-

Posts

243 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ISPKI

-

I see you noticed that I did nothing with the manifold. I am planning I getting headers and custom dual exhaust so I decided not to bother cleaning the manifold up at all. What type of headers do you recommend? I have read both good and bad things about all the standard options (Pacesetter, twicepipes). I have 240z front and rear bumpers that will be going on, and I was going to modify the lower grille to take up the space under the bumper but we will have to see how it will fit. I am aiming to keep the total cost of this build under 10,000$ total. I am currently 2500$ into it which includes the initial purchase and new manufactured floors and rails. I just have a ton of fabrication and repair work ahead of me. Once the vehicle is restored to daily driveable condition, I might look into a turbo setup or V8 swap - my buddy wants to give me a 5.0 ford V8 for this vehicle so I may go that route.

-

Here is the last update so far. I got a good deal on a front air dam from a gentleman on here. I have always liked the look of these air dams so I could not pass it up (even though the vehicle needs mechanical work more than visual effects). It took several hours and many broken bolts but i finally got the old front valance off and test fit the new air dam. I just has the bolts on the ends holding it on but looks like it fits pretty well.

-

Next step - While cranking the motor, sometimes it would make a brief grinding noise. I pulled the starter off and found the teeth on the gear on the starter to be torn up really bad as well as the teeth on the gear in the transmission - Looks like the starter was only engaging on the edge of the teeth and just ended up breaking off about six inches of teeth. New starter installed and no more grinding. Fortunately, I will be ditching this automatic transmission in the near future so I wont have to worry about any long term issues with this. After replacing the starter, I picked up a 1980 280zx distributor with the e12-80 ICM and swapped the car over to that ignition system as well as picking up a pertronix flamethrower coil.

-

I got everything bolted back on with new gaskets on everything - thermostat housing, throttle body, intake/exhaust manifold. Everything has shiny new stainless hardware (except the studs). I also clear coated everything to try and preserve it a little longer. The fuel rail components were media blasted and painted. They had what looked like copper all over them and it darkened when i clear coated it which sort of bummed me out since it now looks like rust from a distance. I also replaced all the harness plugs with nice new plugs from yet another fella on here (cant remember his name). They are so much higher quality and cleaner looking than the old, dry rotted and broken plugs.

-

Pulling the injectors out was the most difficult part I believe. Phillips head screws should not be on critical components in a car! Almost all of them stripped out or broke off - I pulled more out with vice grips than I did with a screwdriver. Picked up another helicoil kit along with all new gaskets and stainless hardware for reinstalling the injectors. The injectors themselves were actually very clean and seemed to function properly, the holes they were in were extremely dirty and packed with grime and oxidation. Once I had the injectors out - I picked up some super clean from the parts store and dunked the entire manifold into a solution of super clean and water. That took most of the bulk gunk off the manifold and cleaned the carbon/oil buildup inside. I included some close up before and afters of the injector ports - I polished these with a conical brass brush on a dremel tool.

-

While I had the thermostat housing off, I decided to just dive in and do some more work on the manifolds, rail, injectors etc. I hate having a dirty/grimy/rusty looking engine bay so I pulled the pieces of the fuel rail apart, yanked the intake manifold and exhaust manifold and basically ripped apart everything attached to the engine on that side. I cleaned up almost everything - between media blasting and polishing with stainless steel brushes and sand paper, I think it looks much better than it did before - its not as clean as I wanted it to be, but it will have to do for now. At least I dont hate opening my hood anymore. Many of the holes/threads for the 8mm studs were severely stripped out, and I could not get my new coated studs to thread into some of them so, I broke out the helicoil kit and redid just about all of them.

