-

Posts

2774 -

Joined

-

Last visited

-

Days Won

15

Phantom last won the day on June 22 2024

Phantom had the most liked content!

About Phantom

- Birthday June 20

Profile Information

-

Gender

Male

-

Location

Hauser, Idaho

-

Interests

Z cars and finishing off my new home.

Phantom's Achievements

-

stock suspension with custom wheel and tire size

Phantom replied to Flippy's topic in S30 Series - 240z, 260z, 280z

With my stock suspension I went with a 16x7 wheel with 0 offset. With that setup I was able to run a 225/50-16 tire and have it clear the suspension and the fender. Stock size tire is a 195/70-14. A 205/60-15 would be the standard +1 to maintain the same tire diameter as the stock and thus not screw up your speedometer. If you stay with 15" the best size combination for a stock wheelwell is 225/55-15 on a wheel with a 0 offset. -

Mine ended up 48 front/52 rear with the LS1/T56 combo. The LS1 obviously has a lower CG than the L28 and it sits farther back with everything but the accessory drive behind the steering rack. Having driven the car for 31 years now (20 years with the LS1/T56) I'm confident that the handling is at least equal to if not a bit better than the L28. It does require more finess as the L28 never gave me lifting throttle oversteer which I can get with the LS1. The Ls1 also improves throttle steering in corners once you get the car figured out. One thing - it does not forgive stupidity with the throttle.

-

For what it's worth my car ('77 280Z) was used by JCI to develop their LS1 conversion components. I have an LS1/T56 combo in mine. I had my280Z axle weighed with 3/4 tank of gas before the conversion and it was a perfect 50/50 with 1400 lbs on each axle. After the conversion it was 1400 front and 1430 rear but that was with a heavy torque tube design underneath. With standard transmission & differential mounts the distribution would probably not have changed at all. Just know that when you sit down in the car about 2/3 of your weight will be on the rear axle. Yup, with a driver, you'll be tail heavy.

-

Lawrence, The JCI kit was developed on my '77 280Z back in 2002/2003. My drivers side mount for my LS1 is centered below the front two exhaust port which obviously puts it in the front half of the block. I have a great photo of the passenger side mount but don't seem to have a good one of the drivers side.

-

How were the axle shafts themselves? Were the u-joint pockets snug or were they a bit loose? They should be snug or your problem will come back quickly. I just had to replace the u-joint on the driver side half-shaft only to discover that it took locktite on the axles to get them to stay put as they were worn. 250K on the car and the last 50K with an LS1. Passenger side still has original 1977 factory u-joints. That is a really scary thought at this point. CV joint halfshaft upgrade in the near future.

-

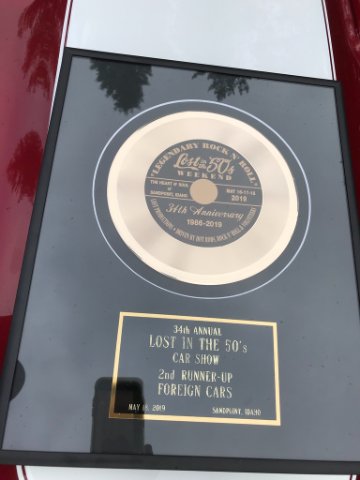

Thank you Madkaw & DuffyMahoney. I'm always very careful whenever i make a big change in my car. Y'all gave me some peace of mind. DuffyMahoney - I see you are from Sandpoint. You ever go to the Lost in the 50's events? I was up there in 2019 for it. Got 3rd in class. Here's a pic of my buddy and I at the show. He's from Sagle. .6ADD874C-0E3A-4E59-8CEC-F5947E11E769.heic

-

Did you install yourself? Were there any issues or things that I should be aware of prior to installation? How long have you had them? Any interference with stock ebrake cable or sway bar? Looks like you have a 240Z? Are you running an R180 or R200?

