-

Posts

599 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by luseboy

-

Got it figured out. According to a guy who made custom flywheels for maxima 6 speed swaps (the same problem arises as in my case, but with a different flywheel than the 350z flywheel), this timing ring does not index the engine and instead indicates engine speed. In other words: it's indexing/clocking/position doesn't matter. All that matters is the sensor being positioned in a way that it can read the timing ring. Just in case someone else in the future runs across the same thing, and finds this thread.

-

So I'm in the midst of doing a budget VQ swap, a '96 i30 VQ30de mated to a '06 CD009 and '06 350z oil pan. I'm starting to figure out the best option for transplanting the timing ring from the flex plate of the VQ30 to my ebay 350z flywheel. I'm planning on throwing the flywheel on a lathe to cut off the 350z timing ring, then line up the vq30 timing ring and either weld it on or drill and tap some holes to bolt it on. However, I'm wondering if anyone happens to know how this 180 tooth ring times the engine? I can't find any missing teeth or anything like that to indicate TDC to the sensor. However, I have read on maxima forums that the flywheel has to be clocked properly for the engine to run. I know there's also the crank position sensor on the front that reads off the harmonic balancer, which does seem to indicate TDC. I'm trying to figure out where to mount this ring (in terms of clocking position). The crank position sensor is changing positions due to the different oil pan, and if I don't need to figure out where exactly to mount the timing ring that'd make things a lot simpler. Here's a couple pictures comparing the 180 tooth maxima ring (looks zinc plated/dirty) to the 350z ring on my ebay flywheel.

-

So obviously I wasn't satisfied with the drilled thermostat set up, and decided to make an external bypass. I was able to get 3/8 copper hardline locally by the foot ($5 a foot), as well as a tee that has two 5/8" hose barbs and one 3/8" hose barb. Unfortunately, I can only find the tee in plastic but I wanted to see if the lack of an external bypass was actually the issue so I went with that for now. I pulled my thermostat housing off and took the temperature sending unit out of the adapter. While it was out I used some boiling water and a digital thermostat to test my gauge and sending unit. It's not dead on with the digital thermometer but pretty damn close. It's not like the gauge has a fine scale or anything anyways. I drilled and tapped a new 1/8 NPT hole next to the factory 1/4 BSPT hole in the thermostat housing, and screwed my sending unit in. Unfortunately, I didn't take into account the shape of the thermostat housing and how that effects how far the Autometer sending unit goes into the housing (close to an inch, surprisingly far), and when I test fit the thermostat it hit the sending unit. So then I drilled and tapped another 1/8" NPT hole in the bottom of the thermostat housing almost pointing into the cylinder head. Now the thermostat would sit right and the sending unit was properly probing the coolant, and in the direct flow of coolant as well. Then I cleaned the housing really well with soap and water and a brush to get all the metal shavings out and put it back on the engine. I then spent some time bending the copper tubing into the right shape and getting it as flat as I could otherwise and put some little halfway done bubble flares on each end. I put a short section of 3/8" radiator overflow hose between the hardline and the tee with the heater core exit hose, with fuel injection clamps holding them on since I had some extras anyways. I put a 1/8 NPT plug in the hole I drilled that didn't work. It didn't get super tight before it started to sink into the housing so I had to take the housing back off and re-drill and tap the hole to 1/4 NPT. When I initially tapped it to 1/8 NPT I was on the phone with my dad and I wasn't paying attention and tapped it too far. After cleaning and reinstalling the housing again, I bled the system and went for a drive. It stayed right at 180F almost the whole time. I put the heater on full blast and it stayed at 180F, even at 45mph for an extended amount of time. It seems to run better too, which is a plus. However, it does still creep up in traffic to 205 or so. It also got up to maybe 200 on the freeway when I was romping on it a bit. Cruising on the freeway though it fell back down to 180 and stayed there. Plan is to build a shroud and maybe replace my current puller fan with a bigger and stronger puller fan as well if that's not enough. I don't want to run a mechanical fan and shouldn't have to. Also I suspect that the cooling system is not bled all the way, I'm gonna buy one of those spill-free funnels and spend more time bleeding it. Oh, and I'm gonna get rid of the scary plastic tee that I know will break when I'm in the middle of nowhere leaving me with a significant coolant leak. I can't seem to find it in another material but I just need to look harder. I mostly wanted to update this in case someone else is dealing with the same thing and comes across this thread, I hate when I'm trying to figure something out and I find old posts where someone is dealing with the same problem but doesn't update how they fixed it. Moral of the story: don't deadhead your water pump.