-

Hey folks. This is going to be my log thread of all the work I am doing on my 77 280z. The S30 is my dream car, I searched for years before I found one that I could restore and I finally ended up with this gem. It was a metallic sky blue originally I believe (the old paint scheme can still be seen on the frame rails and some areas underneath the car). It was repainted a pepsi cola sort of blue. The vehicle did not run when i purchased it for 1400$ up in MA and it has some rust issues. The biggest problem is the area under the battery tray...or where the tray was supposed to be. It seems as though a battery had cracked and dumped acid all over the area which ate everything, including a hole in the body that is just large enough for the battery to fall through. For the time being, I tack welded a metal support for the battery to sit on. I will do almost all the work on this vehicle, the delicate body work will be done with the assistance of my very good friend who is a Baron Tech graduate in Auto Body. The first steps were to get it running. I dropped the gas tank and cleaned it and undercoated the entire area while it was off. I also unbolted the rear bumper and mounts. I replaced all the fuel lines going from the tank to the pump and from the pump to the filter. Also repaired the connections for the pump as the wires were horribly frayed apart. I also put a clear filter inline from the tank to the pump and replaced the pump and the fuel filter. Next, I did some general maintenance - oil change, filter, coolant flush, brake fluid, spark plugs, cap, rotor etc etc. We got her running after all that and I got to take my first drive down the street in it. I moved on to some more complicated stuff - firstly, the fuse box in the cabin and the fusible links. All the links had been burned up, some were replaced with incorrect size wires, the link holders were burned and had no covers. I decided to convert it to Maxi Blade fuses. After that, I pulled out a ton of useless wiring for kill switches - old crap sound equipment, etc etc. The wiring was so messy and there was so much that did not belong, that i decided to rip out the entire sound system and discard it. I pulled out about 100ft of wire that was supplying eight 10w speakers. Moving on from there, I was trying to solve the rough operation of the engine. I suspected that the coolant temp sensor might have been bad and they are cheap enough to replace. Also - the thermal transmitter was faulty as the gauge did not function properly. When I tried to unbolt the temp sensor, the thermostat housing broke in the area right around the sensors. I purchased a used housing from a fella on here, polished it, painted it, picked up all new sensors and plugs and gaskets for it, helicoiled the holes in the head and put it back in with shiny new stainless hardware.

-

That is going to be my next step. I have cleaned up/replaced/upgraded a ton of electrical on this car already (Replaced all the harness connectors, AFM, TPS etc, removed and cleaned manifolds, injectors, replaced all the seals, redid the fuse wiring with maxi fuses etc, cleaned and replaced and in some places added grounds). Unfortunately my alternator on my honda civic just kicked the bucket so I had to skip removing the throttle body and cleaning it this weekend. The bypass screw on the AFM does not seem to have been tampered with, it appears to still be sealed up from the factory. We will see what happens with the TB bypass.

-

The idle does not gradually drop the way it should. It is high (around 1200ish) when it starts and then plummets down to 450-500ish after a random period of time. The hotter the ambient temp, the less time it takes to drop. With our current temperature outside, it drops after about 20 seconds or so. Is 36~ PSI at idle actually too high? The FSM says that is what it should be...

-

Thanks for the Info Tony. I found an interesting lead that I overlooked when I tore down the manifolds and cleaned and reinstalled them with new gaskets. I unthreaded the idle set screw all the way out and the idle popped up to 1100ish. The end of the set screw was caked in carbon that I had to scrape off. I am wondering if the passage that allows the additional air through for idle is clogged? I spoke with a friend of mine who is a mechanic and he said that if that passage were blocked off, then your idle would be lower and you should run rich since that air flow is not regulated by the AFM.

