-

Posts

1194 -

Joined

-

Last visited

-

Days Won

30

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 74_5.0L_Z

-

That type of fuel cell is only good for drag racing and mild street driving. I had something similar in my car when I first built it. When I started auto crossing the car, I found that the fuel had to be kept almost full to prevent starvation during braking and cornering.

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

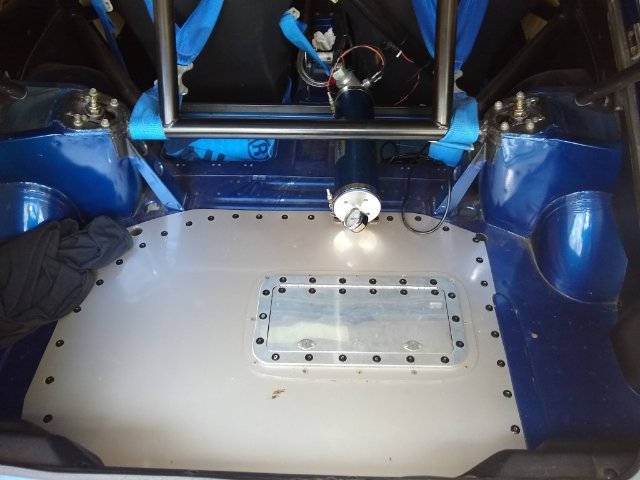

The access panel is to get to the fuel filler neck. I think I got the panel from Allstar Performance. I wish the panel was just a little bigger so that I could remove the filler plate though the opening. The one I have is just a little too small... -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

I have the ATL 12 gallon cell in mine. I also use the ATL Black Box sump with pump. The fuel return dumps into the top of the Black Box. I can use pretty much every drop of fuel in the cell without fear of starvation. My cell is below the rear deck and offset to the right for weight distribution reasons. You can just see the bottom of the cell in this picture: -

You don't really need the brake line differential pressure warning switch. It does function as a decent junction block. You are also likely to want an adjustable proportioning valve instead of the stock unit unless you plan to run stock brakes.

-

Those struts look really long. How much can they be shortened and still maintain sufficient travel?

-

When I installed my small block Ford in my car there wasn't a kit available to mount the engine and transmission. So, like you, I had to figure it out on my own. A particular challenge with these cars is that they are small and you will end up with a very short drive shaft. Because of that we have to pay particularly close attention to driveshaft angles. We need the axis of the engine to be parallel to the pinion axis, and to keep the u-joint angles as low as possible. If you don't do these things you will have drive line vibration that will make the car very unpleasant to drive at high speed.

-

It's hard to tell from the pictures, but it looks like you could lower the engine quite a bit if you used a remote oil filter.

-

I don't know how you have the engine placed, but I would offset the engine about 1 inch toward the passenger side. The drive shaft angle is easier to minimize with the engine shifted in-line with the pinion. This also makes the weight distribution a little better when you are in the car.

-

This is the only picture that I could find of the car with the 16x8 wheels and stock bodywork:

-

I'm currently running 15x10 wheels with a 5.25" backspace on all four corners. I use 23.0x10.5-15 Avon Slicks or Hoosier 275/35-15 tires on all four corners. I run a 1/4" spacer on the front and it just barely clears my coilovers. No spacer on rear, and I have at least a 1/2 clearance to the strut. I have a modified version of the SubtleZ body on my car which provides an extra 1.5 of clearance at all four corners. Below are some pictures with the 15x10s and SubtleZ kit.

-

When I was running the stock bodywork I used to run 16x8 with a 5" backspace. I could fit 245/45-16 under the rear and 225/45-16 under the front without rubbing. Availability of 16 inch is an issue these days. Research tire availability before committing to running 16" wheels.

