sstallings

Members-

Posts

84 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by sstallings

-

Wiring questions?? '77 280Z to '90 TPI & T-5

sstallings replied to sstallings's topic in Gen I & II Chevy V8 Tech Board

Dudeboy, That is a great source. I'm sure I will be scouring this site for wiring diagrams for every sub-system in my car, but, that being said, I didn't find a single circuit designed for the two-speed fan (which is consistent with what Dennis told me in his e-mail). Thanks for the new material. I'll keep working on the details and posting my findings. Steve -

Wiring questions?? '77 280Z to '90 TPI & T-5

sstallings replied to sstallings's topic in Gen I & II Chevy V8 Tech Board

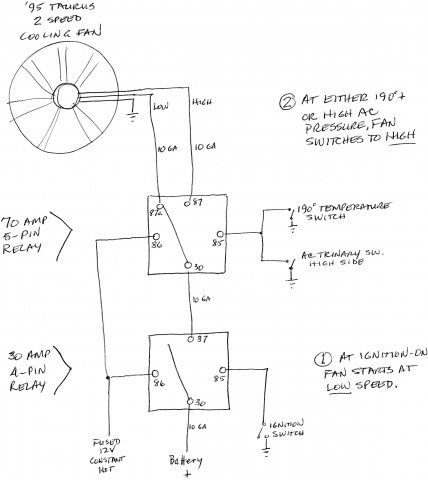

Strotter and Deja, Thanks for the posts, and the information in them. I'm still making progress (with a little help from my friends). I designed a circuit for the 2-speed fan and ran it by the tech support guys at Painless Wiring (since I buy my components from them anyway). As it turns out, Dennis Diehl at Painless has a buddy with this fan in his streetrod, so I sent him my design, and he's critiqing it as I write this. It currently meets three of my goals, and when I have his input, I'll post an update. My design is attached as a .jpg file. It supports: 1. Start the fan on low speed at ignition start/run. 2. Automatically switch to high speed when either the temperature goes over 190 degrees, OR the AC trinary switch exceed the high pressure rating of the system. 3. And restart the ignition on speed high if either is still too high (after a short shut-off period). 4. But, the one thing my circuit won't do is allow the fan to continue to run after the ignition is turned off if either the temp or AC pressure is still too high due to heat soak. Dennis should be able to help with this detail for those who want it. What I'm trying to avoid is a manual switch so that I don't forget to check the guages often enough and roast something expensive unecessarily. As I move forward, I'll post as much of this stuff as people want to see. I'm still no electrician, but nothing will stop this conversion process. I'm having a blast. Thanks, Steve -

Wiring questions?? '77 280Z to '90 TPI & T-5

sstallings replied to sstallings's topic in Gen I & II Chevy V8 Tech Board

Okay, So now I'm answering my own questions, but that's okay -- I think they call that "learning." I found a good book on automotive relays and answered one of my questions. I can wire both fuel pumps through the existing fuel pump relay as long as the combined amperage draw of both pumps does not exceed the rating of the relay. I should also leave a margin of safety in case of a surge at start-up (not usre how much so I'm thinking about 20% should do it). If the total is too much, I can run a new relay in parallel using the same source circuit to trigger it to support the additional low pressure pump to the inline surge tank. I still haven't figured out the Ford Taurus two-speed cooling fan circuit, but hopefully I can get Ford wiring information without having to buy another Helm book (or whoever prints Ford manuals). I've got the tach and ignition wires sorted, and I'm working my way through the rest of the 280Z to GM TPI connections. When I'm finished, I'll publish the whole set so the next guy will have a better starting point. Although I'm still waiting to hear from someone who's done this before me, if only to verify my connections. Keep the shiny side up. Thanks, Steve -

Time to upgrade and need some advice!!!

sstallings replied to madden87's topic in Gen I & II Chevy V8 Tech Board

Madden87 Regarding your question about aluminum heads paired with an iron block: This is fine as long as you keep your coolant up-to-date. If not, the coolant will allow electrolysis, which is similar to what happens inside your battery, where the slightly acidic water, and low volatge electricity scavenge aluminum from where ever it can be found in the system. If that happens to be an inexpensive water neck, it doesn't cost much to replace, but it could also be your expensive heads or intake manifold (I speak from expereince - not the good kind). I change my coolant every year and use radiator caps with a consumable anode as insurance (see www.radcapproducts.net) so that my heads, intake, and water pump are protected from damage. The same is true for the stock L24-L28 Datsun engine which has an iron block and aluminum heads. I've seen some heads that were pretty messed up by running water only as coolant. Steve -

