artishard116

Donating Members-

Posts

68 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by artishard116

-

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

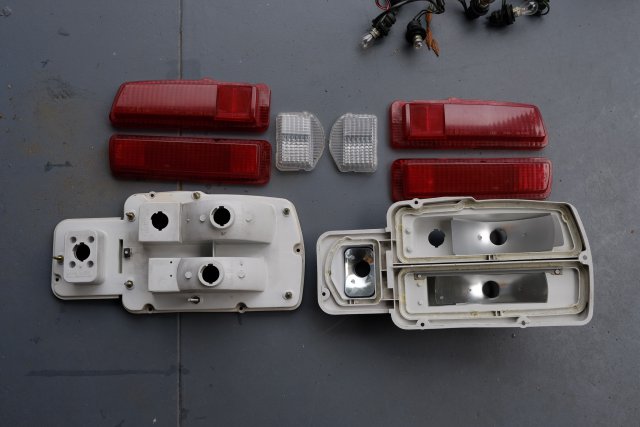

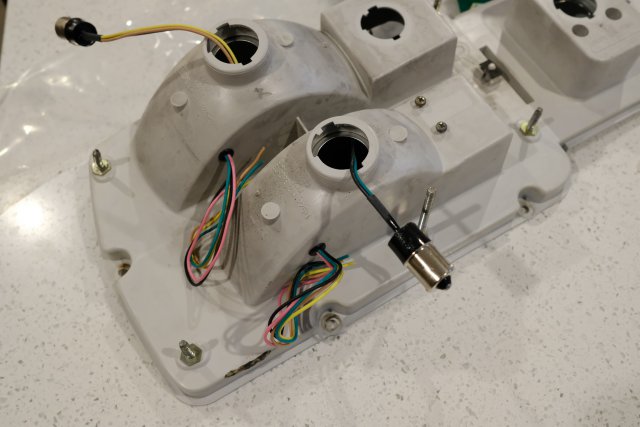

Had some downtime while waiting for my fabricator's schedule to clear up so I kept myself busy by restoring the original tail lights and installing Dapper led boards. Cleaned the grime off. Pried open the lenses. Dapper lighting boards wired up. New sealant added. Polished up the lenses with a buffing wheel on a power drill. Added some clear coat. Painted the worn out chrome trim black. Testing. Doesn't appear I'll have any trouble backing up at night... -

Wow nice deal. I'd be all over this if I hadn't already bought most of that stuff separately. Probably 10k in the motor alone. Good luck with the sale.

-

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

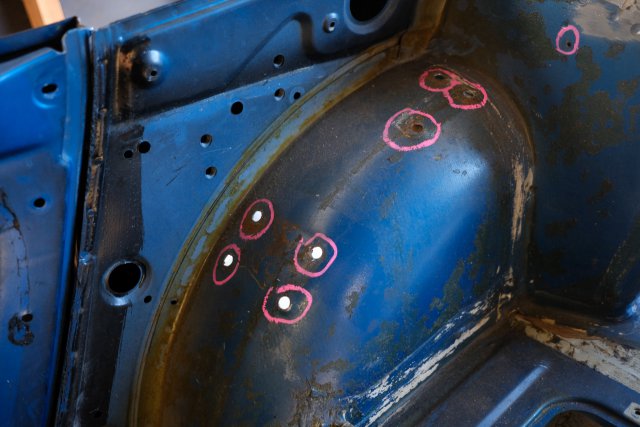

Fabrication/metalwork starts thanks mostly to my friend BDR Fabrication. POR15 in the seatbelt pockets Pockets welded shut and standoffs for the main hoop added in 1/8" steel. It was tight, but managed to keep the stock seatbelt bolt holes accessible. Test fitting main hoop. We used the diagram floating around on this forum and it fit great. I hadn't welded since college, so I practiced by filling some holes. Removed some plates that were welded over the original sway bar holes by a previous owner on the front frame rails. Parts start to trickle in. IMG_5883.MOV -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Teardown begins: Lots of POR15 in the floors and spare tire well, slightly concerning. Many extra holes for weight reduction(?). Kept a couple things and sold a ton of parts. I wanted to ditch the stub axles all together and wanted an e-brake integrated with the calipers. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Besides looking structurally sound, the other reason I bought it: Came loaded with a few spare parts: -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Day 1. The car arrives. A little rough around the edges and lots missing, but seemingly little rust: A quick wash to see what we're working with. Parked it next to my brother's expensive Volkswagon. In a strange coincidence, this guy who came to buy some parts off me said he had seen one being trailered recently in the area... he took a very grainy video of it and send it to me and it happened to be mine on its way home from Florida. IMG_5511.mp4 -

*Finally getting around to documenting my build. Will continue to update the text as I go. Happy to answer any questions. Feel free to also follow along on instagram for more frequent updates. I fell in love with the S30 chassis at around the age of 13 and tried to buy one or two as my first car. Unfortunately, being from the north east, anything I could afford had rust holes in structural areas you could put your hand through. After watching the price trend over the last few years, I decided I better act before I missed the boat. -Purchased sight unseen in October, 2018 from another member here. -The car started it's life in California, was shipped to Florida by the P.O., and then I shipped it back to California. I was living in Germany at the time, so the plan was to store it with my family and make trips to work on it whenever I found the time. -I purchased it as a roller since I'd always planned to do a swap anyway. It came with a lot of T3 and AZC suspension bits already in place, most of which I sold.

