X64v

-

Posts

543 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by X64v

-

-

Z-ya's sticky identifies my Bosch green top injector (same part numbers) as having a 1ms opening time, so that's what I've used since I got them. I've also run them as Peak and Hold's with pwm settings also per Z-ya's sticky.

Today I decided to switch from two squirts simultaneous to two squirts alternating in preparation for running my larger injectors (doubles the instantaneous on time of each bank, giving better idle quality). When I did, I found the engine ran lean through its entire range. I did some researching and found (on msextra.com and some dodge neon forum) that this was because the injector opening time was incorrect, so as it switched the number of times it pulsed, the amount of fuel changed. I also found that the opening time is set correctly when you can change the number of squirts per cycle (or switch between simultaneous and alternating) without causing a change in AFRs (which is most noticeable at idle).

I began experimenting with my opening time setting, and found that at .7ms my afr's stayed steady at idle (when they're affected the most) when switching back and forth between the two squirt modes, which seems to mean that's the correct setting. I suspect the true number is closer to .72-.75ms, but MSI only allows .1ms changes.

Anyways, why would there be this discrepancy between Z-ya's tested opening time value and the one that works best when experimenting? To be clear, I'm not doubting Z-ya's methods or accuracy, just wondering why the measured value wasn't what worked practically.

-

I'm wondering if on MSII you can use manifold vacuum change for throttle enrichment (I know other ECUs can do this).

I know for a fact on MS-I with the MSnS-E code, you can. A few friends of mine had problems with the acceleration enrichment causing the engine to stumble for a sec because it saw a tps change that wasn't there. They switched to 100% map based accel (isn't Cygnusx1 running that, too?), so besides datalogging, their TPS sensors don't do a thing.

So the SU/TB idea is a go

Edit: Yes, Cygnusx1 is (or at least was) running full map-based accel enrich on his MSII.

-

Interesting trick.

I'd like to relate a small tidbit from having to pass emissions a few times with my L28et. I've never had a problem with the loaded test on the dyno (in AZ for my year, it's steady state at ~30mph), but the idle test is what always proved just a little tricky. I've found that (at least for my car) I can never pass idle at 13:1 or higher afr, the engine stumbles a bit and the hydrocarbons go through the roof. I always pass right through at 12.3:1 to 12.5:1 idle afr, and that's where I keep it all the time, it seems to like idling that rich.

-

yes i do believe there is a govenor, because i give it full throttle, and it hit 85 really fast, and then it slows down then speeds up tyo 85, and repeats. I want to drive this car semi stock for now, and i have seen the stock 280z's hit 120, so how did they do it? how do you modify the govenor? I will do some more searching on the govenor.

They did not come from the factory with a governor. If there is one, some one put it in on their own, it's not original.

-

aerodynamics i think thats the device thats restricting you

You can't be serious, right?

-

Your comp ratio should not be causing that pinging. On my L24 (8.9:1 SCR with open chambers like the N42) I ran 10psi, non-intercooled, on 91 octane with ~21 degrees of advance and 10.7:1 AFRs. No ping, no problem.

-

TR is correct, the PCV is designed to close when the intake manifold pressurizes.

-

The engine really intrigues me now. It's a P90/F54 with optical dist, but NA everything else.

Don't take my word for fact, but I think the JDM cars (and perhaps the Aussie and Euro cars as well?) never got the p79, or even n47. They just had the square port heads, n42 all the way up until the p90.

Nice find btw, looks great!

-

To answer your question definitely, yes, there is no problem with it.

-

I was lucky enough to see the plenum at MSA. It's a work of art for sure

-

It depends on the BOV, but I think 1/2 open might be too much. My 1g DSM BOV is open at idle, but not more than 10% or so, and it closes with any more throttle. I can't hear it at all unless I snap the throttle shut on or near boost.

-

How hard would it be to hotwire your car just by bypassing your keypad? It'll probably be even easier to get to the wires, too.

That's what I've always wondered about. How hard is it to just pull the keypad off wherever it's mounted and connect the right wires together?

-

Yup, the contacts are all good, nothing intermittent. I checked the plugs today, the lean plug followed the fuel injector. The #3 plug is now white and #4 is dark. I don't like having a 10% difference in flow rates, and I want bigger injectors anyways (these 338's won't cut it soon) so I'm going to just order some bigger ones that are better flow matched with an o-ring rail and go from there. My flow test was only at 100% duty cycle, perhaps that injector is taking longer to open than the rest, making it flow even less fuel (which would be why adding 12% to my fuel table didn't work).

