X64v

-

Posts

543 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by X64v

-

-

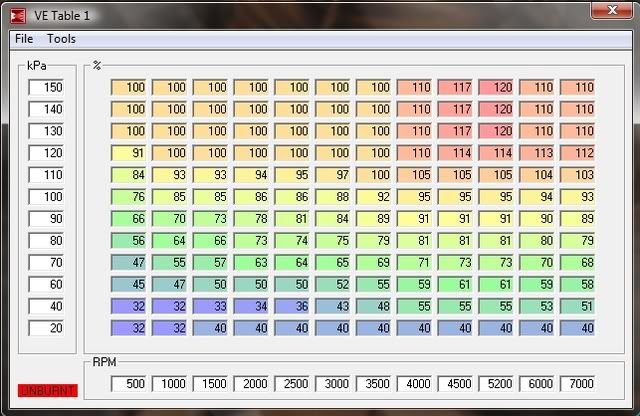

Here's a map for a fairly unique engine set up, so it might help someone who wouldn't be able to find it anywhere else. L24, E88 head (8.8:1 CR), stock 280zxt t3 turbo and exhaust manifold, 2.5" dump pipe, stock 280zx n/a "A" cam, 338cc (32lb) injectors, stock 280zx fpr, non-intercooled, 7psi (creeps to 9psi at higher rpms). Tuned on an Innovate LC-1

I just got it to a nice 12.0:1 afr line under boost from onset of full boost (~3000rpm) all the way to redline (7000rpm). It's also tuned to 15.5:1 at 75mph (2800rpm and 55kpa on my car), low 15's from 55mph to 80mph, low 13's at super high vacuum (engine braking), low 12's at idle (it's the only way it likes it), and low 14's around town, though I'm still working on those a little. The 40's at the bottom of the map have just been left there because they're below my minimum injector on time anyways, so it's just 1.1ms squirts no matter what.

The spark map I use with it:

-

Tucson, AZ zip codes make it $16.99.

-

I can struggle with the problem as well. I deal with it by putting the laptop away (in the other room, in my backpack, whatever). Say I have a few minutes to relax before I need to start on some work: Instead of grabbing the laptop and getting sucked in, I'll just grab my ipod and a crossword or sudoku and relax for a few minutes. When I get bored or finished with one, there's nothing else to do there, and I can remember to move on to my real work, instead of spending hours in the black hole that is the internet. If I really need to use the computer for work but not the internet, I turn off my wireless card.

-

Kept uncluttered so as not to bother me in my pocket.

-

+1 on what Jon said, that edging and angled cut looks awesome. Great setup for a track car.

-

Or you can go to victoria's dragon an pay way too much for them.

So Victoria really does have a secret..

-

I get 26mpg highway cruising at 75mph and passing lots of people at 7psi (two lane highway). Stock l24 longblock, t3 turbo, 7-10psi (depending on what I feel like). AFRs at highway cruise are 15.0-15.5.

-

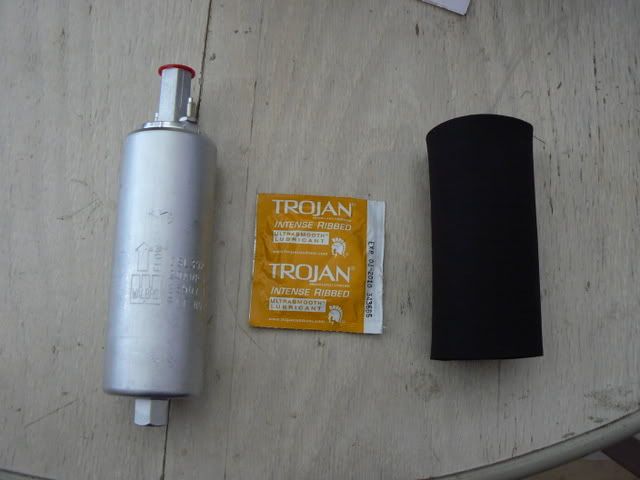

Required Items

1 - Fuel pump, external (as shown: Walbro 255lph)

1 - Foam, isolating

1 - Condom, lubricated (optional: undesired style and/or brand)

-

My spark output is set to inverted, that's how it runs.

I believe that means it pulls low (ground) instead of pulling high (+5v or +12v). Whatever it means, that's how my car runs.

-

Well I retract my previous statement, I looked over some datalogs and ran the numbers, and that is 100% correct. Now I've got hours of calculation ahead of me to figure out why my engine even ran the way I had it tuned.

-

Okay, you have a nice clean RPM signal into Megasquirt. You can now ignore the trigger input segment (other than trigger angle) and concentrate on the spark output circuitry.

For starters, you have done this mod, yes?

http://www.msextra.com/manuals/MS_Extra_Ignition_Hardware_Manual.htm#singlecoil

Secondly, in Megatune, File -> Codebase and output functions. Make sure LED17(D14)function is set to 'Spark Output A'

-

I've got a compression set, but I'm concerned about doing a dry test on an engine that has sat that long unlubricated. It would be nice to comp it before I buy it though. What's usually considered acceptable on these cars, 150psi+ IIRC?

It's a project car. Unless negotiation of the final price depends on condition of the engine ("The engine's fine, gimme $1000" "The engine might need to be rebuilt, I'll give ya $800), then I wouldn't worry about it. Assume the engine needs to be rebuilt; if not, woopie!

