-

Posts

1194 -

Joined

-

Last visited

-

Days Won

30

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 74_5.0L_Z

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Do you plan to do any chassis reinforcement? Cage? -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

What size tires will you be running? What rpm are you expecting to set as redline? Also, your calculator has the speed profiles for the option 3 and option 4 swapped. You will have a higher top speed with the 3.3 gear. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

I track my Ford powered 260Z. My personal experience is that transmission gearing is extremely important to getting the most fun on the track. In Florida, you will most likely be doing track days at Daytona and Sebring. Both tracks have very fast sections. Before doing track days, I autocrossed the car. In autocross, you only really need second gear if you have the right differential / tire height. I used Hoosier 275/35-15 tires and have a 3.36 rear end. With a 1.94 second gear in a T-5 and 6,500 rpm, 2nd gear was good for 73 mph. When I started doing track days, I needed all the gears. I had replaced the stock 1st through 4th with G-Force gears and shafts, but fifth gear was still stock. With that set-up, these were my gear ratios. 1st 2.95:1 2nd 1.94:1 3rd 1.33:1 4th 1:1 5th 0.59:1 Worked great until I needed 5th gear. that big a drop absolutely killed the fun (no acceleration in 5th). After my first time a Daytona, I changed 5th gear to 0.81:1. The .81 gear absolutely transformed the car. Now 5th gear is warp drive. The transmission that you show probably doesn't have a good selection of gear ratios, and probably won't hold much power. If it were me, I would get the new TKX with the close ratio rears. That transmission will handle the power and maximize you fun on track. If I didn't already have so much invested in my T5, I would get a TKX. This is the TKX I would get: https://www.speedwaymotors.com/TREMEC-TCET18084-TKX-Close-Ratio-5-Speed-Ford-Manual-Transmission,452007.html?srsltid=AfmBOoq-x1paVSDoNvgI38myLy79UBWXzZFW-QeQ4bK1_vWnSHM7bEEJ Gear Ratios 1st - 2.87, 2nd - 1.89, 3rd - 1.28, 4th - 1.00, 5th - 0.81 -

Anyone ever used Gyraline DIY alignment tool?

74_5.0L_Z replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

Thanks for being the guinea pig for this. I was hoping for better results. -

Do you still have all the stock rear suspension attach points in reasonable condition? If so, I would install the rear control arms so that they are symmetric. If you are using aftermarket eccentric bushings, then make sure the left side and right side are mirror image of each other. When I first set up my suspension after chassis mods this is what I did (using the eccentric bushing). 1. I installed the front and rear bushings on the rear control arm such the the holes were outboard and up and one of the flats on the eccentric bushings was level to the floor. I took a straight edge and laid it across the bottom flat of the bushing on either side of the car. If the straight edge sat flush on the flat of both bushings, then I knew they were square to each other. I did this for the bushings at the front and rear of the control arms. This gave me a good starting point that was symmetric and square to the car. This step above doesn't guarantee 0 toe, it just established symmetry and squareness to the rear attach points. The next step is to set the toe (at least roughly until you can get to an alignment shop) 2. Scribe a line near the centerline of both rear tires. I do this by jacking the tire so that it is a few inches off the ground. I then support a scribe or small flat head screw driver near the middle of the tire and rotate the tire by hand to scribe a line around the circumference of the tire. 3. Set the tires back on the ground and settle the rear suspension. 4. Measure the distance between the scribe lines at the front of the tire and at the back of the tire. Try to measure as high up on the tire as possible and measure at the same height front and back. 5. Subtract the front measurement from the back measurement. If the front side is longer you'll get a negative sum and you have toe out. If the rear side is longer, you'll have a positive sum and you have toe in. You want to start with zero toe (front and rear measurement equal or slightly toe in (<1/8" total) If you do need to adjust, do it equally on both sides by turn the eccentric bushing on opposing sides an equal amount but in opposite directions. You want to try and maintain symmetry in your rear suspension set-up.

-

cant figure out steering clunk/pop

74_5.0L_Z replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

Have you made sure the bolts that secure the front cross member to the frame are tight? What about the bushings on the T/C rods? -

What struts to use in 2024?

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

Yes. Jon is correct. The bore in the housing has gotten deformed and the bearing is no longer a press fit. The car has 400 lb/in rear springs and no rear sway bar. In the front, I have been running 500 lb/in springs with a 20 mm sway bar, but I recently changed to 425 lb/in springs with a 25 mm sway bar. I'm running 15x10 wheels with Avon 23.5x10.5-15 bias ply slick on all four corners The old set-up worked well for autocross, and the new set-up works for road courses. I will probably just stick with the Konis. I may step up to the 8611-1259 instead of the 8610-1437. Anyone have experience with those? -

I currently have Koni 8610-1437race struts installed at all four corners. I sectioned my struts and installed them about 15 years ago, and mostly I have been happy with them. The original strut housings that I sectioned were from an early 260Z. One of my rear strut housings has worn out the bearing surface where the stub axle presses in. The stub axle slides in with no interference fit on the bearing, and I am starting to get some bearing noise. So, I have purchased some 280Z rear strut housings and plan to section them. However, before I go down that road I want to get opinions whether there are better options than the Koni 8610 struts? It has been a while, and technology improves. I wouldn't mind upgrading as long as the upgrade cost isn't significant. So, in 2024, what struts would you use? This car is only used for track days. I run 500 lb/in front and 400/lb/in rear springs rates.

-

I ran 16x8 with 245/45-16 Hoosiers under the stock fenders. The Hoosiers have a cantilevered sidewall, so would be similar to running a 16x9 wheel. The key is getting the backspace / offset correct. I was running 5" backspace with coil-overs. Coil-overs are required to run that much backspace. A 16x9 wheel is 10" wide from outside to outside of the lips, so a 5" backspace is equal to zero offset. I know from experience that a 16" wheel with 5 inches of backspace clears the struts and coilovers (I am running the old GroundControl coil-overs). The rear wheels have more clearance than the front. On the front I had about 1/8" clearance, and on the rear I had about 1/2"-3/4" clearance with 16" wheels and a 5" backspace. You could run a different backspace front to rear if you wanted to push the rear wheel in further. Or, you could buy wheels that optimize the rear wheel placement and run spacers on the front. When you run the 16" wheels tucked to clear the stock fenders, the front tire will contact the frame and or Tension / Compression rod at full turn. To fix that, I made some simple limiters for the rack.

-

I have a 260Z with SubtleZ body kit and Ground Control coil-overs at all four corners. The SubtleZ kit provides an additional 1.5" of clearance between the fenders and tires compared to the stock fenders. The car currently has 15x10 wheels with a 5.25 inch backspace. On these wheels, I have run Hoosier 275/35-15 and Avon 23.0 x 10.5-15 race tires. I run no spacers on the rear and use 1/4" thick spacers on the front. I have previously ran 16x8 inch wheels with a 5 inch backspace on all four corners with no spacers and the stock body work. Clearance was perfect with 245/45/16 Hoosiers. The key is getting the backspace correct to clear the coil-overs. Then specify you width to fill the fender. For 15" wheels, the maximum backspace that you can run is 5". Any more than 5" backspace requires a spacer on the front wheels. The rear wheels can accept a little more backspace than the front generally. On my car the rear tire clears the strut by ~1/4" with 15" using a 5.25" backspace. The larger diameter wheels can run a little more back space, but then you get into making custom wheels. The pictures show the car with the Avons and the Hoosiers.

-

WTB 3.54 ring and pinion gears for r200 longnose

74_5.0L_Z replied to G-Tech's topic in Parts Wanted

There are a few rare Long Nose R200 differentials with 3.36 gears (I have one in mine). I believe they were stock in the 1977 280Z 2+2 four speed cars. I would love to find an even higher gear 3.15 or 3.00. -

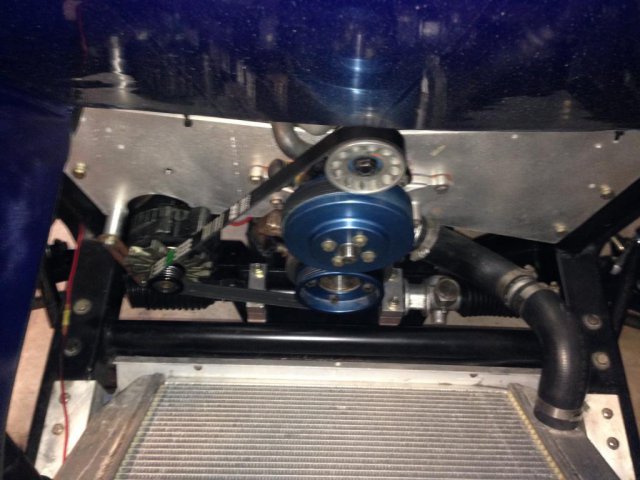

The hood won't lift if you give the air an escape route from under the hood. All the air that goes through my radiator exits through the duct in my hood. The air inlet is sealed to the front of the radiator and the outlet is seal the back of the radiator.

-

1974 260Z 300ZXT CV Axle Conversion

74_5.0L_Z replied to Zachs260z's topic in S30 Series - 240z, 260z, 280z

There are several ways to gain some clearance. First, you can install adjustable bushing in the rear control arms and adjust them for maximum negative camber. This moves the strut outboard and gives you more clearance. The problem is that this may give you more negative camber than you want. If you have rear camber plates then you could move the top of the strut outboard as well to tweak the rear camber and gain more axle clearance. Second, you can lower the differential. The axles are shortest when they are in a straight line from the differential to the wheel. If the differential is low enough, then the stub axle at the wheel will always be above the shaft coming out of the differential. This works for low vehicles with limited strut travel, and is what I have done. I use bushings above the mustache bar to lower the rear, and adjust the angle at the R/T mount at the front of the differential. Third, in theory you could shift the differential forward or aft to gain clearance (same concept as lowering the differential). The axles would always be angled as seen from above, but the CV joints can handle that. -

steering rack issues; vq37 swap into S30

74_5.0L_Z replied to zTrollop's topic in Fabrication / Welding

It looks like you could get better angles on the steering shaft sections by rotating the pinion down toward the firewall and come in below the ear on your timing chain cover. Also, is the engine as far back and toward the passenger side as possible? -

Body harness wiring diet or aftermarket harness?

74_5.0L_Z replied to 280Z-LS3's topic in Ignition and Electrical

I used an EZ 14 circuit harness mounted on the top of the driveshaft tunnel near the firewall. Mine is strictly a race car (no radio, no Heat/AC, no windshield wipers, etc...). I use a modified ford engine wiring harness between the ECM and engine while the EZ harness supplies all of the other body functions (ignition switch, brake lights, tail lights, gauge illumination, etc..) as well as power to the ECM and fuel pump. I like the compact fuse panel and the 175 amp circuit breaker that come with the kit. It definitely made it easy to clean up the wiring. -

Where are you getting contact? Tire to fender lip or tire to strut? With 17" wheels and coil-overs, you should be able to run more than -20mm offset. That equates to 4.46" backspace I run 8" springs, but my rear spring rate is 400 lb/in (probably not street friendly). With 15" wheels, I could run 5.5 inch backspace. With 17"wheels, you could get away with 5.75" backspace. Its always better to have more backspace than you can use because you can compensate with spacers. If you don't have enough backspace then there is no way to adjust besides getting different wheels. I use 5.25 backspace on all four corners, but only use spacers (1/4") on the front.

-

What are you using the car for (street, drag strip, track days,...)? What size tire are you trying to fit? If you choose the right wheel diameter and backspace, contact of the strut tube is not the limiting factor. On the rear, if you have coil-overs, you can run at least 5" of back space with a 15" diameter wheel. I run 15 x 10 wheels with 5.25" back space. With Hoosier 275/35-15 tires I have about 1/2" clearance at the strut tube. As you increase the wheel diameter to 17 or 18", you can increase the backspace of the wheel. The inner wheel tub is the limiting factor for modern (17", 18") diameter wheels.

-

You will loose camber gain.

-

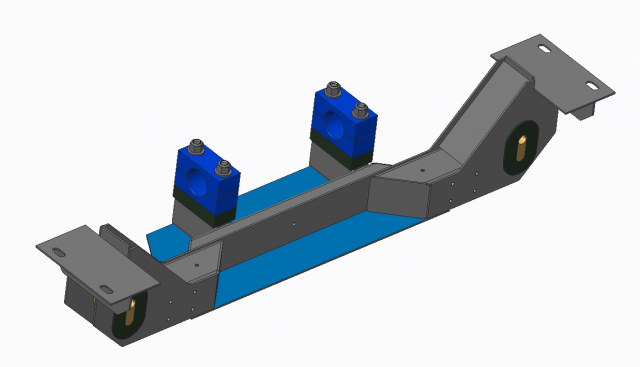

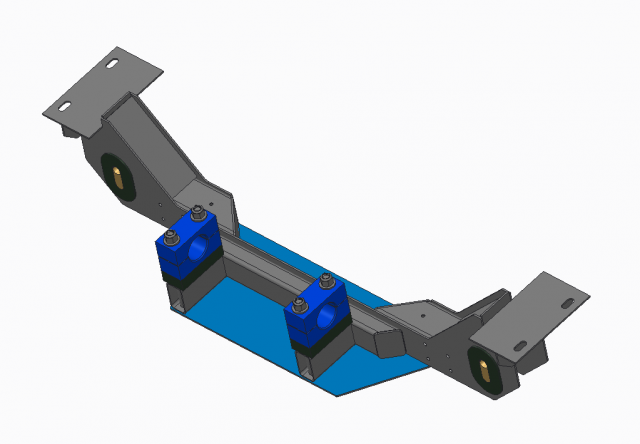

When I designed my new cross-member, I added notches to positively locate it laterally relative to the frame. The bolts don't take any shear load.

-

With the mount arranged horizontally like that, you are putting a bending moment into the side of the block. The lower bolts at the block are in tension, and the upper edge of the mounting plate is trying to push into the block. Typically, the mount is angled normal to the face of the block to assure that the mounts don't apply bending loads.

-

I haven't had issues with it, but I do want to add a locking mechanism to support lateral loads trying to separate the rack tube from the rack pinion housing. Right now the engine is out of the car, so it might be a good time to revisit. An even better solution would be a nice Woodward rack. Do you have one I can borrow😀?

-

You could try making your own cross-member like I did. The other thing that you can do is move the whole cross-member forward so that the engine drops in behind. This will also add caster and require custom T/C rods. crossmember.pdf

-

280z 1975 Steerin Rack Rebuild Question

74_5.0L_Z replied to BMAC's topic in S30 Series - 240z, 260z, 280z

https://www.classiczcars.com/forums/topic/48621-steering-rack-disassembly-and-refurb/?&page=4#comments- 1 reply

-

- 1

-