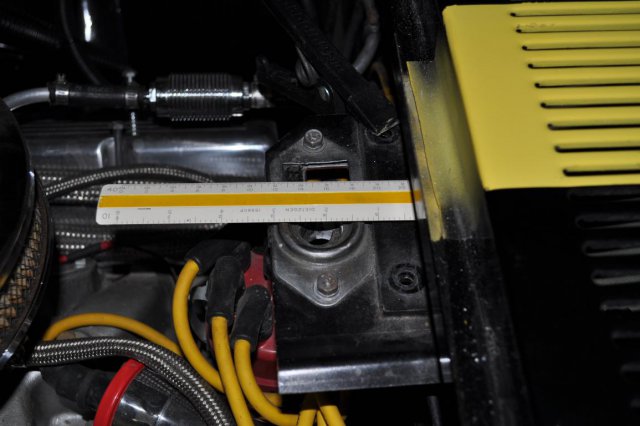

I've got a GM 350 in my late 74 260z. the oil filter sits right on top of the frame rail and a real chore to change. what do you suggest for a remote filter assembly and where to put it? Thanks, Jim

-

My(late 74) 260z has had the top chopped off to make it into a convertible (still haven't figured out how i'm going to do the roof) and now has a GM 350 and a Camero T5 installed. it's a beast to drive. anyway, here's my problem. I decided to go with the original suspension, so I go new KYB strut inserts and found used springs. the alignment shop says the springs are sagging so much they can't adjust the camber. plus, the ride is really jarring going over the slightest bumps. I've seen springs advertised on EBay that are supposed to be replacement springs for a 260Z, but with the changes I've made to the car, I don't know if they would be any better. I'm trying not to go the coil over route to keep the cost down, but just want something that's a little less jarring to ride. Suggestions? Thanks Jim

-

Success!!!! Well, at least mostly. The hood looks much better than it did before--still not concours perfect, but acceptable. here's what I did: 1. Removed the latch mechanism and installed hood pins where the hood bumpers on the firewall were. 2. closed the hood and loosened all the hinge bolts. pushed down as hard as I could while tightening the bolts. This is definitely a 2 person job, but I had to do it by myself. that was a struggle. 3. loosened the bolts holding the hood to the hinge. pushed down and back as hard as I could while tightening those bolts. now all I have to do is fine tune the hinge pins to get the rear of the hood perfectly even with the fenders. Thanks for all the helpful advice. Jim

-

I had this same problem and finally just mounted it on the transmission tunnel just under the dash. That way it was centered and easy to get to. However I sold the original dash and made my own custom dash which made it a lot easier to route wires and figure out what wire goes where. trying to figure out someone else's wiring (like the original Datsun wiring diagram) and adapt it is much harder than starting from scratch and doing your own basic system.

-

Right now, I'm seriously considering hood pins.

-

after all this trouble, I'm thinking I'll just install some hood pins instead of the latch.

-

OK, after 3 hours of loosening the hinge bolts, the bolts that join the hood to the hinges, removing the latch mechanism, and adjusting, tightening bolts, loosening bolts, tightening bolts, here are pictures showing the results. after I hold down the hood in the correct position, and tightening the bolts, the front of the hood would jump up about a half inch due to the spring. this is not a 1 person job. anyway, here is the front of the hood: and here is the resulting rear hood gap: and here is the position of the cowl latch mechanism. as you can see it is only about 2 inches from the cowl. the plate the cowl mechanism is attached to is too short to allow me to move it forward. and yes, the pointed part of the hood latch does touch the wires of the distributor. Where do I go from here? PS thanks for all your advice. I wouldn't have gotten this far without your help. Jim

-

the wiper motor has a different lead for each the low and high speeds. I used a 3 position rocker switch for my wipers (high/off/low). the power goes to the switch and then from either high or low position to the appropriate wiper wire. and, naturally from the wiper there is a ground wire. see a posting I made last year asking which wire on the motor was which. there were several excellent replies. I only used the high and low speed wires.

-

Miles, the pictures you provided look exactly like my setup. It did have to be moved to make clearance for the distributor. it's present position is 2 1/2 inches from the firewall. I'll try moving it another 1/8", but I am not too hopeful. Answers to questions and statements above: there is clearance between hood and air cleaner--not much, but there is clearance. also, when the hood is closed, the latch mechanism does pull the hood back into the correct position, but it a extremely difficult to open again. the long term reliability isn't an issue since this car will never be driven more than a couple of thousand miles a year.

-

I've tried everything I can think of. I've taken it off, put it on, adjusted every bolt every which way and it's still an inch short.

-

OK. Here is the best picture I can get of my problem. As I said, the latch needs to be moved towards the rear of the car by 1 inch. The male part on the hand latch has to be pressed in order to get the barbed part into it's hole. if you do that, you can slam the hood and the spring part of the latch will pull into it's hole. the hood fits the way it should against the wiper cover. However, you have to pull very hard on the inside the car hood release and then fight with the hood's hand release in order to get it to release. Now in addition, a Nissan mechanic doing the wheel alignment tried to be helpful and make it easier to close by rotating the spring/hinge up and toward the rear. now, the front of the hood sits up above the fender by an inch. HELP! PLEASE!

-

-

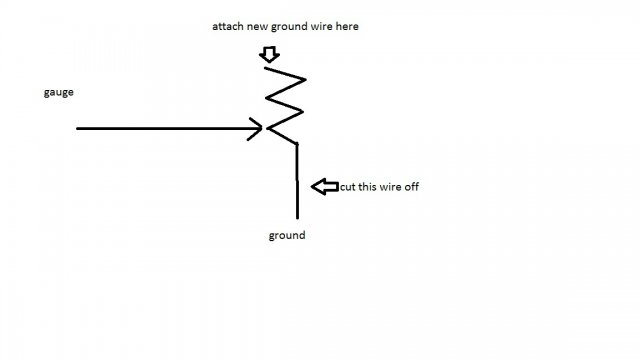

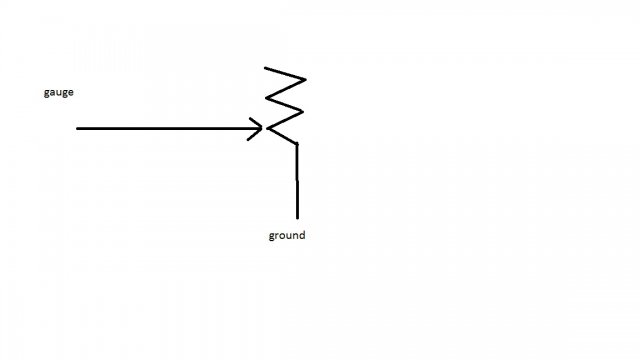

here is a poorly drawn schematic of the sender. If a wire is attached to the floating end of the variable resistor, wouldn't that make it read correctly?

-

I meant that now the gauge is connected to the variable arm of sender resistor and the ground is connected to 1 end of resistor. If a wire was attached to the other end, it should read correctly.

-

Would it be possible to attach a wire to the opposite end of the variable resistor on the sender?