-

Posts

632 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Danno74Z

-

Thanks John. Danno74Z

-

Trevor mentioned, NEAPCO 2-2-899-1 for R200s thru 1978 (except 1975) as being the flange yoke we need to use and I believe this to be incorrect. Below are the spcecs. for that flange and they do not match the one I received from JTR. JTR uses a 1310 U-Joint and the 899 uses a 1210. Some of the dimension are similar but others are not compaired to the JTR flange. My take is that these are custom flanges from JTR because even if you research the Spicer 1310 series flange nothing matches the JTR. Flange Yoke 1210 series, 4xØ.328 Holes on 2.750BC, Ø2.250M pilot Spicer 2-2-899 Code: SPI-2-2-899 Price: $52.43 Design Style Snap Ring Design U-Joint Series 1210 we need 1310 Universal Joint Retaining Width 2.688 we need 3.469 Universal Joint Bearing Diameter D 1.062 Flange Diameter A 3.406 Bolt Circle Diameter B 2.750 Horizontal Distance Between Holes (center to center) 0.000 Vertical Distance Between Holes (center to center) 0.000 Bolt Hole Diameter .328-D Bolt Hole Quantity 4.000 Pilot Diameter (M-Male, F-Female) C 2.250M Centerline of Joint to Flange Face G 1.484 Compatible U-Joint Kits SPI-5-443X,SPI-5-736X Notes Fits several Nissan & Toyota pick-up trucks Cast/Forged

-

I would like opinions on which final drive ratio(3.9 or 3.7) I should use behind a LS1/T56 engine transmission combo? Also is 1 gear useless except at the drag strip to heat up the tires Just use second gear from a stop? Thanks. Danno74Z

-

78 Datsun 280z ------> 5.3 build

Danno74Z replied to SUNNY Z's topic in Gen III & IV Chevy V8Z Tech Board

Sunny Z I'm not sure if the 5.3 block has the same external bosses but be aware on the driver's side of the block (at least on the LS1 5.7) is a protruding rectangular piece of the block casting. This casting must be removed before you tighten up the header or you will squash the primary tube. I used a short blade on a sawzall and sliced off about 1/4-1/2 inch of material. Since my block is aluminum it cut like a hot knife through butter. Again this might be a moot issue for you but check it out before you tighten up the headers. And yes they ARE expensive but they are well made and the fit is very good if they send you the correct ones! Danno74Z -

Hello All, I think all the online retailers us the same rebuilder - A1 Cardone. I ordered a pair of axles for the 300ZX turbo (84-89 with the 4 mount holes) and the order was completely jacked up. Then I tried NAPA and too was jacked up. Here is my 2 cents. I went online and asked for a quote for the axles I needed. I got back 3 quotes from salvage yards and out of the three one guy knew exactly what I needed. His name, number is Scott (518-587-0129)Thoroughbred Auto parts scottatthoroughbredauto@gmail.com. The axles came out of CA and they are PERFECT. I thought I would have to get them rebuilt (Here in Denver we have A1 Axle rebuilders) but they are fine. One is short the other is long and they are from an 86 TURBO!!!!! The key in my opinion is NOT to send them away for rebuilding as you WON'T get back the ones you sent in and will have to start the whole process over. IF you have to rebuild use someone local in your area and make sure they do it there!!! Danno74Z

-

Well I guess I kinda did the same thing. Yesterday, I went out to the shop and FORGOT I had an extra set of stub axles which I bought YEARS ago. (I really need to have a yard sale). I was digging around looking for something else and found this box (what the hell is in this box) and saw two axles, great. I thought they were from a 280Z because that was what the salvage yard said. As it turns out they must be from a 240Z because the spline area is a lot smaller then the 280. I did not count the splines or measure but now I can see the difference (I will do that today). Both fasteners on the axles are the same diameter but the splines are different. Had I remembered I had this spare set I could of answered my own question!!!!! THANKS.... Danno

-

OK thanks for the information. In my case both are 27 splines which is good. I thought they might have made a third stub axle (odd ball) for the 260Z like a 27 spline but small diameter like the 240Z. Danno74z

