Wedge

-

Posts

551 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Wedge

-

-

I have had a good forum thread form a french civic forum about CF and molding ill post the adresse maybe Google translattion could work ?

Original=French original

Translation=My linkgoogle translation

Its very informative i did a pair of motorcycle mirrors following this guide and you can even add vaccum bagging if you want

-

Just some heads up if you want a Bosch 044 fuel pump i got mine on amazon for under 200$ check it out. Good luck

-

In for GB if they have the offset of the RBR's available.

-

Thanks Tony, I always clean up every bolts, nuts and surfaces I torque and try to always use new hardware. I jut want to make sure I follow the RB26 FSM correctly to not overtighten for nothing. I do think that a good clean and new bolt or nut being torqued to FSM spec is safe for my applications.

-

It could be the transmission but when you start the car you push the clutch in thus putting it in neutral state it shouldnt lock if you have the clutch all the way in or maybe the clutch is not working. I hope you didnt break a valve . Good luck

-

Dont we all ... my RB26 swap isnt going as fast as yours because im doing some body work in the same time i have the engine out.

-

300 $ is a good deal IMO. thanks for the all info you put out.

-

Thank you very much ! Merci beaucoup mon ami !

Yves.

-

Hi, everyone I feel kinda dumb for asking this but my mom always said their is no dumb questions so ill go ahead and ask. I am trying to understand what torque numbers do i use in my FSM I have a RB26DETT going in my Z and the FSM states ,for lets say a random bolt, the torque to use is 16-21 (1.6-2.1 , 12-15)N'm (kg-m, ft-Ib)and at the begining of the FSM they state "When X to Y N'm (kg-m, ft-Ib) is indicated, the standard tightening torque is the mean value". I dont understand what the crap that means ? I know i got to convert it in inch/pounds for my Torque wrench that i got it but what number do i use 16n*m or 21n*m or something in between ?

Thanks

-

Thanks ill have to check I think I dont need the nipple my filter screws on the adapter. Why would you think i need one ?

-

I guess its going to be fine then thanks. Im not to sure about the Ebay coolers I keep reading they work and they dont leak but they dont cool as much as "brands" I/C. Id prefer to pay 100$ more to have a quality cooler then getting a ebay one that does the job halfway. People told me I have to pick two Fast, Good and Cheap so im picking Fast and good.

-

Im just looking for some approval will this intercooler do the job for a 400hp RB i know it says 600hp but most guys with RB26 are running the big 31x12x3 Chinabay coolers ?

The price seems good for a brand cooler.

thank you.

-

For a non gaming rig I always recomend AMD cpu's they are less expensive. But if you want an intel base pc go ahead this Pc could do anythibng you want and the price is pretty good.

-

Hi everyone, just wondering if we had any members touched by the tornados in Missouri and is their a way we could donate to these members throught the forum ?

Best regards, form Canada

In hope everyone and their familys are safe and sound.

-

Id love to have GTR or Z32 brakes on the front that would be nice keep us posted.

-

Same on my car i had the lower front fender part brass soldered to the fender. I think its an half assed way of repairing or welding something but im am probably wrong i dunno much about welding.

-

I had been warned previously before starting to weld about the danger of the UV so I have proper gloves, pants and a fire proof lab coat from work and a big 20lbs fire extingisher next to me. Thanks again for the tips .

-

Thanks Bruce83 ill have to go back to the shop to see if they will trade my bottle for some 75/25. I was told to not use Co2 since im working in my garage and dont have alot of ventilation I was told it makes alot of smoke.

-

Id bring one if i would do a long drive trip but everyday driving id get a fix a flat or just get this http://www.slime.com/product/74/Tire-Sealant.html had it in my bikes tire and it works great.

-

thanks Jon. the problem i have with my machine is that I only have two settings Max and Min last time i tried I didnt notice a diffrence ill have to do more training tomorow.

