-

Posts

473 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

Well... I found a big problem... Last Sunday, I decided to verify that the vacuum advance was working correctly. I disconnected it and ran the engine with a timing light, and was surprised to see very little movement. I decided to take apart, clean and lube the appropriate areas of the advance mechanisms in the distributor, as well as verify the vacuum advance was working. Afterwards, I was amazed to see that it did make a difference - I got a few more degrees of ignition advance from it. I reset the timing to only provide a max of ~ 34 degrees BTDC. After doing this, I took the car for a short drive. The engine was making a fair amount of noise... It had been since I took it to the dyno, and while I had been trying to say it was just my imagination, I decided it really wasn't. It really was making a lot of noise and it sounded like it was coming from the valve train. I checked the cam and rockers... everything looked great. I checked my valve lash, and found several to be .4 mm which is like 16 thou, so I tightened all of them up to .012". When I started the car, the noise seemed even louder, if that is possible. I ran it less than a minute. And, I shut it down in disgust. Not knowing what was messed up, I decided to do a leak down test. I got percentage loss for 1-6 of: 4,5,3,2,2,4. I then tried to see inside the spark plug holes to examine the bore walls. I saw a vertical mark or two, so I decided to buy a "borescope" and take a detailed look inside the bores. That cam on Thursday, and with it I was able to see quite a bit more. And what I did see looked like shiny have moons in the exhaust valve reliefs on the tops of about 3 of the pistons! That got me thinking... valves hitting pistons would cause LOTS of noise. And just before I took the car to the dyno, I had removed the Kameari cam chain tensioner to check into some unusual noise it seemed to be making. It turned out to that it just wasn't quite tight enough - there was nothing wrong with it. But, maybe I screwed up the cam timing when I took it off? A check of my cam timing was next. I was able to find the time to do that today... and sure enough, it was wrong. My timing chain had slipped one tooth on the crank sprocket when I was messing with it. That retarded the cam 18 degrees, (20 tooth sprocket - 360 degrees), however my adjustable cam gear is set advanced by 3 degrees. So, the net amount it was retarded was 15 degrees. And in that state, I went to the dyno last Saturday! Again using my Borescope, I ran the camera down the front cover of the engine. I was able to jiggle the chain to change it's position on the crank shaft and verify it with the camera. With the marked lower and upper timing chain links aligned properly with the lower sprocket and the cam gear, I started the engine. And the "clacking" - the noise was gone. Go figure, huh? I took the car for a brief spin tonight and MAAAAAN, what a difference. The power is soooo much better. And, I am not sure why, but the AFR's are much improved at lower RPM and heavy throttle inputs. I even tried what before would produce 10's, and could not! Next tuning session will be interesting. When I got back, I did another leak down test. This time the engine was warmer, and from 1 through 6, I got percentage losses of: 3,4,3,4,2,3. Now, I will get back to tuning. Hopefully, no problems crop up in the coming days or weeks related to the valves hitting the pistons. We shall see.

-

Yes, that makes alot of sense. It is just half a millimeter, but I had a few thoughts about this. First, siphon action is what delivers the fuel to the auxiliary venturi. Logically, a "very low" level of fuel will require more siphoning "action" to pull the fuel than a "very high" level. I'm guessing that siphoning action difference between these two different levels can be compensated for via changes to the jetting, but I do not know this. When I attempted to set my fuel level to the Honsowetz spec, I actually used a section of wire that was .815" instead of .826", because my attempt to mark it was a bit off. That resulted in a fuel level that was .032" "high" vs. the .847". It is still within the +/- 1 mm range in the manual, but given the problem I'm having, I'd rather be on the low side than the high side. In my particular circumstance, I am experiencing AFR's in the low to mid 10's across a very wide range of main fuel jets. Right now, with main fuel jets of 130s to 180s, I get 10's when I apply fuel throttle at low rpms (I do this in such a manner that I can rule out the pump nozzles being the culprit). So, my "high" fuel level may not be part of my problem, but I'm going to set the level to ~ .847" below the jet hole surface, and see if it helps the problem I am having at all.

