-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ohmster101

-

Again, I would urge those of you who doubt me to take it to Facebook. The Facebook groups have a significantly larger following than on the Forum and have a much wider demographic.

-

Here are a few threads on Facebook to reference (might need to add as a member) https://www.facebook.com/groups/480008718866422/permalink/1468722426661708/ https://www.facebook.com/groups/TheZGang/permalink/3660193107349134/ https://www.facebook.com/LowDownCustoms/posts/10225562962527838 https://www.facebook.com/groups/TheZGang/permalink/2645789198789535/ https://www.facebook.com/groups/509038132596988/permalink/1715759885258134/ https://www.facebook.com/groups/v8zcars/permalink/1153018791540530/ https://www.facebook.com/groups/386021341481608/permalink/2191203597630031/ https://www.facebook.com/groups/386021341481608/permalink/2180998111983913/ https://www.facebook.com/groups/480008718866422/permalink/1612964158904200 And a few I have saved on Instagram https://www.instagram.com/p/CNlT5xiFTMe/ https://www.instagram.com/p/CNDGwoNnhf7/ https://www.instagram.com/p/CM5_zEhsFYf/ https://www.instagram.com/p/CMgcLzAHb5m/ https://www.instagram.com/p/CMGLp8wnvcP/ https://www.instagram.com/p/CMF3PiXl0eR/ https://www.instagram.com/p/CL-KU_jhr64/ https://www.instagram.com/p/CKqBZrunoYQ/ https://www.instagram.com/p/By_0R7KhqBY/ https://www.instagram.com/p/CKkF5Q8HduYjlktsgLk0-CclUy17sVQHcpioV40/ https://www.instagram.com/p/CKX4aQSMdz8/ https://www.instagram.com/p/CAHO_GIHxrclo5DdH5f4Wr7pL543dzd5LOw40U0/ https://www.instagram.com/p/CJmTmPiL_hM/

-

Few irregularities I want to address here. First and foremost, as stated before the First few who ordered our Rear suspension kits have had issues with delivery times, axles, and fitment. That being said I have addressed those on this thread on September 25, 2020. That being said Matthew, otherwise known as 05plst4 was one of the first who ordered our rear suspension kit. He purchased it on 7/11/2019. So the issues with lead times and quality are present as the early buyers. (also highlighted phrase in pictures attached) That being said, Me and Matthew have agreed on a set of Front Control Arms, discounted and shipped for free to Canada, along with an extra set of ball joints and boots. We did not "Give up on the customer" (see attached) That being said we are slightly over 1.5 year old of a company when he purchased so the growing pains are apparent as found in any new start-ups and was still working part-time at the time. I'm not giving excuses, just some insight as to the situation. Now to proceed, If a customer ordered a rear suspension kit in the last couple of months we had them shipped (as long as they were not custom and a popular diff/wheel bearing option) we were able to have them shipped in 2 to 4 weeks. Complete, with axles, all hardware plastic wrapped and packaged in a double walled box. We have finished ALL the Ford 8.8 to 370z axles, ALL the Ford 8.8 to 300zx axles, All the 300zx to 370z. The last few 300zx to 300zx are finishing up and are on to the R230 diffs. We are also caught up on ALL Black Friday orders since March 12th (unless custom) Which is considerably better than other vendors who still are not caught up. We all know the unhappy customers voice will express their thoughts and experience more than the happy customers, and rightfully so, it's their right and helps push companies to strive higher and perform better. We are not a company that has been around since the 90s like AZC or early 2000s like T3 we had our first control arm sold in 2018 and slowly started building products after, so we are still learning the ropes. Furthermore, we invested in the machinery to make the Axles and the CNCs to make products faster and in house. In the last 8 months we spent nearly 7 figures on state of the art CNCs, New Welders, 3D scanners, More team members, packaging equipment and now are moving into our largest facility yet on the 21st of this month. Forums (IMHO) seem to bring a one-sided view point to any company, I would highly recommend asking the Facebook groups and see the high customer satisfaction rates and growth of them over the recent years. Ask customers about their experiences and watch customers post their videos of their S30s running and driving with our suspension kits. About 38% of our customer base are repeat customers. Those who bought parts and keep coming back to us, Many of those are professional installation shops, Godzilla Race works, Fitted Garage, and MA Motorsports to name a few, if they were not happy with their products why would they keep coming back? I've apologized before and ill apologies again for those who purchased early kits and seen the poor craftsmanship, poor fit up, and long lead times, we have addressed those issues over the last year and continued to provide better results as a time went on. Again, I am rarely on this Forum unless someone messages me about it, so email me if you want a faster reply. Thanks - Apex Team

