-

Posts

56 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by baby_Carlton

-

SLA S30 Front Suspension Conversion

baby_Carlton replied to baby_Carlton's topic in Brakes, Wheels, Suspension and Chassis

Small update: Completed reverse engineering of the Cortex spindle, nice design and less tall than I anticipated. Unsure how I feel about the ~1.5-2" drop design but it will have to do for now until I can get everything articulating nice. Next step is designing a 17" wheel as it seems like all the models I'm getting off GrabCAD are not to spec. For the inboard UCA pickups, I'm at the point where I'm just trying to choose an angle for the UCA, the consensus is ~7° though I've seen some guys on the Locost forums go up to 10-15°. From my conversation with Maier, I remember him mentioning anywhere in the 15° range is too high for these kinds of cars. Anyway, back to the books for me. -

SLA S30 Front Suspension Conversion

baby_Carlton replied to baby_Carlton's topic in Brakes, Wheels, Suspension and Chassis

Completely agreed and I am by no means a suspension expert. Following the fundamentals of suspension design is pretty straight forward when everything is static. Once parts start getting loaded up and components start moving around, things get a lot more tedious (which where I’m at right now). S54B32 shortblock, stripped head, and crankshaft with machine work done by Flying Colors Racing. Super happy with the quality of the work done here and I’ve always wanted to throw one of these in the Z. If it gets you driving the car more then more power to you. I don’t trust drivers in my area and the mountain roads are infested with double yellow-crossing IS250 drivers and morons in daddys Audi flying off cliffs. For a fun street car I want airbags and actual crumple zones so I’m trading the street for a controlled envrionment. -

SLA S30 Front Suspension Conversion

baby_Carlton replied to baby_Carlton's topic in Brakes, Wheels, Suspension and Chassis

Update: after speaking to Cortex and getting some spindle dimensions from them for CAD mockup, looks like I’ll be using their Radial X spindles. Very exciting stuff, I am a bit weary about using aluminum spindles but the car is a track car and last weighed at ~600# over each front wheel so I think I’ll be alright. Thanks! Excited to share my progress with you guys. I’d eventually like to make my work/design open source and see what more talented suspension engineers can do with it. If I didn’t just buy one of these yesterday I’d offer to trade you a complete kit for one of them KN20 heads XD. A bummer indeed, just another bump in the road! Funny you mention Stock Car blade-swaybars. It’s basically all I’ve been looking at for switching over to that design. Plus the parts are pretty cheap & standardized. Thanks everyone. -

Small update, I've moved to a new thread on designing my own front SLA suspension. Regarding the OTS kit from AE, its nice, the tubular front cross member is perhaps the best of its kind on the market. Part of me wishes they used slot-nuts instead of their current configuration but its not a huge deal. Interesting, sorry to hear. I find their rear suspension pretty well designed, the rocker ratio is 1:1 which is not great but nothing you can't fix by making your own. Though for $4000, I feel it should've been disclosed at the very least. Their new packaging system for hardware is great, though their shipping packaging is quite bad. Their customer support offered to replace some parts that were damaged in shipping, need to follow up to check what the ETA on those RMA'd part is. Regards to you giving them feedback, not surprising. I've also tried starting a technical discussion with them that they didn't seem super interested in, understandable they're running a business and are more concerned with keeping the doors open than answering questions from a guy that already paid them lol. These guys are developing kits for a bunch of Datsun/NIssan chassis, and now the E36 chassis so I doubt they have a lot of time for guys like us.

-

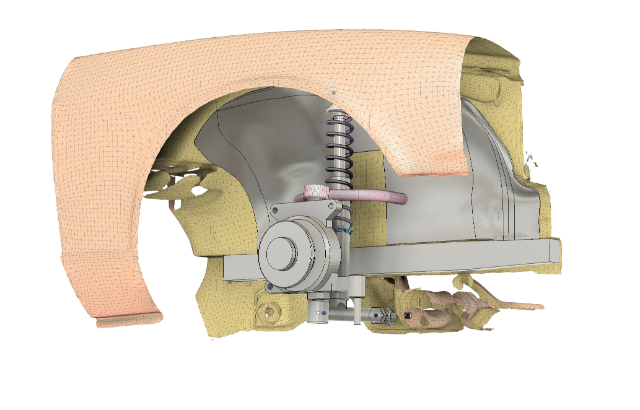

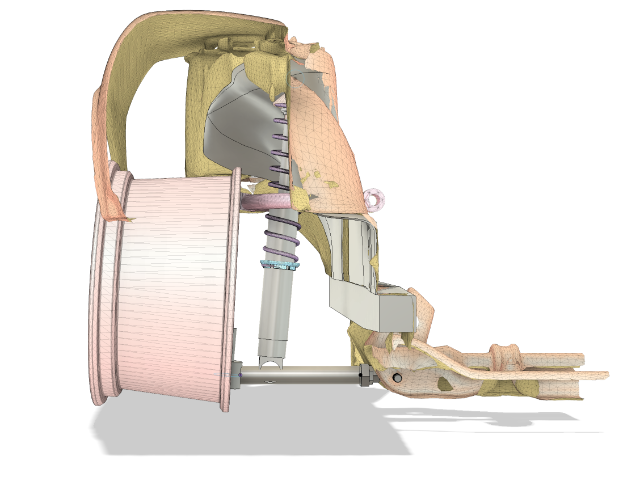

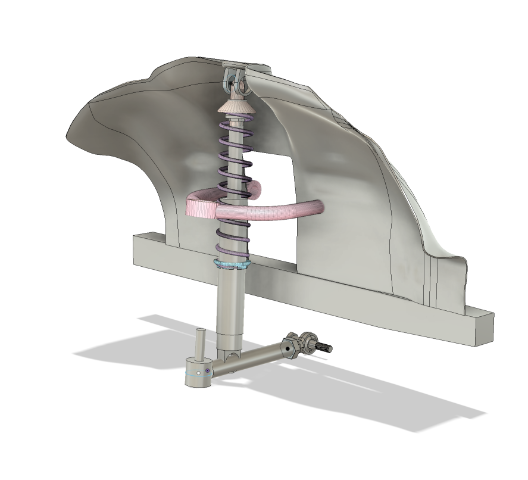

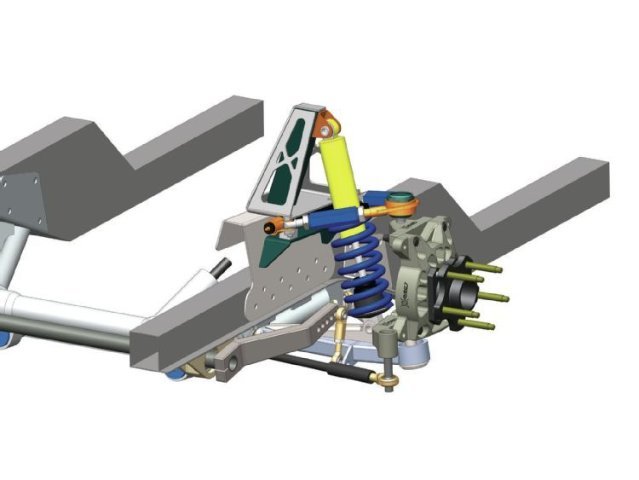

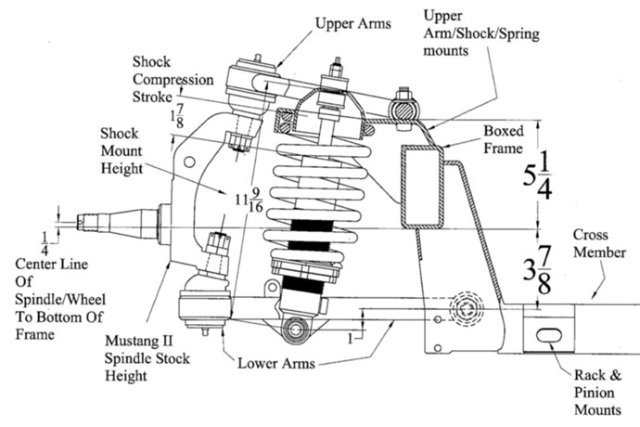

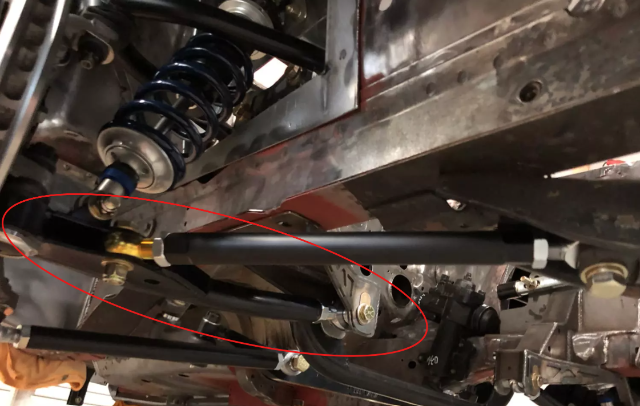

Hi HybridZ, Some of you have already seen my Apex Engineered Track Attack information/discussion thread here, I've decided after reviewing the design of the Apex Engineered front suspension kit, the best solution moving forward is to design my own. In this thread I will be documenting my progress and hopefully gaining knowledge on suspension design from you guys (or from what's left, f**k Facebook groups). To start... Why don't you just use the AE kit? It was $4000, you're just gonna waste $4000??? (Yes) Not enough shock travel, that's pretty much it. Once I received the shocks from Viking I realized immediately that 3.20" of stroke was not going to be enough and thus set out on a fool's errand to find alternative solutions. Viking shocks, from what I've found, have the most shock travel per the physical dimensions of the shock that I've seen so far. They're compact and the adjustment knob is well-designed to take the least amount of space with respect to the rest of the shock body. Very nice, but I will ultimately use either JRi's Mod series DA shocks or Penske's 7800/8300 series DA shocks as now, getting a shock long enough to reach between the strut tower and the LCA is more important. Design (pictured with 17" diameter wheel) The most prominent feature of my SLA design is the UCA pickup being located within the engine bay. The shock tower must be cut and a box structure is welded to the frame rail. This design is based on both the Maier Mod 2 design and Cortex Racing SLA kit seen here: Maier SLA Design Cortex SLA Design The reason I moved the chassis pickup for the UCA inboard was to extend the length of the control arm which should allow for a more compliant spring than the offerings from Apex. Mike Maier inferred the reason for the obscenely high rates was to keep the super short UCA from camming over and ruining the geometry. Fine for a super stiff autocross car but for a road-course car with kerbs, burms, and undulations in the track surface? Unacceptable. With this shock, I'll be looking at around 7-8" of total shock stroke travel. The remaining part of the design lies with the spindle (not shown) and the boxed-structure (also not shown). The boxed-structure was fairly straightforward to design - shout out to @Ben280 for sending me frame rail measurements while my car's been at the body shop. The boxed structure welds to the chassis frame rail located in the engine bay which the cross-shafts then mount to. The spindle is obviously not straight forward, fortunately for me there's plenty of resources on the LocostUSA forums for me to look at as well as Chassis Design and Race Car Vehicle Dynamics by Milliken and Milliken. Once the completed version 1 of the design is done, I’ll