-

I am working through my Mikuni tuning issues... and I think I found something that anyone still messing with Mikuni's and who is using Honsowetz's How to Modify your Nissan/Datsun OHC Engine should know. On page 112 and 113, it says: "To check fuel level without disassembling the carburetor, remove the jet cover - center top of the carburetor and remove one jet block. The fuel level should be visible in the jet-block hole. The recommended fuel level is 0.826-in. (21mm) below the float chamber top surface - horizontal surface at the top of the jet-block hole. This directly relates to a fuel level that's 0.787-in. (20mm) above the horizontal center of the throttle bore on 50mm and early 44mm models and 0.940-in. (24mm) above the throttle bore on later carburetors." My Mikuni PHH Carburetor Manual has a drawing (Fig. 3) on page 3 that shows the fuel level in the carb body. It does indeed indicate that the fuel level should be 24 mm +/- 1 mm (this is for 44 PHH - the dim is 24.5 +/- 1 mm for 40 PHH) above the horizontal center of the throttle bore. However... I have a 44 PHH carb body in my hands at the moment, and measuring with a caliper, I am coming up with a different measurement than published in the Honsowetz book. On the front face of my carb, between the two throttle bores, there is a step in the casting right at the throttle bore horizontal center. This makes for very easy measuring. From that step ("the horizontal center of the throttle bores") to the "float chamber top surface", which is also the same surface at the top of the jet-block hole, I measure 1.792". Now... If 24 mm, when converted to inches, is 0.945", then the recommended distance to the fuel level below the float chamber top surface should be 1.792" minus the .945". So, the distance down to the fuel should be 0.847". In other words, instead of using 0.826" for the measurement from the jet-block hole down to the fuel level, I should be using 0.847" Can somebody else confirm this? Interestingly, I have the jet block holder... and an OA jet block in hand also. With the jet block installed in the holder, the jet block stick up .285" inches above the jet block surface. If I add the .285" and the .847"... I get 1.132" which sure looks to me like it puts the float level exactly in the middle of the "fat" barrel portion of the jet block - the part that is widest in between the 4 elongated, lower holes in the jet block and the eight round holes above.

-

Well... Only because I've never come across anyone running mains and air correctors that far apart, I guess. Recently, I came across some guidance that when you are just looking for a starting point, use air correctors that are about 30% higher than the mains. Since I appear to be not even close... I kinda was following that. 140 Main 220 Air Corrector, and move the pump stroke from middle hole to lowest hole... that is what you are suggesting I try? Electromotive TecGT and TWM throttle body setup with fuel rail, injectors, and even a custom harness for a z car is sitting in a box in my garage... But, I am trying to learn something about these Mikunis... After I struggle with them and live with what I am sure will be lots of compromise, I will switch and I will love fuel injection.

-

Engine is basically a 3.0 stroker... only it is 88 mm bore instead of 89 which makes it a 2.933. Comp ratio is 11.15:1. Running on 93. Cam is big: Intake Seat duration 320 degrees .050" duration 290 degrees Valve lift with zero lash .565" Hot valve lash .015" Net valve lift .550" Exhaust Seat duration 315 degrees .050" duration 274.8 degrees Valve lift with zero lash = .565" Hot lash = .015" Net valve lift =.550" Cam currently Advanced 3 degrees (101.5 ICL) Porting and polish done to both the head and intake.