-

Thanks guys, appreciate the input. Will let the shop know.

-

Interesting, I learned something new today thanks. It doesn't look like as clean of a seam as in the back, more like random cracks. Any thoughts on how to repair/strengthen them?

-

In the front? I knew the one in the back (B?C?) pillar was.

-

Thank you sir. This place also sprayed an inhibitor. The metalworks guys personally went over the prep process with the shop doing the primer so should hopefully go smoothly. On a slightly unrelated note, this one has me stumped. The shop sent me images of the areas they found needing attention and one of them is this area where the A-pillar meets the roof. They said it looks to be failing but not due to rust. Anyone ever encounter this? What would cause such a thing?

-

Man this car has been all over the place. Was originally sold in California and then shipped to Florida by the previous owner, where I bought it and shipped it back haha.

-

Interesting, I thought e-coat and epoxy were different things. I did look around a little for primer dip solutions but couldn't find any. At this point after shipping the car from California, it's all getting pretty expensive. I think I've found a reputable place to spray epoxy and then I'll likely drill access holes and shoot something into the interior spaces.

-

Never heard of epoxy dipping, you know some place that does it?

-

Thank you for the advice, that makes sense to me. I believe the pans are worth saving, they're mostly solid but I'll poke around a bit more. It was dipped by Metalworks in Eugene, OR.

-

Recently had my car dipped to remove old paint, undercoat, and uncover/neutralize any rust. Overall it came out pretty good, not too many surprises. A couple places will need to be patched as there are small holes. My question however is about the pitted areas. There is quite a bit of surface area on the floors and spare wheel well that has pitted but not eaten through. Do I need to cut all that out or is it ok to epoxy over now that the rust should theoretically be gone? A couple pics below.

-

Structural Reinforcement to Handle 500rwhp

artishard116 replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

-

Structural Reinforcement to Handle 500rwhp

artishard116 replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

^Shamelessly 'borrowed' this idea from your build thread when I did my main hoop. Hard to imagine the roof flexing much afterwards. -

Structural Reinforcement to Handle 500rwhp

artishard116 replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

Considered doing this as well, my original paint is showing the beginnings of cracking in that area. What’s the best way to remove the filler? -

Structural Reinforcement to Handle 500rwhp

artishard116 replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

-

Structural Reinforcement to Handle 500rwhp

artishard116 replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

I'm right in the middle (nearing the end?) of this stage so I can share some pictures of some of these things. Read that chassis prep thread many times and would have benefited from some detail shots. Lots of great info though. It's taken me around 2 solid months to get to this stage, but I've been pretty lucky in the rust department. Still need to finish my frame rails and seat mounts. -

Big price drop.

