-

Posts

471 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

The detail for attempts 1 to 5 respectively: Attempt #1: Sunbelt cam - New - made from Estas cam blank which is a "chilled casting" and Nitrided OEM Nissan rocker arms - New - came in Nissan boxes - bought on eBay Mobil 1 full synthetic 10W-30 Attempt #2: Sunbelt cam - Used/Polished (same cam as attempt 1) - Still Nitrided OEM Nissan rocker arms - Reground by Delta Camshafts Mobil 1 full synthetic 10W-30 Attempt #3: Sunbelt cam - New - made from Estas cam blank which is a "chilled casting" - Not Nitrided OEM Nissan rocker arms - Reground by Delta Camshafts Redline synthetic 10W-30 Attempt #4: Reground by Cam Grinder who originally made the cam (same cam as attempt 3) - Not Nitrided OEM Nissan rocker arms - Reground by Delta Camshafts Redline synthetic 10W-30 Attempt #5: Reground by Cam Grinder who originally made the cam (same cam as attempt 3 and 4) - Not Nitrided OEM Nissan rocker arms - Reground by Delta Camshafts Brad Penn Racing - Break in Oil - 30 weight -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

Interesting set up! I can't really see anything spraying... it just looks like each lobe has a narrow band of oil on it at all times. Were you able to see how long it took from start until oil flowed from the journals? Could you verify that the spray bar was contributing anything at idle speed? Maybe I should do the same... -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

I'd be interested in seeing a video of that. Probably becomes a mess once oil starts flowing out of the cam, but it would be interesting to see how long that takes... at like 40 degrees for example. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

I hadn't learned that I needed to install a pump that had been filled. I never had any issues before... and I have always installed them dry in the past. For the record, I've done 5 attempts: attempt one - new, nitrided cam, possibly a dry oil pump - my engine builder installed it. attempt two - polished journals on used nitrided cam, reground rockers. Oil pump did not come off - it was not dry attempt three - new cam, reground rockers, oil pump did not come off - it was not dry attempt four - reground new cam, reground rockers, possibly a dry oil pump - my engine builder installed it - pressure kit installed on oil temp sender before start up, most likely back-filled pump. attempt five - the most recent - pump was not dry My cam is a Sunbelt cam made with an Estas blank. It probably doesn't need break in either. I just wanted to run it at some RPMs that were high enough beyond "Idle speed" that psi would be up. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

Ah... I see what you are saying. The pump is not dry... you are just turning off the engine, and the next time you start, you get it up to 2000 quickly rather than just start and idle. Ok... good to know. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

Given my past experiences, I am conflicted about jumping right to 2000 RPM. I understand that with spinning the engine faster, the pump primes faster. But, the faster lobe rotation without oil flowing for a few seconds (this is assumed, not measured) scares me. Given that the oil has to "follow the tortured path" inside the block, head, cam, etc., as my engine builder likes to call it, the unknown is just how long it takes to get oil to the cam under the different scenarios. Obviously, you are not seeing any priming at 800. Do you put oil in your pump before you install it? On the attempt before last, when I used the pressure kit, the engine fired on the first try. It coughed and stuttered for the first 5 seconds, but by second 6 or 7, revs reached north of 1500 and I started rolling the throttle to try to keep between 2000 and 2800 RPM (I have a video of this start up session). The rockers/cam had the most damage of any prior attempt that time around. For that session, I had not primed the oil pump. I had not put any oil inside it and it was dry, as it had been off the car during the engine tear down and inspection. I didn't learn the lessen that my dry oil pump wouldn't prime until after that attempt. After that attempt, I took the pump apart to check that everything was ok there. I put it back on the car dry. Using my fake aluminum shaft, I tried repeatedly to get oil to the cam and couldn't. Even with the drill at full speed for something like 10 seconds, I got no oil to the cam at all. When I pulled the pump off, it had no oil in it. I was only successful with the drill and fake shaft after I filled the pump with oil before re-installing. It could very well be. I'm glad I found these new ones with help from Zredbaron. My engine builder liked them a lot more. He said they were much more consistent across the 12 as far as lb rate specs at important measured heights. And using an installed height micrometer I was able to juggle valve spring shims to get installed heights within .001" of the necessary installed height spec for each. -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