-

I'm not sure that there's a way to calibrate the autometer gauges, but I'm looking into it. I did buy an autometer fuel gauge that was no good, so maybe this one isn't any good either. It seems to be reading the same temperature as the fan switch though, as the fan kicks on and off at the right points compared to the gauge. Of course this is no calibration by any means but at least an indication in that direction. I will look into that further. If I use aluminum I'll make sure and insulate it from the engine. The heater core is plumbed the same way as the factory did it as far as I can tell. I'll triple check everything when I plumb in the bypass.

-

Ok so I cut the little brass nipple valve off and drilled a 7/32" hole in the (cheaper) thermostat today to test out the bypass problem. When I pulled out the thermostat I looked at the coolant sender and realized that it's actually on 2 adapters: a 1/4 BSPT to 1/4 NPT, then a 1/4 NPT to 1/8 NPT adapter. I'm not sure what I was thinking, but there's definitely the potential that an air bubble is staying put within the adapter set up. At any rate, drilling out the thermostat seemed to help a lot in traffic, where it would creep up to 205-210 before it was drilled out, it now stays closer to 180 for longer but eventually starts to creep up to maybe 200 or so. Also it will now get up to 180F without sitting in traffic, and will stay around 180F while going less than 25-30mph. Once it gets going 35 or faster the temps drop back down to 150 on the gauge. I then closed the heater valve, and noticed it did not start leaking coolant again (probably because I pushed the hose on further and tightened the clamp more, but still). With the heater valve closed it did seem to heat up a little faster but still would run at 155-160 above 25-30mph. On the highway it even got down to 150. So then I put a piece of cardboard over half of the radiator and with the heater valve closed and have the rad blocked it ran at 165 on the highway. I'm thinking maybe the hole is too big and also that it's probably not fully bled, even though I ran it with the cap off, the right front wheel on a ramp, and raced the engine a few times to get a good amount of air out. I also think that I need to make a fan shroud and either see if I can fit the pusher fan as a second puller, use them as the bread in a radiator sandwich, or maybe get a bigger puller fan. I'm also going to make a bypass above the intake manifold, and use the current 1/4 NPT port for it, and drill and tap an 1/8 NPT port for the gauge sender so it can work properly and not trap air. Any idea what size tubing I should get for the bypass? I'm planning on making it out of hardline if I can. I'm wondering if I can get away with aluminum for this if I can insulate it from the block with rubber? The rad is aluminum so galvanic corrosion would already be an issue. I don't think my flaring tool or hands can handle stainless of a bigger size. Is there anything in particular that I'm under or over thinking? Anyways read above for the heater valve. It seemed to make some difference with warming up but once the car is driving it doesn't make a huge difference. Of course this is only after I drilled out the thermostat, I should've tried it before I did that but didn't have time to. When I closed it the first time and it leaked I was on my way to a friends house and didn't want to mess with it right then.

-

Ah okay this seems like something work looking into for sure. I do not have any sort of bypass like that, or the su manifold so no water lines for it. I'll have to decide if I want to plumb a bypass in or drill the thermostat. I like the theoretical function of the bypass better but anything that adds to the possibility of coolant leaks (like more plumbing) is possibly worth avoiding. I'm guessing the little little hole that's already in the thermostat is not big enough? Also can you explain how the lack of bypass would make the engine run colder? Or are you saying it just makes the gauge read lower? This really seems like it could potentially be the problem. I did try warming the car up and driving it around today with the heater valve all the way closed, which lead to a small coolant leak that went away when I opened the valve back up. The coolant was leaking on the passenger side where my radiator hose meets the radiator (water pump inlet side). I'm assuming the real problem was a clamp being loose, but maybe it is also indicative of the deadheading problem you're talking about. Maybe the heater is being used as a bypass normally, causing it to never really get up to temperature since it's bypassing through the heater core? Ok yes this is definitely pointing to the lack of bypass. I hadn't even considered that I needed a bypass at all, it didn't even cross my mind. Where the external bypass spits back out into the coolant line next to the alternator, I have one side of my heater core hooked up. The other side is hooked up to the port near cylinder 6 on the head, it's what feeds the heater. I think coolant is circulating around the block and not really moving to the thermostat housing at all really, since coolant is just moving through the heater normally possibly. I wonder if my car is actually overheating most of the time but the hot coolant isn't accumulating at the thermostat housing so it doesn't read hot on the gauge. And yes I have both, currently they're staggered so that one of them is pulling from the left side of the rad while the other is pushing on the right. I think it would be better if I made them stacked on top of each other, and better still if I added a shroud. I'll have to make a simple shroud up. Maybe that will even improve warming up since it will also act as a bit of an airflow block when the fan isn't on. 1. I have, sorry if the way I explain things makes it sound like I don't understand 2. The temperatures have been cold in 100 degree weather, and 40 degree weather. On hot days in the summer it would definitely heat up a lot faster and would run a little warmer but overheat more easily. 3. Maybe 165, usually closer to 150-160 4. That's not a bad idea, I'll give that a shot! 5. I'm definitely feeling confident in the radiator's ability to cool. I think the fans need some tweaking and I need to figure out the bypass thing.

