-

Posts

471 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

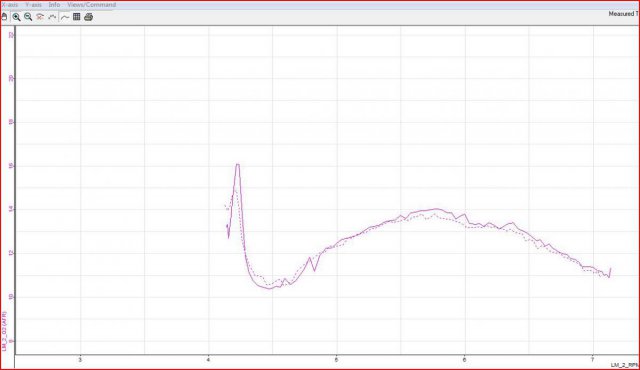

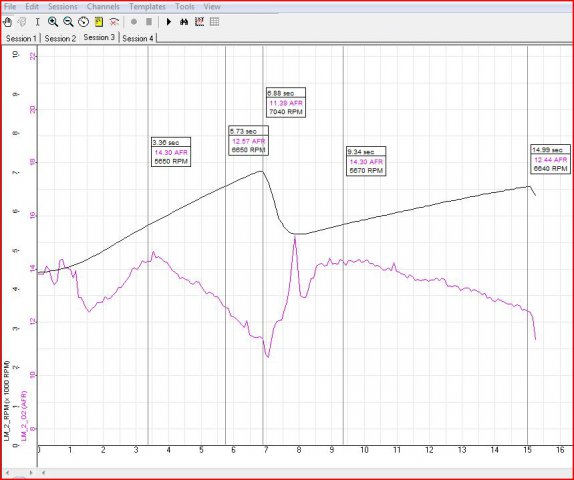

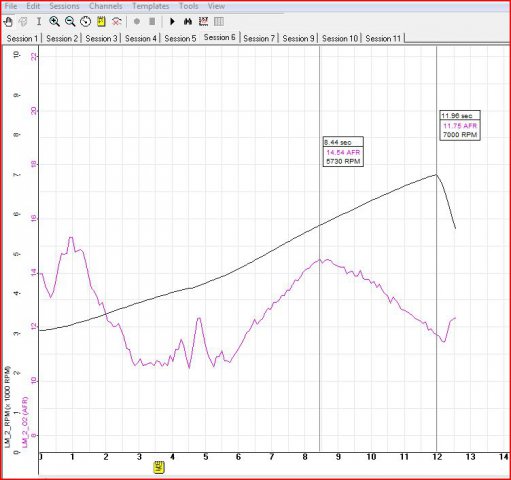

I've been trying to lean out the top end as of late. But, I have found that even substantial size increases has little to no effect in AFR at the high RPM range. For example, here is an AFR vs. RPM plot of the following jet combinations - the dotted line is the run with a 250 air jet: Main 190 Air 250 Pilot 57.5 Pump 50 Choke 37 vs. Air 270 I bought the 270's this past week and tested them this weekend. It seems no matter how high I go, I can't change the AFR at the high end. Here is another plot. This one shows a comparison of a much earlier run when I had 180 Mains and 220 Airs (dotted line), and everything else is the same vs. the latest 190 Mains 270 Airs that are in the car now. This is the problem... I can't get the upper range to lean out. What could be the problem? Are the carbs somehow not getting enough air? -

NA 3.1L=>head & camshaft questions. No shortcuts, max

inline6 replied to zredbaron's topic in Nissan L6 Forum

There is some nice art here - thanks for it. Here is the oil pan that mortensen was speaking of. Seriously consider it. I got one not that long ago... I think 4 to 5 weeks is lead time much cheaper than the Kameari one. The shiny "sliver moon" on the right side of my pic indicates exhaust valve to piston contact. My leak down before and after the chain being off a tooth is the same 2 to 5 % across the cylinders. I think I got lucky, but will have to check again after some more miles to know for sure. -

Any updates?