Guys, I don't want to waste anyone's time, so I've reviewed all the threads I could find, read the JTR Z and TPI manuals a dozen times, and bought and studied the Helm GM, and Diamond Pubs Nissan factory manuals. I've removed all of the headlight, wiper, AC, PS, and other extra wires from my EFI harness, and isolated a few of the Datsun wires that I'll need to keep for guages. But wiring has never been one of my strengths, so determining which of the remaining wires from the bulkhead and 15-pin connectors on the EFI harness match which wires on the Datsun harness has been holding me up for a few days now. I'm not frustrated yet, but I am confused. I have to admit that the GM wiring seems much more straight forward than the Datsun wiring. Has anyone successfully tackled this same conversion (or close to it) that I can correspond with as I try to sort out these last dozen or so connections (primarily fuel pump, ignition, fuse panel, VATs, 2-spd electric cooling fan, etc.)? Also, it seems that I should replace the existing fuel pump relay with a double-pole relay to control both the low pressure pump to the surge tank, as well as the high pressure EFI pump. If that is correct, does anyone have a wiring diagram for that circuit? I've read a couple of threads that recommend wiring the two-speed Ford Taurus fan for a manual switch. Has anyone wired it for a thermostatic switch as well as an AC switch? I plan to use a Vintage Air AC system with a switch to bump the fan to high when the AC is on, as well as a thermostatic switch. Is that the right way to go, and if so, does anyone have the wiring information for the electric fan controlled by two separate switches? I think I'm getting close, but I still need some help. Thanks, Steve

-

240z, 260z or 280z, chassis/body differences

sstallings replied to Teekass's topic in Brakes, Wheels, Suspension, and Chassis

There's a ton of little stuff, some not worth mentioning, some interesting. Since I can jump from my '77 280Z directly into my '72 240Z, the little things get your attention. For example, the column mounted ignition key in the 240 is much more awkward to find in the dark as it is higher, angled slightly differently, and directly behind the accessory stalk. The original wheels (who has those anymore) on the 240 were only 14X4.5 wide, while the 280 was 14X6. The 280 bumpers required a spotwelded sheetmetal fill panel to close the gap between the rear pan and the heavy bumper. This may have been mentioned already, but the 240 has a smooth hood, while the 280 has the pair of plastic louvers for under-hood heat removal (of course placing the right one right over the fusible links was a design flaw IMHO ). I can't think of any other differences worth mentioning that haven't already been covered. -

Frnt Diff. Mount Counterweight???

sstallings replied to sstallings's topic in S30 Series - 240z, 260z, 280z

Thanks for the feedback. I see that I can save another 8-10 pounds as part of this conversion Curious though that my Z was never an automatic transmission car. I'm the second owner, and it's all very original, except that I pulled the four speed manual and replaced it with a 5 speed from a wrecked '77 2+2 (and that one was original too, until my son wrecked it!). Anyone need a paperweight? Thanks again, Steve -

Guys, I've had this '77 280Z for over six years and never gave this component a second thought until now. I'm fabricating a Ron Tyler front diff mount for my 350 SBC/T-5 installation using the JTR kit, and I know I'll be modifying the original mount to provide clearance for the driveline angle changes. These plates are 3/8" thick each, and the stack is 2 1/4" tall in front of the mount (just clears the 3/4" sway bar) and 3/4" thick behind the bar, all welded together. (see attached pictures) So, is it a factory piece? Or is it aftermarket? Either way, what purpose does it serve? Is it of value to other Z enthusiasts? (I should also tell you that this was originally equipped and sold as a Texas car without catalytic converter, heat shields, or heat sensor and warning light. Otherwise, it's stock, for the moment.) Thanks, Steve IMG_0154.zip IMG_0155.zip

-

Drummingpariah, In the last six months in Street Rodder magazine, Comp Cams www.compcams.com has been advertising a new line of "Thumpr Cams" that claims to have the nasty lope that everyone wants with streetable performance. I don't know anyone using one yet, but Comp is a reputable cam manufacturer, so you may want to check it out. Personally, I like performance and stealth, a sleeper that catches people off guard, but I have to admit that I always take notice of a car with a healthy cam lope at idle. It suggests more than stock muscle under the hood. Good luck finding your cam. Steve

