-

Posts

419 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by yellowoctupus

-

-

Quick Pic Time:

As a note: I did not have to modify my oil pressure pickup piece (Some guys shorten it because of steering clearance?), and my oil filter should still mount to the block like it did from the factory. I've never been a huge fan of external mounts, it's just more potential failure points. Sometimes you gotta, sometimes you don't.

One BIG thing I'll have to do is make some sort of throttle body to MAF tube. I want to run the stock hood, and I used the battery box area last time for the air cleaner. I'm thinking I'll have to 'glass one up, but I'm not sure that's the best route.... sounds like a lot of work even IF I get it right the first time. Radiator hoses are also not the same, but that shouldn't be a HUGE deal.

-

Engine's in. Fits fine. Honestly doesn't look much tighter than the SOHC, I think because the 'wide' measurement from the DOHC comes off the cam cover, which sits in front of the shock towers, so it's somewhat a moot point. I'll get some pictures of of the latest surgery tomorrow....

-

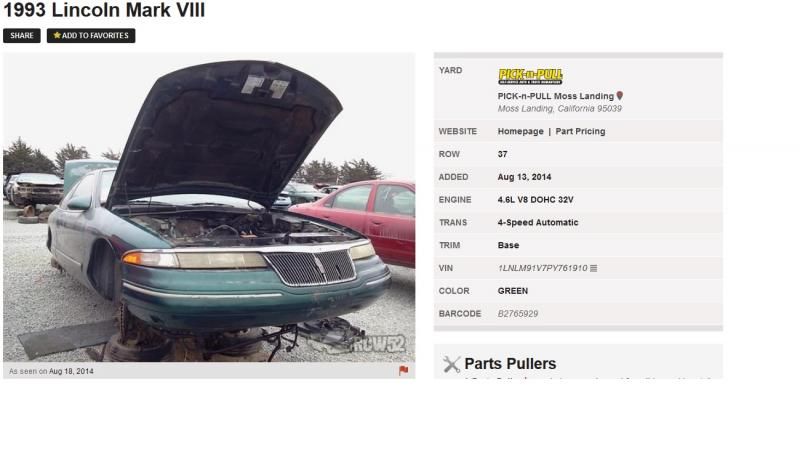

I thought this was a funny picture. See how the engine bay on this green '93 Mark VIII is gutted already? I beat the junkyard to getting their stock photo for their online inventory page.

Turns out the stock cobra exhaust manifolds will bolt on and should meet up with my custom 'GT' SOHC Y pipe. That's a relief. I'm all set with making any more weird custom headers. That's a pain, especially with the clearance I'm sure I'll have on that side of the engine.

-

Out with the old................

.........and in with the new. To be continued...1993 Mark VIII, 110k, failed smog, assumed still running at least OK. $180 for a complete engine at Pick n Pull. Sounds like the cheapest possible way to gain 70hp (Mark VIII 285 vs Mustang SOHC 215hp) AND drop 75#! The Teskid aluminum DOHC blocks are supposed to be crazy strong, and undeniably lighter. Internet specs for the two engines are 500# SOHC, 425# DOHC. WOW.

(vin for my reference...) 1LNLM91V7PY761910

-

DOHC time. Blew a head gasket going to work on Thursday, and well, why not. Off to find a Mark VIII at the local yard....wish me luck.

-

Hmm....unique. Well, look around at everything other people have done, then don't do any of that!

(I know, I'm a jerk...)

Honestly though, I'm more of the opinion that projects should be planned from the end goals going backwards. Ie, if you have a limited budget, but want a *blank* car, you do a lot of wheelin/dealing and prioritize what items will get you closest to that goal. I wanted a V8 sleeper, totally stock looking, but clean and different. So, I installed an engine I've never seen anyone put in a Z (and on the cheap!) and bits and pieced the body/interior together over the years to achieve that goal. Just saying 'unique' could mean you build it into one of those burning man looking monstrosities, or you fit a fiberglass boat body to it so you can ford rivers with it! What are you trying to do with this car? Stripped out autocrosser, or amphibious swamp car? -

Finally got rid of that stupid Wilwood pull cylinder. I actually broke down and bought a new one back around Christmas and it's given me nothing but problems. I actually had better luck with my old REALLY beat up one that I made a custom piston for. Went through about a half gallon of fluid in the last few months and a pile of o-rings...

Ok, off my b*tchin' box.

I got PN 12210 from Autozone $11.99, it's one of their common stocked items (I found it by digging around the back shelves of my local store.) You can't find the application at the store, but you actually can by searching their website. There's a tab for 'Vehicle Fitment' that I'm sure has been there for years, but I've never seen before. It fits: Mazda B2000 1986/1987 and Mazda B2200 1987-1993. It has a 3/4" bore, and over 1.3" of stroke before the piston starts to protrude from the bore. The weird thing that I'll have to check at the junkyard is I don't know what the inlet line fitting should be. It's M10x1 straight thread, but there's no seat at the bottom of the threads for an inverted flare, and even the 'long' tube nut bottoms before the line gets tight with a bubble flare. I ended up (I know, for shame) using a 1/8" NPT, and it went in about 3 or 4 threads, which is good enough for now, but I'm thinking maybe it's supposed to be a banjo fitting? Seems weird, but I sure saw some weird master/slave cylinders when I was digging through the Azone stock.