-

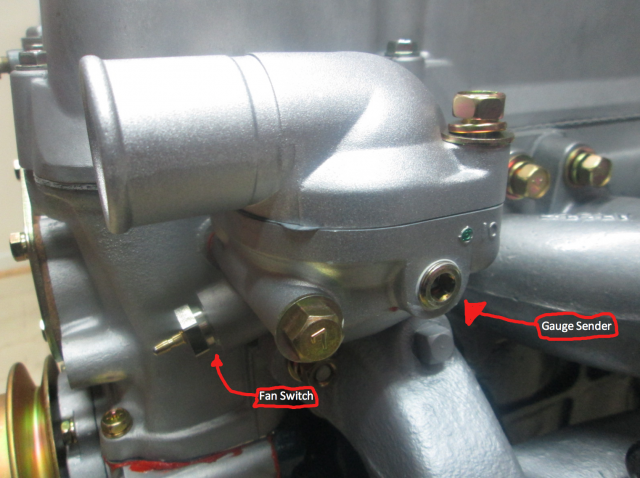

What do you mean by bypasses? I'll attach a picture showing where the fan switch and gauge sender are tapped in. The fans are blowing in the right direction, the temperature controlled fan is a "puller" and the switched one is a "pusher", the idea being that in most conditions I'd want a puller fan but in traffic a pusher might help too. I've not tried running the switch fan with the engine cold, mostly because it already takes so long to warm up. I'm curious as to what your though process is here? I'll give it a shot. Here's a picture of how I have my thermostat housing set up. Note that this is not my picture or my engine, just a representation of how I have it set up.

-

The first one was a brand new stant unit. The one I got today is a brand new motorad cheapie that I got in case I needed it. I tested both of them to get some comparison between them, they both seem to work properly in hot water. I'm thinking the creeping problem is probably a fan problem. Is there a known rule of thumb for an acceptable amount of creep in high heat situations like traffic in the summer? I'm not convinced that a different brand of thermostat will fix this at this point. I'm sure the Nissan thermostats are much better, but I would think these should function well enough to be used in an otherwise up-to-par setup in normal conditions without too much of an issue, right?

-

Interesting, I didn't realize this was a problem. I had filled the block and head through the thermostat housing and topped off the radiator before running the engine and getting it up to temp. It very suddenly started gushing out of the top of the rad, presumably when the thermostat opened. I guess if nothing else it shows that coolant is flowing lol. Yeah I was just thinking that. I actually just drove around for a bit to see if I noticed anything else but didn't close off that valve. I think I drove it around with the valve closed off for a few days months ago but I don't remember the temps being any different, I'll have to try that again. I'm at a loss as to what else could be causing it to run cool though. I can't imagine my cheap aluminum radiator is cooling too much for the L28, is this even realistically possible to this level?

-

Haha you replied while I was replying. It uses a temperature switch that was oem on some other car (A honda of some sort), located on a different point in the thermostat housing. It's odd huh? It's either too hot or too cold. Every once in awhile it will stick around 180 for a bit, but once I start moving above 30mph for more than 5 minutes it's back to 150-160. This makes sense, it seems that it isn't equilibrating properly for some reason. I have a universal hot rod heater from summit or jegs, it's a pretty large core and I just have a little manual shut off valve that I pretty much always leave open. When I had the engine apart, I opted to reuse the water pump because it looked to be in great shape. Perhaps I missed some detail, but it had no play, no indication of any leakage, no messed up fins, and it spun nicely. When I first filled the system with coolant I left the cap off and brought it up to operating temperature and suddenly had a gallon of coolant on the ground that rushed out of the open radiator, leading me to think the pump is definitely moving coolant. Of course, I realize that none of this gives any actual indication of water pump health but it seems unlikely to me. This does bring up an interesting thought though, could the heater be plumbed wrong and causing these issues? I have one side of the heater core connected to the passenger side water inlet, and the other side connected to a big NPT port between cylinders 5 and 6 on the head on the passenger side as well. I remember looking into this and thought it was an okay way to run it but maybe I missed something then.