-

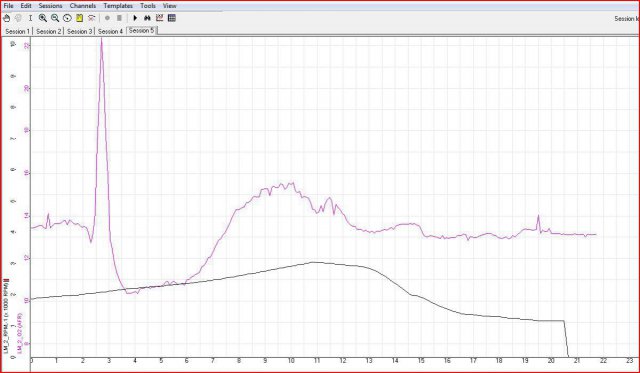

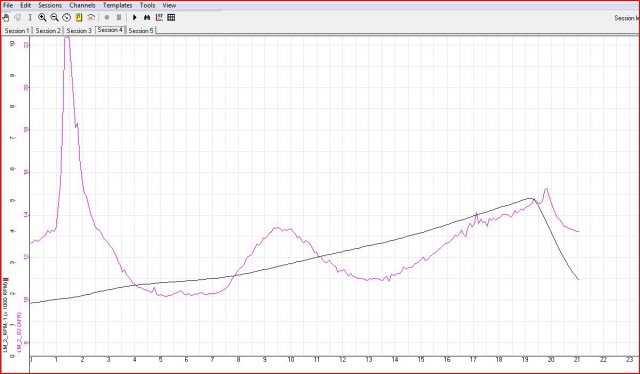

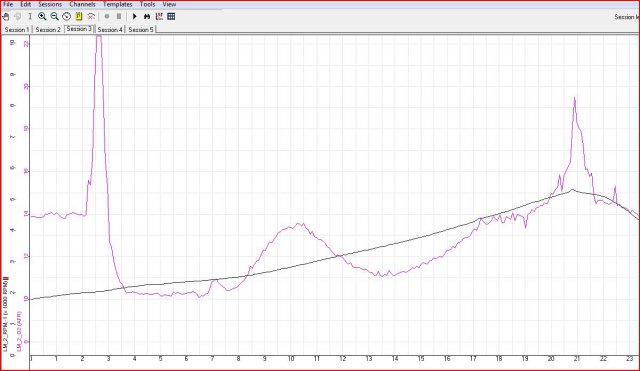

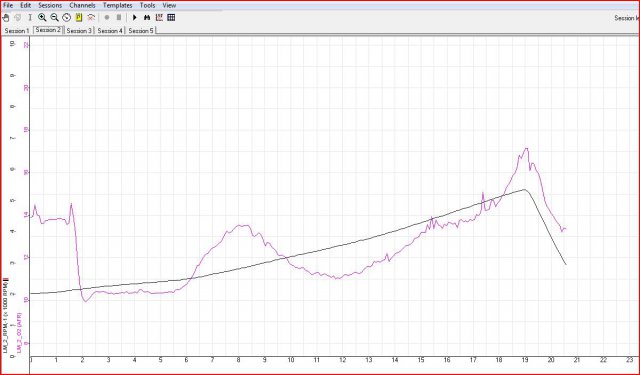

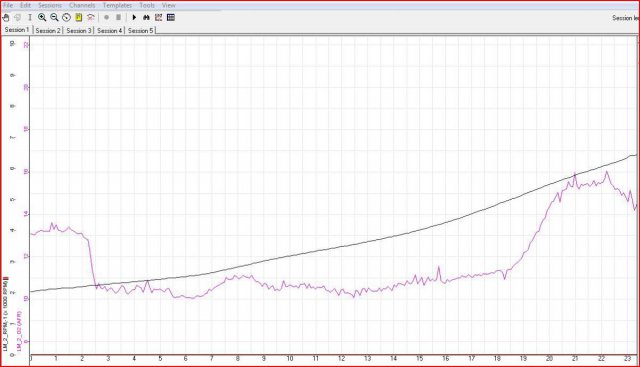

Well, I did my first ever attempt at tuning on the dyno today. Unfortunately I am baffled by the engine behavior I saw. First, some basics: All floats have been checked, checked again, and triple checked. The last method I used (Honsowetz book) was marking off .826" on a length of wire, removing one jet block per carb, and sticking the wire down the jet block hole. The fuel "jumps" to attach to the rod when it touches. The .826" measurement is from the fuel level to the jet block hole surface. My floats are set correctly within .020" of the specified measurement. Ignition is a Crane Hi 6S and is triggered by a Crane optical trigger in the distributor Distributor is a Nissan Euro unit with a functioning vacuum advance Timing verified to be no more than 34 degrees advance. Initial advance, if it matters is about 17 degrees at "idle speed". Fuel pressure is below 3.5 and above 3.0 psi. Initial jetting was determined by doing mainly half throttle pulls in 3rd and 4th on the street. I attempted full throttle pulls, but the LM-2 would show low 10's AFR when I "dumped" the thottle (even several seconds later). Initial jetting: Main 180 Air 240 Pilot 57.5 Pump 50 Choke 37 I didn't want to be at 10's for extended periods of time. Rather, I figured, I'd be able to find the right combination when I took it to the dyno. So... Listed below are the changes that I made in order to attempt to get the mixture somewhere close. I did all runs in 4th gear. The dyno operator told me that once I was in fourth, to snap it to full throttle and hold it to redline. From my prior experiences, I figured it the AFR would drop down to the low 10's and struggle to do anything... but what the hell. Once in fourth, I was around 2000 and went full throttle. The AFR dove to low to mid 10's. The engine struggled to build RPM. It felt like it was mis-firing ... Eventually, the AFR climbed up and out of the 10 zone... and the engine ran well for a short range of RPM... I'm guessing around 4000-6500 RPM, but RPMs were not increasing very rapidly above there, and I there were a few misfires, so I let out. Unfortunately, my LM-2 plot wasn't any good for this run. The dyno operator told me to make it less rich. Next, I went with: Main 170 Air 230 Pilot 57.5 Pump 50 Choke 37 Once in fourth, I was around 2200 and went full throttle. The AFR dove to low to mid 10's. The engine struggled to build RPM. It felt like it was mis-firing ... Eventually, the AFR climbed up and out of the 10 zone... and the engine ran well for a short range of RPM... I'm guessing around 4k-6k, but rpms were not increasing very rapidly above there. Unfortunately, my LM-2 plot wasn't any good for this run. Given essentially a repeat performance, I was told to make it less rich. Next, I went with this: Main 160 Air 210 Pilot 57.5 Pump 50 Choke 37 Once in fourth, I was around 2200 and went full throttle. The AFR dove to low to mid 10's. The engine struggled to build RPM. It felt like it was mis-firing ... The AFR climbed up and out of the 10 zone... not achieving a 12 AFR until 5150 RPM. The engine ran well for a short range of RPM... Looking at the plot from the LM-2, I'd say 4000-5500k RPM. RPMs were not increasing well above there, and the AFRs were going higher than before... into the 15s, so I let out. We were pretty confused as to why the changes weren't making a bigger difference. In an attempt to try to go too lean, I went with this next: Main 140 Air 210 Pilot 57.5 Pump 50 Choke 37 Once in fourth, I was around 2150 and went full throttle. The AFR dove to low to mid 10's (stayed there about 4 seconds). The engine struggled to build RPM. It felt like it was mis-firing ... The AFR climbed up and out of the 10 zone. As the AFR got into the 11 range, the engine ran better. Looking at the plot from the LM-2, I'd say 2500-5100 RPM, but rpms were slow to build, and the AFRs after 5k going higher than before... well into the 