begin FEA with a safety factor of 1.15-2.00 at some lateral load to make sure everything should work without buckling. Until then, I have two separate designs, one utilizing Mustang II style cross-shaft mounting structures and one using Maier’s. The main difference being the orientation of the cross-shaft mounting bolts to the boxed-structure with the Mustang II’s bolts facing down, and Maier’s facing sideways. With the bolts facing sideways relative to the longitudinal axis of the chassis, side load is transmitted into the boxed structure through the bolts on their axial axis as opposed to their shear axis. Bolts do not like shear, however the Mustang II design is insanely popular so I suppose I could be overthinking this. Maier Cross Shaft Mounting Design Cortex/Mustang II Cross Shaft Mounting Design Methodology Starting with a 3D scan of the 240z that I re-topologized into ~10000 quads, I modeled an accurate-enough solid body of the fender well and shock tower. From there, I (roughly) modeled the Apex Engineered LCA (will probably try to use the T3 ones I currently have installed on the car as they are boxed structures), the Penske 8300 coilover at ride height, and upper control arm. You may have noticed the bottom of the shock clipping into the LCA, please ignore that, you didn't see that. In regards to swaybars, I will try to get the OEM sway bar design to work with my suspension, however due to the bottom of the shock being mounted on the LCA roughly where the swaybar links, this may be difficult to engineer. I could copy Maier’s LCA design, using a bent-tubular lower arm picture here: Moving forward, it might be easier to design my own boxed structure and try to mount a blade-style sway bar instead. Procurement While there's going to be a lot of custom laser cut metal from SendCutSend, I wanted to keep this kit as OTS as possible. I am not particularly interested in spending buku-bucks on one-off billet parts nor am I keen on dipping my feet into scaled automotive aftermarket product design & manufacturing. That being said, the spindles will likely need to be entirely custom if I can't find an alternative OTS. If I can find an upright on the market that fits my criteria I will definitely go for that, I’m trying to avoid using a Mustang 2 spindle as its shorter than I’d like it to be and completely wastes my steering knuckles and 370z spindles supplied from Apex Engineered (though steering knuckles and spindles are relatively cheap). Next Steps The complete version 1 of this design will be complete soon. Once I've finished my spindle and boxed structures the real work starts, articulating the design through all of its axes of rotation and movement will reveal conditions of binding and the dynamic geometries of the suspension. I started work on this project about a week or two after I placed my order for Apex Engineered SLA kit and have been doing it in my free time which is quite difficult to come by. God willing I shall endure.

