-

Posts

529 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by nismo kid

-

With the 4.8 together I needed to find a clutch. I originally ordered clutch but they requested I buy theirflywheel. Which informed that would be useless for me. Well that struck a cord with them. So I explained my setup & they told me the LS wouldn't even fit in car. I told them to Google my car which must be mystical unicorn ROFL. Got my refund and began searching for another option. Found a couple options. In 1 hand there was an affordable 700-800$ clutch. In the other there was a 2100$ clutch that was way more than I needed. The 1st clutch appeared to fit my needs & had a nice price to match. So I gave the clutch maker a call. They informed me that my set up would be pushing to the limits of that clutch. They've had people make 800+hp but on less torque producing V6's. Not wanting to be held back by my clutch I went with option 2. It hurt in the beginning. Hell this clutch cost more than my car, turbo, engine & transmission combined lol. But it'll aid me obtain my goals & pay for itself in the long run. Due to the fact it's a twin disc & can be rebuilt. I went with Ceramic & Rigid Organic disc combination per Clutch Masters recommendation. The clutch comes with acustom flywheel that allows you to back the LSX with a Z32 transmission. With that said they're made to order. I was quoted 3-4 weeks for them to make it. I figured it was likely another week for shipping. Boy was I wrong. My clutch was delivered in just 10 days! While I was waiting on my clutch I went ahead & had my starter rebuilt.

-

-

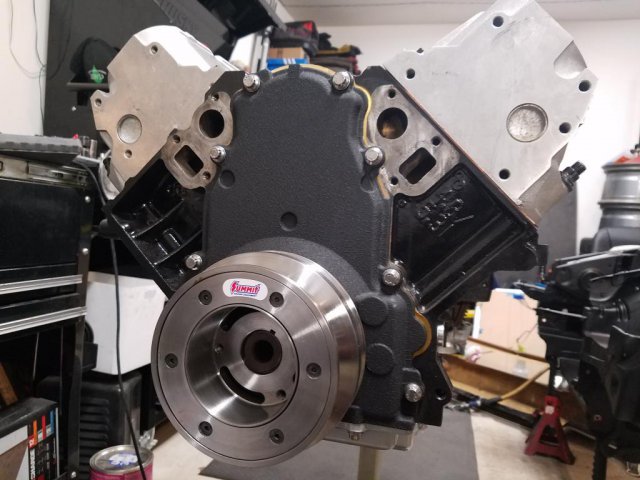

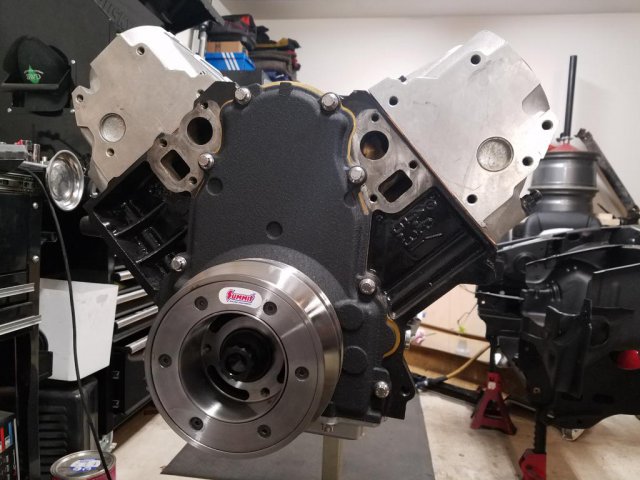

The balancer started looking lonely on my work bench so I slapped it on followed by the ARP Balancer Bolt.Installed the F-Body windage tray & pick up tube. Rotated the engine a few more times to check for clearance. Then tossed the oil pan on.

-

Moving on I installed the Improved Racing oil pan baffle into my F-Body oil pan. It's a shame that something so nice won't be seen.I also deleted my oil level sensor but using Dorman Drain Plug 65221.

