-

Posts

529 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by nismo kid

-

I'm pleased with how it came it. I chose not to wet sand the paint. Mainly because my car isn't a show car. I personally believe it went on pretty smooth. I also think the rubber under coating came pretty nice too. As for the temporary spray booth I was highly satisfied. It captured 100% of the over spray & about 90% of the fumes. If I was to do it again I'd add paint pocket air filters between the cloth & Activated charcoal air filters. That way it gets rid of all the fumes. Another change that made is the engine I'm using. In the beginning I had planned to use my early LS1 with a set of 243s. But that was all changed when I acquired a complete Gen 3 4.8 with ls1 intake for 50$! I purchased from a friend of a friend. My 50$ 4.8 has 165k on the clock and has had nitrous ran though it a majority of its life. The previous owner went to a larger cubes on his build. Here's how it looked when I 1st purchased it.

-

After the paint fully cured I Prepped off the engine bay. Minus the transmission tunnel & the frame rails up to where the engine crossmember go. Then coated the wheel wells, frame rails, & transmission tunnel with 3m professional rubber undercoating.

-

-

-

-

-

These are the steps I took to paint my engine bay. Note steps 1-3 were prior to the booth being constructed (1) Used wire brushes & 80 grit to knock all surface rust away. (2) Feathered bare metal areas back towards factory paint with 220 grit. (3) Scuffed all paint with red Scotch Brite (4) Prepped surface with tack cloth & acetone (5) Coated all bare metal with 2 coats of Rust Encapsulator. Waited 1hr between coats. Allowed 6-8hrs before Primer. (6) Prepped surface with tack cloth (7) Coated engine bay with Eastwood's 2K AeroSpray High Build Urethane Primer. (8) Waited 3-4hrs & knocked down highs with 400 grit. (9) Prepped surface with tack cloth (10) Sprayed 3 coats of Eastwood's 2K Ceramic Underhood Black Aerosol. Waited 2-5 minutes between coats. Scuffed the entire engine bay

-

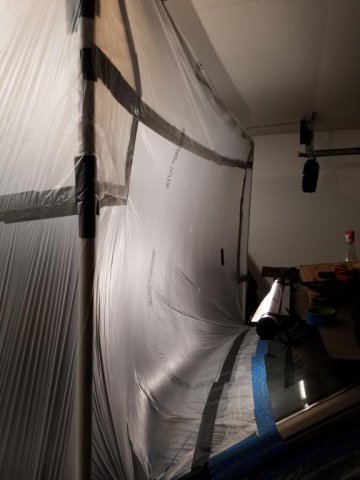

With my engine bay to my settled liking, I began to search for a body shop. I originally was trying to shy away from rattle canning it. Well after spending 2 days searching for a body shop I failed to find any that were interested. There was only 1 body shop that was willing to do it only if I painted the entire car. An entire paint job wasn't in my budget. So that left me with 1 option. Paint the engine bay myself. I came to the conclusion to tackle my wheel wells too. Majority of spray paints tend fail to hold up most against fluids found in an engine bay. I've used engine paint in the past with pretty good success. Then I stumbled on Eastwood's 2k Aero-Spray paints. It's a 2-component coating, without the paint gun. Figured I'd give these try, so I purchased 6 cans of Eastwood's 2K Ceramic Underhood Black Aerosol & Eastwood's 2K AeroSpray High Build Urethane Primer Aerosol. I also ordered 2 cans of Eastwood's Black Rust Encapsulator. With all my paint ordered I moved onto constructing a temporary spray booth inside my garage. Ideally most prefer a positive pressure spray booth. Due to the fact it is less likely to draw in contaminates. But I chose to do a negative pressure spray booth. I personally felt it kept the overspray to a lower minimum over the positive pressure booth. My booth was very well sealed & I never had an issue with contaminates entering the booth. Here's what I used 12 sticks 3/4" PVC for my frame cut them down to 7' 3 20" regular box fans (A big no no I know) 6 20"x25" Regular air filters (enough for 2 sets of changes) 2 20"x25" Activated charcoal air filters 8 3/4" 90°corners/3 way T 3 3/4" T fittings 2 3/4" 90° fittings 1 old shower curtain for the floor 10 rolls of gorilla glue duct tape 1 tarp zipper 2 rolls of painters tape 3M tear-resistant plastic sheeting(body shops use it. I used it for my walls & ceiling. This is what it looked like all assembled.

-

I quickly decided that I wasn't going to weld all the 6mm holes in the entire engine bay. My solution was 3m seam sealer. Many people may not be keen on the idea but it worked flawlessly for me. It's sand-able, Non-Shrinking, Non-Cracking, & Paintable. I only used it on the 6mm holes. I finished off all the filler plates with Evercoat rage gold for a nice smooth finish. This is hands down the best body filler I've ever used. It sets quick & sands nicely. Once the seam sealer & body filler were fully cured I blocked the entire engine bay. The blocking was followed up by tack cloth & acetone.