They look fine to me... -

New Cam and Rockers - odd looking at 500+ miles

inline6 replied to inline6's topic in Nissan L6 Forum

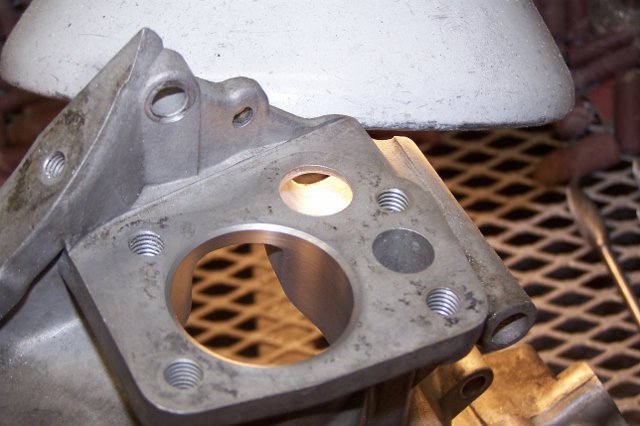

So, there has been a long silence because I damaged the cam a third time on fire up weeks ago. Yes, for a third time. Things changed for the third attempt were: Block sent to engine builder, dissembled, everything checked, only change was a touch up hone There were no blockages Cylinder head galleys checked for blockages. There were none - I cleaned them while I was there. Cylinder head oil supply hole opened up to .125" Nissan Comp head gasket opened a touch at Cylinder head supply hole for correction of alignment Brad Penn 30 wt break in oil - high zinc content Red line assembly lube on cam lobes Use of pressure oiling kit to blast oil through all oil galleys just before startup Rebello camshaft spray bar - I replaced the factory oil spray bar Same induction set up - everything adjusted as prior, when engine last ran - assures quick initial start up I hooked up the pressure tank to the oil sender location on the block. Opened the valve until I saw oil come out of the cam lobe that can be seen with the oil cap off. I closed the valve, removed the tank supply line from the block, put the oil pressure sender back on, and sprayed a touch of starter fluid in the carb air horns. The engine fired immediately. I ran it only for four minutes, pulled the valve cover, and most of the rocker pads had deposited some of their pad material onto the cam lobes. Third time was not a charm. Sent cam off for repairs (again). Sent rockers off for repairs (again). Received rockers back from Delta, 10 of 12 were good. Two had to be sent back. One of those came back good, one was about .013" out of plane with the rocker tip surface and had to be sent back again (this was like regrind four, or five, or six on this one - I lost count). Many hundreds of dollars later... I made a shaft out of 1/2 inch diam aluminum from Home Depot. I modded it to the fit the oil pump so I could drive the pump with a drill from above the distributor mount location. I tested that out with a dry oil pump. Despite repeated tries, oil never flowed. Don't ever put a dry oil pump on your l series. I then put some oil in the pump through the inlet/outlet holes and re-installed the pump with my "fake" shaft. I attached the drill and then squeezed the trigger to run the drill slowly. Wait for it (drill still running) wait for it... drill still running... and finally here comes the oil out of the cam and the Rebello spray bar. You can see a video of this here: https://www.youtube.com/watch?v=pzW6H88qWF4 It is scary how long it takes for oil to start coming out of this cam. Today, I very carefully went about getting the engine started. The changes from last time were: Use of a block heater (a heating pad my engine builder sent to me) to heat Brad Penn 30 wt oil prior to starting - shop temperature was only something like 50 degrees Don Potter oil pump spring kit for oil pump bypass. Only one washer installed for maximum oil pressure kit supplies New valve springs which allow .050" to coil bind instead of the old ones which were around .028" to coil bind. Moly oil lube used on cam lobes Rocker arms left off, spark plugs out, for initial attempt to get oil to come from cam. Once the oil was up to very warm temperature, with the oil pump and the real oil pump shaft installed, and with the rockers left uninstalled and the spark plugs not installed, I turned the engine over with the starter. I did this tentatively at first. First just a few seconds. Then again, a little longer. Then a little longer... until I finally had some oil come out of the camshaft lobe holes. Next, I installed the rockers and adjusted them to .015" clearance (both intake and exhaust) per cam manufacturer. I poured the Moly lube/oil onto each of the cam lobes. Again, I turned the engine over with the starter. And again, I did it tentatively. I checked camshaft lobes and rocker arm pad for any issues. I re-lubed the cam lobes between attempts as I progressively increased the amount of time of engaging the starter. I did this until I finally got some oil to come out of the cam lobes. Even with a fully pre-lubed engine... which is left to sit for only a few minutes, my guess is that it takes something like 10 seconds of free spinning the engine (without spark plugs) via the starter (gear reduction one) for oil to come out of the cam! Next, I put the spark plugs in and fired the engine. It fired immediately, and I held RPMs at about 1200 for a minute, and then set the throttle linkage to hold about 2100 RPM for 20 minutes straight. I then shut it down and pulled the rocker cover. There is no damage. However, this thing with oil taking forever to get to the cam is not good. I'm not going to be able to preheat my oil every time I want to start this engine. So, looking back on this whole multi-year ordeal, why did I have this much trouble getting this engine fired without wrecking cams? I am not convinced that I am out of the forest yet. A thought comes to mind. I seem to recall that this cam is "rifle drilled". Could it be that there is more open volume inside this cam that takes longer to fill, and this is contributing to oil starvation during say, the first ten seconds of start up? Next, I'll be replacing the oil filter with a new one. And the very next time I start it, I'll be preheating the oil again, but I will drive the car at least 150 miles or so to try to get a bit of break in. Then, the 30 wt Brad Penn is coming out. I'll replace the filter again and put in Valvoline VR1 Racing 10W30. Going to be researching AccuSump... and looking at other options to get oil to the cam faster. G -