I made up some brackets and mounted it to the side of the transmission, which worked ok, but I couldn't put it directly inline with the clutch arm, so I had to weld an extension bar offsetting the push rod about .75" to the side. I also had to make an extension to the pushrod that came with the slave, but I don't have any pictures. I basically just took an aluminum rod, threaded the end to take a button head screw and drilled the other end out to slide over the stock pushrod. (ie, the button head screw is the contact point on the clutch arm, and is adjustable.)

Overall it works really well, it's still a pretty firm feel to the pedal, but the MC stroke required to get the transmission disengaged leaves the pedal a few inches from the floor. Not a big deal for me, but I think maybe now my wife can drive the car (she couldn't reach the floor with the clutch pedal before, which was required with the Wilwood pull cylinder).

The bolts that have rusty rod welded to them may seem like overkill, but they're really hard to reach in the trans tunnel, and they acted like studs for the bracket to bolt to the trans to. Drop the assy in from the top, slide the blue bracket up onto the studs, put the nuts on, Done. For a one time installation, it's not a huge deal to hold the bolts on top, but when it's gotta come on and off 10 times in an hour the first time you're making it...it really is a time saver.

Oh, and the big 'notch' cut out of the bracket is to clear the reverse switch and plug.

Including finding the parts at Azone, this took from 6:30pm to 11:45pm. No dinner....

but it works

but it works

-

Old school cool with the Clevor. I thought about it on my Mustang, but figured they'd hurt my tight engine bay worse than the stock heads do already. I didn't realize Edelbrock was making a manifold for the old Cleveland heads. What's the advantage of the Cleveland heads over say the GT40's?

-

Yeah, the whole 'no replacement for displacement' is the first kick in the shins for a 302 vs 351. Similar mods to either engine will get you similar gains %wise.

I do however believe it's a better swap in engine if for no other reason besides you can tuck it right against the firewall without having to dink around with hood latch relocation work etc. That and when you say you have a V8 Z EVERYONE assumes it's a Chevy, so it's nice to be able to surprise them.

-

Yeah, it's weird that the link above didn't work. Brian's site's still there, and so are his prints!

http://www.lainefamily.com/240Z_V8_Conversion-files/240Z_Conversion_Prints.htm

http://www.lainefamily.com/240Z_V8_Conversion-files/240Z_Conversion_Prints.htm

For some reason when I insert the link as a hyperlink on the forum, it redirects to some bogus site, when it's just pasted in as text, it recognizes it's a hyperlink and takes you to the right place.....

-

FYI to me: Wilwood PN's for the o-rings. If replacements are purchased from McMaster Carr etc, they should be EPDM. (Glycol, DOT brake fluid compatible).

210-1330 small: SAE dash number =

210-1328 large: SAE dash number =

After years of rebuilding my old ( and definitely worn out) slave cylinder, I finally broke down and paid $80 for a new unit. Two weeks later, all the fluid's gone again. I'm hoping it just had old seals and they went bad. Wilwood sent me another set of o-rings, but I'm still not real pleased about this.

-

This is a really old thread. But I can tell you that with the window louvers on, my hatch (if not locked down) will open at exactly 80 mph. That was before adding the spoiler. I have tested this with the hatch unlocked since adding the spoiler. No more opening and losing loose papers all over the interstate.

Ha ha, YES! I'm glad I'm not the only one this happened to. I don't think I had my louvers on yet, but I have a set on now. (No noticeable difference.)

An interesting thing I found out last year is that if you keep your hatch open about 6" you will get air from the back of the car to flow forwards and out the front windows. I thought it it was a low pressure zone above/behind the hatch that it would draw air from the front windows, and flow out the back, but apparently there's still MORE low pressure by the front windows (coming off the windshield/front of the car). I don't have fume issues but it was weird to drive on the highway, have the windows and rear hatch open and have no perceptible air movement inside the car. The flow is low, but enough to create a high pressure pocket inside the car. You can put your hand 2-3" past the windows before you feel any turbulence again.

-

Why do you want the motor centered? I have mine about 1" offset to the passenger side and it's still REALLY tight getting the oil filter out.

-

I don't see why not. I didn't have a tubular xmember, but that would have saved some weight for sure.

-

I'm totally digging the intake build man! I'm planning on building an intake for my Mustang sometime soon, and love to see the ideas come together on serious homemade stuff like this. Thanks for posting pictures!

-

Neat. Where did you get your tubing from?