-

It's surprising how far some elbow grease & plenty of patience can go. I would've never thought it could clean up as nice as did. With the engine bay & wheel wells cleaned up I began removing all the brackets I no longer needed. This was also the perfect time to massage my transmission tunnel. When a Z32 transmission is used in a Z31 you have to massage the transmission tunnel for starter clearance. It may not be pretty but it's functional. Then I made some templates for all the holes I was going to fill. (That's what she said) Then transferred the patterns over to 22ga sheet metal. Using a pair of shears & my dremel I careful cut them all out. After plenty of file fitting they were ready to be welded in. I also repaired my damaged headlight bucket/fender mount. With my buddies tig being tied up I borrowed another friends Hobart 210. So dangerously armed with the Hobart 210 WITHOUT gas, incorrect sized flux core wire I went to town.(Hobart/Miller advised me not to even to attempt to weld 22ga with Flux core wire) But I was in a time crunch. This was by far the least enjoyable welding experience I've had with the car. But I made it work. After the welding was completed I removed all the surface rust & grounded the welds smooth. In the harder to reach areas I used Loctite Naval jelly.

-

-

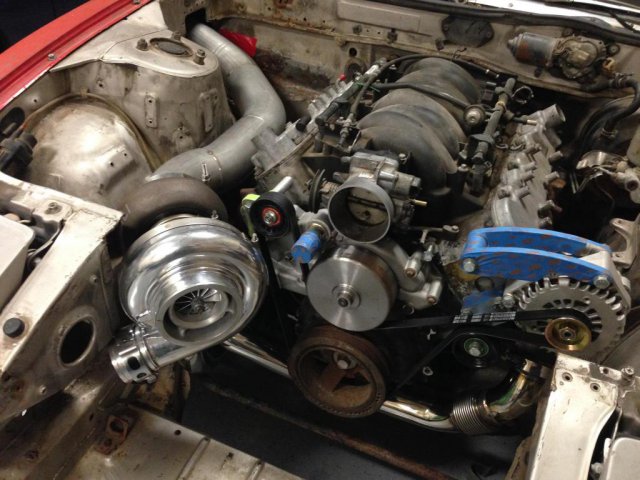

It's official! Theme has come for the long over due update of my build. So I changed a few things with my build. First on the list was addressing my filthy engine bay/compartment. Up until this point I had never even cleaned it. Lol Knowing that I had to do justice to my turbo kit a plan of attack was formed. I was going to semi-shave my engine bay! So out came the engine & transmission. Wanted to see how my hotside looked on my engine outside of the car.

-

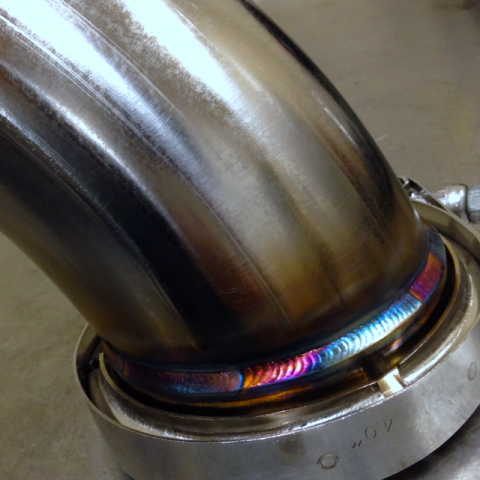

I just saw this thread. As jshapaka stated you can use his or my build thread for reference. I tested several oil pan options and the Fbody pan was the best fit. The truck pans work if you modify it but you'll lose oil capacity. The LS2 C6 pan kinda works but you'd need to modify the firewall to make room for the transmission bellhousing(I'd add this pan to the list of DO NOT FIT.)The GTO, C5, Autokraft, Trailblazer SS & SSR oil pans DO NOT FIT. If you'd like to take the guess work out of the engine mounts you can get the direct bolt in Dirty Dingo mounts which allow 3 inches of adjustment. At only 150$ they make life much easier. I'd buy them even if I didn't Co-develop them. As for the radiator the factory radiator or the Champion 3 row work just fine. To fit the TH400 or TH350 you'll need to massage the transmission tunnel with a BFH( Big F*cking Hammer). I highly recommend if you're going to solid mount the engine to also solid mount your transmission. You'll quickly find out what'll flex the hard way if you mix and match solid & rubber/poly mounts( It won't be the chassis. It'll be your transmission). If your dead set on having power steering use the gm power steering pump then have custom lines made at a hydraulic line shop( I.E. Taylor Made). I personally have no problem steering my Z31 without power steering. For my last recommendation I'd weld vbands on those headers for ease of installation while helping with clearance. I hope this post helps you with your build. Nice car man . Oh here's a link showing My Vic Jr test fitting. The EFI and Carb Vic Jr intakes are basically the same design, only difference is the injector holes being drilled out. http://z31performance.com/showthread.php?25250-LSX-Vic-Jr-Intake-Manifold-amp-Aaron-elbow-Z31-test-fitting