-

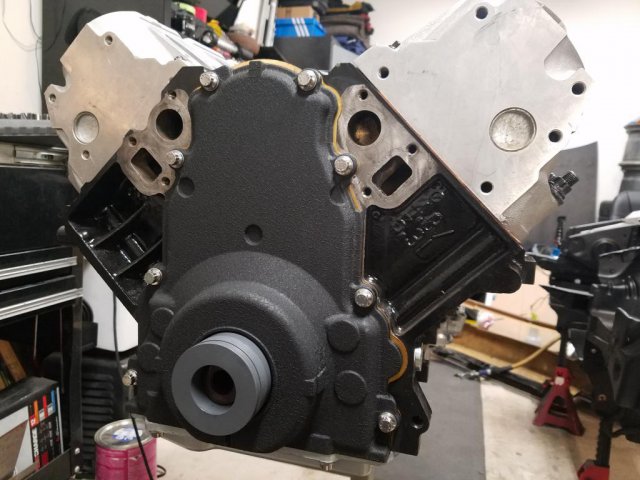

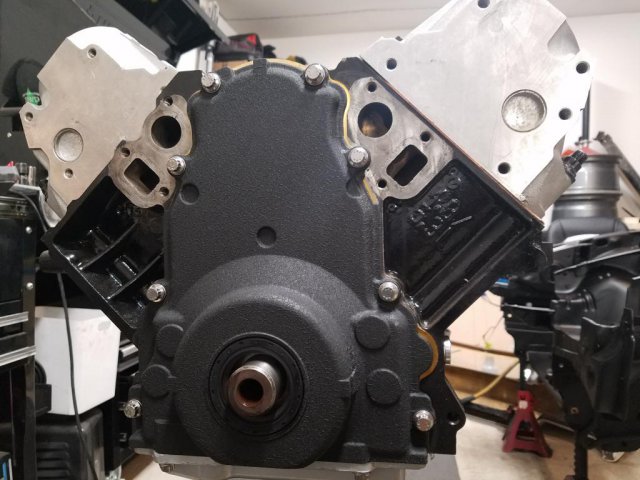

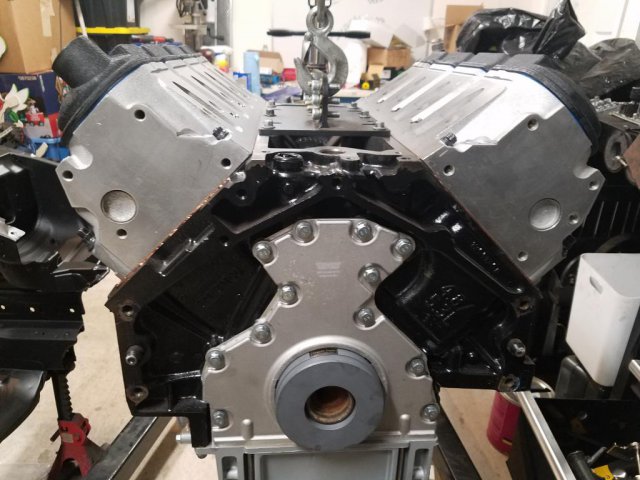

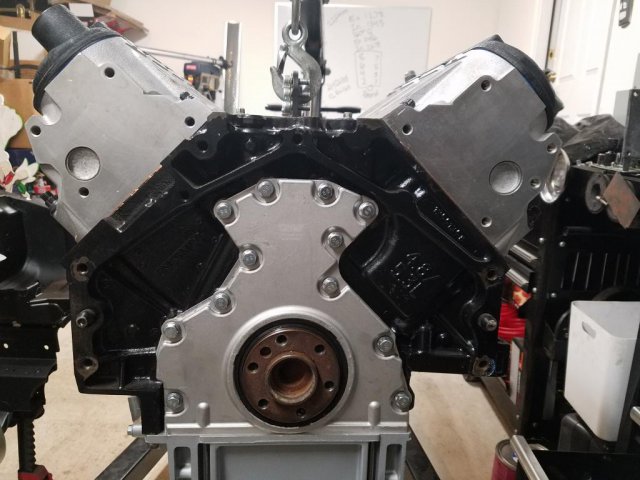

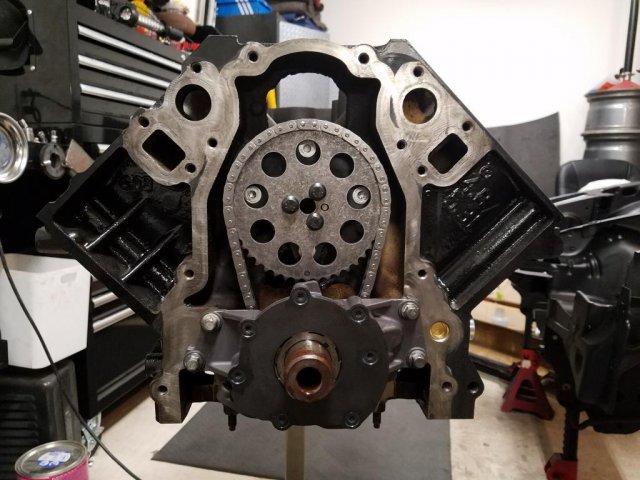

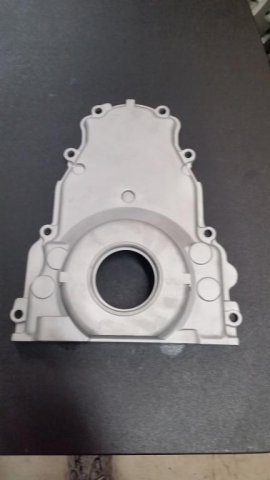

Next I installed my timing & rear main seal covers using some Alignit tools. These things come in handy. After the covers were aligned I installed the seals.

-

After a few rotations I double checked all the rocker arm bolts with my torque wrench. Now that made sure I had no binding issues it was time to install my valve covers & Meling oil pump. I installed the Meling oil pump following their directions. Using 3 .0025 feeler gauges equally spaced between each