-

Apex Engineered: My evolving experience

ohmster101 replied to BoulderCharles's topic in Non Tech Board

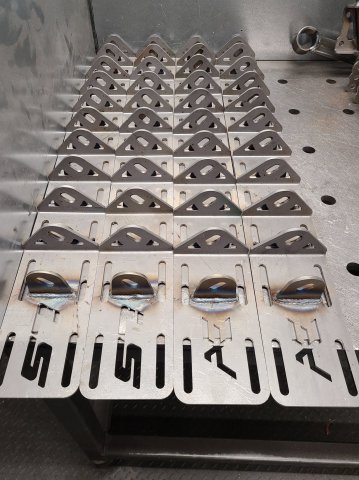

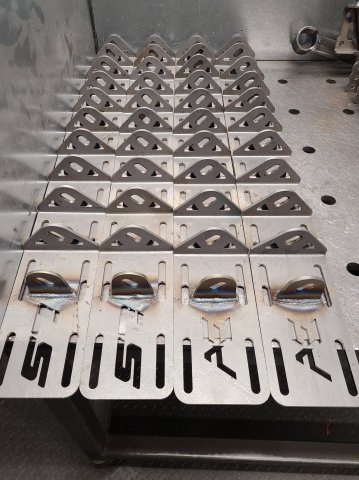

Hello Charles, and everyone, Intro Its Ohm from Apex. A few guys linked me to this forum to chime in. First off, ill like to publicly appologize to Charles and anyone else who has encoutered frustation with axles and components from us. Those who have ordered the first few kits when we first released were impacted with long wait times, and missing hardware. When i first launched the product mid last year I didn't realize the demand it would cause (also from the Hellz youtube video) and the sourcing i needed to do in order to ensure met lead times. We rushed the product to the market in fear of competition and left alot of things open-ended. For example the fixture we made, was not at the production level they should have been. They were very heavy, not welder friendly and the welders were having to fight the figture to take the subframes out when they were fnished being welded. This caused long lead times, poor build quility in some cases and frustrated customers in most cases. Axles Secondly Axles, i dont even know where to begin with this, to start off we were un-familiar with the axles, how to machine them and manufacture them correctly and effiecently so we relyed on outsourcing them. Due to that we used aftermarket axles thinking "easier to find, and cheaper to buy, Win-Win" NOT THE CASE we realized that even if we bought from one company in the aftermarket world, there are too many variables and the aftermarket guys are constantly changing their axle splines or size or something, so if one year it works, they can come up with the update, and our axles are non-compatible. So, we had to chew the cost of new finished aftermarket axles and buy OEM ones for all of them and start fresh. We since had to fight with axle manufactuers to get the axles and / or continully find new ones. It wasnt untill last month when I pulled the trigger to buy our own CNC 5 axis machine to make the axles in house under our tollerance and guidlines, however we are still doing initial tests to get them into production and outsourcing the axles untill we can get it figured out on our end. For the customers who are waiting on axles we are giving them a refund cost of the axles along with the schematic print of the axles along with hardness tollerance. We are nearing our 4th vendor now and at this point we are still looking at new ones, i recently contacted RCV performance to see if they would be intersted if this one falls through. What ive learned is to just be proactive and tell the customers about delays instead of being fearful of their responce and agrivate them futher from them comming to me for an update, trying to find somone who can email faster than me or to set up a online order tracker. Improvements On the otherside i would like to point out the imporvements / changes made. since customers had missing hardware we purchased a packing machine that vaccume forms the hardware to a packing list of all the necessary hardware which also gets put on a scale to measure the weight of the packaged part to see if any hardware is missing (attached pitcures). We have also incorporated alot of automation into our product lines allowing us to have ALL OUR ITEMS in stock and ready to ship in the lead time shown on the site. (except for axles 😥) We have also finished / working on around on around 30 new products to various product lines however are we are having them tested on cars, and are making sure we can manufacture them in voluime with acceptable lead times before we release anything to not have this issue repeat itselt. Conclusion As a whole, we are a team of 5 employees. 2 welders, 1 machiest, 1 packaging/shipping and 1 powder coating guy and myself. I do the designing and product development along with take care of the customer service side. I try to get to my emails everyday and reply as fast as i can (and my wife helps me on emails too) but since covid we have been buiser then ever with everyone at home working on their builds i have had to assit on the floor untill i can find a empoyee who can fit our team. Im an engineer trying to learn the buisness side of things but am learing on the way (mostly from my mistakes) and reealsing this product as the single most frustraing mistake i made in the buisness (hopefully ever) -