-

-

Just thought I'd put this out there. In all of my researching on the forums and elsewhere, I have never come across this value. Honsowetz says 1.5. I've seen several mentions of 1.0 in these forums (which is what the Mikuni Manual shows for 40 phh). The Mikuni Manual does indicate 1 1/8 turns out, however. G

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

inline6 replied to zredbaron's topic in Nissan L6 Forum

On my engine, I believe the Kameari tensioner will allow the chain to loosen enough to slip one tooth on the crankshaft gear sprocket. That happened to me recently (though I pulled the upper tensioner part out completely when this happened). The car wouldn't rev right and the engine was louder. I was thinking that the valve adjustment had gone out of wack, so I tightened up the clearances a couple of thousandths. However, that made the noise worse - so I shut it down. I bought a bore scope and found that the exhaust valves were tapping the pistons. That and recently messing with the tensioner led me to suspect the cam timing was messed up - which is what the problem was. Here is a pic of the bore scope LCD screen: Any changes with the tensioner that might have allowed the chain to slip a tooth? G -

NA 3.1L=>head & camshaft questions. No shortcuts, max

inline6 replied to zredbaron's topic in Nissan L6 Forum

I've had cars that burned oil in the past. At 500 miles per quart it becomes very noticeable. How much oil was actually left? At several quarts per 100 miles, there really will be a constant smoke screen. I think you can rule burning it out - also, go to rear of the car and check the rear panel... if it was burning it, there is going to be tiny oil droplets all over the entire panel. A leak of some sort is far more likely... to lose that much oil in that brief a period of time. Look under the car from the engine back for evidence of any leakage. That much oil leaking is going to coat some portion of the underside of the car. The coolant system couldn't take on that much oil either. I think the entire capacity is like a little over two gallons... Easy enough to check if there is oil in the coolant. Just drain and examine. I have the kameari chain tensioner. When it is too tight, it does make more noise, but you really can't put any significant load on the engine by having it too tight. Cross that one off. Very sorry that this happened. Do what you can to distract yourself from it... until the emotional part dies down. Don't dwell in it. You'll get it back to where you want it to be. Just watched the video. Are you running an open exhaust? -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

I just rediscovered this suggestion from you last night while reading back through this thread - it helps to have all of this info in one place to see where I have been and to hopefully inform where to go next. I am playing with AFR vs. RPM. Will see if I can get some plots together. -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

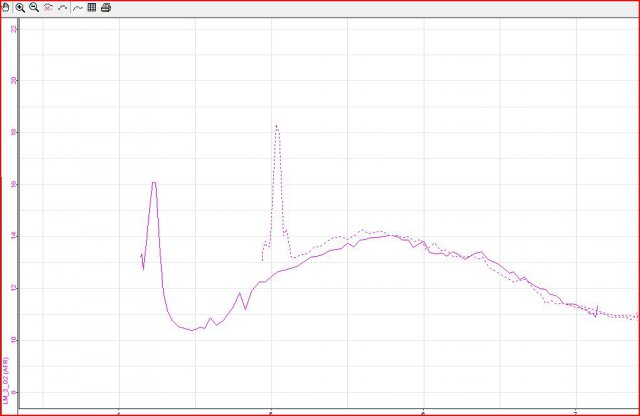

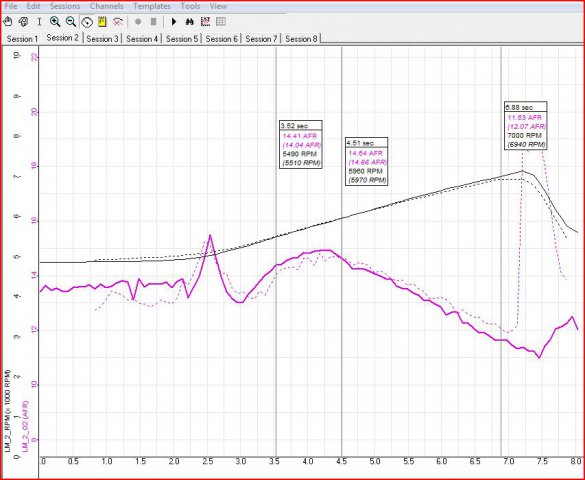

Spent the time to adjust the accelerator pump lever throws to the Mikuni manual spec. - 7.5 mm. They were about 4 to 5 mm prior to doing so. I went out after that change and got new baseline curves. That is the solid line in the plot below. Interestingly, my lean spike at WOT is back now. What I had in the carbs for the baseline: Main 185 Air 250 Pilot 57.5 Pump 50 Choke 37 Also in the plot are the dotted lines which is the change to 190 mains after recording new baselines (no other changes): No matter what jets I throw at this thing, I can't get that hump in the middle hammered down. Stepping up the size of the mains is making the curve richer for the entire RPM test range. While the bump in the middle shrinks, the AFR at the ends - just after WOT and full throttle above 7000, also descends. Combo in the car is now: Main 190 Air 250 Pilot 57.5 Pump 50 Choke 37 I am pretty far outside any other jet combo for Mikuni 44's than I have seen for any other 6 cyl. Z engine. Seems like I have something weird going on... wish I could identify it. Need to start thinking outside the box. Maybe I should revisit my cold air intake system... or maybe I have some weird fuel pressure fluctuations as RPMs change... -

