-

Posts

1455 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Savage42

-

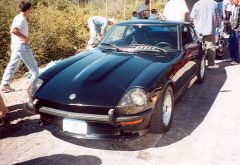

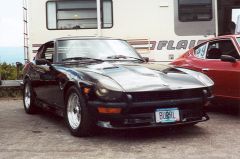

From the album: Dustin's 400 SBC 240Z

-

-

Guys, now that I've got most of you up to speed on the car, I wanted to let you know why I'm actually building it. I've built a couple 510s over the last decade and had a ton of fun with them. My buddy and I have had a sort of rivalry at the local autocrosses, where it often was all about "him vs me". We both have class championships and have set several Top Time of Day, but it was the simplicity of his car (240Z w/ 400 SBC with springs, sway bars & race tires) against my 510s, which had exotic type stuff to try and run with him. I got tired of always having to work on stuff to get the 510 to compete with him, so I thought "next time I'll try a Z". Well, coming from a family with a significant racing background ( http://swedesavage42.tripod.com ), I've been lucky enough to not only race my own cars locally, I've been able to drive many different cars across the county and even Canada & England. In memory of Swede, I've been driving the original '70 Plymouth AAR 'Cuda factory Trans-Am car. The one thing I really enjoyed was sticking kids in the car and being able to impact them in such a positive way. A couple of years ago, I met with Gary Manley. He used to own one of the sister AAR 'Cudas back in the '70s and originally ran the Pinto in Trans-Am. (no jokes needed) Anyway, Gary was a cancer survivor and he had a vision to use racing to really impact children with cancer. He put together the Caring Hearts Children's Cancer Foundation. The program was designed to go to the hospitals along the west coast, to spend time with the kids and also take the ones that are well enough to local car shows, exhibitions and races. It's amazing how a day of fun for a child can make all the difference in their attitudes and attitude is a huge key to beating cancer. I know, my sister died after a 6 year battle with leukemia and the doctors originally only gave her 6 months, but her positive outlook gave her the will to keep on going. On the last night my sister was alive, she talked to my brother about my racing and how much it meant to her that I was "continuing the tradition". She has been a huge motivating force behind my racing and this program. So, this car is being built in association with many great companies who have helped us in different ways to put it together. (Besides, promoting products made for the Z and getting some added recognition for Hybridz is a good thing!) I'm doing all the work myself and we'll be taking the car all over the west coast to spend time with the kids and take them for rides, etc. Gary Manley died at the end of last year, but his vision lives on. We are continuing the mission and combined with my racing background, family history, and an awesome cause, we've setup several magazine articles and will be featured on an episode of Xtreme TV, a local show in the Seattle area. Since we were going to build a car, I thought I'd use my experience with Datsuns and with the great people I've met since 1991 when I bought my first 510, I knew we could make this program and car something special. "If you are going to do anything, you have to do it right." Thanks for all the help and input, guys! It's going to be a fun year with the car and the kids. We'll have our website with sponsor links and acknowledgements up real soon. There's more to life than just making a living, it's about making a difference! http://album.hybridz.org/showgallery.php?cat=500&ppuser=8934

-

From the album: 280Z-06: Brakes & Suspension

-

Suspension & brake pics

Savage42 replied to Savage42's topic in Brakes, Wheels, Suspension and Chassis

Here's the rundown on how I built the control arms: Bought 2 Grade 8 bolts (5/8" by 2.5") & jam nuts. I cut the control arm at 6.75" from the end, which put it just into the hole that's drilled on the bottom of the arm. (You can see it on the pic) The head slides in and actually butts up against the second plate that is inside the arm. That worked out perfectly. I blasted the inside so we could get a clean weld in there, also drilled a 1/2" hole through the top & bottom where the head sat, so we could weld it into place there and the hole was big enough to grab the edges of the bolt head. I then used some 1" flat stock and drilled a couple 5/8" holes in it and cut 2 sections that were 1.30" long with the hole in the center to cover the end of the control arm. This gave us a nice edge to weld the plate to the end of the arm and around the bolt itself. Of course, I ground the zinc plating off the bolt on the 2 sides of the head that we welded to and where it went through the plate. After some cosemetic work with the angle grinder, it came out pretty good, although I'll be cleaning them better before I have them plated along with all the other bolts, brackets & stuff for my car. Might as well make them look good. As for the TC rods, my buddy Jerry sells them. They are designed for the bracket to be solid mounted. While it may look like you could put a bushing in there, it would take away the performance gain that you get from getting rid of it. With the arms and potentially the upper strut mount (if running camber plates) being more solid mounted, you wouldn't see much of a difference in road noise and there isn't anything harsh about this setup. You'd get more or less road noise from tire choice more than anything else. This setup eliminated deflection under braking, where a bushing isn't optimal, especially if you are after max handling. He builds the piece that bolts to the control arm, which mounts into a clevis, LH/RH threaded sleeve with heim joint and the custom mounting bracket. If you are interested in the setup, Jerry not only makes the TC rods but also builds the arms after I told him and showed him what I did. He makes 3 different styles of lower control arms; one with a mono-ball where the bushing goes, one that is semi-adjustable, and the full adjustable like mine. His email address is: qship510@juno.com There you go! Tell him Gary sent you. -

Thanks. I can't take all the credit for that one. My buddy, John, who was a Z guy way back when I first got into 510s, started doing that setup on many Zs in this area. It has a 1" square tube frame underneath, so it's stout. He likes to drop them all the way down to the frame rail, but I wanted it up a little bit. With a nice custom cover for that corner, the battery disappears while keeping the weight fairly low and I don't lose any room in the passenger compartment. It works really well.

-

Then maybe I'll get mine in there, unless they just decide to make Bill's cars permanent fixtures on that site. He's going for Z's of the Decade!

-

After holding it up to the car, everything lines up very well. All the ones I've seen are cars look really good.

-

Alright, I added more pics of the stuff going in the car. You'll have to wait for the finished look only after we build the custom dash, which should be in the next month or so. Stay tuned.

-

I figured I'd add more pics of the exterior parts that are going on the car. Pics of them actually on the car are coming soon!

-

Suspension & brake pics

Savage42 replied to Savage42's topic in Brakes, Wheels, Suspension and Chassis

OK, I added more pics to this section. I'll get the assembly pics up soon. -

From the album: 280Z-06: Drivetrain & exhaust