16s, so I let out. Additionally, I note the presense of a midrange bump in AFRs centered at about 2900 RPM (look at seconds 6-10 in the plot) If we were confused before, we were baffled now... as to why the changes hadn't elminated the dive in AFR to 10's when transitioning to full throttle. Because we had tried lowering the main and air jets many times and didn't see the kind of change that we expected, I started thinking that there must be a completely different problem... outside of the main and air jetting. Even though I knew the pumps only are a factor briefly in these running conditions, next I changed the pump nozzles from 50's to 35's to see what would happen. Main 140 Air 210 Pilot 57.5 Pump 35 Choke 37 Once in fourth, I was around 2000 and went full throttle. The AFR dove to low to mid 10's (stayed there about 4.5 seconds). The engine struggled to build RPM. It felt like it was mis-firing ... The AFR climbed up and out of the 10 zone. As the AFR got into the 11 range, the engine ran better. The midrange bump in AFRs is still there and in the same spot (2500-3200 RPM). With the 35 nozzles however, now a lean spike has been introduced when going to full throttle. Continuing with changing something other than main and air jetting, I began to think maybe there is a lack of air flow. Though the air filter and cold air tubing seemed adequate, I thought I would remove the air filter next and just see if it made any difference. Removed K&N air filter Once in fourth, I was around 1800 and went full throttle. The AFR dove to low to mid 10's (stayed there about 4 seconds). The engine struggled to build RPM. It felt like it was mis-firing ... As the AFR got into the 11 range, the engine ran better. Looking at the plot from the LM-2, I'd say 2500-5000 RPM, but rpms were slow to build again. Knowing that AFRs at the high end were going above 15, and seeing no substantial difference with the air filter off, I let out. The same behavior... including the lean spike by the 35 nozzles introduced when going to full throttle. Finally, just to use the remaining time, I did one last desperation attempt to go too lean. Next I ran: Main 130 Air 190 Pilot 57.5 Pump 35 Choke 37 Once in fourth, I was around 2000 and went full throttle. The AFR dove to mid to 10's (for about 2.5 seconds this time). The engine struggled to build RPM. It felt like it was mis-firing ... The AFR climbed rapidly and was hitting 15s before I even got to 3k RPM, so I let out. I'm not sure where to go from here. I'll be studying these plots, my previous tuning attempts, and think about how to proceed.

-

I'll be sure to post. By the way, my car is HLS30 - 16511. Yours and mine were made pretty close together in the same factory about... 45 years ago.

-

So, quoting from the article, this seems to be the reasoning for why during the intentional ignition misfire, the pre-cat O2 is showing rich spikes: "The O2 sensor is made up of two platinum thimbles (one exposed to the atmosphere, the other to the exhaust) separated by a solid zirconium dioxide electrolyte. The exhaust thimble, being made of platinum, is a catalyst much like a catalytic converter. If excessive CO or HC is present in the exhaust, it can be catalyzed on the thimble, using up the oxygen next to the thimble and causing a low-oxygen (rich) indication despite the fact that a high-oxygen content exists in the exhaust. This explains the mysterious rich O2 indication in my April 2000 column on using pre- and postcat O2 sensor readings to predict ignition vs. fuel sensor failures." Interesting. This is followed a bit later by "In its normal environment, the O2 sensor is very accurate at measuring exhaust oxygen levels, thereby making an accurate assumption of fuel mixture. Outside of the normal range, however, the O2 sensor’s response can be somewhat unpredictable, rendering its assumption of oxygen content and fuel mixture unreliable." I am thinking engine misfire from a lean mixture is an event similar enough to the above intentional misfire test... I am going to spend 2 hours on the chassis dyno this Saturday! Should be quite informative.