-

Another update: Taking a look at my old blown head gasket, it appears that I'm only pinging on cylinder #4. The gasket was blown out the side on that cylinder, but still almost perfectly round on every other cylinder, not egg shaped at all. Taking a look at my plugs (the 7 heat ranges), they were all pretty black except for #4, which is much lighter than the rest, telling me it was lean. I ran some commercial-strength fuel injector cleaner through but it didn't seem to help. I pulled and home flow tested the #4 and #3 injectors (#3 as a known good one), and #4 flowed less, but only 10% less. I reinstalled them and tried adding 12% fuel to compensate, but the pinging remained. I switched the #3 and #4 injector around, and will drive around for a few days to see which cylinder runs lean, but I really doubt the injector is the cause of my problems, I think it's always been like that. Its spray pattern was nice and conical, not lopsided or messed up in any way.

Any last ideas?

-

I use that (except in 2.5") for my quiet exhaust. Flows reasonably well, and is very quiet.

-

A good oil restrictor size is .060". That's about 1/16", which I would estimate is about the size of the tip of a ball-point pen.

-

Alright, I've been running the BPR7ES plugs, and I pulled my timing to 25-26 degrees at 7psi, but I'm still getting moderate detonation with 85 degree ambient temps and 175 degree water temps. I'm going to try some BPR8ES plugs, but it's strange that I should have to go so cold. My L24 turbo motor was fine on 6's all the way through 10psi even with outside temps pushing 115, with the only difference being the bottom end (which had a much higher comp ratio, 8.9:1).

-

Thanks for the response Paul. The bit about your N/A engine wanting 7s clears it up: if this heat range is what the engine wants, I'll just run them. I know for a fact the timing mark is correct. I verified it when I built the engine a month ago, and immediately set my trigger angle in Megasquirt to match. As far as the thermostat goes, I was under the impression that 160 degree thermostats were run to keep the engine at about 170 degrees normally, correct? Well, with my 180 degree thermostat, Megatune reads 170 degrees around town. Also, I already run distilled water with Water Wetter and a JTR aluminum radiator.

I have read through that thread, and it wouldn't surprise me if my E88 head has different coolant flow patterns or casting flashing in different places that make it just a tad more susceptible to ping. But like I said, if the engine likes 7s on the street, 7s are what I'll run.

-

Have you considered that your intake might be sucking air causing the pinging by running too lean...?Somewhere between the intake and head?

I'm running megasquirt, vacuum leaks don't cause the engine to run lean. Also, I said above that my wideband reads 11.5:1 to 11.7:1 under boost.

-

A little update: I filled back up on 91 octane and switched to BPR7ES plugs gapped at .028", and that actually worked even better than the race gas. Ping is gone in first and second, just barely there in 3rd, and not nearly as bad in 4th and 5th. I think if I pull 2-3 degrees of timing I can eliminate it completely. My only question now is why am I having to run a 7 heat range plug to get rid of ping? I'm only at 7psi and 7.9:1 cr, and my manifold air temps never really rise above 170 (I do most of my driving at night).

-

Well, I think I've confirmed that it really is ping. On 97 octane, the ping sound was totally gone in 1st and 2nd gear, and was greatly reduced in 3rd and 4th.

Now, I have two more questions. First, why would this engine setup be pinging now, and so badly? Everything's identical to my previous engine set up with the exception of the bore/stroke size and the compression ratio. And second, why isn't this ping blowing my head gasket? I blew a head gasket a few weeks ago from fuel starvation on a hard left-hander (the light ping turned to heavy knock), but otherwise I can hammer on the motor all day with this light ping and it doesn't seem to do anything.