Since I've been having various issues trying to tune my Mikunis for a new engine, I decided to check my pump lever stroke measurement - this is something that I did not check when I put the carbs on the car. The Mikuni manual clearly shows that the pump lever is supposed to move 7.5 mm when a cotter pin is used in the center of the three holes on the rod - for 44 PHH carbs. With the carbs still on the car, I used my borescope and a piece of stiff wire with the 7.5 mm measurement clearly marked on it. Operating the linkage to full open, I saw the pump lever move about half the 7.5 mm distance. Now, two of my Mikuni carbs were near new when I bought them, and one is obviously a bit older. However, all three of them have about 3-4 mm of stroke instead of the factory spec. The spec being off, especially for the new carbs is really surprising. I can't believe it... and then the older carb was set the same. I even have another rebuilt one laying around, and I checked that one too. It had about 4.5 mm of stroke. Is there a chance that factory manual is incorrect? Anyone else ever gone through the trouble to check their pump lever stroke dimension? I have now pulled each of the three carbs off the car and am proceeding with setting the rod such that the pump lever travel is 7.5 mm when the linkage is operated (using cotter pin in middle hole). I hope I am not making a mistake because its a pain to go through all of this for a misprint.

-

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

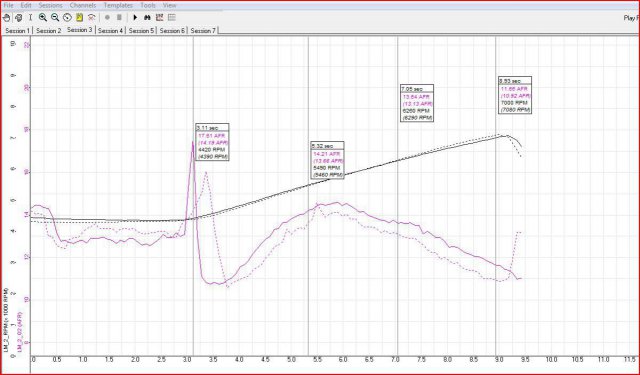

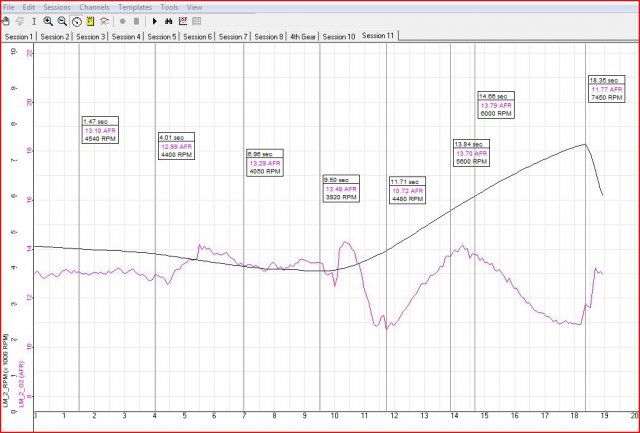

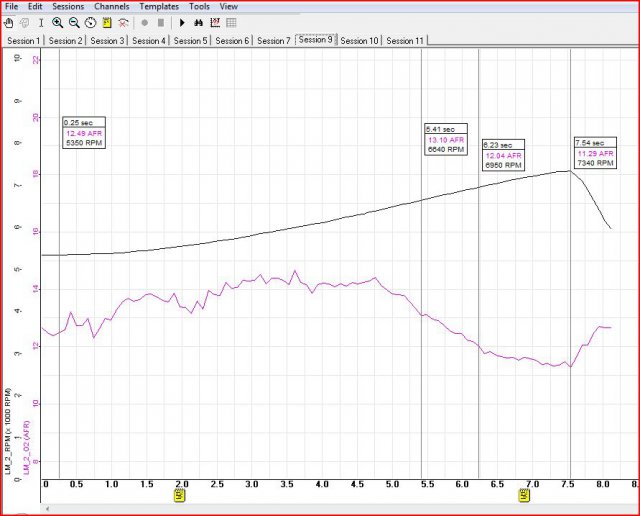

I managed to get a few runs in despite the rain showers. One goal for today was to check to see if tightening down the intake manifold and header nuts changed anything. I saw essentially no change due to that. Next, I discovered that the front carb was being held to the manifold by only the top two nuts. It took me forever scrounging around my boxes of Nissan hardware to find a couple of 8 X 1.0 mm nuts for the carb isolator studs - what an uncommon size! I also changed out the pumps to 50's because I have seen that anything less causes a spike on full open throttle for the tuning runs I have been doing. Here is a comparison of 45's to 50's: The brief "jump" to lean at WOT, is essentially gone with the 50's. This is a run in both 3rd and 4th: It's not exactly easy to see, but the AFR curve is actually very consistent - just compare the same RPM in 3rd vs. 4th. As you can see with the stat markers I have, it doesn't matter what gear, the curve is essentially the same. I've logged a large number or 3rd and 4th gear pulls now, and I have overlayed them and compared the differences. Right now I have this combination in the car: Main 185 Air 250 Pilot 57.5 Pump 50 Choke 37 By looking at 3rd in this chart, all I am dealing with is revealed. Even with many main fuel and air correction jet combinations, the shape of this curve generally does not change. I have low 14's at steady state cruise 3100 RPM in 5th. I have low 13's at steady state 4600 RPM in 3rd. I can snap open the throttle at 4600 RPM in third without a lean spike. The AFR drops very briefly to low 12's, then climbs. It crosses over to the 13's around 5200 RPM. 5800 RPM is often the peak in lean AFR around and is about 14.4. Then AFR turns downward again. I don't see below 13 until about 6500 RPM. AFR keeps marching downward linearly from there until about 7000 RPM - where it hits low 11's. It does pretty much level off right at 11... I have rarely been going much above 7200 for now. Since low 12's for WOT through the power band of this cam is the goal, my next move will be to throw some 190 main jets in. 250 airs are as big as I own at the moment, but it looks like I'm going to need to buy something bigger. 300 airs is the largest size - I am at 250 now. Perhaps I need to start thinking about some larger outer venturis to reduce the "pull" on the aux venturi. -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

That makes a huge difference. If I squeeze the throttle, AFR on the screen of the LM-2 doesn't go as low, and the engine doesn't misfire. I have to squeeze slower in higher gears vs. lower (4th vs. 3rd specifically - I haven't even tried full throttle in the .745 overdrive in 5th anytime recently). I have to squeeze slower at lower RPMs vs. higher. Anything over around 4500 RPM right now, even in fourth, and I can snap the throttle open and I am ok, meaning I don't get the low to mid 10s and perceived misfire - the AFR still drops into the low 11's initially though. Haven't done that yet. I can put it on the agenda for this weekend. Bummer is I have to travel about 6 miles through stop and go to get to my "test area" on the interstate. I could schedule another dyno session. I've got an R200 4.11 in the car. Here is another plot from when I had the best set up in the car thus far. Because the tune was improved with the change I made for this run, I decided to snap open the throttle at lower RPM in third than I had been doing - to test that issue. I eased off until I was around 4k instead of 5k, and quickly went WOT. -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

I started out thinking I could tune these carbs for "acceptable" AFR with full throttle application in 4th gear from 1200-7700 RPM... even with this big cam. Right now, I can't use full throttle at below 4000 RPM in 4th without a dive of the AFR to mid 10s along with experiencing what I perceive to be engine misfire. The taller the gear, the more prevalent this issue is. If I am in first, it isn't a problem. My understanding is that I am a still a long way from what I can yet achieve with these carbs (and my specific engine) from a tuning standpoint. But, yeah, I am starting to realize that I won't be able to achieve the original goal until I switch to the Tec GT and the TWM fuel injection. -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

I'd like to think I can figure it out, but I am wondering if my cam and my intake as well as cylinder head porting haven't made that too tall of task for the limited action of swapping out jets. I also could be experiencing some reversion... I'm going to try to get the AFR curve from 3500 RPM up to be "right" and then see where I am with full throttle dumps at 1200 RPM (that is as low as I go - it is my idle speed for this cam) up. -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