Hello, im adding back to this thread as i was tagged by a few people in it so i have copied my responce from another thread. Hello everyone Intro Its Ohm from Apex. A few guys linked me to this forum to chime in. First off, ill like to publicly appologize to ervyone who has encoutered frustation with axles and components from us. Those who have ordered the first few kits when we first released were impacted with long wait times, and missing hardware. When i first launched the product mid last year I didn't realize the demand it would cause (also from the Hellz youtube video) and the sourcing i needed to do in order to ensure met lead times. We rushed the product to the market in fear of competition and left alot of things open-ended. For example the fixture we made, was not at the production leve l they should have been. They were very heavy, not welder friendly and the welders were having to fight the figture to take the subframes out when they were fnished being welded. This caused long lead times, poor build quility in some cases and frustrated customers in most cases. Axles Secondly Axles, i dont even know where to begin with this, to start off we were un-familiar with the axles, how to machine them and manufacture them correctly and effiecently so we relyed on outsourcing them. Due to that we used aftermarket axles thinking "easier to find, and cheaper to buy, Win-Win" NOT THE CASE we realized that even if we bought from one company in the aftermarket world, there are too many variables and the aftermarket guys are constantly changing their axle splines or size or something, so if one year it works, they can come up with the update, and our axles are non-compatible. So, we had to chew the cost of new finished aftermarket axles and buy OEM ones for all of them and start fresh. We since had to fight with axle manufactuers to get the axles and / or continully find new ones. It wasnt untill last month when I pulled the trigger to buy our own CNC 5 axis machine to make the axles in house under our tollerance and guidlines, however we are still doing initial tests to get them into production and outsourcing the axles untill we can get it figured out on our end. For the customers who are waiting on axles we are giving them a refund cost of the axles along with the schematic print of the axles along with hardness tollerance. We are nearing our 4th vendor now and at this point we are still looking at new ones, i recently contacted RCV performance to see if they would be intersted if this one falls through. What ive learned is to just be proactive and tell the customers about delays instead of being fearful of their responce and agrivate them futher from them comming to me for an update, trying to find somone who can email faster than me or to set up a online order tracker. Improvements On the otherside i would like to point out the imporvements / changes made. since customers had missing hardware we purchased a packing machine that vaccume forms the hardware to a packing list of all the necessary hardware which also gets put on a scale to measure the weight of the packaged part to see if any hardware is missing (attached pitcures). We have also incorporated alot of automation into our product lines allowing us to have ALL OUR ITEMS in stock and ready to ship in the lead time shown on the site. (except for axles 😥) We have also finished / working on around on around 30 new products to various product lines however are we are having them tested on cars, and are making sure we can manufacture them in voluime with acceptable lead times before we release anything to not have this issue repeat itselt. Conclusion As a whole, we are a team of 5 employees. 2 welders, 1 machiest, 1 packaging/shipping and 1 powder coating guy and myself. I do the designing and product development along with take care of the customer service side. I try to get to my emails everyday and reply as fast as i can (and my wife helps me on emails too) but since covid we have been buiser then ever with everyone at home working on their builds i have had to assit on the floor untill i can find a empoyee who can fit our team. Im an engineer trying to learn the buisness side of things but am learing on the way (mostly from my mistakes) and reealsing this product as the single most frustraing mistake i made in the buisness (hopefully ever)

-

Hey @Robo I sent the FEA in a messege over facebook with a link, sorry it took so long, been swapped. @NewZed you can look at our LLC filling online at https://www.wdfi.org/apps/CorpSearch/Search.aspx? or under wisconsin state tax filing, we are a registered LLC, we have only been around for around 2 years so still relatively new. We are a new company and im trying to learn how to run the buisness and still keep my head above water. As a whole, we are a team of 5 employees. 2 welders, 1 machiest, 1 packaging/shipping and 1 powder coating guy and myself. I do the designing and product development along with take care of the customer service side. I try to get to my emails everyday and reply as fast as i can (and my wife helps me on emails too) but since covid we have been buiser then ever with everyone at home working on their builds i have had to assit on the floor untill i can find a empoyee who can fit our team. Im an engineer trying to learn the buisness side of things but am learing on the way (mostly from my mistakes)

-

Also just a heads up, i won't be able to reply that often so please be patient as I am running this company and a few others and get pulled in various directions. thanks