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Just looking at the picture that you posted of your steering shaft, it looks like the u-joints aren't phased correctly. It may be an optical illusion from the angle of the picture. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

When are you hoping to get this car on track? I'm hoping to do an SCCA track day at Sebring in February. It would be nice to see you guys there. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

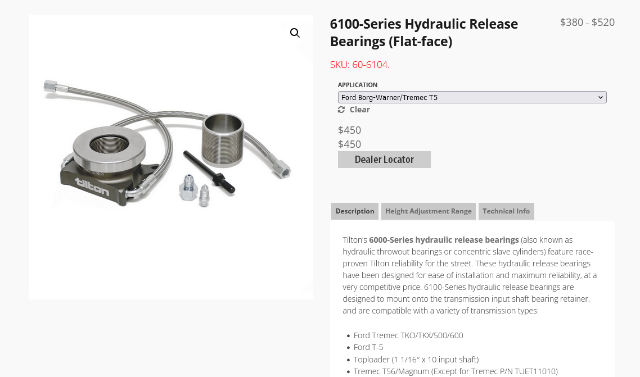

I like the external slave cylinder. You may have to clearance the driveshaft tunnel a bit, and it will create another obstacle to routing headers. I'm using a Tilton hydraulic throw-out bearing. Works great and doesn't take up space in the driveshaft tunnel. The downside is that if it leaks then you have to remove the transmission to fix it... -

They are Spinwerkes series 82. Unfortunately they are no longer available. I bought them around 2007. 15x10 and weigh 12 lbs

-

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Hopefully you are converting to all SAE / AN brake fittings. It's a real pain to have a mix of metric and SAE. I routed my brake lines inside the cabin to get the brake lines away from heat. I'm running a Wilwood Tandem Master Cylinder (7/8" bore) and use a proportioning valve installed on the drive shaft tunnel. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

That is an interesting master cylinder set-up. I haven't seen that before. I assume that you will be running all new brake lines. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

The dyno chart for that was from my old 331 stroker: Stock Roller Block (4.030" bore) Eagle 3.25" stroker crank and rods Mahle 4.030 Pistons Custom Hydraulic roller cam (.571" lift) AFR 185 heads 1.75 Long Tube headers 30# injectors I scattered that engine at Daytona My new engine is a 347. Dart SHP Block (4.125 bore) Scat 3.25" stroke forged crank and H-Beam rods Custom Hydraulic roller cam (.625" lift) AFR 185 heads Long Tube headers 42# injectors I use Megasquirt MSPNP 2 to tune both engines. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