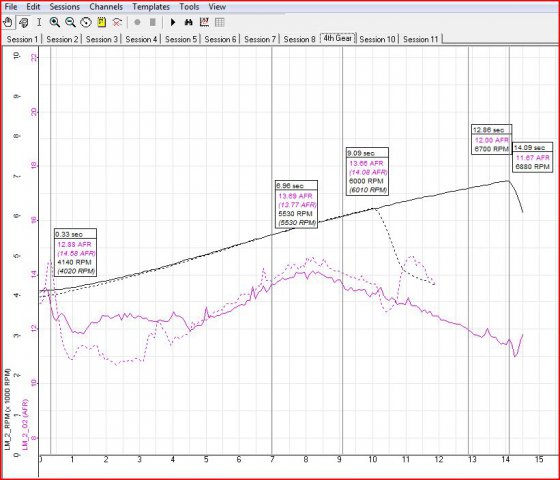

I was able to work on the tuning some more yesterday. I started the day with: Main 180 Air 250 Pilot 57.5 Pump 45 Choke 37 Last change was going from 240 to 250 air correction to try to produce a leaner AFR above 6700 RPM. Here is what actually happened - the dotted line is the previous run with 240 airs - the solid line is the current run with 250 airs, both are in 3rd gear: Interesting that the bigger air jet caused the range between 5300 and 6000 to lean out more while causing the range from 6000 up to get richer. Isn't that the opposite of what you'd expect? Because the AFRs were at or above 13 for all of the graphed RPM range except above 6600, I decided to try upping the mains another step to 185: The dotted lines are the 180s from the previous run. Only the mains were changed - again in 3rd gear. The AFRs were made richer across the test RPM range. Here is a comparison of two 4th gear runs. The runs differ only in that the prior run (dotted lines) had 180 mains. This run has 185 mains: Interestingly, when I went to full throttle on the 185 mains run, AFR didn't dive into the 10's as has typically been the case. I am more conscious of the problem, however, so it may just be that I am squeezing to full throttle over a couple of seconds instead of snapping to full throttle. Since going with the bigger 250 airs richened the top end and leaned what has been consistently the leanest RPM area on many plots, I'm thinking the next step will be to lower the airs to something like 230. My prediction is that my plot will flatten out - richer in the 5300 - 6000 range and leaner in the 6000 plus range. But first, I'm going to tighten up the manifold nuts. I may have some slight leakage at the header, and I want to be sure that is not the case. I'll do that and make a plot run. If nothing has changed, then I will change to the 230 airs and see what happens. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

Well... you are onto something there. Years ago, I had a Datsun 510 that I put a 490" / 290 cam in. I think it is in the How to HotRod your Datsun book that any lifts over .490" require the addition of an external spray bar for the l series 4 cylinders... (I don't feel like taking the time to double check the specifics right now). Anyway, I had the cam in the car and it was fine. But on a trip back home (college days) I spent some extended time at 100+ miles per hour, and when I got home I had one wiped lobe (around number 5 or 6). Tom Howen (friend and co-conspirator of David Weber of Malvern Racing Fame) put it in his "varsol" tank and shot the fluid through the cam bolt hole and observed the flow. It became obvious in an instant that the location of the oiling hole for the lobe that wiped was 180 degrees from optimum placement. So, on the new cam that went in, only one mod was made - Tom set it up in his mill and drilled straight through the oil hole in the lobe that had failed. Thus, that one lobe had two oiling holes, and the cam was unmodified otherwise from the previous one. I had no issues ever again - and I beat on that car mercilessly. So, you could absolutely "fix" a lot or improve things substantially by better placement of the oiling holes. That said, I do recall someone saying that oil "spray" from a spray bar in addition to cam oiling helps cool valve springs which will extend their life. FWIW. No, I haven't primed without the bar. And, I am not running a cooler, but I do have a competition pan from DP Racing. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

I don't have a pic, but I do have a video showing it rather well. -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

Just came across this thread which discusses reversion. Kind of seems like what I am experiencing. Darn it. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

Yikes! I am sorry that happened... it's disheartening when stuff like this happens. I did ditch the Nissan spray bar - I have a Rebello unit now. As often as I am taking off the valve cover, I think I'll be putting some red loctite on those bolts this very next time! -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

I don't know if I buy the argument that these carbs can't be tuned to work across the entire engine range. TonyD has repeatedly chimed in on many threads. He is saying that it can be done - it is just harder. From another perspective entirely, when folks go to the dyno, at the end of the day, they can typically take home some kind of chart that has a full RPM sweep with max torque and max hp. I'd have to concede that with my engine combo, I wouldn't be able to do that. I'd have to settle for a curve from like 4000 to 7700. I don't think I'm ready do that yet. Regarding too big on airs: per the Mikuni Service Manual, air correction jets affect "the flow of fuel mainly at medium and high-speed...". Because my AFR is dropping to low 12s or high 11s right now at the highest RPM range for this engine (6900 - 7400, with redline supposed to be 7700 - I just haven't gone that high yet), and larger air correction jets lean out the mixture, then I should actually be going with bigger air correction jets, not smaller ones to try to raise AFR a bit at this engine speed range. Hmmm... I don't know. As long as I can put more fuel in with "bigger" main fuel jets and with "bigger" air correction jets (speaking relatively here) and still achieve a "power" target AFR, then I should be making more power vs. "smaller" main fuel jets and "smaller" air correction jets, right?. Even if I do give up on tuning for full throttle at below 3000 RPM, I wouldn't go with smaller mains and airs at this point because my AFRs are not too rich at middle engine speeds. I mean, I am currently seeing above 14s from 5700 to 6500... and above 13s from 5400 to 6700. That is too high for good power. If I did go smaller, I'd experience lower total power output and probably an increase in fuel economy. But, that is not really the goal. Actually, I already did this while at the dyno a couple of weekends ago - with the caveat that the cam timing was off, I know. But, I changed the main and airs to be much smaller several times, trying to eliminate "rich" completely - trying to get to a "too lean" condition. Basically, as I went down in size, a "hump of leaness" became more and more prevalent in the mid-range RPMs, and I still was not able to get rid of the 10s at snap open throttle and low RPMs. You can see more detail about those runs on the dyno in this forum thread if you would like. Yes the cam was mis-timed, but I don't think that the general behavior vs. correctly timed would be completely different. In other words, if correctly timed, I believe the overall trends I experienced would be the same... just different RPM points would be in play. You may be right, however, I'm not willing to give up just yet. -

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

inline6 replied to inline6's topic in Fuel Delivery

Ha ha! It's been two more years, and I am finally back to tuning. I've been through a ridiculous amount of hassle with the engine, but hopefully I am past all bad stuff. Those issues are detailed in other threads however. So... I've been reading and re-reading Mikuni tuning info in the forums and thinking about how these Mikunis work - at times with spare disassembled carb in hand. First, a description/re-iteration and some story telling of things using a hypothetical situation: I'm on the chassis dyno in 4th gear with the engine turning say, 2000 RPM. The throttle plates on the Mikunis aren't open much to do this, so the carbs are running entirely on the pilot circuit. The pilot circuit is drawing fuel from the same fuel source as the mains... up through the jet block holder - my Mikuni carbs have separate "pipes" for the pilots than those of the mains. Air for the pilot circuit is drawn from fixed diameter holes in the top of the jet block. Air and fuel are mixed together within the pilot jet. Downstream of the pilot jet, the air fuel mixture is traveling, again in a separate pipe. This pipe travels out of the jet block, along the top of the throat of the carb, crosses over top of 4 bypass holes on the front side of the throttle plate, and one more hole on the backside of the throttle plate. At 2000 RPM, with the throttle plate is open maybe 5-10%, there is no fuel/air mixture coming out of the auxiliary venturi. There is a high degree of vacuum in the manifold (9" mercury), as the throttle plates are near shut. The six pistons going up and down at 2000 RPM are causing some major sucking at the backsides of the throttle plates. This is drawing the fuel from the pilot system. The only fuel mixture feeding the engine is coming from the pilot screw outlet hole (backside of throttle plate) and perhaps some of the bypass holes (in front of the throttle plate). The pilot screws are set at exactly 1.5 turns out and the wideband AFR is showing 14.4 (air to fuel). Now, I slap the throttle to the floor as fast as it will go. The throttle plates jumps to wide-the-frick open. What previously was major sucking at the backsides of the throttle plates now becomes nearly no sucking at all temporarily (0" mercury). Without the sucking the pilot circuit goes basically dead... and a massive glob of air leaps towards the pistons - partly drawn by the pistons jumping