-

In my experience, it depends on the condition of the rings (assuming the engine was in good working condition the last time it ran). If you get good compression numbers, it should be fine. After my L24 sat for 16 years, the comp. numbers had all fallen. The engine would run, but it really wasn't great. However, a friend's L24 that has sat for as long (but was rebuilt just before it sat) is still putting out 170psi + on all cylinders, and therefore should be fine.

-

PW(fuel) = Req.Fuel x MAP/(100kpa) x VE/(100%) + E

I believe that's incorrect. In my experience messing with it, it does not take MAP/(100kpa) into account. That's why for the same afr at two different kpa values (say 100 and 110 kpa) one must multiply the 100kpa value by 110/100 to enter into the 110kpa box.

So, for VE to equal PW, make Req.Fuel. 100ms. Then, where VE is the number you put in the fuel map, you get:

PW(ms) = 100(ms) x (VE/100) x k (k for a correctional constant, using air temp, warm up enrich, etc)

which equals

PW(ms) = VE(ms) x k

so then you just enter your desired pulse widths into the fuel map. My question is whether you can enter decimal values into the fuel map, and how MS I (or MS II) will interpret that.

-

Good to hear you found your culprit.

NGK makes some of the best quality OEM replacement wires you can get. I would use them in all L6 applications where you retain the distributor. For L6s with DIS (no disty), I've used Jacobs and Summit universal kits with great success.

Good to know. I always liked the fit and quality of them, hopefully they will fix the miss as well. My fuel pump (OEM junkyard pump) just went out the other day though, so we'll have to wait until my Walbro 255 gets here to see.

-

Excellent, thank you. I'm about to go down Rustoleum road as well, and if shooting 60/40 through an HVLP makes it turn out like that, that's great news, i.e. less wet sanding.

-

Jon - Just to clarify, those four most recent shots are before wet sanding, correct?

-

So I hear, I'd love to try some, but really I can't afford to drop $80 on a set of wires right now. The NGKs worked before, and at $25 I can give them a shot.

-

Ha, that's pretty cool. Did you ever put a seat on it?

-

Ding ding ding, I think we have a winner. I just commented that it started when I switched to spark control. Well, when I did, I switched dizzies, and while moving spark plug wires from cap to cap, I broke one. I substituted in a fairly new taylor I had from something else that fit just fine...

Taylor wires have been a bane for some MS users.I'll be ordering a new complete set of NGK wires and we'll see if that fixes it.

-

You can cut up an 18mm Sparkplug Non-Fouler for use as an o2 bung. You can make two bungs from one piece, two pieces to a pack, the packs are $4 at autozone. You do the math.

-

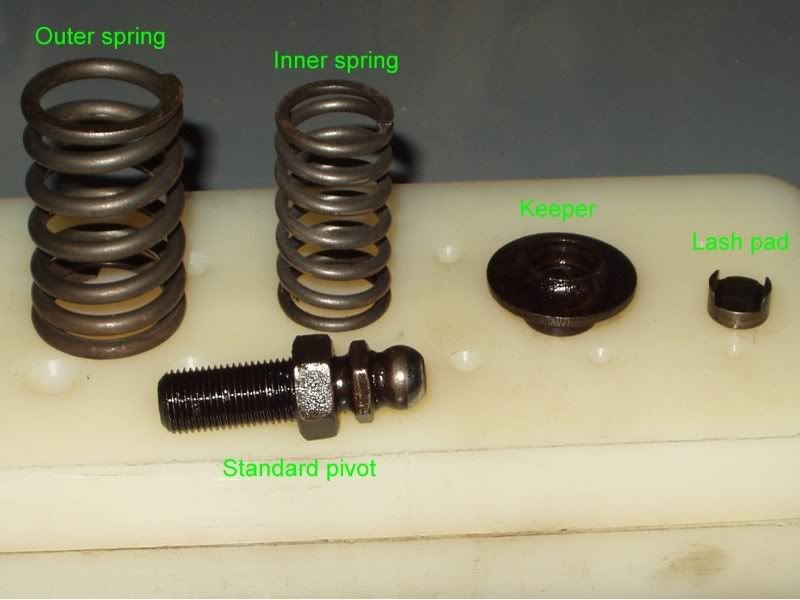

TR - The rocker arm pivots (shown below for absolute clarification, labeled 'Standard pivot') are the same in all mechanical lifter L6 heads. Picture courtesy Dragonfly.

-

Thank you guys, awesome information for sure. I've taken a good look at the flags, and I'll try to relax and keep everything in mind. I'm not too worried about driving fast, I'm confident in my driving ability, and regardless I'm not embarrassed to be passed, I just want to stay safe out there and keep out of everyone's way.

-

Hey guys,

I'm getting close to my very first track day (Jan 26th/27th), car's just about ready, but I really feel that I need to know more about track etiquette. Obviously I'm gonna make some beginner mistakes, but I don't want to establish myself as that 'stupid noob' that gets on everyone's nerves or potentially causes a dangerous situation out on the track.

I've read up all I could find in a google search on the subject (which surprisingly wasn't all that much), but I'd like to hear from everyone some tips to good track etiquette, especially things that lots of beginners tend to do, or things that may not be obvious to do/not to do. Also, I'm probably going to buy a book on the subject (not high performance driving, but more track day tips/etiquette), any suggestions as to good/bad books out there?

Sean

IMSA rear flares w/pics

in Body Kits & Paint

Posted

Another shot for those that didn't see the other threads: