-

Posts

473 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

Anyone know of a running 3.35L LD28 (gas powered)?

inline6 replied to inline6's topic in Nissan L6 Forum

Awesome amount of work (and money) you've got in that car of yours - I looked through a bunch of your pictures. Very nice! What kind of transmission are you running? With the standard deck height, I'm guessing you have about a 5.4 inch rod. The bore on the dyno sheet is listed at 3.5" (89 mm). So the stroke has to be 90 mm to get 3.359 L. Still looking for anyone out there with an LD28 "tall block" with similar bore and stroke but with a 6" rod... -

Anyone know of a running 3.35L LD28 (gas powered)?

inline6 replied to inline6's topic in Nissan L6 Forum

The engine Les' built for the green hornet car utilized an N42 block. That is my assumption based what I gather from searching the forums, yes. The LD28 block has gaps for coolant to pass between all bores. That bit of info, and comments about several sonic tests seem to make the case that the cyl. walls do not share the same OD as the N42 or F54 blocks. -

Anyone know of a running 3.35L LD28 (gas powered)?

inline6 replied to inline6's topic in Nissan L6 Forum

Sorry, typo'd the title - meant to say 3.35L. This Rebello video makes reference to a "tall deck" block/engine. The stock V07 crankshaft per Dave is "with a shorter stroke" than the Brian Crower crankshaft... And the longer of the two rods in the video is about a 6 inch rod. The block is likely an LD28. So, from the various comments in the video, it appears the engine being built was a 3.35L, with a 6" rod and a custom billet crankshaft with a stroke longer than 83 mm. So, who has one of these? -

Curious if anyone knows of one of things in actual existence. Rebello calls it a "tall deck".

-

One of my two N42 blocks has been disassembled and sonic checked. Here are the results. "x"s mark exhaust valve location. The "T" measurements are top of the bore and "B" are bottom. The thinnest measurement was on cylinder 4 where coolant flows between cylinders 3 and 4. The measurement there was .220". There is also a spot on cylinder 2 that was .230". We're looking to bore out the block to 89 mm. To do so, we have to take .059" out of the cylinder wall all the way around. So, at the thinnest point, we could be at .220" - .059" = .161". And at the .230", we'd be at .171". My engine builder recommends going no lower than .180". My recollection of the guidance from several here on hybridz is for normal aspiration (NA) going no more than .125". I have read that some have had to check 4 or 5 blocks before finding one that will take an overbore to 89 mm. If the .125" guidance is acceptable, and our measurements are correct, it seems this block would be good for 90 mm. It seems that I have gotten lucky with the first of the two blocks. If we offset bore cylinder 4 directly toward cylinder 5, we should be able to end up with .170" (.010" offset) or ,180" (.020" offset), but perhaps that is not necessary?

-

If you can dig up or recall any further which Ford, let me know. I will certainly will look into that.

-

Well, that's going to be too much I think. I have a tally on the new engine and new safety equipment that is already around $15k, and I'm sure there are some less expensive options in this case that will work. Thanks for the info though.

-

Is http://www.vistaproauto.com the place? Have any build spec details?

-

I am looking to see if there have been any new developments/options regarding radiators for our z cars. I found the following: KoyoRad makes radiators for the Z These are all aluminum, and available for around $300 or so. Then there is the Stealth Conversions option. They discourage using all aluminum radiators outside of race car applications. What are you folks who are running greater than 300 hp using or wanting to use when you get around to your next upgrade?