-

I know there's lots of info out on the net about making your own driveshaft so I thought I'd organize my go to links here.

Depending on what you've got for parts and what tools you've got available a DIY driveshaft might be a good option.

This should be your freakin' BIBLE when doing any driveline work:

Dana Spicer Installation Manual

Dana Spicer Installation ManualHere's some links below that give some torque ratings and dimensions of different joints and just interesting reading:

And one of the most concise DIY builds:

Everybody seems to do steel, but if you have a tig welder, well, why not do an aluminum one? They're on Trucks, Explorers, Aerostars etc.

And, if you have yoke problems, remember you can always take material off, but it's a bi*ch to put back on!

-

Im probably not looking hard enough,

Yup, I can agree with that. Brought up lots of times.

http://forums.hybridz.org/topic/61000-ford-v8-conversion-writeup/

It's the first post pinned to the top of this forum. Read it. Read Brian Laines website too.

I have a 4.6 in mine with a dual fan (Escort) with a stock 280z radiator, it always keeps the temp right around 200. Cold, hot whatever.

-

Keep them pictures coming! I love seeing other hardcore fab guys making stuff. Gets the ol' noggin going.

-

I have an older Craftsman Professional 1/4" Die Grinder that I got when my grandfather passed away, it's stronger than my air die grinder I'd say. Not sure it has the same top end RPM though... It might be something you could find reasonably priced on evilbay?

-

Yeah, I'm kinda wondering how Wilwood would know the stroke you have on an old Z car at the pedal vs. what you need at the clutch arm. If I can find them, I'll put up a picture of the excel sheet I used to figure out the right master cylinder / slave cylinder arrangement. (EDIT, Found it. ) I think you'll run out of travel at your master cylinder early based on my measurements on this post:

http://forums.hybridz.org/topic/97812-460zgt-project-build/?p=983253

Master Cylinder "Determiner" Inputs 0.750 Pull piston diameter 1.400 Pull piston travel 0.750 Master cyl piston diam Outputs Master Cyl Travel 1.400 0.619 Volume (in3)

Master Cylinder "Determiner" Inputs 0.750 Pull piston diameter 1.400 Pull piston travel 0.875 Master cyl piston diam Outputs Master Cyl Travel 1.029 0.619 Volume (in3)

Master Cylinder "Determiner" Inputs 0.750 Pull piston diameter 1.400 Pull piston travel 1.000 Master cyl piston diam Outputs Master Cyl Travel 0.788 0.619 Volume (in3)

SORRY about the crap format. Apparently this forum style doesn't like direct copy paste from Microsoft programs....

I just used the stock fuel lines. Literally, I don't think I even changed the fuel line length! I used the stock Z fuel filter and mounted it near where the battery tray is. I don't think I have a recent picture of that setup and how I mounted my MAF/ airfilter either. Why are you running a surge tank? To put a higher volume pump in? I'm not sure what the stock pump is rated for (gph at 36psi) but I seem to remember looking into it and realizing I would be fine.

-

Most excellent work so far. I'm guessing this is your write-up: http://community.ratsun.net/topic/54796-1974-260z-46dohc/

Couple of things to note, the Mark 8 headers are nice because you can 'work' (cut/weld) them for better exit angles to get around frame rails, steering and what not. Wish I had that option when I dealt with exhaust and my stupid cast manifolds.

Make sure you have the master cylinder you need for that stroke. I know the wilwood slave only comes in one size; I had to run a 1" master cylinder to get the full stroke out of the slave after I put in a new clutch. A 3/4" MC would probably work with a worn clutch though, so be careful (especially if you can still return the 3/4" one...).

-

Cool another convert! Where are you on your swap? You realize that now YOU have to start putting up pics too

The gauges took me too long to put in because I'm kinda anal. I trimmed down a bit of the speedo/tach pod to get things right, and they work pretty good now. I think I could have used two speedo pods and then the back lights would have been easier to work with, but I didn't want to chop up too many sets of gauges. Seeing how little they cost me, it really wouldn't matter, but oh well. They do work pretty well.

The gauges took me too long to put in because I'm kinda anal. I trimmed down a bit of the speedo/tach pod to get things right, and they work pretty good now. I think I could have used two speedo pods and then the back lights would have been easier to work with, but I didn't want to chop up too many sets of gauges. Seeing how little they cost me, it really wouldn't matter, but oh well. They do work pretty well.

-

I'd guess about 600#. If I'm doing something that requires a truck, I'll grab my truck.

Where can I buy a SBF (5.0L) engine swap kit for my 240Z ? ?

in Ford V8Z Tech Board

Posted

What I'm wondering now is would a mod motor fit on those mounts with the early (ie, Mark VIII) style mounts. I have a set that just came off my DOHC when I put the GT mounts back in, and they've got that 'U' + pin style of mounting to the K member like the 5.0 mounts shown in Brian's picture. Probably a fox body engine swapper guy would know the answer to that one...