NA 3.1L=>head & camshaft questions. No shortcuts, max

inline6 replied to zredbaron's topic in Nissan L6 Forum

Just wanted to get back to everyone on this thread and let you know that I was able to track down a set of valve springs from Jim Wolf Technology for the Sunbelt Race #2 cam that are perfect. Item number: AVG3E-SPRNG Spring/Shim Set VG30E, VG33E Outer Spring Only, I/H 1.600 80 LB on seat .480" lift max. The "L6" spring is no longer available. I had these new springs sent to my engine builder and he came up with the following measurements on the new springs using a valve spring testing tool: At installed height of 1.690" - 65 lbs. (This is the seat pressure - valve closed) At 1.140" - this is the dimension at .550 max lift (which the Race Cam #2 has) - 195 lbs. Coil Bind occurs at 1.090", or .600 max lift. Thus, with my cam, I have .050" until coil bind with these new springs installed at a height of 1.690". Plus, my engine builder said each of the springs was extremely consistent, whereas the consistency was not as good with the set I received when I originally bought the cam. I am thrilled to have these springs instead of what I had before. Thanks again! G -

Whenever mine did that, I had a way to rich situation, not way too lean... but easy enough to check. Similarly to Tony's point, how is the syncing of the carbs? Ztherapy can't do that - it has to be done on the car.

-

I think you have a fuel delivery problem. The 23 mm measurement for float level in the Factory Workshop Manual (FSM) is from the fuel level with the float sitting in it, to the highest point on the inside of the roof of the float chamber cover. How are you checking that dimension? Since I couldn't determine an effective way, I used a section of a nail cut and then ground to a length of between 14 to 15 mm (the other spec shown in the FSM), and then pulled the SU tops off, used some wire nose pliers to hold the nail in position between metal strip on the float top... to the inside of the roof of the carb cover. I would then adjust the float arm just far enough so that when the float, nail, and top were all "bottomed out", I could not blow air through the fuel inlet pipe (with my mouth). You said you had the advance in the distributor reworked. I would hook up a timing light and spec out your advance functionality so you can verify it is not contributing to the problem. You should be able to see initial advance at idle, and then record advance movement as rpms increase. Full advance (record that amount) will probably be achieved somewhere between 3000 and 3500.

-

OS Giken TC24-BZ1 dyno run from just last month...

-

I am putting together a set of three and would like to find one parts carb with a good body. Prefer to spend $150 ish... so missing parts ok! If you think you have what I am looking for, please reply with pics in post. Thanks in advance. Garrett

-

How does pressure relief valve work in oil pump?

inline6 replied to inline6's topic in Nissan L6 Forum

My engine builder did blueprint the passages - which I was not expecting. I am running the datsun comp oil pan and pick up for now. I've not understood the external pick-up set up when I have looked at pics. I'll be sure to check that out again. -

How does pressure relief valve work in oil pump?

inline6 replied to inline6's topic in Nissan L6 Forum

Thanks Tony. I follow. I guess without the relief, if the shaft speed keeps increasing, the oil pressure would become excessive. I took off the bottom of the oil pump today and saw that that the post on the piston bottoms out on the aluminum casting in such a way as to set the piston top (base of the post) flush with the side of the cavern that oil flows into. I think it is a "depth" setting thing... so the piston doesn't come out too far. I've ordered some of the stiffer springs from Don Potter's widow - she sells them on ebay. Going to play with setting it up to provide 80 psi at high speed since this engine is supposed to get to 7700 RPM some day. On a not so fun side note, I tried using a dummy shaft I made out of 1/2" aluminum and a drill to pump oil through the engine today... ran it a full drill speed repeatedly. Ran counter clockwise, as that is the direction the shaft is supposed to turn, and got no oil flowing at all. Pulled the pump again, and there was no oil in there at all. And yes, when I pulled it to swap shafts, I did put it on there "dry". Guess I won't be putting it back on without filling it with oil ever again. -

Was verifying that the pressure relief valve in my oil pump was installed correctly today, and after confirming how it is assembled, I really don't understand how it works. Can someone explain it to me? Was reading this post: http://forums.hybridz.org/topic/98987-l6-oil-pump-differences/ What do the posts/nipples on the pistons do?

-

Did some searching for options and I see a few things: Taurus fan won't work well unless it is a puller, and won't fit as a puller with the L6. Two 10" fans are not recommended - use 12" instead Anyone have experience with this kit on ebay for $230? I don't know if I just missed it or what, but I don't know the size of these. I also see these Hayden fans at Summit Racing for $165. This pair is rated at a total of 1600 cfm. A video at the Summit Racing site recommends 6 cyl start at 2000 cfm I'm running a Jags that Run radiator - which is a lateral flow oversize 2 core chevy unit of some type. Never had overheating issues, but the new engine is going to turn 7700 rpm some day soon and I really don't want a mechanical fan on it at that point. Engine is likely to have ~ 250 to 260 hp when final tuned... That's where I am to start.

-

I did. I bought the timing gear idler gear setup and an adjustable cam gear from them, back in 2011.

-

Well the 115 hit the lowest it has been since October 2007... Come on Daddy needs some new shiny Kameari parts!

-

Looks like the Yen is at a low compared to the dollar as of late: http://www.bloomberg.com/quote/JPYUSD:CUR Makes those http://www.rhdjapan.com/ prices look a little better. How about a set of Kameari big valves for $400? Of course you'll need the full set of big valve seats to go with them for $215. Don't know if it works, but RetailMeNot has a 10% off coupon code for them too. G

-

LOL, I saw the same ones a day or so ago and sent a note to my friend who is always telling me to "sell that piece of shit" and get something else like a Jag XKE. Well, I sent him a link to those examples and joked that it looked like my piece of shit Z car is starting to command XKE prices (not convertibles of course).

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

inline6 replied to zredbaron's topic in Nissan L6 Forum

Interesting... and wow, more info than I expected you to be able to retrieve. Couple of things to share: Yes, my paperwork said pretty much everything you have in the top half of your post including "use 1W901 one outer spring only". I am, in fact, running one spring only. However, this part of what you shared was not in my documentation: **Note: The exhaust valve spring installed height was 1.650" on race cam #1 and it is now 1.680" on race cam #2. It needs to be installed at 1.680" so that there is .035" clearance between full lift and coil bind. Well... Basically, the 1.680" dimension is the distance from the head surface (where the bottom of the valve spring sits) to the underside of the spring retainer surface. Typically, when you install a valve in the head, put a spring retainer on with the little keepers to hold it in place, and then measure the distance from the valve spring seat to the underside of the retainer, you will see a dimension of greater than the 1.680" - say something around 1.730", for example. To get the 1.680" specified, you place suitable thickness shims on the spring seat. You do this so that when you install the spring, the distance from the bottom of the spring to the top of the spring with the valve closed is 1.680" inches. And at that height, the pressure the valve exerts on the valve seat is supposed to be 54 lbf. And again, per the specs, when the cam lobe is in the position of max valve lift off of the seat, the "open pressure", or the amount of force the spring is "pushing back" is 193 lbf. And here is the issue in a nutshell... If I were to set up my springs (those Sunbelt sent me) at the previously mentioned 1.680" installed height, then with my (and your) cam which has .550" lift, as the cam rotates around, and it actuates the rocker, and it compresses the valve spring assembly by .550", then at that max lift (which is the same as max spring compression), the spring compresses from 1.680"... minus the .550"... which results in a fully compressed height of 1.130". The big problem here is that by my engine builder's physical measurement, my springs stack solid at 1.132". They cannot compress any further than that - they cannot compress to 1.130". So... to buy a small amount of room, he installed my springs at 1.710" installed height. At that distance... minus the .550", I get 1.160", or .028" before stacking solid. My engine builder also measured 56 lbf at that installed height and 190 lbf at .550" lift (which is pretty close to the specs Integral Cams provided). This part of your response was also very interesting: When I had Integral grind my cam, they couldn't source the springs and referred me to Jim Wolf Technology at (619) 442-0680. After some digging, they called me back claiming to have what I needed. My receipt (dated 12/13/10) says: Item number: AVG3E-L6SPR Spring/shim set VG30E & L28 Outer spr. only, I/H 1.600" 68lb. on seat .490" lift max. Notice that .490" lift max number? That is .060" less than our cam has. This max lift number is usually a number which is related to the point where the springs stack solid. As a general rule, you need to stay about 050" to .060" away from the stack solid dimension. So, one could (but probably shouldn't) assume that this spring may stack solid (or coil bind, whichever you prefer!) at 1.600" minus .490" minus "spare" room of say... .050" thou. That results in an assumed coil bind at 1.050", for example. If this spring truly stacks solid at something like 1.050" instead of 1.132" like mine, then this info could be greatly helpful to me. Because... In theory, running the AVG3E-L6SPR at 1.680" installed height will buy another .080" thousandths of clearance before stacking solid - (i.e. instead of I/H 1.600", the new installed height is that dimension plus .080"). Then, putting in the .550" cam, we get 1.680" minus .550" minus .050".... which results in a distance of 1.080". And this is still 30 thou away from where the "coils bind"! We hope! By the way, running a taller installed height than that specified (i.e. the 1.680" instead of 1.600") will also lower the amount of lbf force... to something less than the specified 68 lb. After all, when you relax a compressed spring a bit, the amount of force it exerts lessens... Perhaps, it might even be something like the 54 lbf that Integral specified. Again, we hope... So, long story short, based on the info you have provided, the AVG3E-L6SPR spring could be different than those that Kinetic sent me. I sure hope so at this point, as those that I have don't have enough room to spare before "bottoming out". Thanks very much for the info! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