-

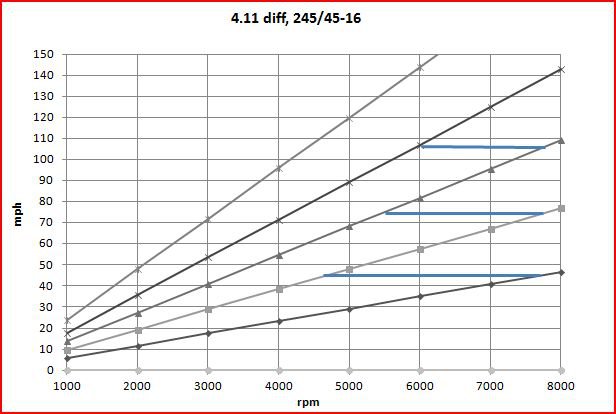

There is a lot to be said for this... a very well designed package that is backed with success in the real world. That said, here is my reasoning: My personal preference... I like the sound of our venerable L6 when it is revving at 7700 more than when it is revving at 7000. I have the Sunbelt cam, springs and retainers in my possession... which is to say I have a sunk cost of upwards of $1500 USD in camshaft related hardware (cam, springs, retainers, rockers) that if sold would be lucky to fetch 1/2 of that. I like the engine characteristics with the Sunbelt cam. It was streetable enough... had a lope at idle, and revved easily at the high end, all of which, I like. Though with the 3.3 L displacement vs. the 2.9 L I had before, my understanding is that those characteristics would be altered a bit. With my current transmission, differential, and rear tire size, the 7700 RPM works well to keep engine operating range in the torque/power making rpm zones for all gears I would use at the track: Though again, this transmission will have to be a short term solution as the torque output is too high for it over the long term. However, I have been given a lot of info outside of the forums that I am still processing.

-

I found these two places - BHJ lists the Datsun L6 application at $868. http://www.bhjproducts.com http://www.ccaracing.com Anyone know of other available options? I've also read of some who apparently bored holes through sacrificed cylinder heads.

-

Seeing dowels installed in the cranks in the "How to Modify Your Nissan/Datsun OHC Engine" book by Honsowetz years ago, I thought their only purpose was to aid more strength to keep the flywheel from sheering off. Now I see what else can happen if you don't have them, so I'll be sure to add them to the next build.

-

You are wrong to relegate me to one of those who has grasped onto a paradigm that the L6 can't rev safely beyond X. I am well aware of your L20 powered car (have commented in the past on such) and others who have revved various displacements of the L6 well beyond the "7200", "7500", "8000", etc. so called "limits". I don't have enough time outside of work, or a staff of minions to do my bidding, or the desire to spend the potentially couple of tens of thousands of dollars (on engines and test equip, further ed., etc.) it would take for me to learn first hand what others (who, to my knowledge, are not competitors BTW) already know. If I did have those things, I would do/utilize them. To be clear, it is not an inability to get off my ass, nor is it that I am lacking in brain capacity. Instead, given the constraints I do have, I believe it is wise to seek the commentary/advice of those in this community who are more knowledgeable. This piece of what you had to say was valuable: The L28 has no practical limitation, and the issues about 'dwelling' in the region on-track were already adequately addressed by John Coffey in his comments. John's comment was read, processed, and stored when he provided it - it was very helpful, specifically because it was a solution backed up via real world experience to an important issue I wanted to learn more about. I'll add to my knowledge in this subject matter area as I can. I'll apply it in the most judicious way I can for my particular application and hope it will lead to good results and good fortune. Along the way, I believe some others will get value from my efforts to share here also. You snicker at other's... because they have inaccurate information, because they have less knowledge in a given subject area, because you have a preference to be acerbic along with your teaching, or because of their misfortune, as you wish. Garrett

-

Hmmm. For the street? Will it be "soggy below 6(k)" per another one of your recent posts? I think you were specifically speaking of use in an L24, but how much different would this 8500 rpm cam be in a 3.4L? Different enough to be good for "on the street"? Just trying to understand because I'd really, really, like to use my Sunbelt cam in the 89 mm X 89 mm version with Honda rods for the bottom end (3.3 L). Toward that goal, I recently sourced a factory nos P90A with the bigger combustion chambers...

-

Yes, I have been emailing Les quite a bit as of late. He shared that video with me and I've watched all of the others that his CA customer has put up thus far. Pretty awesome. I've been considering building the 3.3L with Les' kit, but I'd like to use my Sunbelt cam which revs to 7700 and that really isn't what the 3.3L is about.

-

Same bolts and flywheel were undamaged upon removal after the first 1000 or so miles of operation on this engine. I had some cam break in issues and ended up pulling the engine out, pulling the head and sending the short block off for examination and a re-hone while I had things apart. Plus, 2 (opposing) of the six are ok. So... this damage to the threads was definitely not from bottoming out. Flywheel is Fidanza aluminum. Pressure plate and disc are Clutchmasters - I'm trying to remember, but I think the FX100 in the 240 mm size. I have a guess as to what happened. Looking at the flywheel... The flywheel bolt holes have thread marks only on one side of each hole as you can see in the pic. I mentioned before that the middle section of rod number two got wedged between the big end of rod number 1 and the bottom of bore 1... and locked up the engine at something like 6500 RPM. I think when the engine stopped rotation that suddenly, the mass of the flywheel, pressure plate plus the fact that the car was in fourth gear all combined to jerk on the flywheel hard enough to allow it to shift under the heads of the flywheel bolts - causing the threads of the bolts to imprint the sides of the holes. This created a sideways pre-load on the bolts, and even though I "cracked" them loose... diagonally opposite and rotating around, before backing any of them out very far, the flywheel was still tweaked and the holes were not centered on the bolts as I continued to remove them... While I was completely oblivious to this, I kept trying to back them out and met very heavy resistance. I remember being totally confused as to why the bolts weren't coming out as they always had, but I couldn't figure out what was wrong. I got rather frustrated after I knew the threads were "f"ed, and had to power them out with a breaker bar. This seems much more likely than friction welding from torsional crankshaft vibrations now but I still don't know much about those (torsional vibrations) or how the damage from them manifests itself.