-

Confirm 280zx Upgrade is as good as it seems to be

ISPKI replied to ISPKI's topic in Ignition and Electrical

Alright folks I have an update. I purchased a 280zx distributor from a member on here and have it almost converted over, I just want to confirm that I have the wires done correctly. I followed the guide from the above link from atlanticz. I have the new dizzy installed with a new ground on the mount as my car did not have one. The wires going into the coil are as follows: Positive post has one wire for the condenser, One wire going to the "B" slot on the E12-80 module, and the black w/ white stripe wire that was the +pos supply going in to the ballast resister. Negative Post has one blue wire that was the -neg supply on the ballast resister, and one wire going to the "C" slot on the E12-80 module. Now what I want to confirm is, all the wires going in to the transistor ignition module can just be insulated as none of those wires are used for anything correct? I had thought that power went in to the transistor unit then to the ECU then to the ballast resister and then to the coil, or is that incorrect? Do the wires going in to the transistor unit simply form a loop back to the ECU so there is no need to connect any of the wires going in and out of the transistor ignition module? -

I switched my links out for a maxi fuse block with an 80 amp on the alternator, but he knows that already (I buy alot of parts from him). I really hate the cheapo fuse block that I got, maybe I will change it out for a set of individual mega fuses.

-

You know what, I had not even thought about that. The fuse would blow just starting the car. I wonder what he intended in saying it would be a good idea to have one.

-

the 120 amp fuse would just be for the starter. I honestly do not think it is really needed, the cables running to the engine bay will be spiral wrapped and in conduit etc etc, the jacketing will not be exposed anywhere along it's length except for where it connects to the starter and battery.

-

We have very few u pull it yards up here in ct, only one in fact and its pretty far away. I ordered some 2 gauge from a welding supply company, they and the automotive fellas said that it should work fine. My plan is to run one cable to the regular grounding location at the transmission and another, shorter one to the chassis behind the seat where the bat will be sitting. Also - they recommended having a fuse on the + cable just in case since there will be so much more cable that could get damaged and burn the car down. I picked up a 120amp mega fuse and holder for that. Is the ground cable for the battery usually just bolted to the transmission? Also - I will need to run wires for the ignition system as well and will need to replace the fusible links that are completely corroded. What is the rating for the two fusible links that run off the battery?

-

As noted earlier, read up on your state laws, some states require inspection of even older vehicles. I believe it is unlawful to tamper with emissions and safety equipment but I also believe that is per VIN number on your vehicle so this turns into a grey area since your car did not have that equipment originally. I know in my state (CT) it never becomes an issue since we dont do emissions or inspection on older vehicles, but again, it pays to get informed.

-

Great, thanks for the responses guys. I stand corrected, I believe I have 1 gauge cables at the moment. I mentioned this to my local parts store (great group of fellas running the wholesale auto in Granby CT!) and they seemed to agree that 1 gauge should work just fine...now if I could find a good source for a dozen or so feet of it... Funny that you said to check my local audio shop xtreme...you clearly have never been to Granby CT before ahahha...ya know, cuz we dont have an audio shop... *sigh*

-

Hello Folks! I am finally getting some time in with my 77 280z rescue and that means...lots of questions! My 280z had a battery leak that literally consumed the entire area around the battery so I have decided to relocate the battery to the cabin to make the repair of the area a little easier. I had already replaced the cables with (I believe) 00 cable (the braid is about 1/4" thick), Stainless battery terminals and nicely soldered copper connecters. I will be placing the battery behind the seats in the little cubby holes that the previous owner so delicately hacksawed open. I will also be grounding to the chassis and to the block so there will be several large dia cables running around. My question is, do I need to run even larger dia. cables to compensate for the significantly longer length or are my current cables fine? Also - I have read that you want the ground cables to match the size of the positive cable, so I will need to run 00 cables for all the grounds correct?

-

Hm, it didnt attach my second image.