-

I've been doing some tuning of my Mikuni 44 set up as of late with the assistance of a wide band o2 sensor, and I have learned a few things that may be helpful to some others. Generally, I recommend determining these in the order listed: Pilot Screws: One bit from Honsowetz in the How to Modify Your Nissan Datsun OHC Engine which is a very specific instruction: run your pilot screws 1.5 turns out. I have mine set at 1.5 dead on, and the engine likes the 57.5 pilots at that setting. AFRs are where they should be for idle and low speed operation. The engine runs well in both of these conditions. Mains (Fuel Jets) and Air Correction (Air Jets): This bit came from TonyD... and that is stay out of the pump nozzles when trying to determine what the engine wants for main and air jets. Accelerator pedal movement may engage the pump circuit and if it does, this will throw fuel into the mix from that circuit. This will "mask" what is happening with the main circuit and you won't know what is what. According to the Mikuni manual, accel pumps are in play from 0 to 30% of throttle. So use inputs like 50% or 100% and ignore where the 0-30% is most likely occurring. Since the pump circuit has a known volume... and the duration of the fuel "injection" from the nozzle is specific to each nozzle, you could time the length of the injection duration if you are so inclined. Then you could ignore that time duration (from throttle open) in your Wideband AFR (Air Fuel Ratio) plots. Pump Nozzles: This one came from my engine builder. Know that sometimes wideband o2 sensors/loggers may show you rich readings when actually the engine is lean. This can occur when there is any engine misfire condition. The rich reading is resulting from a chain event of the flame going out too early, and the subsequent passing of remaining unburnt mixture through to the sensor. When you open the throttle quickly, if the engine is sluggish, but doesn't misfire, and your wideband shows rich, you are rich. However, if the engine misfires, and your wideband shows rich, you could be lean. Regarding this last one, I think that is what I am currently experiencing. I will be testing that theory out soon. As I have changed the pump nozzles from 50 to 45 to 40, I am fairly certain that I have been experiencing a more prevalent misfire when applying large throttle inputs (I haven't been doing much full throttle yet and there has been a fair amount of time involved from when I swapped nozzles one to the next to the last). I was going smaller and smaller because of the rich readings I was getting on the wideband when "throwing large throttle inputs" at the engine. Last tuning session, I was getting a large amount of misfire for the first couple of seconds of full throttle... even when in first gear. I am going to switch back to the 50's next and see if that situation improves.

-

Hi Mark, As an alternative to the TWM one, there is this one from England. I don't think you have to pay tax, but there is shipping and customs. It should be under $300 delivered though and it is better quality than the TWM. It is essentially a copy - just made better. It will still rub the shock tower unless you do something different elsewhere in the induction set up.

-

I didn't read any prior posts to your latest, so you may have said what you use your car for previously... street, autocross, track, etc. I thought I'd chime in here and say that I initially went with 200/225 and the short Illuminas. However, I found that I was bottoming out on the bump stops in the front too frequently. Lowering the car a lot can take travel out of the suspension. Even with struts modified to fit short inserts, bottoming out can still be a problem. The initial spring rate recommendation from Ground Control was 225-250 up front and 275 in the rear. I had gone with 200/225 for fear of being too stiff. But, to try to stay off the bump stops, I swapped in some 250/275. That did as intended and seems to be a very livable setup for street driving also - it's not too stiff.

-

Crane HI6 suddenly doesn't have spark.

inline6 replied to inline6's topic in Trouble Shooting / General Engine

The correct, replacement optical trigger fixed my problem. The old one was dead. The first replacement was incorrect - it is for XR700 and XR3000 only. Original ignition unit is fine. For anyone searching in the future - the 700-0020 trigger works on 5 volts. The 715-0020 works off of 12 volts. That is why you need to use the 715-0020 with the HI6 CD ignitions. G -

ZG Flares in stamped steel or injection molded plastic

inline6 replied to RebekahsZ's topic in Body Kits & Paint

For all of those who posted interest in steel flares, I happened to come across this and thought I would pass it along in case anyone would be interested. http://www.zccjdm.co..._FENDER_FLARES_ -

Crane HI6 suddenly doesn't have spark.

inline6 replied to inline6's topic in Trouble Shooting / General Engine

During all of my searching over the past weekend, I came across some info online that got me thinking the optical trigger I bought two weekends ago might be the wrong one. I called Crane Tech Support on Monday and had that confirmed. My new optical trigger (part number 700-0020) with the grey, black, and white wires is for the XR700 and XR3000 ignitions only. It operates on 5 volts. The correct one (part number is 715-0020) with red, black, and white wires is now on the way to me. So, I probably did diagnose the problem correctly: the original optical trigger died. The new ignition was probably not needed. I will be able to determine for sure when I get time to install the new, correct optical trigger. -