inline6 replied to zredbaron's topic in Nissan L6 Forum

Hi Mark, I've enjoyed reading your posts here in the forums. It seems you were kind of taking time off from Z cars when I was ramping up my efforts to build a new motor. I've had some issues which have delayed me a bit, but I wanted to pass along some info to you in case you need it at some point. Your cam is not unobtanium. Kinetic/Sunbelt is not doing Datsun as far as I can tell, and Jim is no longer there... yes... true. As you commented in a post a while back, Integral Cams was making the cams for Sunbelt. The owner of Integral Cams shut down his business, but I was lucky enough to track down down the company that bought his "masters" including the Z-Car L-Series E30 Race Cam #2. I bought one originally from Jim, but that one got trashed and I have bought one from this company now also. If you need one in the future, they are Megacycle Cams in CA. By the way, I paid $800 for the first cam from Jim. And close to that for the one from Megacycle... so you got a good deal! That or I got crappy deals. Separately, I wonder if you can help me out. The valve springs that Jim sent me to use with the cam... they are a problem. I was wondering if you could dig up the paperwork you got and find a part number for the valve spring set? I am showing that I got a set with the number 1W901. Problem with them is the specs I was provided are as follows: Integral specs: Installed at 1.680" with 54 lbf. Open height = 1.130" or .550" lift with 193 lbf But when installed at the spec height, they coil bind at just under the .550 lift. The ones I got will coil bind at 1.132". So, the springs they shipped me will not accommodate .550" lift! Now, my engine builder actually set the springs up at 1.710" because he saw what was going on, and at 1.710" installed height, the spring loads on the seat and at max lift are close to the desired specs listed above (actuals at 1.710 are 56 lbs. and 190 lbs. - installed and open, respectively). But, he flagged that as a problem... saying I really should have at least 40 to 50 thou before coil bind. And since I am wiping lobes within minutes of start up... repeatedly, this known issue (only .028" room until coil bind) is resurfacing as a potential cause. Any info you can provide about the springs (part number, specs) you got would be helpful. Thanks. Garrett -

Need valve weight: SI brand part 8001SG Nissan Comp 99996-N1100

inline6 replied to inline6's topic in Nissan L6 Forum

Yeah, I'd like to have contact info for anyone in the area who is really knowledgeable with L-series cylinder heads, cams, and tuning Mikuni's - if they are looking for that kind of business. -

Need valve weight: SI brand part 8001SG Nissan Comp 99996-N1100

inline6 replied to inline6's topic in Nissan L6 Forum

Last I heard, all the Datsun people that used to work there were gone. I bought the cam and the valve springs from Sunbelt in about 2008 from Jim Thompson who is no longer there. I've tried a bit to track the Datsun people from there, as I saw mention in these forums that some of them opened their own shops in GA. If I recall correctly, it looked to me like they closed up those shops too. From what I was able to tell, a company called Integral Cams was a big part of the SunBelt/Kinetic development picture. Steve Gruenwald, the owner of Integral Cams, was one of the few in the country to have invested in a very expensive cam machine (I can't remember what it is called). I think it makes development of cams much easier. I think my engine builder knows what it is called and that it is a six figure dollar item. Anyway, they shut down the business and sold their cam "masters" to Megacycle. So, Megacycle was able to make a replacement for me.