-

240z 280z Suspension/Steering/Exterior Parts

artishard116 replied to artishard116's topic in Parts for Sale

Availability updated, few things left -

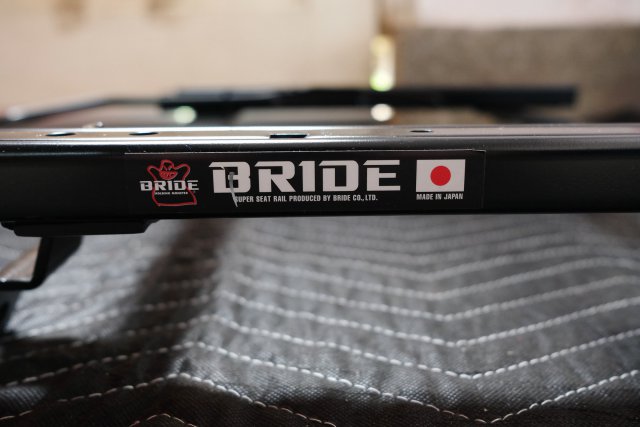

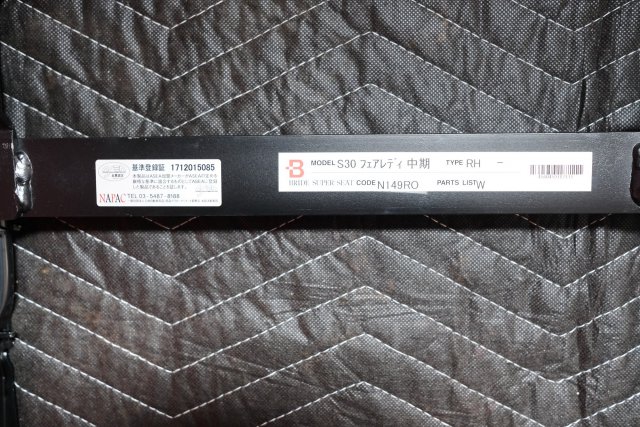

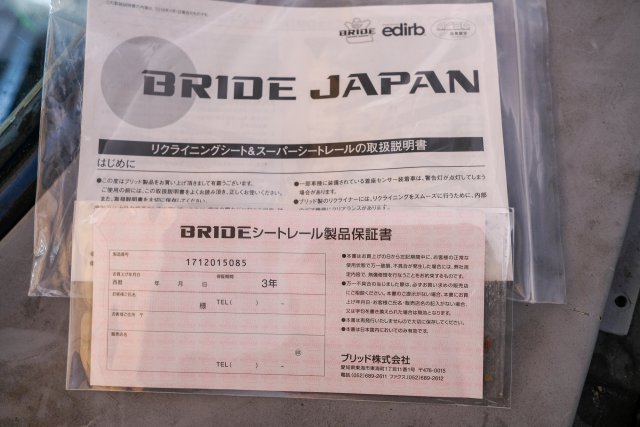

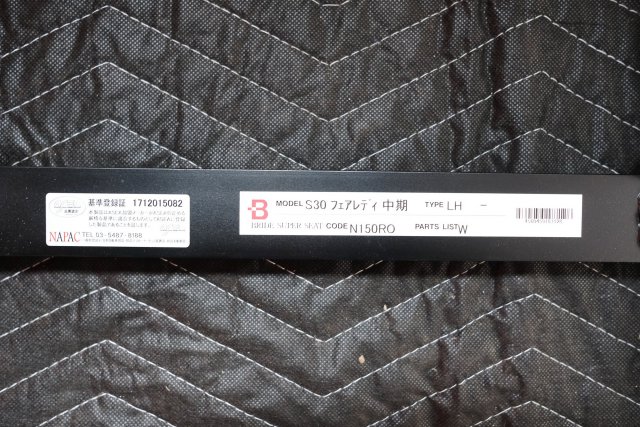

Have a new set of authentic Bride RO rails I ordered from Japan. They are unused, just taken out of the box to test fit and unfortunately didn't work with my seats. These are double locking sliders that bolt directly to the stock mounts in cars manufactured between 10/74/ and 6/76. They will fit a variety of Bride and Recaro seats (please check). Please note that the driver's side mounting tabs are a little higher than the passenger's (I suspect this is so they clear the hump in the trans tunnel). If you've already bashed your hump, it would be pretty easy to mod the tabs to be at the same level as the other side. Will ship at buyer’s expense, pickup available in Santa Cruz, CA. Asking $350 $300 for the pair. Part Numbers: N149RO N150RO

-

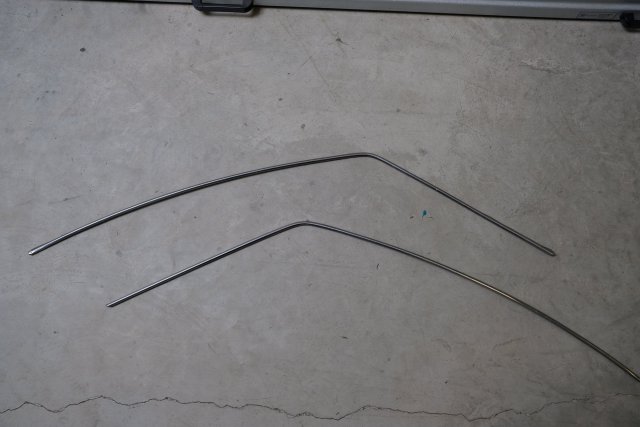

Selling a bunch of parts, mostly from my '76 280 but some stuff for other models/years. All parts are in good shape unless otherwise noted, many refreshed. Pickup encouraged in the bay area (Santa Cruz). Willing to ship most things at buyer's expense. -Front control arms (pair, with new poly bushings) - SOLD-TC rods / washers / new poly bushings (pair) - SOLD-Steering knuckles / good ball joints / boots (pair) - SOLD-Techno Versions r200 diff mount - SOLD-Chrome window trim set - 80-Wheel chocks - 20 -Turn signal lenses w/gaskets - SOLD -Fuel filler neck - 25 -Seat rails (one side has a couple extra holes drilled by p.o. but original ones are intact)- 50 -Steering rack with inner (new) and outer tie rod ends and new boots - 200 -Fuel vapor tank (in hatch) - 40

.jpg.a458eea32ea07bcabd59e52142a4a6bf.jpg)

.jpg.c780bc63f4a0c4dbc45112d07246facb.jpg)

.jpg.95dec584ff7c607ae1b2ede792eb25be.jpg)