up and down in their bores at 2000 RPM. Though it looks like a lean fire in the cylinders is imminent, there is also this stream of fuel that was launched from the pump nozzle right when I started to slap the gas pedal down. Per the Mikuni manual, once the throttle was open 30%, no more fuel was added to the pump circuit, but the stream (which is suspended in Matrix "bullet time" animation at the moment) will last as long as it takes for the fixed volume of fuel to pass through the hole size in the pump nozzle as dictated by the properties of physics (fluid mechanics specifically). This stream is meant to keep the flames alight when the glob of air gets into the combustion chambers... and until the separate and new supply (a guyser really) of air/fuel mixture can be mustered to come forth from the main circuit. Now... The main circuit is a bit different in design. There is basically this big, brass screw (jet block) in the jet block holder. At the bottom the jet block is another screw with a hole in it. This main jet is totally immersed in the gas within the carb float chamber. The hole meters the flow rate of the fuel from the chamber. At the top of the jet block is another screw with a hole in it. The air corrector jet is totally above the gas in the carb float chamber. The hole in the air corrector meters the flow rate of the air which comes from outside the carb body, through channeling in the float chamber cover and into the jet block area, above the fuel. At 2000 RPM, the pistons are jumping up and down, the stream of fuel slips into the glob of air headed for the combustion chamber. As the first bit of fuel from the nozzle gets consumed by the voracious pistons, they speed up a hair. Additionally, the pipeline of air from the cold air intake to the combustion chamber starts to get a move on. The part of this air that passes through the auxiliary venturi speeds up relative the to air around the outside of the aux. venturi. The air passing by a hole in the aux. venturi creates a "depression", which in turns "draws" on the main circuit. The fuel level in the float chamber is sitting a touch lower than waist high on the jet block. As the vacuum builds from in the aux. venturi, the "negative pressure" sucks the fuel higher within the jet block hole. Fuel travels through the main jet, then through 4 ovalized holes in the bottom of the jet block and works its way up around the sides of the jet block. At the same time, air is drawn in through the hole in the air corrector jet... down into the jet block. It exits via 8 small holes around the periphery of the jet block. These holes are above the correctly set fuel level in the float chamber. The main and the air corrector inputs work together to set the mixture of air and fuel that is drawn up high enough in the jet block hole to where it has reached the exit of the jet block holder hole - the pathway to the aux. venturi is downhill from here. We are nearly to the question of the post now - don't stop me, I'm on a roll! The guyser of fuel now enters the aux. venturi where it is met at 90 degrees by a screaming banshee of air. It smashes into the fuel constantly... turning it into a spray of bazillions of droplets. This new source of air/fuel mixture then makes its way to the combustion chamber. AND... wait for it... Upon first being consumed, the AFR turns sharply downward to around 10.8 (which causes me much stress, as well as washes away the nice protective layer of oil that should be on the cylinder walls). Now, I will admit that for this one run, I saw the 10s and let the throttle off the floor to allow recovery, but by 6.5 seconds I've been back into it, the pumps are outta the picture for sure. Jetting at the time was: Main 180 Air 240 (up from the 220) Pilot 57.5 Pump 40 Choke 37 This is really the opposite of what should be happening. What could cause the AFR to go very rich just after a full throttle snap-open situation such as this? One obvious answer might be "too rich, go smaller on main jet", but the rest of the run isn't indicating crazy rich at all. Another potential answer: "go smaller on the pumps". Well, the chart already is showing that upon initial throttle application, the mixture goes lean for about a second (centered at 1 second). Full throttle, not much depression to pull on the aux. venturis... a big cam that doesn't pull air through the intake a lower engine speeds... How does this translate to "hard pull" on the mains... providing an overly rich mixture? Here is another run a few moments later, also in third. I start at much higher engine speed to avoid the low speed, throttle dump problem. Pumps are done within the first second or so... the AFR climbs into the 14's from 5700 to 6400... then marches down to ~12 at 7000, where it levels off quite a bit. Sure doesn't look crazy rich in this rpm zone! Ideas? Could something be going on with the air supply channel - where the air correctors draw their air from? I am running a cold air box... I did remove the air filter for one of my runs on the dyno two weeks ago - it had no noticeable effect. Based on these charts, I've got 250 airs in the car, ready for the next run. That's where I am for now. -

