davek

Members-

Posts

81 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by davek

-

Received my booster back today UPS.. Looks nice, fresh black paint, new rubber bellow grommet. Won't know for months how it performs but I say I'm satisfied now. I would attach a picture but I don't see the icon for it. Anyway it's shiny black and looks new. I did get a call back from Long Motor(VB(Black Dragon) They cannot measure a unit to see if it's 8 1/2" and they are out of stock with no restocking date. They know absolutely nothing about what they sell but tried to be helpful. I used them- VB --on an MG project in the past and had the same results. You probably knew this.

-

Stopped in to O'Rielly's to send my unit off to A1-Cardone today. They highly recommend not sending it. Said Cardone looses more than they ever return. Manager said he would not send his own parts to Cardone. Searching the old web I found and talked to a rebuilder in Portland Or. I felt comfortable with him and will send him my core for rebuilding. $149 plus $21 return shipping. 4-5 day turn around. Power Brake Booster Exchange. I'll post again with pictures and review when it returns.

-

My plan is to have O'Reilly's be my medium to A1-Cardone next week. I have not tried MSA. Tony, a picture with a measuring devise in the photo for reference as I have shown would be appreciated for myself & others to see. Obviously there are differences between the 2 models. Ps: I don't head back to Shanghai area until Feb. I know from other posts you live in the Philippines. I did 135 days in China/Korea in 2014. Much less time in Asia this year I expect. Dave

-

Napa--NOT Cardone doesn't offer a phone number. Only email to their service department. I sent an email. O'Reilly's sent Cardone a "check availablilty meassage and it came back-Part not available. I did find a place on Cardone web site that does take units sent to them and return rebuilt as Tony pointed out. However they only work thru a business customers of theirs. O'Reilly's said they will work with me. I'll continue with this topic but will be week of Jan 5th before I can send the unit to A1-Cardone. I still would like to see how others managed to FIT a 10.5" booster in there 240Z. Tony can you take a picture of your 2+2

-

I will check tomorrow at Napa but the web parts function reads similar to all the other local and internet sources(rock auto etc etc). Searching it seems Cardone in the only remanufacturer of all vacuum brake booster no make what make or model. I'll call them soon after the holidays and see if I can find the reason for not servicing the 8.5" booster. I'd guess too small a market.

-

I have not tried Napa Miles. I will Friday.

-

Hi guys I started this topic with AGAIN because it has been discussed on this forum and others several times but I have not seen pictures to document the interchangability. I have a 73 and have had no luck finding a replacement so far. I have not contacted Black Dragon to see if the 8.5" is available. I tend to stay away from them but need too. 3 main boosters for the S30 cars and please correct me if I am wrong. 7" for 70-72 cars 8.5" for 73 to ?? 78 10.5" for ??? 76 to ??? There is another 10.5" which to my knowledge only difference is longer studs on the firewall side. Again, correct me if I'm incorrect. all 3 have the same MC side stud pattern 60 x 85mm 7" firewall side stud pattern is 70 x 80 and the other two are 70 x 100. Using the 7" booster would require drilling new holes. This does appear to a good option as it seem the holes will interfere with peddle mounting bracket on the inside of firewall. I'm not saying it's no possible. I read you can use the 10.5" and flip it over. See pictures why this won't work on my 6/73 Measuring from clutch MC to throttle bracket I get 9.25". Measuring the 10.5" booster straight across the mounting studs I get 9.5" in standard mounting position. If I would flip the booster over and measure across the studs I get over 10? Impossible to fit. Please show me picture of how others have made this fit. Flipping the booster will make for a none aligned fit to the brake peddle arm I would think. Mayb ethis is a non issue. Is it possible 73 model has clutch MC and throttle plate closer than other years? Tony said he did it in his 2+2. I need a measurement as I have shown please. FYI the 7" & 10.5" I purchased from O'reillys. 8.5" is my leaking booster. I asked for 76" booster for the 10.5" and a 71" for the 7" Please guys show me how it's done. Merry Christmas. Dave ps: I can't find spell check:)

-

That looks great. Making me rethink mine Here's the prototype my buddy made for me a couple months ago. The next one will have the Z rotated better and slightly more curve.

-

Is there anyone who has mounted GM IAC on 280z intake manifold

davek replied to Meguiars's topic in Nissan L6 Forum

I pulled mine from a junk yard Taurus for $9 with connector. Simple 2 wire IAC valve. Mounted on my 83Turbo manifold. I made a special adapter plate because the holes don't line up. I can send anyone the drawing for the plate. If you have access to a milling machine it's fairly simple to make. The 2 air passage hole are milled thru the plate on 34 & 15 degrees.The mounting holes also needed drilled out to fit the 8mm studs. I have not tried it out yet but I don't see why it won't work. My engine is still on the stand. -

SDgoods That's a good idea Did it quite the swoosh down to almost nothing?

-

-

oops sorry NPR Once again searching turns up jiltch. I see many of you guys are using NPR IC's but can some of you be more specific? What year, models etc. for an S30 L28ET swap works good with the least modifications. I'm in China for an extended stay and thought I'd sniff around here for a good buy. thanks

-

ya I caught that How would they know with that companion flange in there. That seal is 40 x 72 x 10. $10 each I'll bet you can find it cheaper.

