X64v

-

Posts

543 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by X64v

-

-

Sean Wright

1973 240z

Tucson, AZ

-

Sweet! So how many people didnt cheat?

I only looked at others designs once, even though it was very tempting...

I only looked at others designs once, even though it was very tempting...Heh, I looked at all the designs, but never copied outright from any of them. I took what I liked from each and incorporated my own parts to make something that I liked the best.

-

Wow, excellent pictures Ron.

And Careless, I really, really like the colors in the first garage one for some reason.

A friend and I were flipping through some pictures I'd taken about a year ago, and he helped me edit a few, since he has such a good eye for shots.

Original Picture. Nothing really special at all, lots of nasty reflections and unwanted things in the picture (including a sleeping cousin). I took it because I had no other way of capturing the scenery.

Edit Ver. 1

Edit Ver. 2

I don't know how many of my friends have asked what movie that second edit is from.

Another:

-

Anyone experiment with slings/catapults?

It seems like the simplest idea for a lot of the levels, but because of the constraints of the available items, they tend to be more complex than other solutions. I've definitely thought about them though.

-

My solution for awash:

http://FantasticContraption.com/?designId=1233522

I've found most of mine look like cars or buggies or tanks. Hmmm, wonder why...

-

I was reminded that I'm overdue to post up my maps.

Full Set-Up:

Stock turbo bottom end

Stock T3 and exhaust manifold

P79, unshrouded valves, minor exhaust port work

Stock N/A "A" cam

400cc injectors

Unintercooled

Stock FPR

3" mandrel downpipe and exhaust, no muffler

N42 intake, stock 50mm TB

BPR7ES plugs, gapped at .030"

Fuel Map:

Spark Map:

The fuel map puts me at 12.5:1 to 13.0:1 at idle, 14.7:1 to 15.5:1 at cruise in all situations, and ~11.5:1 under all boost levels.

The y-axis graduations above 100kpa on the spark map are approx. 2 psi increments.

Both maps tuned up to 172kpa (12psi in Tucson, AZ) (~2400' ASL, ambient pressure usually 90kpa indicated). I have no pinging whatsoever, and the fuel map is completely smooth with great transitions.

-

Yeah, I might as well. I'll post them here, too.

Full Set-Up:

Stock turbo bottom end

Stock T3 and exhaust manifold

P79, unshrouded valves, minor exhaust port work

Stock N/A "A" cam

400cc injectors

Unintercooled

Stock FPR

3" mandrel downpipe and exhaust, no muffler

N42 intake, stock 50mm TB

BPR7ES plugs, gapped at .030"

Fuel Map:

Spark Map:

The fuel map puts me at 12.5:1 to 13.0:1 at idle, 14.7:1 to 15.5:1 at cruise in all situations, and ~11.5:1 under all boost levels.

The y-axis graduations above 100kpa on the spark map are approx. 2 psi increments.

Both maps tuned up to 172kpa (12psi in Tucson, AZ) (~2400' ASL, ambient pressure usually 90kpa indicated)

-

...you mentioned that the quench area seemed somewhat negligible...The thinking is to provide a pad where a flat top piston pushes nearly everything out of one section, and that movement inside the dynamically combusting chamber assists proper ignition and helps prevent detonation.

When I say quench area, I mean the effective quench area between this specific head and these specific pistons. Yes, this head has a large quench pad, but the area of that pad used by my pistons is what I'm deeming 'negligible'. (Although, looking back at my pictures, it's a little larger than I thought)

In actuality, the stock turbo pistons, with their dish, pretty much by definition kill the quench effect of this head (almost?) entirely. TRUE utilization of quench pads only occurs with well matched flat top pistons that nearly impact the head at TDC, and if a relief is needed for compression then the piston relief mirrors the CC in the head as much as possible.This was exactly my point in my posts with Six_Shooter. Not only does the turbo piston not have much area to make use of the quench effect, it does not come close enough to the head to quench at all (or so I've read, correct me if that's wrong).

That's also why I'm a little stumped as to why this head works better than the other one. They're both more or less open with the dished pistons, why does the P79 work so much better? Or another way of looking at it, why did the E88 work well with flat tops, but not dished pistons?

-

This is where I've been getting to play for a few months, since I work there:

There's two more lifts out of the picture, totaling six.

When school starts, I get to go back to a carport.

-

Most of those cars have electric speedometers, but I do know one or two have mechanical ones, so you're correct. However, has anyone driven a car with an electric speedometer that bounced?