-

Welcome to the site. I've been driving my stock 280Z for about six years and I can tell you that they handle MUCH better than any of my late 60's and early 70's Camaro RS, El Camino, and Nova SS of that era (all SBC cars). Even with the manual steering which is only heavy at parking lot speeds, the car feels tight and stable at up to 140 MPH (which is as fast as my stock engine would take it). Compare that to any of my power steering equipped muscle cars that feel light and floaty anywhere above 90 MPH. However, it does not handle as well as cars on the road since the mid- to late 1990s or newer. So I guess it depends on what you're used to driving. That being said, I am now converting it to a V8 Z and have about a 6-8 month head start on you on this site, and working with several Z V8 vendors. I don't have any seat time yet, but I am convinced that if you think out your conversion fully before you start, your Z will actually handle better when you're finished. You'll have to make your own list (and some guys on this site with more experience may rightly take issue with some of my choices) but here's what I've done/or plan to do for a car I plan to use on the street only. - Upgrade front disc brakes to Toyota 4X4 pick-up ('79-85) - Upgrade rear drums to Datsun 510 iron and add a proportioning valve - Add a roll bar, rear strut tower brace, and front strut tower brace - Add BadDog sub-frame connectors - Switch to a Ron Tyler front differential mount - Replace most of my bushings with Urethane (a few should stay rubber) - Replace my shocks with Illunina adjustables - Replace my springs with 175-200 Lb. (front-rear) - Upgrade my stock front sway bar to the Summit 1 1/8" bar - Relocate my battery to the rear cargo area I've done the math, and my Z will be lighter than stock, much stronger, and a health SBC and 5-speed will make it a blast to drive. I don't know for sure that it will handle better, but it should at least handle as well. Your plan and list of upgrades may differ based on your goals and preferences, but at least this gives you some ideas, and fodder for many other opinions. Good luck. Steve

-

Guys, I've searched every chassis thread I could find in the last few weeks to make the appropriate upgrades before dropping the SBC V8 into my '77 280Z. And, I didn't want to waste your time with a bunch of quwestions you've already answered. I have found BadDog subframe connectors, springs & shocks from Beta Motorsports, and happened upon the Ron Tyler designed Differential Mount. The basic concept of this mount, working as a diff. mount and snubber, allowing driveline angle adjustments for the V8 swap, and eliminating stretching stresses on the stock mount all make a great deal of sense to me. And the added weight is in the right place on the car: low and to the rear. I have two questions: 1. For those of you using this mount, is there any downside or issues I should be aware of (e.g.: wear, vibrations, etc.)? 2. Is anyone selling this mount? (I can weld, but if it's readily available, I may just save time and buy it if the price is right.) Thanks for your insights. Steve

-

espo280zx, Rather than splice two drive shafts together, pick up the JTR diffrential flange adapter. It comes in their conversion kit, or you can get it separately for about $50 and it will save you a lot of grief. The Datsun universal joint is significantly smaller than the GM piece, and it will be the weak link in your driveline of you splice two shafts together. With the adapter, you can use the complete GM shaft, and just have it shortened and re-balanced to fit, which was about $80 the last time I had that done. Good luck with your conversion. Steve

-

should you get the assembly ballanced?

sstallings replied to grumpyvette's topic in Gen I & II Chevy V8 Tech Board

Grumpyvette, The alternative would be to buy a Lunati 383 bottom end kit for a 350, which comes completely internally balanced with matched components. It costs a few bucks more than your approach, but the trade-off is peace of mind that it will all work right the first time. It may be overkill if you already have most of the parts, but if you're rebuilding an older engine, new forged pistons to go along with the crank and longer rods will make a bullet-proof bottom end. Steve -

Suspension components & sources ??

sstallings replied to sstallings's topic in Gen I & II Chevy V8 Tech Board

johnc, I checked out your site and it looks like you're right here in La Habra, CA. Since I'm just down the road in Cerritos, I'll have to stop by and check out the suspension pieces you recommended. Thanks for the advice. Steve -

CFC12 to HFC134a AC compressor conversions

sstallings replied to sstallings's topic in Gen I & II Chevy V8 Tech Board

Mike kZ and strotter, Thanks for the great tips on either living with the R4 or converting to the Sanden 508. One of those will definitely solve my problems. getZ, I also talked to Vintage Air about their smaller Sanden pump on the front runner system. Before you go that route, talk to their tech support. The smaller capacity of that pump has to be matched to the rest of the pulley sizes in the front runner system or you will have disappointing cooling capacity. On my next conversion of my '72 240Z I plan to use their whole front runner kit for an LS1 swap. But for now, my son and I are learning the ropes on his '77 280Z with a '90 TPI swap, and trying to do it right while keeping it low budget (at least as much as possible). I appreciate all the good advice. Thanks. Steve -

