-

Posts

62 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Raami

-

Philly, my revlimiter is now 7200rpm because there is no need for me to rev higher. The reason is because I have stock P90 cam so the power starts to drop after 5500rpm. Only thing what I have done to valvetrain is that I changed stronger valve springs. Next thing is to get a better cam. Those wisecos are not ready pistons. Those had 35mm pin height and flattop so that you can machine to that height you wan't/need to. They said that you can go all the way to 26mm pin height in a turbo engine. Oz, That I don't know are they too heavy or big, seems to work just fine. Those are only longer than stock L28 rods and the small end pin diameter is 25mm stock. I take those to the machine job and they just made new pushes so that those match with the pistons. I have to machine that small end or lighten it from the top a little so that it wouldn't hit the piston's top/crown.

-

I'm running LD28-rods in my N42 block and stock crank. My wiseco-flattops have 28,6mm pin height if I remember correctly. No problems there. The rod/stroke ratio is now 1.77 and it really revs really nice.

-

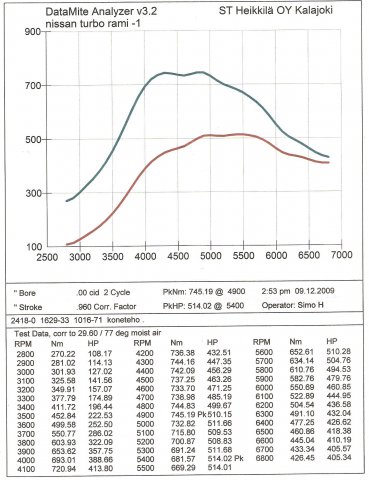

Here is my last dynorun with my setup. I now have Holset hx40super and 4" exhaust and 1,9bar boost in my setup. That power and torque is from flywheel. Not from the wheels.

-

Friend of mine just put Mercedes OM606 in his -72 240Z with mercedes own automatic tranny and Holset. The power will be about 500hp and 800nm. All I can say is that it will be fast in a 1/4mile when tires and all other stuff will hold.

-

Grooves in heads/cylinders: Snake Oil or a Good Idea?

Raami replied to PanzerAce's topic in Nissan L6 Forum

I think those grooves might help if you have P90-head style chambers and dished pistons, then the flame could travel easier. Or not. I was just thinking and as usual I might be wrong. -

I have cleaned every cap of the layers and then used the copper gasket spray. That is the best way I tell you. I drilled those rivets off and take those layers apart from each other. Then when I have sprayed that copper then just put those layers one by one in place. No need to put those layers together by rivets anymore.

-

My L28 setup: N42 block and crank 87mm forged wiseco-pistons LD28-rods NA P90 head (valves/seats 3angle, heavy valve springs) stock intake manifold exhaust manifold by me 3" exhaust all the way 1,6mm kameari metalheadgasket about 8,8:1 CR Boost 1,1bar megasquirt 688cc injectors Holset Hy35 Power: 394hp at the engine Torque: 570nm at the engine

-

Dyno Tuned the Z last night **UPDATE VIDEO ADDED**

Raami replied to wigenOut-S30's topic in Nissan L6 Forum

I would like to see your MS-tables too. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

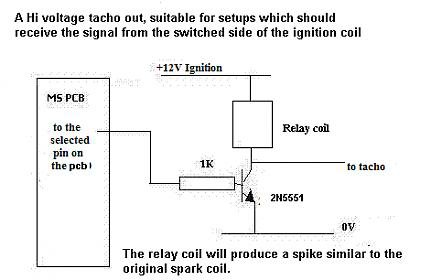

It seems to work very well even on high revs and on boost so I think it's ok. I only have to calibrate the tach a little when I compared the tach reading and MS reading. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

My stock tach works now. I just wired that original black/white wire to the coil pack +12v without the resistor. So that power to the coil pack goes through the loop in tach. So simple that I didn't even think it could work. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

My previous car, which was 240z -73 also had current sensing tach so you are right on that. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

If you really don't have anything to say about getting the tach work, so why are you writing?? I haven't asked three times or have I?? -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

I understand that. That might work what you said and it really is easy to try. I will let you know if it works. I have opened that type of tach and I know how it works. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

I have to find out could this be used. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

I'm using wasted spark coil pack so I don't have single coil. I made 6-1 triggerwheel so I don't have distributor anymore. So I just have to find -73 or later tach. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

-

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

I really would like to leave that stock tach. I will try some other diagrams and I will let you know if I can make it work. -

hooking up outputs with megasquirt-I got a question-

Raami replied to big-phil's topic in MegaSquirt

How can I use my original tach with my MS? My car is 240z -72 and I have understand that I can't use that diagram in big-phil's post. My MS already has that wiring but the stock tach doesn't work with it. I have searched but haven't find answer. -

I just find out that LD28 has short version of that shaft because it hasn't distributor. I'm going to cut that so it will be like the one in LD28.

-

So have anyone tried to cut that shaft when distributor is no more necessary? Or will there be problems? Old thread so you can't say I didn't use search. The engine is L28.

-

Now that brace is ready and installed. I have bad pics of it. Engine also has LD28-rods, wiseco forged pistons and metalheadgasket.

-

That looks very nice. I think I will do that to my intake because I have LD-intake and EFI-intake which isn't very good.

-

Why do you think that brace would be pulling those mains loose? The reason I will put 10.5mm washers and not 10mm washers is that then there will be little gap between block and brace in the outer bolts. (oilpan bolts) So when I torgue those oilpan bolts, there will be little flex on the brace and it will be pushing even more to the mains. My engine won't be running so high RPMs. Or atleast not so high as Tony but I will have turbo on it. It's good that this topic is alive and everybody are saying what they think of it. lammbn: You didn't rock the boat too much.

-

Kiitos kiitos. Minä asun Kalajoella. (means: Thank you thank you. I live in Kalajoki.)

-

No I will put those mains in stock tight and I think it will be ok because the brace will even the stress in one main. And like I said before, that brace will be strong because it will attach so thick and fast. But of course I do know that I might be wrong and the engine might blow up. and Tony: You're doing just fine but it is suomi and paskapää... Have you been in Finland?