-

Posts

40 -

Joined

-

Last visited

-

Days Won

2

baby_Carlton last won the day on December 24 2017

baby_Carlton had the most liked content!

Profile Information

-

Gender

Not Telling

-

Location

Bay Area, California

Recent Profile Visitors

5264 profile views

baby_Carlton's Achievements

-

My friend bought this car! We painted it.

-

Just wanted to update for anyone having this issue in the future. Culprit was the front cover seal being all wonky. When I installed the front cover I didn't take the time I should've and I wasn't making sure the gasket was seating while the front cover was being tapped on. The front cover bolts dug into and thru the gasket. This meant the suction side of oil pump was not sealed against the front cover and a vacuum could not be made. Cam oils, car runs, all is well. Thanks to everyone for the suggestions and help!

-

Haven’t messed with anything in the oil pan and it was working before the rebuild so not sure what could be blocking the tube. I think I’ll have to eventually take the oil pan off and inspect. Thanks for the help!

-

Gauge wouldn’t be a bad idea, I’ve removed the oil filter and turned the pump (CCW), no oil shoots out despite having 5 qts. Does the oil pump AND distributor seal some oil galley I’m not seeing? I think the only seals I need to be mindful of are the front cover to engine block/oil pan.

-

Hi all, I recently built my P79 head (F54 block) and have reassembled the engine and I’m having a problem with the oiling system. The conditions are as follows: -Oil pump confirmed will pull oil in and push oil out (primed and greased) -Car will start and run but internally oiled cam will not spurt out oil -All 5qts of oil has sunk down into the pan. Tested oil passage with compressed air going out from the oil pump and into the oil pump. Output side is working as it should. Input side is not blowing thru. I’m using a rod attached to a 12V drill to turn the oil pump thru the distributor hole in an attempt to pull oil out of the pan but so far no dice. My theory is that the front cover of the engine is not sealed at the oil inlet from the pan and won’t create a vacuum for the oil pump. I’m curious if any of you have experienced this, I haven’t been able to find answers to my issue. Thank you

-

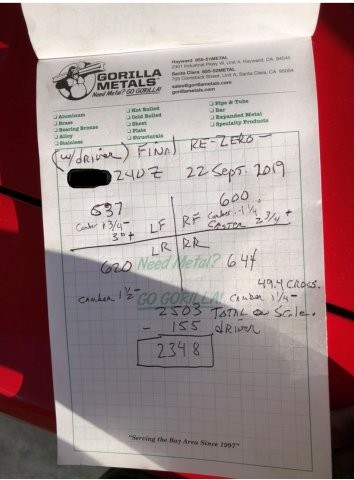

Those are two benefits I'm going for here. My 240's weight distribution is fairly decent as is but I'm chasing less weight over the front axle. Looking at these engine mounts, it doesn't seem like an exceptionally arduous task. The plan is to shorten my driveshaft more (already altered swapping to an R200 long nose), currently looking into cantilevering the transmission back. Attached are my corner weights (roll bar, full interior, half tank, full steel body, alloy wheels). I'm guessing I would shift only about 1-3% of the car's mass backward. Not massive, but interesting to me nonetheless. I've considered this and I believe it is easier (though maybe not better) to move the engine back using steel plates similar to what grannyknot mentioned. Could you show me an example of the chassis rail mounted motor mounts? Yes, I've had to section my airdam to fit my tires and now that I'm switching to a larger tire setup (ZG flares) I think this will become more of an issue. Haven't seen any fiberglass flares that do something similar to what your talking about other than maybe a Z-speed or Rocketbunny kit given how large they make the front end look.

-

Hi everyone, I'm in the process of building an N/A L28 for my 240z and was looking to move my engine back about 2-3" back towards the firewall. I intend on simply fabricating a thick steel bracket that would accomplish this using the stock motor mounts but I'm curious to see what solutions are out there. I haven't found any threads on this topic on any of the major Z websites but if anyone has links I'd appreciate them.