Guys, I've found a number of great threads on this topic, some very well documented with specs and pictures using the Vintage Air AC systems. I've used Vintage Air systems on my El Camino and on my street rod so that is the way I plan to go on my V8Z as well. That being said, I'm installing a '90 Firebird 350 TPI engine which has it's existing AC Delco compressor which will be easier to keep if I can get away with it. The tech guys at Vintage Air tell me it can be used, but I can't find any web sites anywhere (so far) that have rebuild kits with new seals for this pump. What I have found are a number of sites warning me that these pumps are prone to leaking even with the old CFC12. So, if anyone has already been down this path, am I better off modifying my AC bracketry to fit a Sanden 508 compressor on my TPI motor, or should I stick with the AC Delco compressor and rebuild it for HFC134a? If I have to go to a Sanden 508, are there brackets available, or am I going to have to get creative with the plasma cutter and welder? Your expereince will probably save me a lot of work and mistakes. Thanks again, Steve

-

Guys, The 5.7L TPI engine and T-5 are being trial fitted into the 280Z for the first time this weekend to check clearances for the clutch slave cylinder, locate the rear trans mount, run fuel lines, throttle cable, exhaust routing and other details. Then it all comes back out again, and the interior comes out as well for insulation, paint and sound deadening. Now that I'm getting closer, I need to start looking into the basic safety and handling details. I'd appreciate hearing from those of you with hands-on experience making a V8Z handle as well as it accelerates. 1. Who sells subframe connectors for the 77 280Z? 2. What shocks and spring rates on the rear will reduce squat for a 330 LBFT of torque street driven V8Z? (I'll go nuts later with CVs, adjustables, etc., but for now, I just want it in the ball park for decent handling) 3. Is the 1" front sway bar and no rear sway bar the best way to go for a street driven R200 without a LSD? 4. Is the Ron Tyler front diff mount the right way to go for a JTR kit? (It looks like it makes good sense and provides an adjustable driveline angle.) 5. I plan to upgrade to the Toyota truck four piston front calipers, 510 iron rear drums, and a proportioning valve, but I've read threads on this site that indicate that there are right and wrong calipers to buy. Which ones fit right? 6. I took a lot of pictures at the Z Nationals in So Cal in April and will be adding a four point Monte Carlo bar up front and simple strut tower brace and four point roll bar in the back for now based on some well designed ones I saw there (I may cage it later, but not now). What other bracing should I consider while I have the engine & interior stripped out? (I can weld, and have TIG/MIG equipment and a plasma cutter) 7. I also plan to swap all bushings to urethane, and I may relocate the lower front control arms to reduce bumpsteer, but otherwise, I don't intend to lower it more. I'm running 15X7s with 215R60-15s for now, but plan to go to lighter 17X7s with 215R40-17s at my next tire change. Ground clearance is going to be enough of a problem with dual catalytic converters and a 3" cat-back single exhaust. I read that Dynomax Hemi Turbo mufflers are much easier to live with than other louder performance mufflers. Does anybody have any other good recommendations? At this point the body work and rust repair are done, and I'm ready to begin paint prep on the exterior ('gotta love sanding, and sanding...). The 350 TPI is rebuilt (just needed new bearings, seals, gaskets, and a water pump), engine & trans are painted, and re-assembled. Marrying the wiring from the TPI engine to the 280Z is the only really big task still lurking out there for me. Except for the dozen others I don't even know about yet. Thanks for sharing your experience. Steve

-

Sanderson Block Hugger headers cc1-7/8

sstallings replied to dr_hunt's topic in Gen I & II Chevy V8 Tech Board

rytherwrw is right about the discoloration of bright ceramic coated headers during initial tuning - I've done that as well... The bright silver coating is only rated at 1500 degrees F., which is fine since most primaries rarely exceed 1000-1200 degrees in nornal operation, but in dyno tuning they can exceed that if timing or fuel mixture are off. I'm sure a turbo setup is even closer to these limits. I'm using the semi-gloss black cermaic coating on mine since it is rated at 2000 degrees F. -

Guys, I've reviewed a dozen threads on this topic and I know it's an old one, but I haven't found anything specific to my combination (lots of threads for LT1 guys and JTR books cover it for carberated motors). Can someone point me in the right direction, since I KNOW this information must be out here somewhere. '90 5.7L F-body TPI & T-5 in a '77 280Z. Retaining the Datsun oil pressure sensor for the guage only. Need information on the wiring (and additional components/relays/etc. if needed) for the fuel injection start/run circuit for the TPI motor. Also using the Datsun 280Z fuel pump (for now). Thanks, Steve P.S. Getting set up for the big swap - pictures to follow.