-

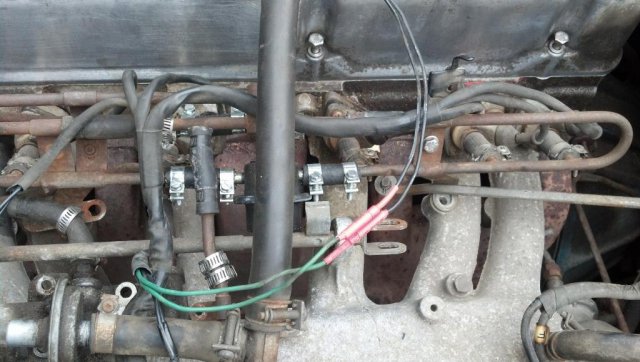

My brother was up for father's day and he ended up checking out my 77 280z that is currently residing at my father's house. He has done alot of custom work on motorcycles and immediately pointed out the exhaust pipes coming down from the manifold. I havent been able to find any good shots of how the factory setup is supposed to look. My pipes look fine until after the 6-2 flange. There are two pipes for about 8 inches after the flange, then it looks as though they were crushed into half circle (not uniformly btw, one is half circle, the other is crushed to about 25% diameter) and crammed into the larger pipe that goes to the back of the car. He asked if the car fouls plugs and that severely restricted exhaust pipes like that could be causing it. My engine runs very rich and very rough. The plugs have maybe 100 miles on them and are becoming fouled. Attached are the two photos I took, the rust sort of blends the lines together. Just let me know what you guys think. I assumed there would be a Y-pipe similar to how most of the headers are.

-

WTB functioning 79-80 280zx dizzy and/or mounting plate

ISPKI replied to ISPKI's topic in Parts Wanted

PMs replied, sale pending. -

Just as the title reads, I am looking to ditch the transistor ignition on my 77 280z and upgrade it to the 79-80 280zx E12-80 matchbox dizzy. I can source the Dizzy itself locally if I really need to but I will need the mounting plate to bolt it to. I am in Northern CT, parts will need to be shipped if you are not within an hour or two drive.

-

Confirm 280zx Upgrade is as good as it seems to be

ISPKI replied to ISPKI's topic in Ignition and Electrical

I noticed that the ignition module itself makes up almost the entire cost of the complete distributor. I think rockauto has them for around 90$ which means the dizzy assembly is 19$... So, I am assuming people run the MSD with the ZX dizzy rather than the 280z dizzy to keep the system similar. Having to keep the ballast resistor for the 280z dizzy would weaken the massive spark (or would the ballast resistor just get fried from the MSD 6AL?) that the MSD ignition module would send out. I would love to eliminate the ballast resistor and as much wiring as possible so I think I am going to look into switching over to the ZX dizzy. -

Hell Folks! I have a 77 280z that had a run in with a leaking battery a few years back. The leak appears to have dripped down onto the tray and fender and the firewall. This effectively had the same effect as in those alien movies with the acid blood and what not, now there is a hole almost large enough for the battery to fit through where the battery tray used to be. Anyway, I was wondering how simple it would be to relocate the battery to behind the seats. Would anyone be able to post some photos of their modification?

-

Hello folks! I have been having electrical issues with my ignition unit on my 77 280z. I ran into this guide about removing the dizzy and replacing it with a e12-80 zx dizzy. I just wanted to confirm that this is as easy as it seems via the following guide, and that it eliminates the stock transistor ignition unit and ballast resistor. http://www.atlanticz.ca/zclub/techtips/distributor/ I also read about people installing an MSD 6AL ignition module along with the 280zx dizzy but I do not understand why that is necessary. Correct me if I am wrong but, the MSD 6AL Ignition unit would take the place of my (77 280z) transistor ignition unit correct? But, the 280zx dizzy already has an ignition unit mounted on the side of it that takes the place of the old transistor ignition unit. So, whats the point in running the two ignition units? Other questions: If I were to replace my transistor ignition unit with the MSD 6AL, would I then also be able to eliminate the ballast resistor? Can that be done with the stock 77 280z dizzy or is the stock 280z dizzy not designed to use the increase in power? The main reason I am looking at these options is because it looks like I will need to replace my transistor ignition unit which is 109$ from Rockauto, while the E12-80 zx distributor is...109$ from Rockauto and is supposed to simplify the system, be more reliable, be less of a hassle, make the car run more smooth (which is my current symptom).