Crane HI6 suddenly doesn't have spark.

inline6 replied to inline6's topic in Trouble Shooting / General Engine

Spent another weekend on this and I can't find the problem. This has become the nightmare that I was afraid it would be. Looks like Crane has different wiring on their optical triggers and this may be what has really tripped me up. Soooo..... My original optical trigger has three wires: black, red, and white. The black wire a ground. The red wire is connected to the coil + wire, which gets voltage when the ignition is switched to on. And, the white wire is the "trigger signal wire". Initial work with a multi-meter and the hi-6 manual lead me to believe the optical trigger was bad. So, I bought another optical pickup. Though this one has three wires like the original, they are grey, black, and white instead of red, black, and white. Figuring that the grey replaced the red, I wired up the new trigger to the original Crane ignition with grey to red, black to black and white to white. That didn't work, so I got sent down the path of buying another ignition unit... more stuff was tried, etc. During one of my web search episodes today, I came across this: correct wiring of optical trigger with grey wire which this person confirmed with Crane tech support. The correct way to wire this new optical trigger is actually: black is the +12v line, the white is the ground, and the grey is the signal output. Why in the world this is the case is beyond me! Is it possible to damage the optical sensor by wiring it wrong? ***edit - I guess not. Just found this which says it is reverse polarity protected and short circuit protected.*** So far, I have tried original crane hi-6 unit with original optical trigger. I have tried the original crane hi-6 unit with a new optical trigger (which was wired incorrectly). I have tried a new crane hi-6 unit with the original optical trigger, and I have tried the new crane hi-6 unit with the new optical trigger: wired incorrectly and wired correctly. My thinking at this point is that perhaps I fried the original optical sensor while trying to prime the engine with the spark plug leads off. And that I fried the second one by wiring it incorrectly. Given this, I went in search of any information I could find on how to test just the optical trigger. I found this: normal optical trigger function With the original optical trigger, the white wire is the trigger signal wire. According to the link I posted above, this wire should see zero volts when the optical path between the LED and the photo-receptor is blocked. This is supposed to be the case when the "disc" with the slots in it does not have the slots aligned with the LED and the photo-receptor. When the slots align, the white wire is supposed to see 12 volts. I am seeing around 10 volts on the trigger wire whether the optical path between the LED and the photo-receptor is blocked or open. With the new optical trigger, the grey wire is the trigger signal wire. When the new optical trigger is wired correctly, I am seeing around 11 volts on the trigger wire whether the optical path between the LED and the photo-receptor is blocked or open. Any ideas? Anyone have hi-6 unit that can confirm what voltages are at the three wires for the optical pickup when things are working properly? Is the light from the LED visible - or is it infrared? I have yet to see any light coming from either pickup. Garrett -

Crane HI6 suddenly doesn't have spark.

inline6 replied to inline6's topic in Trouble Shooting / General Engine

Bought and installed a new Hi-6 unit today... and I still have the same problem. No spark. Diagnostics light on the new unit does the same thing. Lights up solid like it should when the ignition is switched to on. It just dims when cranking - it does not blink as the manual says it should. Manual says the unit isn't seeing the trigger signal. I replaced the ignition rotor also. The old one has quite a few miles on it. I'll go ahead and order a new cap also. Guess I'll be using the multi-meter tomorrow and will try again to figure out what could possibly be wrong. I hate electrical problems. -

Dollar has been gaining against all currencies as of late. Lots of news about it. Now a dollar buys 121 yen. Looks to me like the dollar hasn't finished its run... could be interesting over the next few months. Dollar to Yen

-

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

I was running straight 30 weight until after I finished driving the car last weekend. I changed out the oil while it was warm to Valvoline Racing 10W-30. Of course I haven't started it yet since. And yeah, I could roll the dice and try to start the car without heating the oil, or what you said, or remove the spray bar and use the internal cam oiling only... if I want to risk it. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