-

LS1/T56 pullout or parts car???

sstallings replied to Horatio's topic in Gen III & IV Chevy V8Z Tech Board

Local F body club is a good idea from 1 Tuf Z. Also look into local Junior College/Community College auto body shops for people looking for parts. I sold the front clip from my donor for $1000 which is cheaper than they could get it at a salvage yard, and I'm planning to part out the rest the same way. Keep the donor as long as you can get away with, since there will always be some other part you could have used. -

De-stroke a 400 to a 377 for a boat?

sstallings replied to maverick2's topic in Gen I & II Chevy V8 Tech Board

maverick2 I've been reading this thread without comment since I know absolutely nothing about boats, but I thought I'd lob a completely different option at you to see if its been done before. You stated that you want high torque at relatively low to mid-range RPM with high reliability and low weight. It may sound off the wall, but have you considered a 472-500 CID Cadillac engine of 1968-73 vintage. They make gobs of torque (400-600 Lbft), weigh only 50 lb. more than a SBC due to thin wall block castings made possible by high nickel content iron, and no core shift diue to better tooling. And the more cubes you have to play with, the easier it is to make that much power, so reliability goes way up. Those engines were made to run 200k miles and the torque curve is as flat as a table from just above idle to about 4800 RPM. Add aluminum heads from Bulldog, and an Edelbrock 2115 alunimum intake, and the weight is about the same as an iron headed SBC. The completely stock 1970 10:1 compression 500 CID engine will make 500 lbft. at 4000 RPM all day without breathing hard. They have a 10.815" deck height (taller than a Merlin BBC) and long rods so the rod angle is very low compared to anything else out there. Offset grind the crank .300" for 2.5" journal BBC 6.8 " rods, add some forged or hypereutectic pistons with a 1.511" pin height, and an lightweight flywheel and harmonic balancer you can shave over 800 grams per cylinder out of the reciprocating weight while increasing displacement ot 540 CID without an overbore. That nets you a torque monster that revs quickly like a SBC rather than slowly like a Caddy land-yacht cruiser to about 600 lbft. It has the GM BPO bell housing bolt pattern to I'm sure adapters are available to bolt up your impeller drive. MTS in Delevan, Wisconsin makes one, and there are at least a few others. Check out MTS, The Cad Company, and Potter Automotive web sites if your interested. I know it's not a 377 CID SBC, but it seems to meet a lot of the criterion you've been shooting for, and you have to admit that it's different. If not, then I'd go with the 406 for similar reasons. Steve -

Thanks for the encouragment! After 8 over years, I'll be finished putting three kids through college in about three more months. That alone will give me a $10,000 increase for next year to fuel the budget for my hobbies. Of course, after taxes, and after splitting what's left with my wife, I'l still only have about $1.49 to spend on cars. Steve

-

Wow! This thread went from a scuffed journal to a metalurgy discussion. You guys do get deep into these topics. I thought I was the only guy crazy enought to offset grind cranks for more stroke, have radiuses machines between the journal and counterweight face to eliminate stress risers, and buy special radiused bearings... in other words, let my project budgets spiral dangerously out of control because fast enough and relaibale enought, never is. You guys are as demented as I am. Steve

-

400HP and stock 240Z gas tank ....... Whats the best/easiest

sstallings replied to Racin_Jason's topic in Fuel Delivery

Hey guys, I'm sorry to be wasting time on old posts, but I've only been at this a few months, and I'm still learning to use the forum. As you can tell, I'm searching for every bit of information I can find to make sure I benefit from those of you who have done this before me. I have officially started the swap this month. However, I've been working on my own cars, and specifically old Chevys for about 35 years (and old hemi's with my dad for several years befopre that), so I hope I've learned a thing or two that I can pass on before I can claim to be proficient on Z swaps. That being said, I saw a post getting a lot of attention over the last several days (I hope it's a new one) on 240Z vs. 280Z rear suspension swaps. I have one of each, a '72 & '77 with original suspensions sitting in the garage, so if someone wanted specific measurements comparing struts, control arms, mounting points, etc. I'd be happy to lend a hand. Please be patient with me, and hopefully I can return the favor as I get farther into this hobby/addiction/disease/money pit we call old cars. Thanks, Steve -

Headers for '90 5.7L TPI in 280Z

sstallings replied to sstallings's topic in Gen I & II Chevy V8 Tech Board

I just spoke to the good folks at Sanderson Headers and they told me that welding on the EGR tubes would not void the warranty on the CC5 headers, so I'm looking forward to delivery from JTR next week so I can get them modified and sent out for ceramic coating. It will probably be several months, but I will definitely post a final message on this thread (with pictures) once they are installed and I know whether the CA smog referee station buys them off. That should help others in Calif. with '76 or later Zs in my position.