rotor. Plus 3 more equally spaced .0025 feeler gauges between the largest rotor & pump casing. Then torqued the pump bolts to 18 ft lbs. Then secured pump cover using supplied bolts with a bit Loctite 242.

-

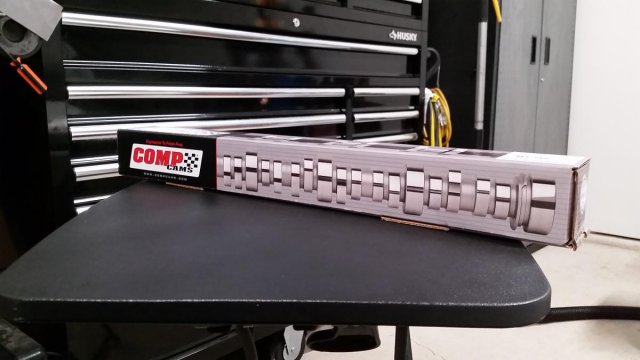

Continuing on I tossed in my pushrods & set the rockers in their respected places. With the engine in the number one firing position, I tightened exhaust valve rocker arm bolts 1, 2, 7, and 8 to 22 ft lbs. Then I tightened intake valve rocker arm bolts 1, 3, 4, and 5 to 22 ft lbs. I rotated the crankshaft 360° & tightened exhaust valve rocker arm bolts 3, 4, 5, and 6 to 22 ft lbs. Last but not least I tightened intake valve rocker arm bolts 2, 6, 7, and 8 to 22 ft lbs.