Here are the specs on the short block. The engine was to be a 3.0 stroker, but sonic testing the walls of the block revealed that we should only bore out to 88 mm and not 89 mm. The rods are about 8 mm longer than stock (but around 180 grams lighter) and the crank was offset ground (and lightened) to increase the stroke to 80.391 mm instead of the stock 280z's 79 mm... vs. the diesel crankshaft's 83 mm. Pistons are custom JE forged units to provide 11 to 1 compression ratio with the larger bores, longer stroke, and longer rods. Head is an E88 that has been milled over .100" to reduce combustion chamber size and to attempt to get "some" quench. If I had it to do again, I'd weld up the chambers and then make them custom to run with flat top, forged pistons... to get the 11 to 1 compression ratio. Cam specs are: Intake Seat duration 320 degrees .050" duration 290 degrees Valve lift with zero lash .565" Net valve lift .550" Exhaust Seat duration 315 degrees .050" duration 274.8 degrees Valve lift with zero lash = .565" Net valve lift =.550" This cam uses an unusual single valve spring instead of an inner and outer. The installed load is only ~ 60 lbs on the seat. At max lift, the load is only about 190 lbs. Max RPM is 7700. I am using titanium retainers. Carbs are Mikuni 44 PHH (sidedraft) with 37 mm chokes. Header is a Nissan Comp unit with 1 3/4" primaries...twin outlet to a merge collector, followed by a 3" custom stainless exhaust. Here is my engine build thread on hybridz if you want to read in more detail: Thanks!