-

Hey Guys, My name is Ohm and i am the owner of Apex, sorry for the late response. anyway it's been awhile since i've been on this forum so bare with me... the 300zx and 370z are options as some people who already have 300zx parts from there r200 or r230 swap they can reuse the parts rather than buy new. and the 370z is an option as they are newer and more readily available than the 300zx stuff which is harder and more expensive to find. we have tested the 370z and 300zxtt axles up to 600hp with no fatigue signs or failure. the stock axle shafts would most likely have broken. the spline on the stock axle stubs are much smaller and not nearly as durable as the 370z and the 300zx

-

Datsun 260Z Turbo S15 6 Speed TechnoToyTuning

ohmster101 replied to tooquick260's topic in S30 Series - 240z, 260z, 280z

quick question, did the T3 kit need shortened axles? what axles did you use and did you have to modify them? -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

you can see in this pic how the frame rails help tie the whole frame of the car together. also the new shocks i made for a custom set up. now this was about a good half year ago or so. the plans for the suspension for this car changed drastically. and i am pretty much attempting something that hasn't been done before. not going to post any pictures yet because i am planning to sell the products. but lets just say its going to be seriously insane . -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

thankyou! -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

this was the new front suspension i fab'd up. looks good. and very functional! all suspension was painted with POR15 for no chance of rust. and then sprayed with a color! all hardware was supplied from Midwest Control Products and turned out pretty good in my opinion! -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

thanks! and i would say tacked unpainted and everything around $150. fully done and painted $250 -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

then i bought the billet brake kit as well as a mustache bar from Arizona Z Car. THEY MAKE A FREKKIN SICK PRODUCT. just saying. it looks gorgeous. then i built control arms for the car using the old arms to make the jig. i bought rod ends and threaded bungs from Midwest Control Products. really good, affordable products. -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

wow. its been a while huh? so this was last summer when i sprayed the undercoating. i used 3M body Shutlz. works well and is though too! -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

then i built a tube bender so i can do my roll cage.... I BUILT IT OF LESS THAN $200!!! I MADE A YOUTUBE VIDEO ABOUT IT ...name: 200 tube bender search on youtube.... username: ohmster101 -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

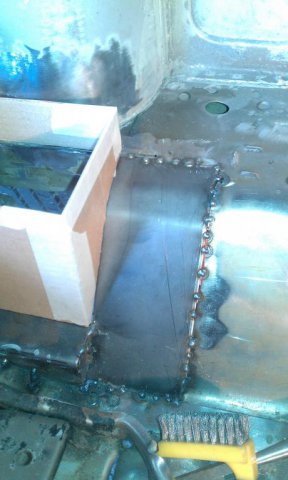

okay, so i closed of the frame rails with a piece of 1/8" mild steel. 1) cut out cardboard template 2) cut it out of steel 3) welded it closed VERY IMPORTANT TO REINFORCE FRAME IF YOU WANT MORE POWWWWAAAAA!!!!! (Jeremy Clarkson voice) -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

then i put in these frame rails...they are 2x3x1/8" wall steel rectangular tubing...made them specifically to raise the floor of the car up 1" so i could have a big more ground clearance when i lower the car...any questions?? -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

I bought this Longevity mig 140....it works well....go on my YouTube channel to see a review...for the roll cage welding that 1 5/8" with 1/8" wall DOM tube it didn't work so well...i will do that with tig -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

i made this brake from...JUST ASK IF YOU NEED HELP TO MAKE YOUR OWN!!!...i used it to make the main hoop mounts....the mounts are made from 1/8" steel...i formed a 1/4" steel plate 4 by 4" and it bent that into a 90 degree angle without any problems -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

Okay so here we goo...back when i first got the car about 2 summers ago...i began with stripping the car completely...i was preparing the car to put in a new floor and frame rails that i would fabricate....i used a needle scaler and a hammer and chisel to get the sound denting materiel off. It was surprisingly fast and accurate....then i used a hardware store glue to dissolve and get rid of the left over glue from the leather that was stuck in the interior -

240Z LS1 T56 R230 BUILD! - youtube me: ohmster101

ohmster101 replied to ohmster101's topic in S30 Series - 240z, 260z, 280z

yea i have...about 1 and a half years of photos...im playing catch up lol -

well here we go....i haven't posted anything on anything on here ever...I began this project on June 24, 2013....I was 19 at the time...i bought it out of California...spend $2800 on the car and then another $1000 on just shipping it here in Wisconsin. over the next few days i will be playing catch up with showing all of you my build over the last year and a half...regretting i didn't start this earlier

-

1972 240z LS1/T56/R230 build

ohmster101 replied to Fuzzydicerule's topic in Gen III & IV Chevy V8Z Tech Board

Did u use the same hoses on the ls1? Like coolant lines...oil...etc