-

I think the sender is designed to be immersed in coolant, but I think with the adapter only the tip of the sender will be fully immersed. I was thinking maybe an air bubble is trapped in there, but I've heard of other people running the same setup with no problems and I don't have any other symptoms of a cooling system that needs to be bled really but I think this could be the case. Another possibility is that the adapter allows for some pocket of coolant around the sender that isn't moving even when the thermostat opens and is staying cooler, but that seems really far-fetched and the pocket would heat up to it's surrounding temperatures pretty quick. The fuel mixture is what I'd call significantly less than optimal, however it is only super rich in certain conditions (I have a 4bbl on an AZC manifold that I'm still working on getting running right). The oil did smell like gas until I hooked up a PCV system, but has smelled normal since then. The way I have it tuned right now, the A/F ratios hover around 12-14 throughout most conditions. The fan does have a separate temperature switch, which I think came out of a honda of some sort. It is on a different port on the thermostat housing. The rad is technically undersized, but it's a really thick core and it is crossflow if I remember correctly. I was going to ask if it's possible that my radiator is "overcooling" but this seems unlikely. Maybe everything's fine and this is how it should be, but I feel like the car would run smoother (and better overall probably) if it was running at the right temp. 150-160 just seems too low of a running temp, but maybe it's fine? If all this thread gives me is some peace of mind I'm totally fine with that.

-

Using an Autometer temperature gauge with the sender in the thermostat housing on the end of a BSPT to NPT adapter. I don't have an infrared thermometer to confirm the readings with but I should probably get one.

-

Alright so I haven't been on here much lately because I've been busy sorting out all the little issues with my car after getting it on the road. It's been having a weird thing happen where it runs at 150 degrees even though it's got a 180 degree thermostat in it. It also seems to take awhile to warm up. Even still, if I'm sitting in traffic or whatever it will creep up to 205 or so and hold there. I suspected that the thermostat was stuck open, so today I replaced it and tested the old and new thermostats, both of which seemed to work fine although the old one didn't close back up till about 170 degrees while the new one was closed at 178. With the new thermostat it runs at maybe 155-160, slightly warmer, but still too cold. The engine is an L28 (F54/P79), it's got a 240z thermostat housing on it, with a universal 3-core aluminum radiator, dual electric fans (one set to turn on at 185 degrees, the other on a toggle switch), and an auto meter water temp gauge/sender. The sender is tapped into the same location it would be on a stock 240z (right behind the dizzy). One thing I just remembered is that the temp sender is 1/8 NPT while the Z housing is 1/8 BSPT, so there is an adapter between them which makes the sender stick a little further out than it would normally. I'm fairly sure I have the cooling system well bled, but not positive. Anyone have any ideas what else could be causing my car to run cool? Is it possible that the radiator is cooling too well for normal street driving? Does anyone have any experience with temp senders being weird if they're on an adapter? I'm stumped, any other ideas what rabbit hole I should try and crawl into next? I should note too that the temp fan only comes on when the gauge reads over 185, so it seems that the gauge is at least somewhat within the range of accurate. Also I should mention that even when the gauge is at 150 the heater still blows quite warm, just as warm as I would expect in any stock car really. Thanks!

-

Hey, I had ordered a set of the D Brinkworth flares a few months back but the guy flaked out on me and I ended up having to get my money back from paypal. I'm now looking for a set of rear flares for my 240z. I'd like to try something different, and would also be interested in widebody quarters. Let me know if you have something interesting. Thanks, Austin

-

I'm not sure if this is the right forum to post this in but seeing as how he makes the D-Brinkworth flares and other body parts this seemed the most pertinent. I'm curious as to whether or not anyone has dealt with buying from him before. I ordered and paid for a set of rear flares from him back in May. He told me 4-6 weeks before I would see the flares. After 6 weeks of no contact I messaged him (on instagram) to see what was up. I had to message him a few times, with my messages being read but not responded to before he messaged me back to say it would be another 4 weeks. Those 4 weeks have come and gone, and yet again I've gotten zero contact and zero explanation. I've been trying to get ahold of him for a week now unsuccessfully. Anyways I'm really feeling like I'm getting ripped off and it was no small amount of money I've paid him. If anyone knows him personally please understand this is not an attack nor an attempt to smear him, just curious if others have had similar experiences or not. I'm really apprehensive as to whether or not I will ever see the flares. I would love to hear anyone's experience, positive or negative. Thanks