-

Stony's Unnatural Aspiration Part 4!!!

nismo kid replied to stony's topic in Gen III & IV Chevy V8Z Tech Board

I just found your build on YB. I had to come here and give you praise too lol. Looks great man! -

Good work man. Sub'd

-

Bolt in LSX engine mounts for the Z31

nismo kid replied to nismo kid's topic in Gen III & IV Chevy V8Z Tech Board

I found this video today while searching youtube at work lol. I just liked it. Great job man -

Bolt in LSX engine mounts for the Z31

nismo kid replied to nismo kid's topic in Gen III & IV Chevy V8Z Tech Board

Nice jshapaka! -

Here's a video showing my Vanjen clamp fitment.

-

Here's a few teasers of modifications soon to come including Front end conversion, S13 subframe swap. Trust me there's much more to come. I have quite a collection of parts. I'd like to give a special thanks out to a few people. First is darkzschneider. I don't just let anyone touch my car. I've been doing all my own work since for a very long time. I'm very pleased and honored to say darkzschneider did my fabrication. I feel we have the same amount of attention to detail. He's by far the best fabricator in San Antonio. I'd like to say one best in the entire state of TX. Your work is truly fanonimal.Thanks again man. Second is Andrew84zx I really appreciate loaning me the radiator at last minute. My car would have been at a stand still if it weren't for your kind gesture. Thank you Third is FlawleZ Thanks for lending me a hand with the removal of the VG30E and the relocation of my car. It helped out a lot. Thank you. I'd also like to thank my all my friends & family for the motivation. This project is far from being completed but it has came a long way. Last but least I'd like my loving girlfriend Katy. She has not move batted an eye or uttered a complaint about this project. Hell she's given me much needed parts for gifts over the years we’ve been together. I’m truly a lucky man. Thanks love. (Ps don't let her know I put her last Rofl. Just kidding she wouldn't mind) That's it folks. Sorry for the long winded build thread. Check back for updates and feel free to post any comments or questions you may have. Thanks for checking my build out. Here shortly I’ll post a parts list that will be simultaneously updated with the status of each modification/part installment. Until next time take care.

-

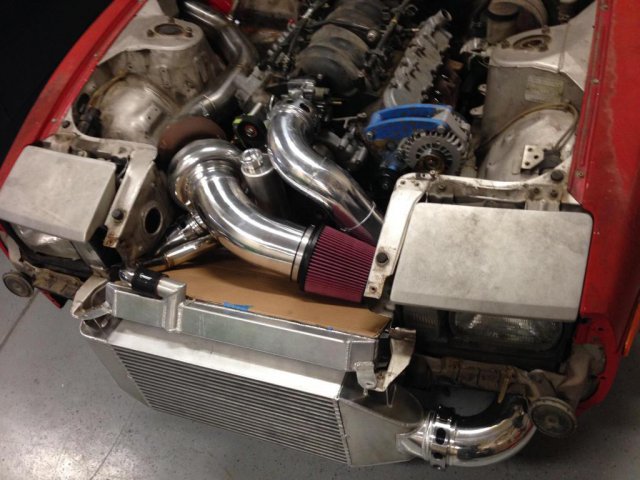

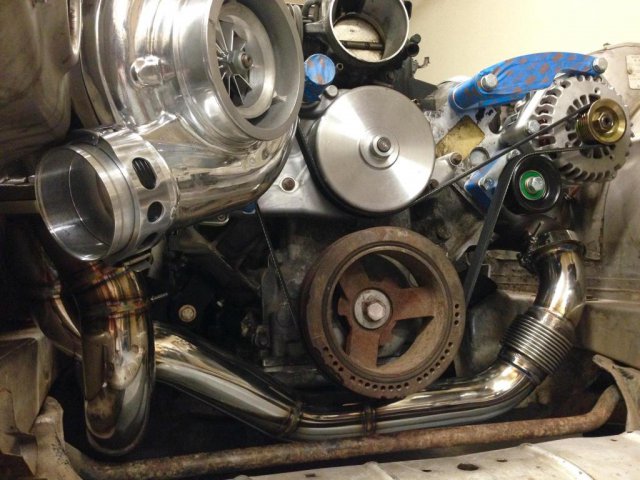

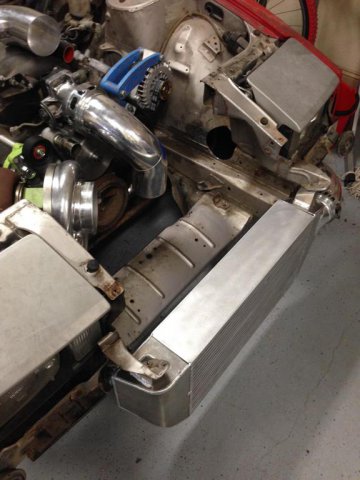

Here's the completed kit & radiator setup. You'll also darkzschneider 2JZ Z31 in driveway with my Turbo LSX Z31. Then it came to it's new home for the 1st time.