-

The reason for replacing them is not for quality, its for fitment. I'm pretty sure Viking offers a coilover long enough to fit with my SLA design but I know the Penske one will work. I just need to check for interference in the UCA throughout travel. Lol well if you wanna save a few pennies on the front kit from AE let me know, I'm going to get rid of mine. That last part is probably true, but more tie rod ends means more maintenance and more failure modes. Dirt and debris entering the ball joint and load fatigue both contribute to this. I've spoke to Viking and they were very helpful. A little confused on the choice to use the C203 shock with the motion ratios given to me by Apex. From their reaction and the assessments from Rob Fuller and Mike Maier I'm standing by my opinion that 3.2" of shock travel is simply not enough.

-

I see, it seems AE just sent me 4 identical C203 shocks from Viking and said have at it. I won't be using them anyway, the entire front suspension kit is pretty much a wash for me at this point. Going to just resell it for cheap once I finish my own design. I'll be either using JRi modular shocks that are 21.7" extended or Penske 24.7" extended. I agree, there's too much usage of many tie rod ends, from an engineering perspective it just adds more and more failure modes, more and more maintenance. I'll edit this post and link my front SLA thread.

-

I'll take the scan if you still got it, appreciate you doing this. I have a scanner at work but its difficult to justify bringing home a $50k+ piece of equipment for the weekend XD

-

I agree, I reached out to Apex earlier this week asking about feasibility using the existing shock stroke with 400-450# springs. Yes, loading the outside tire on burm and then hitting an imperfection on the track seems like it would decimate one of these shocks (same with hitting kerbs/rumble strips) unless I find a way to get more travel. If I could get 5inches of travel I would be very happy but I will try for a full length (~6.5") shock design if I end up copying MMI's Mod 2. Very interesting, would definitely prefer welded to bolt-on but if everything fits up right I could end up using it as a way to test different upper wishbone lengths. The Griggs conversion looks like a pretty strong structure but I don't want to jump to conclusions quite yet. Do you have any photos of your work? Interested to see what your mounting solution looks like. If I can avoid trimming the strut tower and still get the full stroke shock I will.