-

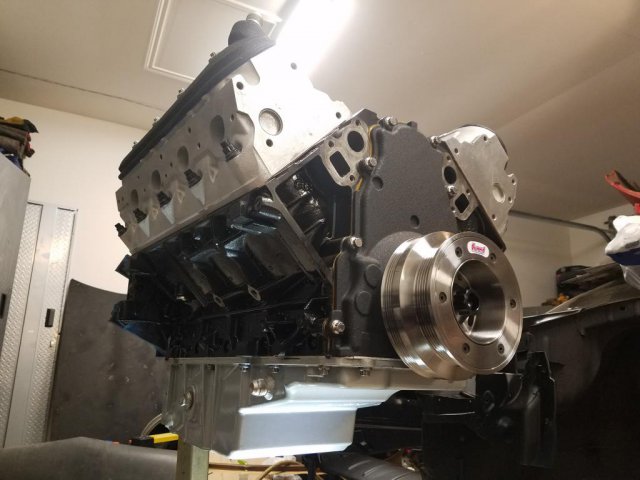

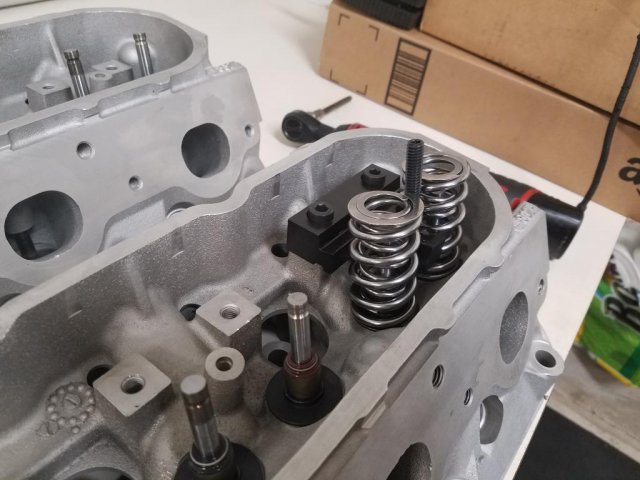

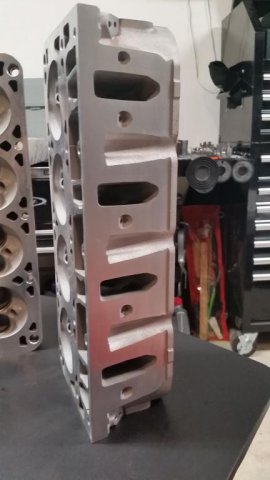

Carefully lowered the cylinder heads down over the head studs.After that I lightly applied ARP lube to the washer & threads of the nuts. Then I installed the washers & threaded the nuts down hand tight. Following GM's recommended torque sequence I tightened the 7/16" nuts in 3 equal steps to 80 ft lbs. The 5/16" nuts were torqued to 25 ft lbs.

-

-

Installed cylinder head dowels. Lightly lubed the threaded sections of the ARP Head Stud with ARP lube. Then threaded them into the block hand tight.

-

-

-

-

-

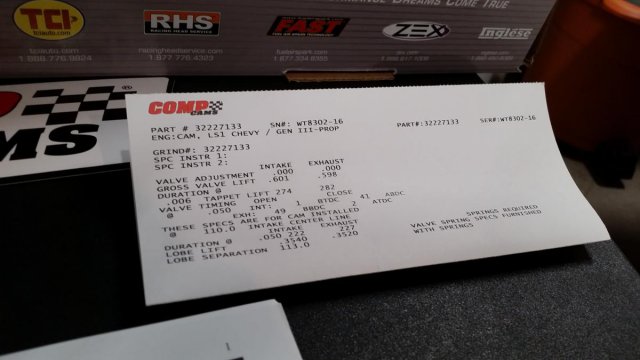

I grabbed my 4.8 cleaned all the bolt holes in the block. Then replaced all the oil & coolant plugs. After all that I proceeded installing the LJMS Stage 1 cam followed by a new camshaft retainer.