-

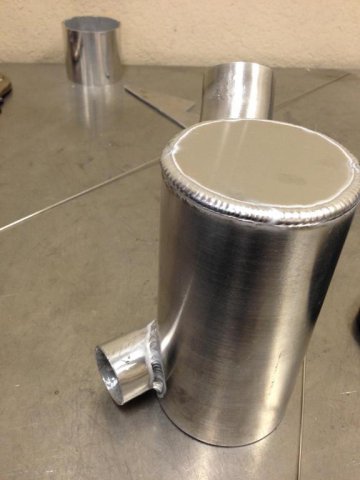

To keep my engine cool I'm using a fully aluminum constructed Champion 3 core radiator. That was purchased from MSA. We had to relocate one of the water necks but other than that is the same off shelf unit. The radiator is connected by fully stainless steel coolant pipes along with a coolant swirl pot. All connections are done with Vibrant silicone couplers and T-bolt clamps. There was a couple modifications made to the water pump as well. One of them being heater core tubes were welded shut. As for the other a piece of tubing was welded to the water pump outlet.

-

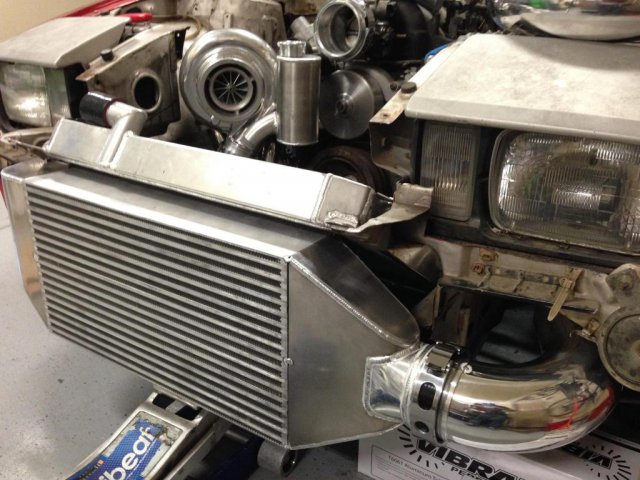

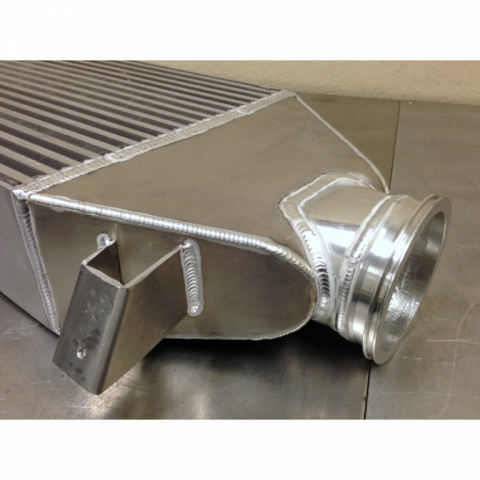

As for the cold side it's 3inch tubing from the compressor housing into a backdoor entrance on intercooler. Then 4 inch tubing was used from the intercooler to the throttle body.The entire cold side is constructed from aluminum. All but 1 connection is assembled with Vanjen clamps. The only V-band is located on the charge pipe that goes from the intercooler to the throttle body and is hidden . Which is finished off by a 50mm Tial BOV.

-

Moving on to the intercooler. It utilizes a Garrett core that's rated for 1k hp. Finished off rolled end tanks.

-

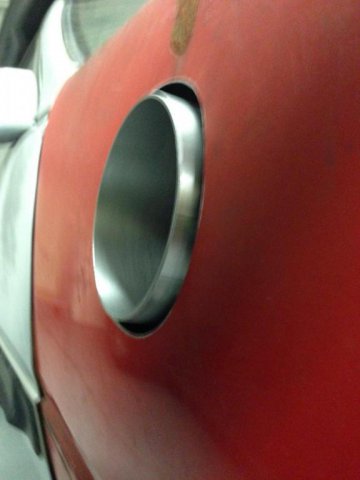

The downpipe is constructed with 4inch tubing and exits the fender. The entire hot side is made of stainless steel and is fully assembled with V-bands.