-

Daeron, that is a good idea indeed, and I happen to already have all the pictures necessary. To recap:

I used a 1973 E88 (One year only, the 'submodel' is N33, it's got 240z valves but a large 47.8cc chamber) with unknown 83mm flat-top pistons (small valve reliefs no where close to where they should be) that popped out of the deck .030" to give a static compression ratio of 8.9:1 on my L24. I ran this set up for a few months at 7psi and 24* of ignition timing with no detonation. I feel that that was a reasonable amount of timing, and so in my opinion this head/bore/piston combo 'worked'. This was unintercooled, with bp6es plugs, a 160* thermostat, and 110*+ ambient temps.

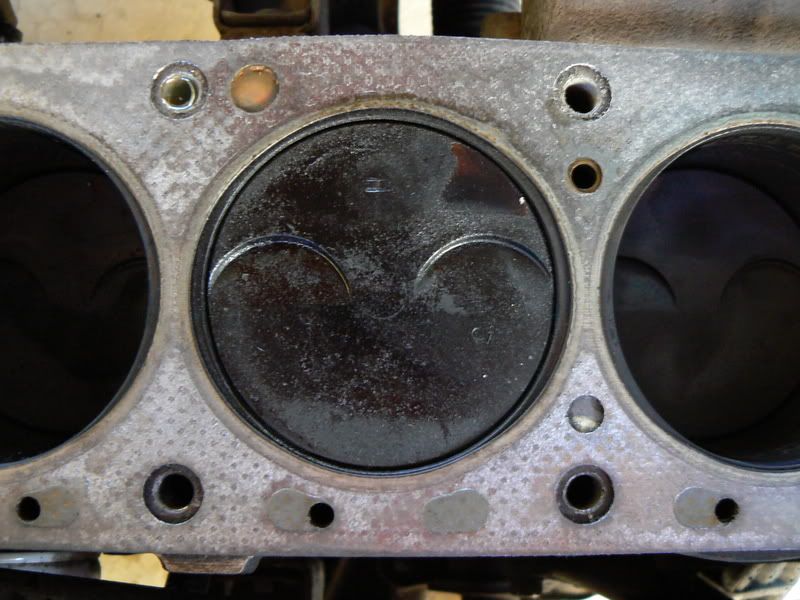

The E88:

The unknown 83mm flat-top pistons:

I then rebuilt a stock l28et bottom end. Standard rod and crank journal sizes, stock 86mm bore, stock P90 turbo pistons. I re-used the E88 pictured above, giving me an SCR of 7.9:1. This is the set-up I had problems with, which is why this thread was created in the first place. After all my fiddling, I was able to run no more than 23* of timing at 7psi, and even then it was pinging residually. I feel that I should have been able to run much more ignition timing, so in my opinion this head/bore/piston combo did not work. This was unintercooled, with bpr7es plugs, a 160* thermostat, and 80* ambient temps.

Same head, but these 86mm stock turbo P90 dished pistons:

As a last ditch effort (and as a bit of an upgrade), I made some small modifications to a P79 (which can be seen in my "members' projects" thread), then had it rebuilt at a machine shop. Using this on the dished pistons shown above, I have an SCR of 7.35:1 (stock l28et ratio), and am able to run 29* of timing at 7psi. I'm currently running at 12psi with 24* of timing with no detectable detonation whatsoever (had the head off for an unrelated reason, and the fire rings were perfectly round). I feel that this is plenty of timing, and so in my opinion this head/bore/piston combo works (as did Nissan). This is unintercooled, with bpr7es plugs, a 160* thermostat, and 100* ambient temps.

The P79 chamber:

I guess the point here is that the E88 liked the flattop pistons, but would not work with the dished pistons for reasons unbeknownst to me. The P79, with negligible quench area gain (IMHO), likes the dished pistons just fine.

Anything I missed?

-

Alright, if that's your definition of quench, then what I mean is the quench area is negligible.

-

Quench does have a lot to do with the raised area at the outside of the piston, that's why it's there. That's where you will measure that "0.040" quench" with a dished piston

Yes, that is where I'm measuring. It's .049" (the edge of the piston comes even with the block, .000" deck height, and then the gasket is .049" thick). Plus, even if it were within quench range, that amount of quench is inconsequential compared to a piston actually set up for quench (a flat top with the dish cut out exactly under the combustion chamber to achieve the desired SCR).

There is absolutely zero quench with the P79 head/P90 pistons, unless you use a thinner gasket, in which case the quench is still very minimal.