Heating the oil is a pain - no doubt. But let's consider what that is doing. Essentially, it is only doing one thing, allowing for quicker flow through the internal passageways at engine start and for a low number of minutes of operation just after start. Once the oil comes up to operating temp from normal engine operation, we have the same thing going on in both scenarios - i.e. pre-heating oil vs. not pre-heating the oil. Since I have driven the car on 3 or 4 different occasions now, for a total of 150 miles, and the cam is fine, then my problem couldn't be cam blank material, or I'd still have the problem. The problem is more narrowly defined at this point based on all my prior info: there has been a lack of flow at the time of engine start which has caused this damage. What I haven't been able to conclusively determine is precisely why that is the case. I have eliminated: poor quality rocker arms/pads (my rockers are OEM) incorrectly reground rockers (pad surfaces were checked after each regrind for parallelism with the rocker tips inadequate pre-lube of cam blockage in oil passages by foreign substance/material inadequate amount of oil in sump wrong oil pump when utilizing a drilled out oil restrictor jet in block (can't use the stock pump - use turbo pump which has more volume - which I am) worn or damaged oil pump broken oil pump drive gear lock pin holding gear to oil pump drive shaft poor oil choice such as those with low amounts of ZDDP Probable culprits, which remember, could be exasperated by this rather high lift, high duration cam are: installation of dry oil pump installation of dry oil filter installation of large oil filter (for example, the OEM nissan ones are smaller capacity than some of the "correct" aftermarket ones) rifle drilling of cam core (for weight reduction - has increased empty volume displacement inside cam) dual cam oiling (internal and external at the same time - more outlets reduces oil pressure at the orifices) It seems likely to me that the actual cause or causes are in this second list, and my current thinking is that it is most likely a combination of some of these factors. But I am not emboldened enough yet to not heat the oil and see if my problem is still present if I don't. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

I've put maybe another 50 miles on it. The last time I drove it was two weekends ago. I was recording some air fuel ratio runs with an Innovate wideband O2 sensor. After that weekend I ordered some more Mikuni jets from Wolf Creek Racing. I also drained the Brad Penn break in oil out of it, and changed the oil filter to another new, Nissan OEM one. The plan was to get the jets so I could do some more tuning this past weekend. However... It seems that I harmed the HI 6 Crane ignition while trying to prime the engine prior to starting. Since I had a new filter, and I've been having so many cam lubrication problems, I wasn't going to risk starting the engine without seeing oil come out of the cam first. I heated the oil for 2 hours, I went ahead and re-adjusted the valves since the engine had run 150 miles. I pulled the spark plugs and laid the spark plug wires across the top of the carbs. Tried 5 times to engage the starter to prime the engine, each time dipping my finger into the oil pooled around the valve springs and putting it on the cam lobes. Couldn't get oil to come out of the cam. So I said screw it, the oil pan was actually a bit hot to the touch at this point, so I figured I'd start it and immediately get it up to 2k to get oil pressure rather than screwing around with a gear reduction starter speed to prime the cam. When I had it ready to start, I turned the key and the engine just spun... no hint at starting. Checked for spark on plug wire 1 and had none. Many hours later, I determined that the HI 6 wasn't indicating that it was seeing the spark trigger (an optical trigger in the distributor). I had a new optical pickup in hand from Summit Racing three hours later, but unfortunately that didn't solve the problem. I think somehow while cranking the engine with the spark plug leads off, I fried the trigger circuit in the HI6. That was the end of the plans to test different jet last weekend. This car is really testing me... makes me appreciate the other cars in the garage a whole lot. -

Crane HI6 suddenly doesn't have spark.

inline6 replied to inline6's topic in Trouble Shooting / General Engine

Picked up a new optical pickup from Summit Racing today. Just finished trying it. LED indicator on the HI6 unit still doesn't blink when I turnover the engine... it just dims. And I still have no spark. An entire day wasted and no idea what the hell went wrong. There is a rather prominent message in the manual about never unplugging the spark plug leads and turning the engine over... At the start of the day, I did this. I removed the spark plug leads and the plugs so I could spin the engine to get oil pressure (after an oil change and new filter). The spark plug leads were laying across the top of the engine. Maybe that caused something to fry in the HI6 unit. On the unusual side of things, I note that a strange, high pitched whine comes from the center post of the distributor cap every time I touch the white wire (for the optical trigger) from HI6 unit to ground. That seems to trigger the coil to fire, but the sound coming from the distributor cap is weird. And when I put the distributor cap back on the distributor, every time I disconnect and reconnect the optical trigger harness, I hear the same high pitched whine for a split second and the engine rotates - indicating the coil just sent spark to a plug. Doesn't seem right for it to do this. -