-

Tire selection is Nankang CRS 200TW 245/40R17 front, 275/35R17 rear, I would use their AR-1 100TW however they do not offer a 275 section tire for that model. Car will be almost exclusively a track car but despite my spine's best interests it'll probably see a very occasional Sunday drive. Were these rates with OEM-style strut type suspension? What were your wheel rates? Maier's issue with the shock travel was that unlike an autoX/hillclimb car, a road course car would see burms and 3.5" total shock stroke just isn't enough. Great insight still, thank you. The kit just shipped about 3 hours ago (for better or for worse), when it arrives I'll be able to get those measurements to see. When you say "adequate travel" I'm assuming a that refers to just enough travel for the ~3 inches of travel you've needed for your own car? I'm assuming if I want something closer to 5-6" travel, the upper arms would need to be closer to a foot long. That's what I'm finding as well just looking at Maier's Mod 2 front axle suspension kit. Complete replacement of the front strut towers moving the pickup points slightly upward and a few inches inward to increase clearance between the coilover and upper control arm. I'm not opposed to doing this and I could even keep most of the Apex kit except for probably both the wishbones. Ah yes, old stockcar components on eBay, a true goldmine for (hopefully) decent parts. Definitely have looked at sourcing a fuel cell and oil coolers from there. Luckily I have access to rapid prototyping equipment and fabrication tools so I'm good to go. Not the best welder or anything but I know a few. Thanks for your help tube80z. Only other gripe I have with this design is on the rear subframe; the differential and control arms mount on the same structure and that seems like an exceptionally suboptimal design choice. Time will tell I suppose.

-

Spoke to Mike Maier today seeing as the front suspension is most similar to that of an old Mustang. I wish I could write notes faster because holy hell that man is a wealth of knowledge. Suggested the reason for high spring rates is to prevent the upper control arm from camming over (poor arm design) and that the 3.5" of travel is definitely not enough for a road racing/track car (burms). Looks like my next steps are installing an adjustable upper ball joint that can move up/down to change the coilover angle and shock pot it at ride height looking for the lowest load value. If no substantial gains can be made there it's either back to the drawing board to make a push/pull rod cantilever or cut out the shock towers entirely and try to copy MMI's own Mod 2 strut tower modifications as well as new control arm(s) to gain the ability to mount a full length shock to the lower wishbone. This is becoming more and more of a fully custom project by the day.

-

Update From Apex: Front • Motion ratio: 0.92 : 1 (wheel : shock) • Wheel rate: 0.92² × 600 lb/in ≈ 510 lb/in • Wheel travel with 3.5" shock stroke: ≈ 3.2" Rear • Rocker motion ratio: 1.00 : 1 • Wheel rate: 700 lb/in • Wheel travel with 3.5" shock stroke: 3.5" Some confusing design and hardware choices here. Using a bellcrank/rocker with a 1:1 motion ratio doesn't take full advantage of the system. I will end up designing and having manufactured a new billet bellcrank/rocker with a lower motion ratio to get more shock travel. Highly likely I'll source a Hyperco spring at a different rate but that'll be handled during the bellcrank redesign and is a straight forward task. The front axle is giving me some headaches. The lack of suspension travel could be fixed by adding a bellcrank/rocker, but there isn’t enough space to fit one between the top of the strut tower and the hood. Making room would require major cutting and fabrication to the strut towers. Mike Maier Inc.'s solution to a similar problem was to completely replace the original shock towers with a custom design, allowing a full-length shock to mount higher and further inboard. On the Z, moving the strut tower further inboard could create enough clearance between the upper control arm to let a coilover mount to the lower control arm. But by that point, I'm only a few steps away from designing a fully bespoke 1:1 double wishbone kit, making the OTS kit a useless purchase. I've been drawing up some concept sketches on how I could possibly do a pull rod but that would render the OEM strut tower essentially useless. Alternative to implementing a front axle rocker would be to modify the upper wishbone where the bottom of the coilover mounts to be further inboard which would lower the motion ratio more but I'm not keen on trying that solution. I think I need a sanity check, I'm used to working on strut-type suspensions that have decently high shock travel to the point where coil-bind is a more pressing issue at low ride heights. Is there another solution to a short shock stroke and high spring rate I'm not considering? Or is this a case where the problem is all in my head and having 3-3.5" of shock stroke isn't that big of a deal? I've spoken to Rob Fuller from ZCarGarage regarding this problem who had some great insights on Z suspension, unfortunately he wasn't able to help me much past confirming that the wheel rates are ludicrously high. I'm aiming for a front axle wheel rate in the range of 300# to 450# and even then 450# still seems extremely high for the front axle.