-

Next up was installing my Straub Technologies Trunnion kit into my factory rocker arms. Thanks to thesummit racing tool it was a breeze. I also set those to the side.

-

After that I installed the valves & Premium BTR 660 valve spring kit. Then set the cylinder heads off to the side. After that I installed the valves & Premium BTR 660 valve spring kit. Then set the cylinder heads off to the side.

-

Now that I have my assortment of parts it was time for assembly. 1st I cleaned & began to lap all the valves. After lapping a few I found a couple pits on the seat of the valve. So I decided to get valve job.

-

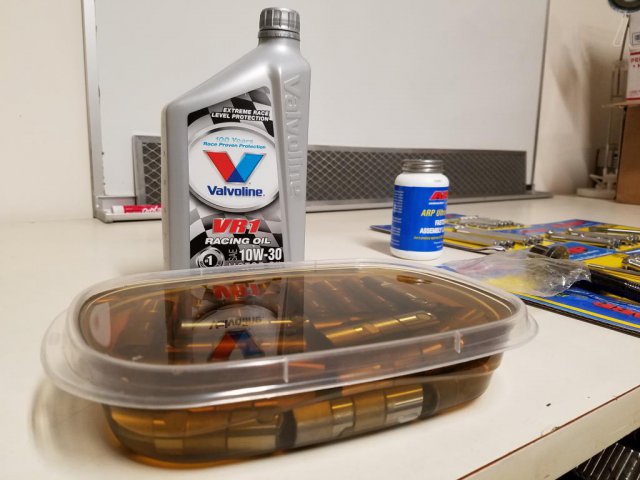

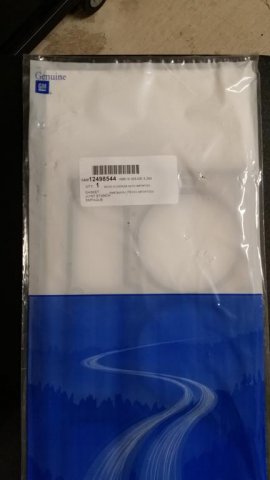

Purchased all these goodies for the 4.8 LJMS Stage 1 4.8 Turbo Cam BTR 660 Dual Valve Springs with Titanium Retainers Comp 7.400 Hardened Push Rods Straub Technologies Trunnion Kit ARP Head Studs ARP Stainless Steel Valve Cover Bolts ARP Stainless Steel Water Pump Bolts ARP Stainless Steel Intake Manifold Bolts ARP Stainless Steel Oil Pan Bolts ARP Stainless Steel Timing Cover Bolts ARP Balancer Bolt ARP Camshaft Bolts Summit 25% Underdrive Balancer Improved Racing Oil Pan Baffle Meling 10295 High Oil Pressure Pump Hinson Racing C7R Timing Chain Billet EGR block Off Plate LS7 Lifters New Lifter Trays GM Performance 12498544 Head Gasket Dorman Drain Plug 65221(Deletes oil level sensor) New GM 12589016 Camshaft Retainer New Oil & Coolant Plugs New Cylinder Head Dowels Dorman 635-518 Rear Main Seal Cover Set New Gaskets for the entire engine MS3 Gold Box Siemens Deka 80 LB/HR Fuel Injectors 3 Bar Map sensor Fast Fuel Rails(Scored these for 50$) 12.9 grade Rocker Arm Bolts

-

Then had my engine crossmember, valve covers, timing cover, oil pan, & a few other things powder coated.

-

-

-

Dropped the heads of at the machine shop it have them cleaned & resurfaced. Also had the valve covers, oil pan, & timing cover media blasted. I also replaced the cam bearings. While I was doing this I figured "Why not step my engine bay game up?". I chose to shave the stand offs & weld -10an fittings on my valve covers.

-

-

I tore it down & inspected immediately. This little 4.8 was pretty damn dirty on the outside. But it was rock solid inside.