-

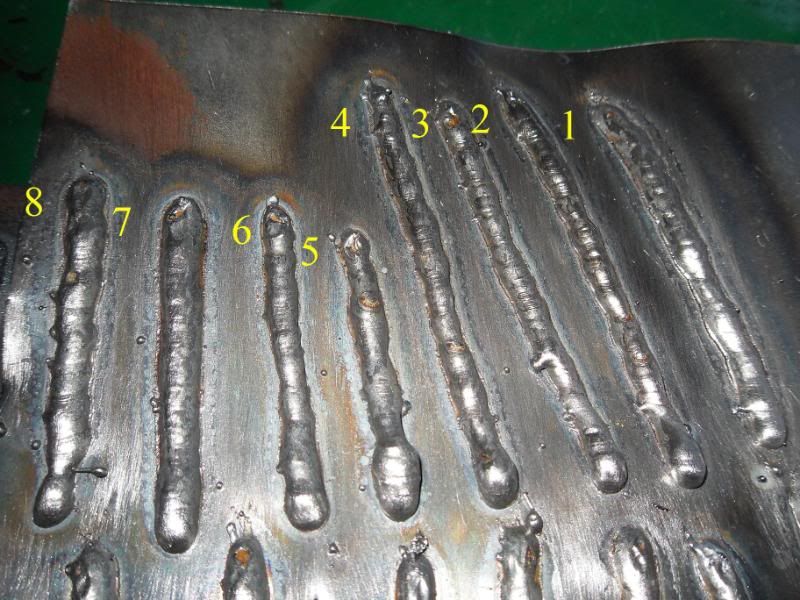

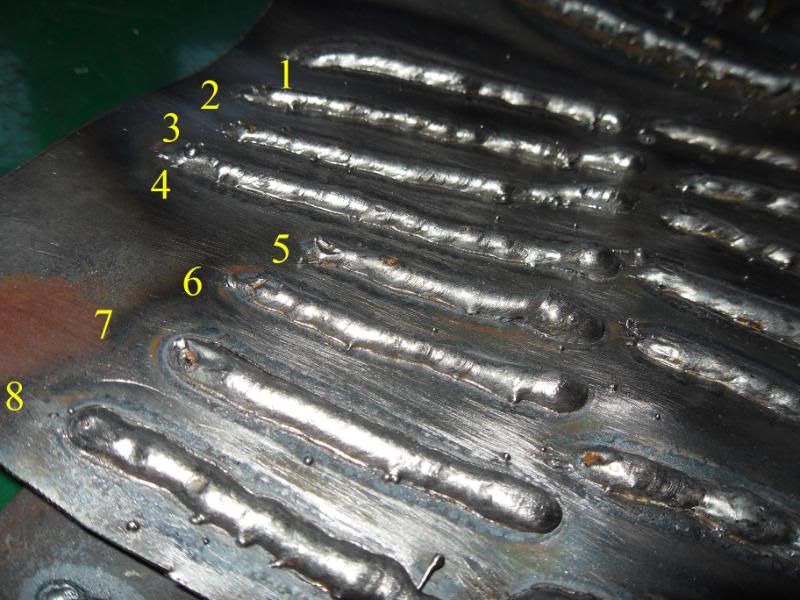

I practiced a little more this morning i think im getting better. I tried something i saw on youtube the man said to do U's with the with the puddle like UUUUUUUUUUU it seems to be easier for me this time i still think im not ready tomove on the car yet. Now time for pictures of test number 2.

First here are pictures of the welder i got and the gas bottle.

now pictures of todays weld. (im welding from bottom to top pushing the weld btw)

they still dont look flat tho i dont why or how yet but ill practice again. I changed my seating position on the second set of welds i did i was sitting lower this time way easier on my back then leaning over the table, only thing i noticed is that i have more troube seeing the puddle i habe to lean on one side to see the puddle or the tip of the gun is hidding it.

Comments are very very welcome please !

-

Thank you very much guys. From what im reading ad seeing on youtube im not letting the gun/heat long enough, on the back side of my plates the metal is just getting blue or orange after it cools down (if that makes sense) so im not seeing the weld getting through or bearly i was scared to burn through i think. Im welding on 1/32 steel to practice my hand on the steel ill be working on the Zed. Ill try my hand at it this week end and ill post more picture. Things im gonna try is leave the torch on for more heat push the puddle by angeling the gun at 45 deg and do my best.

-

Thanks for the advices keep them coming please.

-

Hi, i just got a new 110 volt 88amps mig welder for my projects and i tried my hand at welding yesterday. I have gas sheilding argon co2 mix and .023 wire. I need to know how are my welds .

Thank you here are the pictures

I played with wire speeds and the power setting on the welder didnt really knew what would happen till i pressed the trigger thats how green i am to welding.

I think 6,7,8 are starting to look good in my humble opinion

2,3,4,6 looks ok to ?

Carbon interior

in Interior

Posted · Edited by Wedge

This link is usefull to just Google search you will find Tons of info !

Carbon fiber 101