-

Thanks for the welcome back, this car has certainly had a rollercoaster of a fate over the last 10 or so years of ownership. Excited to build it into the best version of itself (for me). Thanks for the info, seems like Viking is a non-hype brand that offers shocks that do shock things, which I can appreciate. AE is slow on CS communications but that's understandable given the size of their operation. That said, for a ~$9K suspension kit, a bit more transparency and technical detail on their website would go a long way. If I can find a shock with more travel for the same dimensions or when I blow these out I'll swap. JRi's builder series and some of their GM line looks like it would bolt right in, only 0.3" longer extended length which seems negligible in terms of fitment (PN: 100-511-300). I agree, it seems incredibly unwise if that were the case but it wouldn't be the first time I'd seen it. I've seen similar suspension choices in GTAC (cars riding on bump stops) but that's usually done purposefully to keep the aero platform working optimally and not appropriate for a package like this. Considering the shock travel is a mere 3.6", its safe to assume this is an extremely low motion ratio design. It feels like a missed opportunity to fully leverage the bell crank inboard design (traditionally speaking) but perhaps packaging constraints of the S30 chassis left little room for alternatives. I'm hoping the bottoming out feature will be at the upper A-arm which would allow me to mount a 3D printed polyurethane bump stop on top of it. Going to email AE for an update on the wheel rates and now information motion ratios, thanks for the idea.

-

Hi HybridZ, its been a while. Took a long sabbatical from working on my S30 to finish college and get a job. For the last 6 or so months its been full steam ahead, the project is currently being rust repaired at a local body shop and I've been collecting parts as budget allows. The first piece major piece of hardware to arrived is the Viking Performance Shocks from the Apex Engineered Track Attack Front/Rear Suspension kit. I noticed that Apex’s website lacks details on shock and spring selection, so I’m documenting my findings here for others and to start a discussion on their choices. What's Included: Box as it arrives from Viking Performance Serial Numbers of each of the shocks (PN: C203) Viking Performance Shocks Link Part Numbers of Springs (600# & 700#) Initial Impressions: The car will be caged and used primarily/almost exclusively on track, so a stiffer setup is expected. However the spring rate selection still raises some concerns: The S30 chassis doesn’t benefit significantly from extremely high spring rates, even with a roll cage. The rear suspension uses inboard cantilevered shocks, which traditionally increase effective spring rate via the lever arm. This spring selection guide from Viking Performance indicates that the spring rate for a car with IRS and axle weights of ~1200-1400# is a lot lower than the supplied springs. I'm hypothesizing that the high rates were chosen to prevent the shocks, which are short to fit the Z’s narrow frame and tight packaging within the front wheel wells, from bottoming out. I’ve reached out to Apex Engineered to clarify the wheel rates for this setup and will update this thread when I hear back. Let me know if any of you have run this kit or high wheel rates.

-

My friend bought this car! We painted it.

-

Just wanted to update for anyone having this issue in the future. Culprit was the front cover seal being all wonky. When I installed the front cover I didn't take the time I should've and I wasn't making sure the gasket was seating while the front cover was being tapped on. The front cover bolts dug into and thru the gasket. This meant the suction side of oil pump was not sealed against the front cover and a vacuum could not be made. Cam oils, car runs, all is well. Thanks to everyone for the suggestions and help!

-

Haven’t messed with anything in the oil pan and it was working before the rebuild so not sure what could be blocking the tube. I think I’ll have to eventually take the oil pan off and inspect. Thanks for the help!

-

Gauge wouldn’t be a bad idea, I’ve removed the oil filter and turned the pump (CCW), no oil shoots out despite having 5 qts. Does the oil pump AND distributor seal some oil galley I’m not seeing? I think the only seals I need to be mindful of are the front cover to engine block/oil pan.

-

Hi all, I recently built my P79 head (F54 block) and have reassembled the engine and I’m having a problem with the oiling system. The conditions are as follows: -Oil pump confirmed will pull oil in and push oil out (primed and greased) -Car will start and run but internally oiled cam will not spurt out oil -All 5qts of oil has sunk down into the pan. Tested oil passage with compressed air going out from the oil pump and into the oil pump. Output side is working as it should. Input side is not blowing thru. I’m using a rod attached to a 12V drill to turn the oil pump thru the distributor hole in an attempt to pull oil out of the pan but so far no dice. My theory is that the front cover of the engine is not sealed at the oil inlet from the pan and won’t create a vacuum for the oil pump. I’m curious if any of you have experienced this, I haven’t been able to find answers to my issue. Thank you

