artishard116

Donating Members-

Posts

68 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by artishard116

-

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Agreed! Have a lot to figure out still including fuel, wiring, cooling... may be a while until first start. I did hear about a 2nd caliper option for the AZC stuff, I think they were even selling one at some point. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Thanks for the kind words! Whole motor build is right above your post... do you mean running? It's all sitting in a garage right now until I can get back to work on it. Regarding the AZC stuff, the main things were that I wanted an integrated e-brake in the rear calipers, and I also wanted to do away with the stub-axles completely so the rear end kit from T3 made sense. -

Protecting inside of frame rails

artishard116 replied to artishard116's topic in Fabrication / Welding

Would be cool to get a reference list going of which areas to address so nothing gets missed. I'll be tackling this in the next few months and can report back. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Intake manifold coming together. Fitting the dbw throttle required making a weld-on flange. After some deliberation I decided on this gunmetal metallic powder coat. Exhaust manifold and turbo/wastegate mocked up. Plumbing the lines to the turbo. Test fitting fuel rail and Injector Dynamics injectors. Some PRP goodies including R35 coil pack conversion, and a Ross (?) head oil drain kit. All of this will be going in the car with the Apex crossmember and RB mounts. Hoping the hood will close. At this point all that was left was wrapping it up and putting it on a boat headed to California. Corona is in full effect now but surprisingly there were no delays. About 4 weeks later, through customs and safe and sound in CA. And that's about where I left off. Haven't been able to get back to the states in good conscience since Corona, but can't wait to get back to work. Might be a while until the next update, but I'm hoping it will be a big one. Everything as it stands now: -

There's a curved piece of metal going in there, if I'm understanding correctly.

-

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

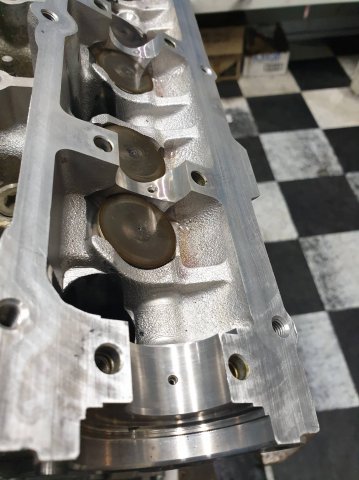

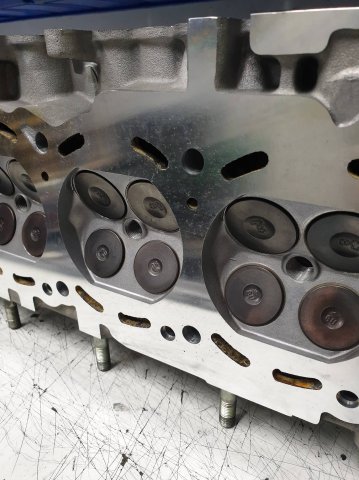

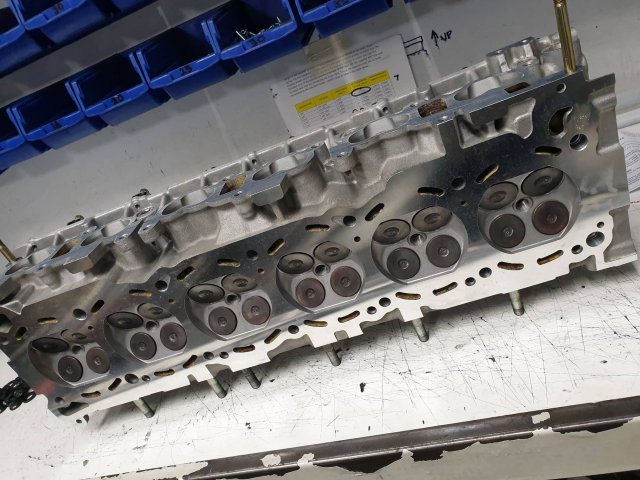

I always knew I wanted a Z with an RB heart and when researching engine builders, R.I.P.S. Racing in New Zealand kept coming up. I got in touch with Rob there and was quickly sold due to his knowledgeability, track record, and willingness to walk me through things (answer one million questions). He assured me that they ship motors all over the world, and that it wouldn't be a problem getting it to California. He was also kind enough to document basically the whole process for me. The brief was to be in the 500hp ballpark with an emphasis on response and reliability. Based on those factors I ended up with an RB30 bottom end, RB25 head, and a Garrett GTX3076 Gen II. The engine was cleaned up and rebuilt using mostly stock components but with upgrades to the oiling system, custom rear sump, custom exhaust and intake manifolds with Bosch DBW throttle, arp hardware, Tomei head gasket, and upgraded timing components, and some extras from Platinum Racing Products. Nitto oil pump. Also fitted restrictors to the head and a head drain. May add an accusump later on for a little more insurance. PRP crank trigger/gear. Also using their cam trigger kit. Will add an ATI damper. Shiny. -

That's a great idea, you could probably sell a fair number of those. Maybe with some tubes to sink through the rails to prevent crushing them.