-

OK, so I did have my car set up as a G nose, and recently decided I don't want to run the G nose on my car anymore (which is for sale/trade now). I've decided to go short nose but there's a few parts I'd like to try and find used: -Headlight covers (smoked preferably) -Front spoiler/Spook (something similar to the BRE spook but I'm open minded) If anyone has any of that for sale I would certainly be interested. My car is ratty and I am more than open to any of the parts above being in ratty condition. Thanks! -Austin

-

If you've gone this far you should drop the tank and clean it out as best you can. If the fuel pump is clogged then there's likely a fair amount of crap in the tank. When I dropped the tank on my Z there was about a 1/2" thick layer of rust and crap on the bottom. I chose to replace the tank with a fuel cell but in hindsight it would have been better in some ways to keep the stock tank. Maybe you already did this and I missed it but just in case.

-

Definitely sounds like a great way to do it! What are you running for a diff/axles? I'm sure that you're running more power than I ever would be able to safely do with the vq30, even with a turbo on it. Ah that could be very useful, I'm sure trying to get it tuned right on my own would be quite a learning curve.

-

My question would be why? I'm not too familiar with the ecoboost engine but a quick couple searches, and I think the sr20det is a much better swap unless I'm missing something. The sr20det seems to be: cheaper, lighter, probably easier to swap since so many have done it, makes more power, and as far as I could find gets about the same mileage. There's also a plethora of aftermarket support, a 6spd transmission available from the s15, and many people import them. There is a bit of a premium on them since the drift kids drool all over them, but they still aren't that expensive. If you want a 2 liter 4 cylinder turbo engine the sr is hard to beat. There's a good possibility that I missed something about the ecoboost engine, and if that's the case I'd love to know what's attractive about this engine to you. Hopefully this doesn't come across as rude or anything like that, just my thoughts.

-

That sounds too easy, and almost certainly my best bet. Did you send your ecu off or did you buy the engine that way already? I definitely don't want to spend days on end tuning and trying to get it running right.

-

I'm not sure how relevant this is but when I replaced my steering rack bushings with poly I took this piece off and the rubber fell off. I figured the piece was there for a reason so I glued on a piece of poly I cut to the same approximate size and shape as the original rubber piece with JB weld. I've hardly driven the car yet as I'm only just able to drive it and still tackling a number of issues before I can really drive it but this may be a good option for others who lose their rubber piece.

-

Interesting, sounds like there's a reason I'm not finding an easy solution for my rear end set up: there's a million options and considerations. I guess what's important for me is that I have something that will hold up, has a limited slip function of some sort (aggressive would be nice but anything is better than open), and something that isn't unobtainably expensive or lands me with a set up that is really expensive or nearly impossible to fix should something go wrong. I really appreciate your insight, I think I'm gonna need to give this whole thing a lot more thought and try and figure out what I want to do.

-

Interesting, I went to Z fever's website (maybe a different Z fever?) where they have a page about swapping the VQ35de into a 240sx and they say they use a standalone system from AEM, and chuck the stock ecu. I just don't know if the VQ30de is different since it came in the '95-'99 maxima. I guess I was hoping someone would know about this.

-

Interesting, I wonder if I should just go the STI route but make a larger capacity finned cover work. I mean I won't be racing or drifting and after doing a little more research, I'd be surprised if I do make 300 ft/lbs, probably more like 250 or 275. It would certainly be much easier, and I'd run it with the sti CV's with a shorter shaft like at least one member on here has done. But I do like the idea of having piece of mind with the R200. So I take it you used a vlsd pumpkin in your case? Are the 280zx adapters for the diff side or the companion flange side? I already have 280zx turbo companion flanges so if I can just use the axles out of a 280zx turbo that would be nice since I already have one piece of the puzzle. Although I believe these companion flanges are 25 spline whereas I have 280z 27 spline stub axles that have been re drilled (by modern motorsports when they were still around) to 5 lug, so I'd still have to get that figured out. I'm assuming if I can find a clsd it'd be really expensive? I also found a post on here about making a frankenstein axle out of a pathfinder front axle with some different ends on one side, can't quite remember the specifics. I'm not at all opposed to running a frankenstein axle as long as it doesn't cost a ton of money. Additionally, according to another post, the Kaaz 1.5- or 2- way pumpkin for converting an s13 to lsd from open will work with 280z r200 diff stub axles and halfshafts. I wouldn't mind running halfshafts for the time being and then upgrading to CV's later on down the road.