-

Over Tightened Shock Nut (Koni Yellow)

baby_Carlton replied to baby_Carlton's topic in Brakes, Wheels, Suspension and Chassis

Hi guys, thank you all for the input. caperix, I liked your idea so I after searching the interwebs, I found a 1/2" drive thru socket wrench with the appropriate sockets and extension. I was not able to loosen the nut unfortunately due to the risk of stripping the top of the Koni shock (which I ended up doing badly on one side). I ended up popping off the nuts by drilling holes on opposite sides of the nut and using a chisel/hammer combination to break the nut off. One strut insulator came off anticlimactically just barely jumping 6 inches after the nut was broken. The other insulator flew off and left a small scratch in my cabinet door. This was a scary process and would recommend people to avoid doing this at all costs. If I were to do this again (with more patience), I would follow 1969honda's advice and use a nut splitter. Lesson of the day: Don't over impact your nuts kids. 🥜 Here's photos of the car as it sat after swapping to a lower spring: Update: Marugen flares from Japan-land Currently taking notes on all the flare FAQs and Forums I've found for this project. Now waiting on hardware to ship and for my balls to grow big enough to cut into my car. ⚽🏀 -Liam- 5 replies

-

- shock removal

- shock absorber

-

(and 1 more)

Tagged with:

-

Hi All, I did a very not-so-smart thing and over torqued the shock nut (top nut going into the insulator) when installing my Koni Yellow shocks into the rear strut tubes. Does anybody know how to free this nut without damaging the shock? In the pictures it is clear how far down the nut is based on the number of threads showing. I believe the nut has gone so far down that it is past the normal shock threads and is "threading" into the non-threaded part of the shock. It is impossible to fit a wrench around the smaller hex end just below the adjustment knob of the shock while also using a larger wrench to loosen the shock nut due to the height of the insulator surrounding it (and yes, despite the pictures being taking when installed, I have taken the strut assembly off the car). I am tempted to use a thick mouse pad to wrap around the shock tube itself and hold it still with vice grips while I loosen the nut but I'm anxious to do so. If anyone has any recommendations or has dealt with this before I would greatly appreciate your help. Thanks, Liam

- 5 replies

-

- shock removal

- shock absorber

-

(and 1 more)

Tagged with:

-

Have a S30 Series 1 Chassis, decent engine makes 150bhp with an L28 mated to a Type-II 5-speed, great suspension and brakes. PM if interested.

-

T3 and arizona z brake kit

baby_Carlton replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

I love the RS8 Watanabes, especially when they're custom barreled to some double digit width. Also thank you! I've seen a few S30s with the Formula TRs on instagram, I think the wheels look great. It would definitely be interesting to see them on more JDM cars. -

T3 and arizona z brake kit

baby_Carlton replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

Yes my wheels fit over the hubs fine though I should've purchased my wheels with more offset so they wouldn't poke as much. Running Fifteen52 Formula TR 225/50R16x8 +0 with non-rolled fenders, should have ordered at least +10. -

T3 and arizona z brake kit

baby_Carlton replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

I'm currently running AZC front brakes and 5 lug hubs and T3 rear brakes with the Ebrake. I think both are equally great quality though I've had issues getting the e-brake function to work on the T3 rear kit. -

Fiberglass Mafia Wide ZG Flares - looking for reviews

baby_Carlton replied to JoeK's topic in Body Kits & Paint

While there's a topic open about Fiber Glass Mafia, I'm curious if anyone's used their "Mafia" Fender Flare Set. Link: http://www.fiberglassmafia.com/store/p34/S30MafiaFlares Look a little different than your standard ZG flares, a hybrid between Pandem/Rocket Bunny and ZGs in my opinion. I like how the rear fender flares don't mount to the door unlike the Pandem/RB kit. -

Have a 1971 Series 1 with complete brakes, suspension and wiring. Going to do chassis chassis reinforcements (Subframe connectors) soon, PM me if you're interested.