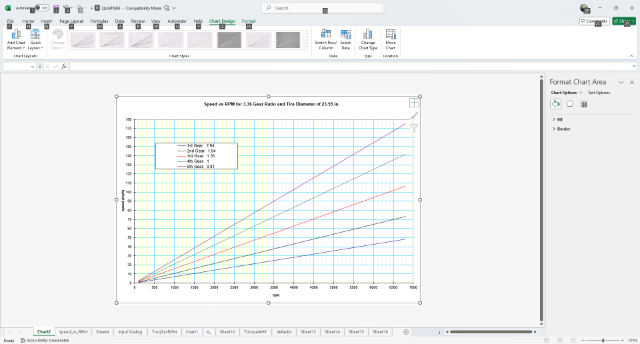

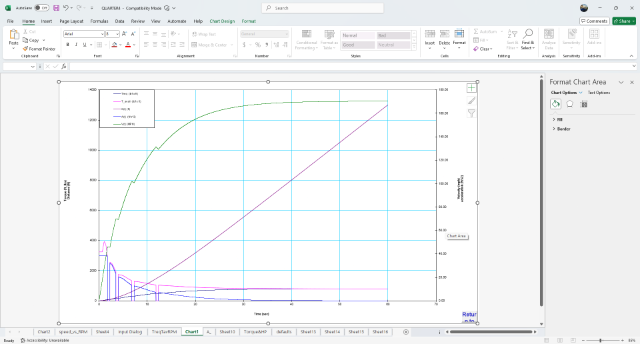

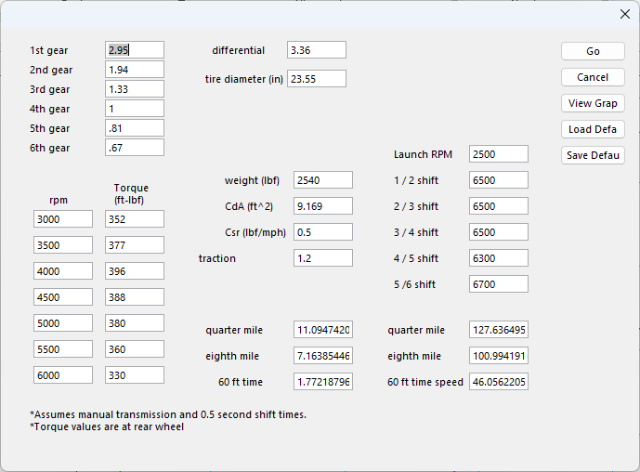

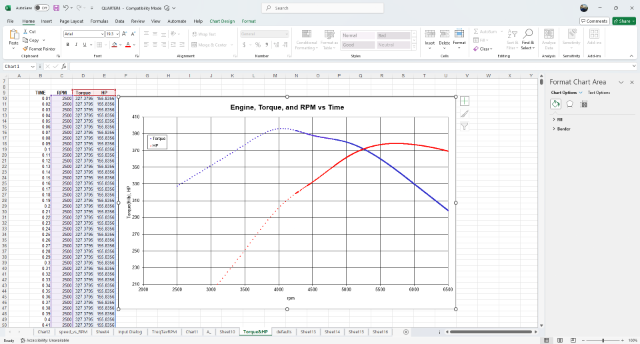

With a good 5th gear, overdrive is wonderful... I have the mythical R200 with 3.36 rear gear. The transmission is a T5 with the G-Force Shafts and gears 1 through 4. I run short tires Avon 23 /10.5-15 on all four corners. When I first installed the G-Force gears I was only auto crossing the car, and really only used 2nd gear. When I started doing track days (Daytona and Sebring), I quickly discovered that 5th gear was horrible. With the stock gears, 5th wasn't optimal but wasn't too terrible (3.35, 1.94, 1.44, 1.0, .67). When I changed to the G-Force Gears, 1st gear was improved but 5th gear sucked (2.95, 1.95, 1.33, 1.0, .58) First time at Daytona, I was redlining 4th gear by the time I came off the banking onto the front and rear straights, and the .58 5th gear would drop my rpms and torque too much to be useful. The .58 5th gear was horrible, so I pulled the transmission and took it to Astro Performance in Tavares, Fl and had them install the A5 5th gear (0.81). The difference was night and day. Overdrive went from a total buzz kill to being my Warp Drive... If you get a transmission with a good 5th gear (TKX with .81 5th), then you'll be fine. This is what the gear spread (speed versus rpm) looks like: Here is what a full acceleration run looks like if you assume 0.25 second shifts: The above uses numbers from my old dyno chart and the following inputs: Dyno graph from my old engine (my new engine makes more power and torque): -

http://www.woodwardsteering.com/PDF/7. Steering Universal Joints, Splined Couplers and Shafts.pdf

-

There are couple of ways that you can attack this. 1. You can add a u-joint and rod end support between the existing to get you under the motor mount. 2. You can raise the motor mount pad to allow the existing shaft to pass under. That may cause other issues like hood clearance and drive line angle. 3. You can shift the entire steering column inboard and down. I did this on my car using some 1/4" aluminum plate at the firewall and where the column bolts to the pedal box. But mine is just a race car. My seat is moved 1" closer to the centerline, and I wanted the steering wheel centered on me.

-

Years ago, I had to add an extra u-joint to get around my headers. I used a Sweet Manufacturing U-joint and a rod end. This was way back in 2003, so I don't remember the specific part numbers. You do need to add the rod end as an additional support. You need to align the universal joints so that they are phased properly.