-

I need a little information on the different stub axle diameters of 240Z vs the 280. My car is an early 260Z model and it HAS 27 splines. A little unusual as I thought it would have the 25 splines like the 240Z. Anyway I know there is a difference in spline count 25 vs. 27 but what is the SPLINE diameter of the 280Z stub axle? Not the bearing surface. If someone knows a link please share it as I'm sure this has been measured. I measured my axle and the spline area is 27.75mm Thank you, Danno74Z

-

I'm pulling my oil pressure right by the filter not up top behind the intake where the OEM sensor is located on the LS1's. Maichor, is this what your doing and getting you oil pressure from? I haven't taken the engine over 2500 on the test stand (just too loud) but it stays right at 55PSI which I'm sure is adequate. Danno74Z

-

Yes to the oil pressure when cold. But it does not vary much from the 35 and 55. I'm using the recommended oil I believe it is 5w30. Thanks for the compliments. Danno

-

I know I know..... YES I need to make one with the revs. It is a loud SOB without mufflers but I live in the country and can get away with it on a limited basis. My wife came home and from the house she thought a semi fired up. I was laughing my ass off. I took the video with my PowerShot digital camara so if I rev it I'm not sure how much distortion I'll get but what the hell. At idle I have around 35PSI oil pressure at it goes up to 55PSI at 2000RPM. How do those numbers sound to you? Danno74z

-

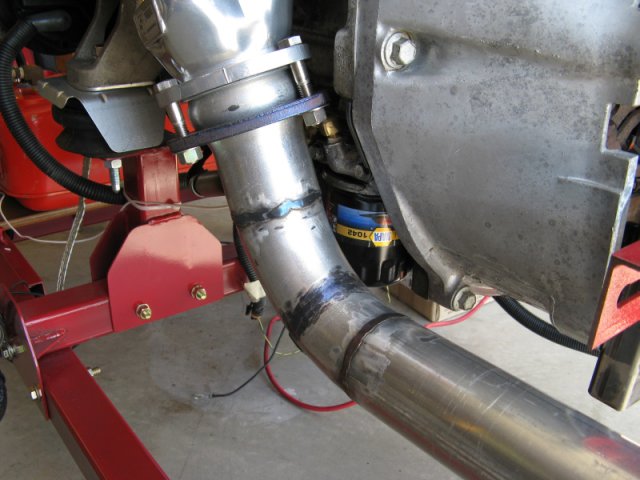

I have always wanted to build an engine test stand so with plans I purchased on Ebay and some tweaking for the LS1 here it is. This came out GREAT!!!. As some of you may know especially Vinh who was a great help in the electrical area this was a very fun and useful project. I now know the engine works well including the wiring, computer, sensors and everything else. No oil leaks and OPEN HEADERS SOUND FRICKEN AWESOME!!!!!!! Video: Take a look and let me know what you guys think. On with the HybridZ machine. I made a couple of mistakes in the video such as I did not make the Sandersons headers and a couple little errors but hey it's my first video.

-

From the album: LS1 Engine Test Stand

-

From the album: LS1 Engine Test Stand

-

From the album: LS1 Engine Test Stand

-

From the album: LS1 Engine Test Stand

-

From the album: LS1 Engine Test Stand

-

From the album: LS1 Engine Test Stand

-

From the album: LS1 Engine Test Stand

-

-

From the album: LS1 Engine Test Stand

-

Hi Gary, You hurt my feelings - Only Kidding. Yes they are not the most aesthetics things but if they work great. You have an awesome car my friend! Danno74Z

-

I have to say the MSD wires are very nice and would probably work all by themselves. In my case cylinder #5 was the tightest fit as shown above. You can actually bend the wires to suite you needs but out of the box they're straight for the spark plug boot and 45* or so for the coil boot. What I did was pre-fit the wires and bend them away from the header tubes then I installed the sock and snap it onto the spark plug. With the sock on it is difficult to know when you are "home" on the spark plug head. So prior to doing anything I took a spare plug (same type that is on the engine) and snapped on a wire and took a visual measurement on how much the silicone boot covered the porcelain. Then I installed them on the engine. Next week, I plan on firing the engine up on my test stand that I built. Danno74Z

-

They were not too bad I guess you be the judge. They run about $40 delivered. http://www.amazon.com/gp/product/B001TOSRQK/ref=ox_ya_oh_product The MSD wires and socks ran $90 total. They come in other colors too. Danno74Z