-

Anyone have a junk/rusty pan laying around? Just need the front 10 inches or so to be in good shape. I need this to salvage my competition front pan which got damaged when a rod let go. Please help - thanks. Garrett

-

Oops... I just realized you had asked a question - I read this post a while back. I was shifting where I had the rev limiter set on the hi 6 ignition - 7400 rpm, or just below. Yes... keep the rpms down below 7300 - it is what I should do. However, I am so addicted to the sound at the higher rpms! The late 280zx box is really not that bad in my opinion with the ratio's... I am running a 4.11 rear and 245/45-16 tires. It was a pretty good combo for Road Atlanta. That said, the new engine (if I go the route above) is going to be too much torque/hp for a stock 280zx box. I've started looking at newer options like the 350z 6 speed.

-

I've been continuing to investigate the 3.3 L option. Right now, it's just ideas, but thinking of going with this: N42 block, sonic tested to verify 89 mm bore is safe Billet crankshaft with 89 mm stroke 137 mm rods Forged pistons - flat top with valve reliefs P90 cylinder head with chambers @ final size of 49 cc Kinetic Sunbelt cam and matching springs with titanium retainers, 45 mm titanium intake valves, 36 mm stainless exhaust valves TWM throttle body fuel injection Electromotive Tec GT fuel injection/spark management Dry sump oiling system With the extra stroke, keeping the compression ratio down to 11:1 is a challenge. A welded N42 is not a good option. I am still trying to figure out the final package. Will be getting some pricing info soon, and then it will be time to make some decisions.

-

RB crank - 89 mm stroke... I liked my engine a lot. Though I only got to run it in its element for a little over an hour, it was sweet. So much more power, and a sweet engine sound at the upper limits of rpm. Power was plenty. I wish I knew what broke it. If I knew for sure it was turns 6 and 7 causing oil starvation, I might proceed differently. But I am freaked out about the torsional vibration issue. It's no fun to spend... let's be conservative and say $8k plus over 100 hours of time building/tuning an engine to have it come apart in a big way during the first track session. The first temptation was to repair the crank if possible, buy two replacement rods, another set of pistons, straighten the cam, another set of titanium retainers (one got dinged badly), and replace the exhaust valves (one was bent, and they easily have over 100k miles on them). And... you have to add to that all the work to the new block: boring cylinders, honing, align boring the mains, assembly, etc. However, the mods done to my crank hurt it from a standpoint of torsional vibration: smaller rod journals... crank lightening... I have no idea how much worse I may have made the problem.

-

My engine builder sent me this pic. We had been discussing how bad the L series ports are in general and I pointed out that the japanese head pics I had seen showed the porting done with out the guides, and the guides installed afterwards. He laughed and called that "lazy" and "wrong". Here is a pic of one of the heads banging around in his shop - it's from a NASCAR engine. I thought it pretty awesome.

-

Been searching, reading, etc. Might go a different direction. I am thinking of building a 3.3 L stroker instead of what I had. I am still investigating, but it looks promising. We'll see.

-

The titanium valves are really a separate issue. Through my engine builder, I've been in contact with the guy that developed the Sunbelt cam I am running, and it wasn't known by me until now that the cam and valve spring set up I am using was designed to utilize titanium valves. So, just going to do that. The blown engine was not related to running the stainless valves.

-

Saw this racing seat in Mark Rolston's latest car. Sure is nice: Tillet B1... bit pricey though huh?

-

I'm running an e88 head and need to source some titanium valves. Anyone know of any that are out there, or do I need to look at custom at this point? I believe David Weber of Malvern Racing told me at one point that he was reusing (after mods) some NASCAR valves... I recall him saying they only ran them one race. Guess I'll start scanning the available titanium valves for ones that are close to the stock Nissan size I need. Looks like Del West and Ferrea will do custom, but that is typically a synonym for EXPENSIVE - as in even more expensive than titanium are already going to be.