-

I've been successful in working through a spate of problems... and for now, the new engine is running pretty well. When I got back from logging some Air Fuel Ratio runs, I captured a short video of the new engine sound. Sorry the sound quality isn't great - I think a lot of reverb is coming from being in the garage, but the picture quality is nice The cam is a Kinetic Sunbelt grind. Exhaust is 3" with two round mufflers, one in the tunnel and one at the back.

-

Well... I found a big problem... Last Sunday, I decided to verify that the vacuum advance was working correctly. I disconnected it and ran the engine with a timing light, and was surprised to see very little movement. I decided to take apart, clean and lube the appropriate areas of the advance mechanisms in the distributor, as well as verify the vacuum advance was working. Afterwards, I was amazed to see that it did make a difference - I got a few more degrees of ignition advance from it. I reset the timing to only provide a max of ~ 34 degrees BTDC. After doing this, I took the car for a short drive. The engine was making a fair amount of noise... It had been since I took it to the dyno, and while I had been trying to say it was just my imagination, I decided it really wasn't. It really was making a lot of noise and it sounded like it was coming from the valve train. I checked the cam and rockers... everything looked great. I checked my valve lash, and found several to be .4 mm which is like 16 thou, so I tightened all of them up to .012". When I started the car, the noise seemed even louder, if that is possible. I ran it less than a minute. And, I shut it down in disgust. Not knowing what was messed up, I decided to do a leak down test. I got percentage loss for 1-6 of: 4,5,3,2,2,4. I then tried to see inside the spark plug holes to examine the bore walls. I saw a vertical mark or two, so I decided to buy a "borescope" and take a detailed look inside the bores. That cam on Thursday, and with it I was able to see quite a bit more. And what I did see looked like shiny have moons in the exhaust valve reliefs on the tops of about 3 of the pistons! That got me thinking... valves hitting pistons would cause LOTS of noise. And just before I took the car to the dyno, I had removed the Kameari cam chain tensioner to check into some unusual noise it seemed to be making. It turned out to that it just wasn't quite tight enough - there was nothing wrong with it. But, maybe I screwed up the cam timing when I took it off? A check of my cam timing was next. I was able to find the time to do that today... and sure enough, it was wrong. My timing chain had slipped one tooth on the crank sprocket when I was messing with it. That retarded the cam 18 degrees, (20 tooth sprocket - 360 degrees), however my adjustable cam gear is set advanced by 3 degrees. So, the net amount it was retarded was 15 degrees. And in that state, I went to the dyno last Saturday! Again using my Borescope, I ran the camera down the front cover of the engine. I was able to jiggle the chain to change it's position on the crank shaft and verify it with the camera. With the marked lower and upper timing chain links aligned properly with the lower sprocket and the cam gear, I started the engine. And the "clacking" - the noise was gone. Go figure, huh? I took the car for a brief spin tonight and MAAAAAN, what a difference. The power is soooo much better. And, I am not sure why, but the AFR's are much improved at lower RPM and heavy throttle inputs. I even tried what before would produce 10's, and could not! Next tuning session will be interesting. When I got back, I did another leak down test. This time the engine was warmer, and from 1 through 6, I got percentage losses of: 3,4,3,4,2,3. Now, I will get back to tuning. Hopefully, no problems crop up in the coming days or weeks related to the valves hitting the pistons. We shall see.

-

Yes, that makes alot of sense. It is just half a millimeter, but I had a few thoughts about this. First, siphon action is what delivers the fuel to the auxiliary venturi. Logically, a "very low" level of fuel will require more siphoning "action" to pull the fuel than a "very high" level. I'm guessing that siphoning action difference between these two different levels can be compensated for via changes to the jetting, but I do not know this. When I attempted to set my fuel level to the Honsowetz spec, I actually used a section of wire that was .815" instead of .826", because my attempt to mark it was a bit off. That resulted in a fuel level that was .032" "high" vs. the .847". It is still within the +/- 1 mm range in the manual, but given the problem I'm having, I'd rather be on the low side than the high side. In my particular circumstance, I am experiencing AFR's in the low to mid 10's across a very wide range of main fuel jets. Right now, with main fuel jets of 130s to 180s, I get 10's when I apply fuel throttle at low rpms (I do this in such a manner that I can rule out the pump nozzles being the culprit). So, my "high" fuel level may not be part of my problem, but I'm going to set the level to ~ .847" below the jet hole surface, and see if it helps the problem I am having at all.