-

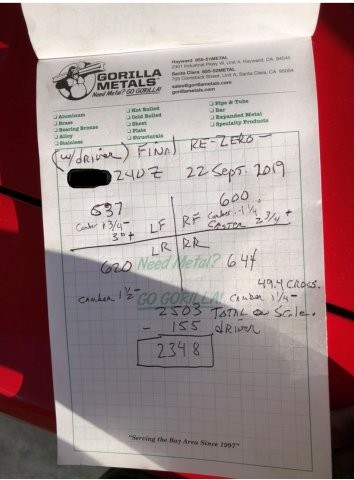

Those are two benefits I'm going for here. My 240's weight distribution is fairly decent as is but I'm chasing less weight over the front axle. Looking at these engine mounts, it doesn't seem like an exceptionally arduous task. The plan is to shorten my driveshaft more (already altered swapping to an R200 long nose), currently looking into cantilevering the transmission back. Attached are my corner weights (roll bar, full interior, half tank, full steel body, alloy wheels). I'm guessing I would shift only about 1-3% of the car's mass backward. Not massive, but interesting to me nonetheless. I've considered this and I believe it is easier (though maybe not better) to move the engine back using steel plates similar to what grannyknot mentioned. Could you show me an example of the chassis rail mounted motor mounts? Yes, I've had to section my airdam to fit my tires and now that I'm switching to a larger tire setup (ZG flares) I think this will become more of an issue. Haven't seen any fiberglass flares that do something similar to what your talking about other than maybe a Z-speed or Rocketbunny kit given how large they make the front end look.

-

Hi everyone, I'm in the process of building an N/A L28 for my 240z and was looking to move my engine back about 2-3" back towards the firewall. I intend on simply fabricating a thick steel bracket that would accomplish this using the stock motor mounts but I'm curious to see what solutions are out there. I haven't found any threads on this topic on any of the major Z websites but if anyone has links I'd appreciate them.

-

Over Tightened Shock Nut (Koni Yellow)

baby_Carlton replied to baby_Carlton's topic in Brakes, Wheels, Suspension and Chassis

Hi guys, thank you all for the input. caperix, I liked your idea so I after searching the interwebs, I found a 1/2" drive thru socket wrench with the appropriate sockets and extension. I was not able to loosen the nut unfortunately due to the risk of stripping the top of the Koni shock (which I ended up doing badly on one side). I ended up popping off the nuts by drilling holes on opposite sides of the nut and using a chisel/hammer combination to break the nut off. One strut insulator came off anticlimactically just barely jumping 6 inches after the nut was broken. The other insulator flew off and left a small scratch in my cabinet door. This was a scary process and would recommend people to avoid doing this at all costs. If I were to do this again (with more patience), I would follow 1969honda's advice and use a nut splitter. Lesson of the day: Don't over impact your nuts kids. 🥜 Here's photos of the car as it sat after swapping to a lower spring: Update: Marugen flares from Japan-land Currently taking notes on all the flare FAQs and Forums I've found for this project. Now waiting on hardware to ship and for my balls to grow big enough to cut into my car. ⚽🏀- 5 replies

-

- shock removal

- shock absorber

-

(and 1 more)

Tagged with:

-

Hi All, I did a very not-so-smart thing and over torqued the shock nut (top nut going into the insulator) when installing my Koni Yellow shocks into the rear strut tubes. Does anybody know how to free this nut without damaging the shock? In the pictures it is clear how far down the nut is based on the number of threads showing. I believe the nut has gone so far down that it is past the normal shock threads and is "threading" into the non-threaded part of the shock. It is impossible to fit a wrench around the smaller hex end just below the adjustment knob of the shock while also using a larger wrench to loosen the shock nut due to the height of the insulator surrounding it (and yes, despite the pictures being taking when installed, I have taken the strut assembly off the car). I am tempted to use a thick mouse pad to wrap around the shock tube itself and hold it still with vice grips while I loosen the nut but I'm anxious to do so. If anyone has any recommendations or has dealt with this before I would greatly appreciate your help. Thanks, Liam

- 5 replies

-

- shock removal

- shock absorber

-

(and 1 more)

Tagged with: