-

Posts

110 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by theBrit

-

Thanks, no idea why the link was broken like that, I think it's fixed

-

Thanks, actualy I did not section them radialy like that, that is just tape form the 1000 of times I tacked them on I have had to re do the arches and re form the rolled lips extensvly though. The front was the worst, that was way off, I took inches out of the top of the arch to make it follow the same arc as the wheel so that it looked right and would not hit when the suspension compressed. The blue Z with VBs that everyone sees also has this done, you can tell bythe way the top of the arch sits in line with the crease down the side of a z, as they come it sits very much lower.

-

I though some pictures of my efforts at cutting the arches back on a 240z might help people out. Some of the pictures are not that great, I guess I am no photographer, but a hand full might be usefull and I tried to add captions to a number of them. There are also a few pictures of the victoria british AKA volkswaggon beetle steel arches going on, I will update this when the rear is attached. http://www.holmesfamily.ws/240zRearArch/index.html

-

Need to gain suspension travel

theBrit replied to theBrit's topic in Brakes, Wheels, Suspension and Chassis

Hey Forrest, you do mean the rubber section between the spring and the body? I ask becasue I measured the old stock ones and from my 73 car they appear to be the same height front and rear, if you have a part number for a thinner one I would be very interested, I am guessing that yours are from a 280z from your signature. The insulators I am running now I machined down so that the coil over hat does sit a little higher - maybe 1/4 inch giveing me a little extra travel but not as much as an inch. Thanks Jon, so I could still get 1.5" given that I will not try to cut the strut to the exact size, I still need to scrounge some more I think. I have not looked, but it occurs to me that if I detach the strut tube from the hub I could weld it back in with the bottom sticking out of the bottom of the hub a little, probably will intefeer with something - it cant be that easy! Mike -

Need to gain suspension travel

theBrit replied to theBrit's topic in Brakes, Wheels, Suspension and Chassis

Thanks for the thoughts, I had thought about going to a shorter tire side wall, but I originaly went with a larger one to gain the compliance it would provide. For now I am hoping to pull this off without changing the tires. I just dug up that MR2 insterts might be better than the konsi for the street PN BZ3099, I know the konis are about 13" long thus I gain 2", but I can't find any specs for the MR2 shock. I will keep digging and hope that MR2 inserts might even give me more travel. Mike -

I am running 17" wheels held up by MM coilovers and tokiko struts. This is a road car, occasional track day. What I have found is that the car sits higher than I would like unless I lower the spring to the point that there is very little suspension travel left. I was wondering if any one had any comments on these ideas. 1. I need to shoot for min 3" of travel from the resting position to hitting the bump stop. 2. For the street, I could use adjustable perches to gain some clearance at the top as they ar ethinner than stock mounts, but the ride might be a little more noisy. I looked at http://www.designproductsracing.com/DesktopDefault.aspx?tabid=512 http://www.designproductsracing.com/DesktopDefault.aspx?tabid=513 And I think I read that this might be worth 1" 3. Section the stuts and use koni 8610 inserts to gain 1.5" 4. Final ride height from the under floor rail is to be 5-6" 5. I could leave the bump stops out (2") becasue I have stiffer springs and it is less likely to compress that much. I think those are the only options I have, any thoughts appreciated. Mike

-

I never liked the flat bar either, looks like a rushed soulution to my eye although I am sure it works considering the number of them out there. This works flawlessly and it makes the tunnel a very rigid hoop, better ground and exaust clearance, I am tremendously happy with it. I know others have done something similar. I'm surprised that Ross or Arizona have not make a nice looking part, this one slides rightup in so location is simple and even then if you screw up it is adjustable. When you weld the reinforcing webs in make sure you line it up so that you can get the nuts on the bolts - ask me how I know Mike

-

From the album: 73 240z transformation progress

-

From the album: 73 240z transformation progress

-

I posted a picture of my T56 mount with details in the Gallerie if it helps anyone. http://album.hybridz.org/showphoto.php?photo=6498&cat=500&ppuser=8397

-

Large plate on the inside of the car is undectable through the carpet. Side plates create a level platform to hold the carrier. Carier may be slotted for lateral alignment. Carrier may be spaced down with washers. I intalialy mounted it with the T56 jambed against the roof of the tunnel to ensure the full range of adjustment. When you are happy remake the mounts and bolt them in if you don't want the slots and washers. Uses stock Camaro T56 rubber mount. Excellent exhaust clearance. Easy removal of transmission, just 4 bolts.

-

LT1 upgrade will start in gear, how to fix??

theBrit replied to love-my-V8-280Z's topic in Gen I & II Chevy V8 Tech Board

This comes from a different angle but I dont see the need for a switch, although if you have one I would not remove it. Driver ed in the UK is much tougher than here and untill I came to the states I had never heard of anyone not using the hand brake and always checking a manual before starting, it's just drilled into you and you don't forget. Similarly here in NJ I often see the few manual trasmission drivers try to leap their feet from the brake to gas and let the clutch out to start up a hill. Obvously this is dangerous as they roll backwards a fair bit. Avoiding this is the primary use of the hand brake in my opinion, to hold the car still on a hill start, whilst you get the clutch biting and then pull away releasing the hand brake. You cannot pass the UK driving test unless you can start up hill without rolling back in a manual. Mike -

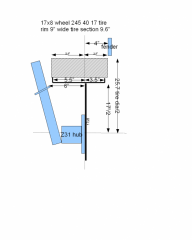

Thanks, there is a snag though, acording to khumo if you go to a 40 serise tire you need to go up to an 8.5 wheel. It's tough to know how it will all play out in reality, I guess I can always kluge it with a spacer aftwards if I needed to.