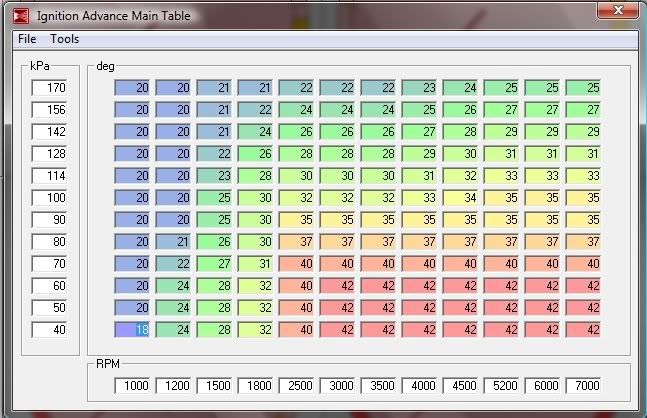

Edit: Here's the spark map I've been running the past week or two.

-

This is just a wild guess, but could it be rod knock or piston slap?

Not rod knock, but I guess it's possible it's piston slap. I don't have a clue what piston slap sounds like. If it helps, the engine doesn't make this sound any other time, when it's warming up or when I'm driving around it's totally smooth and silent.

This can also be caused by the front pulley. I had the same issue that seemed to be related to both throttle and RPM but I could not get it to go away. I finally figured out that it was comming from the crankshaft pulley.What exactly was the problem with your pulley? Mine's bolted down tight, doesn't wobble, and the rubber was in good shape when I installed it. I did change it when I changed engines though.

-

I'm running an LC-1. I've recalibrated it within the month, and always kept it calibrated (not usually more than three months or so in between). Keeping a three-month schedule, it doesn't seem to change before/after a re-cal.

I gapped the plugs when I put them in, but I'm going to check them tonight for evidence of detonation. Also, I just put in seven gallons of 100 octane (making for about 96-97 octane in the tank), and the noise is still there in 3rd/4th gear. I'm not sure about 2nd gear, I need to take it out tonight when there's no traffic and do some more test runs.

-

I've been having a problem with my fresh turbo motor. From 4000-5500rpm, I get a very audible sound that I thought was pinging. However, it will not go away, now matter how much timing I pull or fuel I add. Motor specs:

Fresh L28et stock bottom end

'73 E88 head (N33, 47.8cc chambers, sharp edges rounded)

Stock nissan head gasket, making for 7.9:1 SCR

V3.0 MS I, MSnS-E code

Stock T3 turbo, stock manifold.

Stock wastegate at 7psi.

Walbro 255lph external fuel pump

338cc injectors

1g dsm bov, no intercooler

BPR6ES-11 plugs

The thing is, this noise acts completely like ping. Only comes on under boost after 3800 or 4000rpm, disappears by 5500 or 5700 rpm (basically just during peak torque ranges), isn't as bad in 1st because of the lighter load, etc.

My normal tune is about 11.7:1 afr, 30 degrees of timing at 130kpa and 29 degrees of timing at 140kpa (at this altitude '7psi' bounces between 130-140kpa). At these settings the sound is pretty bad, happening probably 40-50 times on a second gear pull. BUT, I can pull my timing to 20 degrees under boost and richen my fuel to 10.8:1, and it still happens 10-20 times on a second gear pull (even though it feels like I've lost 40ft. lbs. of torque). It also seems to start at 110kpa, which is practically no boost, just about 2psi (ambient here is about 90kpa)

Could this still be detonation? If not, what is it? I'm running 91 octane gas. This exact same cylinder head/turbo/megasquirt combo ran fine on my L24 bottom end at 8.9:1 SCR. Also, I blew a head gasket because of some major knock/detonation caused by fuel starvation on a hard left-hand turn, but this 'ping sound' itself will not blow my head gasket, no matter how long I let it happen. I can rev the motor free or under light load slowly or quickly from idle to 7000rpm with no problems, no ping sound. My next diagnostic step will be to run my gas tank low and then put 4 or 5 gallons of 100 or 105 octane in to see how that affects things.

Any ideas or suggestions as to what's going on?

I knew it would happen sooner or later

in S30 Series - 240z, 260z, 280z

Posted

Because before, the rotor hadn't flown apart yet. I would get a new (quality) cap and rotor and go from there. Check your timing, set it around 10-15* advanced at idle.

If the car didn't start after it cooled down, it's impossible for it to be a vapor lock issue. When vapor lock occurs, you don't magically get air in the lines, it's vaporized fuel that has boiled. As the engine cools back down, so will the fuel, and it will condense back into a liquid.

I'm running a turbo motor without heat shielding just like Gollum, and I don't have vapor lock issues either. You don't need that fuel cooler.