-

The 280ZXT companion flange will fit the 240Z stub axle. I just did it a couple months ago. You just need a different size grease seal. I bought the seal at a local industrial supply company for like $8. In Nashville it was called Motion Industries. I have the seal size at home. Let me know if you need it. it's metric size. FYI The concern/discussion using R200 diff with 280ZXT drive axles and companion flange is that the drive axles are too long and will bind. After I assembled mine I put them in the car minus the coil spring. I moved the strut throught the entire motion to see where the binding was/is. I found with the strut completely extended there is binding. I could still rotate the tire but could see and feel the suspension geometry giving and flexing. When the strut is compressed so the drive axle is straight "level with ground" I could sense no binding however I could not feel any back & forth movement in the drive axle. There is maybe 1/16" movement at "normal ride height". You want some movement. My car is not driveable at this point so I cannot try a road evaluation. I suspect when the strut is completely extended, the drive axle angle is too great and the shaft is binding on the CV hub. The best way to prove this is to disassemble the boot from the CV joint and look for marks. Hate the thought of removing by brand new boots. While turning the wheel it has a lumpy feeling which might be explained by the CV hub having channels for the CV end to ride in. The channels, space, channel, space, channel space might provide this lumpy feel as the axle rides against the hub. Maybe my mind wonders too far. What I may do and I read this somewhere. Machine a new "C" clip ring on the shaft ends further up the shaft "X" amount. and remove "X" amount off both ends of each shaft. "X" amount is the amount the spline will allow you to push the CV end further on the shaft. 1/4" on each would be nice I would think. This will help add some shaft play throughout the strut motion but will not solve the full extend binding. I wish I new My shafts have a "C" clip goove but no retainer clip present. I suspect cutting off a 1/4" wouldn't require a new groove or retainer clip. But it's your shaft.

-

All valuable information. I will discuss with the head shop. The cost is however not in the budget.

-

Stock P90A head is about ready to go to the machine shop for a basic valve job. What do you suggest.

-

Thanks Gollum What psi porting and cams will get us there? But like I said, I'll start small so it seems.

-

Thanks Blu. It sounds like good advise. But for a tight budget will the stock 02 location work OK? How do you go about getting one made? Trailer the car to a specialty shop? Mock one up out of wood. paper mache, anything for a shop to use as a guide for length, bends, angles etc?

-

So sorry to read your post. I am planning a swap that sounds VERY similar to yours. I was hoping for 300 RWHP as well. Did we get mislead or did I not read enough and let my mind think a little to far out there? Have you had any better results lately? I sure would like to read more about anything your learning. I'm sticking to the build plan and will upgrade as needed further down the road. I wish I was at your point right now. It might be later this year to be where your at. good luck.

-

Is it OK or not advisable to use the stock down pipe & O2 location with my T3/T4 swap into my S30. If not advisable what are preferred locations. I read NO 90 degree bends is always the best. A custom downpipe is more down the road as an upgrade. I'm gathering info for my MS L28ET swap. Of course it will be a wide band O2. the intent is 300 RWHP etc etc. basic 13-15 psi IC stuff. I'm slow moving on this project and sure I will need more info later. Thanks

-

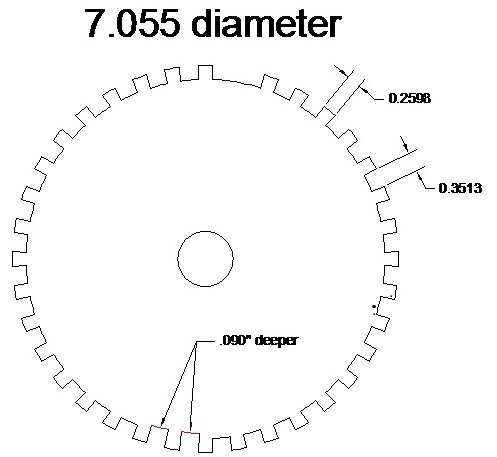

Back to my question--Balancing the unit becomes very simple. I'll make the depth of 2 teeth deeper opposite the missing tooth to make up for the missing weight. Correct?? 2 more questions. a) Using the hall effect sensor from DIY--Will it matter if I leave the crank angle indicator knotch on the harmonic balancer. I would like to leave the notch on a tooth to be able to strobe the ignition angle. I don't know if the small notch would have any affect on the hall effect sensor readings. b)What is the length of line for a tooth? The edge the sensor is reading. I'm thinking the space between teeth is more important. And depends on size of the sensor. The Teeth on the harmonic balancer I draw up are 0.26" with 0.35" between teeth. looks good but I'm no sensor engineer.

-

Bought this 73 in Nov and just starting to get it running. Runs real poor. Taking the distributor a part I see it's missing one centrifugal advance spring. Anyone have a set or at least one I get my hands on. The distributor case is marked D609-58A then 401 under the other numbers. I realize this is an older engine maybe a 71 or 72. The vacuume advance plate had the ball ground into the plate. I surface ground the plate flat and ready to reassemble. Need a spring or a set would be nice. I can send cash or paypal or what ever Or own you one. thanks Dave dk9389@gmail.com

-

I could save a little machine time. The real question is this a good idea or not. I see the trigger wheels have a balance hole in them opposite the missing tooth so my original post is not correct. I'll call the engine shop and ask about rebalancing.

-

Staring at my L28ET in 100 pieces last night I started thing about how I was going to mount the trigger wheel for crank angle sensing. Then I noticed the harmonic balancer looking right back at me. This is a balancer right?? There is plenty of meat on that back side flange/disc I could easily machine the 36-1 notches. I have access to CNC mills and wire EDM. Of course this changes the balance of the unit right? Well doesn't mounting a seperate 36-1 wheel on the crank change the balance as well? Am I thinking way to far out of the box? Anybody done this?

-

never mind got'em at partsgeek -- $72 for both axles. The inner is short as shown on one of these build threads but doen't look like a big deal. No O ring included.