-

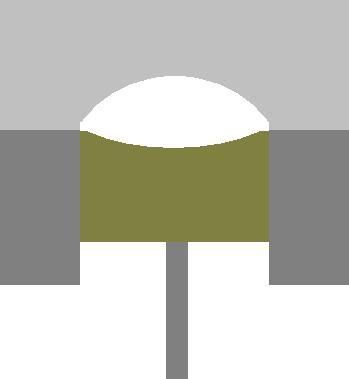

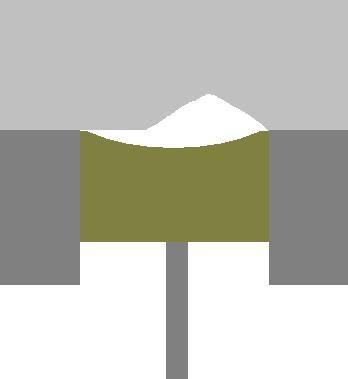

I meant looking at it from the side, like so:

E88 with P90 pistons:

Kinda looks like a lemon.

P79 with P90 pistons:

No longer as open, but there is definitely no quench there. That ring you talk about running around the outside of the piston that's at full height isn't enough to do much, and plus with a stock head gasket (.049" thick) it's out of quench range anyway (from what I read, it must be <.040").

-

Even my brand new Autometer speedometer bounces when I get above 130.I've had several OEM guages up to that speed and beyond and they didn't bounce....

Apples need to be compared to apples. Was the Autometer speedo mechanical or electronic? If used in a Z, probably mechanical. The OEM gauges Gollum speaks of are most likely electronic.

I have no first hand experience with one, but I'd lay down money that an Autometer electronic speedometer doesn't bounce...

And I set a new personal record a few weeks ago, 154mph (5400rpm, 5th gear through an 81-83 5 speed, 3.364 r180, 225/50/ZR15 tires). Car felt fine, even took a slight bend at about 145.

-

Well I'm running dished pistons, so no quench, but the shape of the entire combustion chamber is different, going from a lemon-like shape to...I guess a lemon with a bite out of it.

And no knock sensor. I was detecting it audibly, with it being confirmed by blown head gaskets if it got too bad. I had to pull the head recently for something else after running this p79 at 12psi for a few weeks, and the fire rings were still perfectly round, confirming the absence of pinging.

Edit: I also performed cylinder head cooling re-routing modifications, detailed here, though I have absolutely no proof as to whether they helped or not.

-

They're definitely on my short list of things to see in my life. I have the Völkerball DVD, and watching it makes me wish I'd been there. Too bad they're not touring now, I would have liked to see them if/when I go to Deutschland this winter.

-

As a final follow-up post, it seems to have been the e88 cylinder head that was the root cause. I switched to a p79 and am now running 24* of timing at 12psi with no pinging whatsoever (unintercooled, BPR7ES plugs, 160* thermostat, 100*+ ambient temps).

-

Don't know whose head this is

That would be mine. I was quite surprised when I saw that one.

Here's my desktop:

I'm sure someone knows the band it's from.

-

"A weapon with a twist."

Ha! Excellent.

-

MSA's head gasket is excellent, with the correct factory water cutouts/blockoffs and outline. I run 12psi daily and have no problems with it, even under light pinging. During heavy pinging or actual knocking it'll blow out the manifold side and keep all the water passages intact, allowing the engine to run like normal (other than the psh psh psh) without ingesting any coolant.

Whichever gasket you get (save for an MLS gasket), make sure the outline of the gasket on the manifold side follows the fire ring like this:

So that it can blow out the side like this:

If the gasket just follows the side of the block like this:

Then when you have heavy pinging, it won't blow out the side to act as a safety fuse, it'll just let coolant in from the adjacent coolant passages like this:

(The first two pictures are of MSA gaskets, the last two are of a "Stone" gasket I got laying around at work.)

-

I've not heard of using the teeth, but I know a few people have installed magnets or machined "teeth" into the flywheel opposite of the clutch surface, then simply put the vr or hall sensor through the sheet metal cover on the engine side. A few OEMs do this as well.

-

They work just fine until they collapse internally...

http://www.betamotorsports.com/benchracing/CheapMuffler.html

I have a $40 Dynomax bullet muffler that started doing the exact same thing after perhaps three months of daily-driver use.

I'm happy with my full 3" no muffler system.

-

Ditto on what Clifton said. Match the gasket to the head, not the block.

Z spotted in another movie

in Non Tech Board

Posted

Just noticed a brown 280z in the background of Revenge of the Nerds (the first one). Just before an hour in, at the start of the greek games, it's in a parking lot as the people are rushing in.

And as a fun fact, that movie was filmed at the U of A.