-

I have z31 hubs so I have more back space than a stock 240, I have coilovers and VB flares which dont add a whole lot of space at the front. Set up is 17x8 with 245 45 17 tire probably khumo MX Looks to me like the rim will be 1/2 in from the arch for the tire to clear, I hope this does not make it look like it needs a bigger rim. I checked and with anything over 5" bs on my set up, the tire hit the inner arch at the front for full lock, I guess I will have to live with that to get the tire outer edge inside the fender. I know tires dont have 90 degree bends and it only gets close to the fender at 100% compression so I wonder if I am being too conservative with missing the fender, maybe the wheel could go 1/4 or 1/2 inch further out ?

-

jmortenson, When you say 9" fits do you mean physical outside edge to edge distance ? I have an american racing wheel stamped as a 17x9.5", it actuallly has an outside lip to lip distance or (back spacing + front spacing) of 10.75" - see diagram. When you say 9" do you mean I would order a 17x9 or order a smaller 17x8 that will end up being physicaly 9" wide. I have have not managed to convince myself that everyone describes wheels the same way.

-

RA64 I see you are new, so rather than guess if you have found the private message section I will post here. I have a number of 240 hubs I would be willing to sell, click on my profile and mail me if you are interested. Mike

-

are you going it alone or do you have help

theBrit replied to grumpyvette's topic in Gen I & II Chevy V8 Tech Board

When I was a kid my father helped me repair my car, he never faltered even after spending weeks helping me straigten and respray my mini (orignal mini), he did this 3 times even whan I had the lamest excuse for smashing it. Aged 17 I just could not get it into my head that there is a physical limit to just how fast a corner can be taken! Worse in the south west of England the hedge rows are made of granite - literaly. My brothers have always been into cars and bikes, lots of support there. Any way I moved to America 10 years ago and lost it all and felt is acutly. I slowly found some good budies who would come over and shoot the breeze whilst I wrenched, they were not really car guys but I expect this audience knows how motivating it can be just to have the company sometimes. Then by sheer luck 2 years ago I moved into a house across the street from a guy who builds wild hybrids for a living. Now I still end up doing it 95% of the work alone as I get tremendous satisfaction from it, plus I have had to many experts screw up royally, but it is awsome to be able to wander over the road with a fist of full parts and ideas and have some one to bounce them off (ideas not the parts ) I think I am tremendously lucky becasue I remember how much less fun it was for me when I was on my own. It sounds preechy but I hope I never take my friends for granted and risk loseing what I now have. -

I did the same as clifton except I made a U shaped saddle that bolts on and I put a large flat rubber shim in it. The rubber is just not quite in contact with the bottom of the mount, as the diff rises the saddle support progresivly gets compressed and there is no shock load. Under normal conditions only the stock mount is working so there is no extra harshness. I am very happy with the way it works.

-

I have always been around welders in freinds auto body and restoration shops but I am no pro. When I came to buy my own I had used many welders and I did a night school class to make sure I knew what I was talking about, this also let me try top shelf welders. I bought the Lincon 135 continiusly variable wire and amps. My experience over the years leads me to recomend. 1. get at least continiusly variable wire and amps 2. get an auto darkening visor 3. practice like crazy on scrap Only very rarely do I wish I had a bigger machine, for example when welding the arm on the tractor I had to do multiple passes with the flux cored wire. Mike

-

iskone, sorry I should have been more specific, none of the torq thust style wheels at that much each but colarado custom wheel is > 700 per wheel. I meant to say that I know you get what you pay for and HRE wheels can be 1000 each but even though I only want to spend hundreds a wheel, I dont want them to be out of true etc. As for the 1/2 inch I have measured it many times, to be honnest I dont know how some people fit some of the wheels you read about in stock arches. I assume they don't lower the car much. Maybe my technique is wrong. 1. put the car on stands 2. undo the thread spring perch and losen it right off 3. lift the under the control arm to place the hub at a normal 90 to the floor driving position - this should be worst case for the fender lip. 4. measure in from the hub face to the first thing that hits 5. measure out to the fender lip. I get Front SPRING - 5 3/4 ->|HUB outterface|<- 3 3/4 - Fender lip Rear SPRING - 5 1/2 ->|HUB outterface|<- 5.0 - Fender lip Worse still for the Torq Thust wheel I borrowed, which is listed as 17 x 9.5 the actual rim edges are 10.5" apart making the wheel actually 1 inch wider that you initialy think it is. Thanks for the link, I checked them out and they don't appear to do 17" rims unfortunatly These are the arches, they do not give that much extra space, there is another thread about this some place on here. Mike

-

I found another http://www.coloradocustom.com They do most sizes but are pricey. http://www.etwheels.com 17x8 17x9.5 17x11

-

I am looking for torq thrust style wheels like this I was thinking 17"x9" 245 and 17"x10.5 285 or 295, I have VB steel arches like the ones on that blue car with the cobra stripes that crops up in many posts, 5 lug hubs and coil overs. http://www.americanracing.com sell them 17x8 17x9.5 17x11 - 9.5" is to wide for the front unless I do some extra work on the flares, I feel 8" is too small http://www.billetwheel.com sell them 17x8 and 17x9.5 all too small http://www.cragar.com sell them 17x8 17x9 all too small http://www.billetspecialties.com sell them 17x8 17x9.5 17x11 fronts too big or to small http://www.vintagewheelworks.com sell them 17x9 - YAY 17x11 might be ok YAY. So here are my questions Does anyone know of any company I missed ? Has anyone any experience with Vintage Wheel Works ? I have seen the American racing wheels and they are nice on the outside but not as well finished on the inside. I assume any wheel would be reasonably built/balanced, obviously spending $1000 per wheel gets perfection, but I do not want to get something that then requires a ton of lead on it. Thanks Mike