So, I was going to try working on jetting of the carbs today. But, unlike the past several weekends, when I went to start the engine cold, it didn't fire. No attempt at trying to fire... I went inside to retrieve the Crane HI6 documentation and see what I could find out. There is a single red led. When I turn the ignition on, it lights up solid. Using the troubleshooting part of the manual, I determine that no fault codes are triggering. I check for spark using my timing light. I get none. The HI6 manual says to crank the engine over and check to see that the led blinks. It just dims a bit when attempting to start but doesn't blink. I check power (red wire) and ground (black wire) to the optical pickup. I confirm power and ground. So... I am thinking the problem is the optical pickup. I read where if the white wire it put to ground, it will trigger the coil. I switch my timing light to the high tension lead from the coil to the center of the distributor cap. I disconnect the optical pickup at it's harness connection - wires (red, black, white) go from this connection to the HI6 control box. I pull the trigger on my timing light and ground the white wire. The timing light flashes, and the led on the HI6 control box goes out. I remove the slotted disk from the distributor shaft. I reconnect the optical pickup at its harness. I hold the disk in one hand and the pickup in the other and simulate the disc rotating within the pickup beam. The light on the HI6 control box stays solid - it doesn't blink like the documentation says it should when cranking. So, the pickup just "went bad", right? Am I supposed to actually see a light beam when the pickup is powered up? Because I don't.

-

I've been working on the jetting of the Mikuni 44's on my engine. Attached is a plot showing RPM and AFR. Here are my notes from that session: 3rd on interstate. Downshifted to third and stabilize RPM (about 4800 RPM) Squeezed throttle slowly until near full throttle, shift to 4th, end recording. I've read that main fuel jet adjusts the fuel mixture at all engine speeds, and main air jet adjusts the mixture at "high" engine speeds. Current settings: Main 180 Air 230 Pilot 57.5 Pump 45 Choke 37 What I am seeing rather consistently in 3rd gear runs like this one is a bump up in the AFR in the 5000-5800 territory...(from steady state AFR I am seeing when on the pilots) which is then followed by a descending AFR trend until I short shift to the next gear. Thoughts? I am just trying to get the jetting "close" so I can make the most of my time at a dyno session.

-

Pop/Chatter doesn't describe it! R200 Nissan LSD - 38420-RS660-US

inline6 replied to inline6's topic in Drivetrain

Thanks for the response John. I'll do as you recommend. -

I drove my car for the first time in a year or two the other day. And, I gotta say, the behavior of the rear driveline is brutal. Let me just say right from the start that I searched through this forum and found all kinds of posts about people complaining of popping and chatter from their CLSD units. Popping and "chatter" doesn't even begin to describe what mine is doing. Some background: I bought this Nissan Clutch type LSD unit (see pic of box with part number below) and installed it in a NOS (New Old Stock) R200 4.11 open differential. It's been about 8 years, so my memory is kind of rusty, but basically, I followed the instructions that came with the carrier... I took the back cover off, removed the bolts holding the stock carrier to the diff, swapped out the ring gear to the LSD unit and put the LSD carrier with ring gear in the diff. The instructions provided a spec for backlash - as long as the backlash was within spec, there was indication that going deeper into the diff (redoing pinion gear shims) was not necessary. I used the fluid which came in a container in the box. This pic (which I found on the web) is the same stuff - Veruspeed 80W-90 synthetic for LSD. My recollection of driving the car with it the first time and to and from a couple of track day events was that it made the rear end jiggle a bit on tight turns but it was not too obnoxious. Fast forward a bit, the car has been sitting for a few years and I get my new engine in it. I take the car for a first drive with the new engine and the rear end behavior is much more severe than I recall. I did Ground Control rear upper camber plates while the engine was being built... and having read about the 300ZXT axle shafts being too long on some of our S30's, I became convinced that that was the new problem. So, I organized a group buy with The Driveshaft Shop and got some shorter custom axles made. Well, I have some engine problems... so fast forward another couple of years to last weekend when I take the car for a drive. So... backing up the car is none too fun. Put it in reverse, rev it up a bit and slip the clutch a lot if you don't want it to shudder like the rear brakes are on... Take a tight left or right turn and the rear binds up badly until Gozilla kicks the ass of the car a couple of inches to the side... Do that two to three times and congrats, you've executed a 90 degree turn at a stop sign. And here is the really odd one. Drive down the road in a straight for miles... and then come to a stop just by using the brakes, (no downshifting) put the clutch in as you come to a stop like normal, say, on a completely flat road. Wait for traffic to clear and as you rev the engine slightly and let the clutch out, the rear has to "unlock" before you can go. This is repeatable every time I stop, even from a straight line... to get going again the driveline shudders upon take off. You can elminate this with lots of clutch slippage... by the way. So, that's basically what is going on. Looking up the specs on the part number, there appears to be little info available as to what this lsd unit is, but best I can tell it is a 2-way Nissan LSD unit with 70 ft/lbs break away pressure. Based on my hybridz searching, my next step will be to check fluid level. I do recall some evidence that fluid escaped the vent when I was checking things over at one of my track day events... After that, I'm considering switching to Redline and adding some friction modifier. Anyone else have experience with this particular LSD unit?