-

The 280Z stub axles are stronger than the 240Z stub axles and can withstand more abuse. That being said, if a car is built for drag strip use then eliminating them is a good idea. At that point you should just convert to a solid axle rather than IRS. I've had my car for 29 years and 150,000 miles. 99% of it's use has been "spirited" daily driving which is what my goal was when I built it. Yes, it has been competed but only occasionally. The fact that my stock, original spindles are still doing well after a total of 250,000 miles - yes bearings have been replaced - should give a pretty good indication that they can continue to meet the demands that I put on them.

-

I would suggest you spring for a Nissan Service Manual. They have some excellent wiring diagrams in them. Sounds like one or more of the PO's have fiddled with the wiring some and left you with issues.

-

I have an LS1 powered 280Z backed by a T56 and a 300ZXT R200LSD. The weak link in the drivetrain are the stock original (250,000 miles) half shaft u-joints. To keep running I recently replaced two of the u-joints only to find out that the half shafts are worn where the u-joint caps are supposed to press in lightly. So now I need half-shafts giving me the perfect excuse to upgrade to CV's. Although the LS1 is stock, 325HP/326 torque that is too much for several of the conversions currently offered or the vendor has no idea how much HP the shafts can handle. No - I'm not going to spring for the Ford 8.8 conversion. Great upgrade but too expensive for my current situation. I've pretty much settled on the Z Car Garage CV upgrade but I really need more input before I spring for them. Anyone here that actually has their CV axles on their Z's - and driving/competing them? I am looking for hard factual feedback on perceived quality, any installation issues, and durability. Thank you in advance

-

Actually, JCI is owned by John Radevich, not Ruskin, at 800 Jaguar Lane, Dallas, TX. The "Broken Kitty" is his website: www.brokenkitty.com I own the car John used to develop the kit he sells now. My car has been on the road since June of 2003 and I have had no issues with his components. One point, however. He equipped my car with a torque tube set-up between the T56 and R200 but the kits have a transverse mount for the transmission and the differential maintains it's front mount.

-

Question about potential engine swaps

Phantom replied to Projectcarguy's topic in S30 Series - 240z, 260z, 280z

yup - an exhaust system properly tuned to the engine can make it sound really sweet. I know that my LS1 starts to sing at about 2500 rpm and then just continues all the way to redline - and the exhaust system is responsible for 80% of that. -

Question about potential engine swaps

Phantom replied to Projectcarguy's topic in S30 Series - 240z, 260z, 280z

I had one of the first "on the road LS swaps" It was complete in June of 2003. My car was the development "mule" for the JCI kit (www.brokenkitty.com) In 18 years none of John's parts have failed. My car is running a totally stock LS1 so I'm good with just an R200 LSD and "sticky" compound street tires. FWIW - it is an old wives tail that these cars are nose heavy. Before I started my conversion my car had a 50/50 balance, 1400 lbs of both axles. When I completed the drive train conversion it was 1400 on the front and 1430 on the rear. Then I did an interior upgrade and the car gained 170 lbs that left it 1440 on the front and 1560 on the rear. A stock LS1 is actually lighter than an L28. Quite frankly its the turbo cars that are nose heavy because of all the plumbing that sits in front of the axle. If you opt for an LS3 crate engine (and maybe opt for a cable actuated throttle instead of drive by wire) you start out in stock form with 485 HP. You'll need a stout 6-spd and the Ford 8.8 independent rear end upgrade to handle that. A little cam work and you'll easily be in the 5-600 HP range. -

77 280z LS1 - starter solenoid / Key switch wiring

Phantom replied to mgood77's topic in Gen III & IV Chevy V8Z Tech Board

S30's run the full voltage/amperage through the column switch assembly. It would be better if you installed a relay so that the full current runs through the relay and just actuation current through the ignition switch like more modern systems do. It will extend the life of your switch and keep the wiring sizes more compatible. Bottom line is that the S30 ignition switch really isn't sized to handle the current required for a V8 indefinitely. Overall remember that you have a vehicle with 40+ year old wiring that is getting brittle and you'll be finding oxidation on all your connectors. Anything you can do to reduce electrical loads (LED lights, etc) will be to your benefit.