-

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Thank you, me too. Next up, engine build. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Even though there's a ton of bodywork left and probably a decent amount of metal work, it's hard to overstate how exciting it is to see this thing in primer. Yes, my rear 'axle' cracked. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

The dipping stage. Not too many surprises but for reference, this what a 'rust free' California car looks like. All in all I think I made out pretty well compared to others I've seen. After dipping, the car went down the road to VersionEx Auto (also in Eugene). They assessed the damage for me and patched some of the roughest areas. Previous owner did a pretty messy job of cutting the rear fenders and replacing a rocker panel. Will likely cut a lot of this out and redo it. Ditto with this sidemarker job. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Next step for the car was a trip up to Eugene, OR to Metalworks for an acid bath. At this point I'd be heading back to Europe and saying goodbye to the car for a while, so before that I threw on some shiny parts for a test fit and some glamour shots. Seat clearance. These seats are pretty tight even with all the work I did but I think everything will fit. The driver's seat is almost dead center with the wheel. Plenty of headroom though. Had some fun editing these ones. Here's a link to higher res versions if anyone is interested. https://imgur.com/a/ygCkQHb Saying goodbye. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Ha! That was the first thing to go. Thanks a lot for all the advice/inspiration. It's coming together. I have a bunch more to share to bring this thread up to date. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

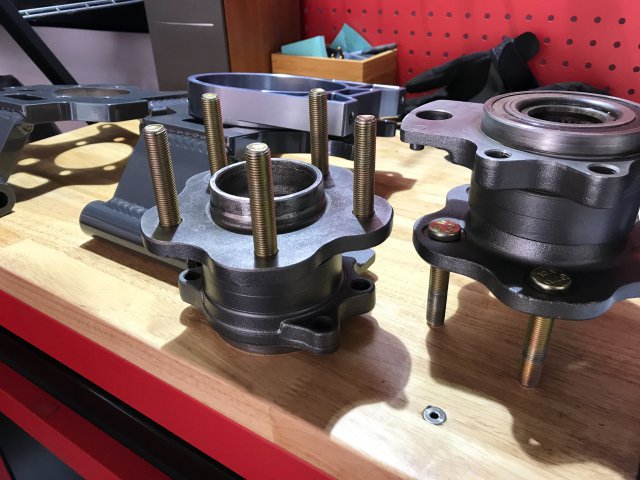

A pair of 300ZX TT rear hubs I cleaned up, painted, and added long ARP studs to. Might be letting these go as my rear end plans have changed. Some more T3 stuff shows up. Not happy about the McDonald's colors, but will fix it later. I hadn't welded since college but my friend left his gear at my place so I thought I'd get some practice and do some stitch welding here and there. Ended up doing nearly every seam in and out with the exception of the areas front and rear of the strut towers. Custom rails from Bad Dog arrived and fit well. I por15'd the old rails and pushed the new ones over them as close to the body as they would go, then my friend welded them up. My old man lending a hand. He's gotten pretty excited about the whole thing. Made my own rear subframe connectors to attach to the frame rails. I can tell just by pushing the car around the garage how much stiffer it's getting. Finished product after I cleaned up the welds a bit. Seat rails made out of some square tube that I contoured to the floor pans. Recaro rails attached. I may rethink how they attach, but this is version 1. Added an 1'8" plate behind the firewall that connects to the supports on either side of the wiper motor area. I wanted to strengthen this part before attaching the tri-strut bar, but couldn't think of anything better that left room for the wiper motor. Borrowed from @JMortensen and tied the cage into the chassis in a few places. Previous owner had hacked some speaker holes in the deck area so I cut out all the ragged metal. Haven't quite decided how to cover this up yet. Some more metalwork details. This pretty much wraps it up which means I can finally move on to the next stage. I've had the car about 8 months at this point. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Thanks! Can't take any credit for the pretty welds, those are all my friend. I had him handle anything structural/safety related. I filled a bunch of holes and stitch-welded nearly the whole chassis. You'll see a ton of ugly ones later that are mine haha. By bracket, you mean the mounting point for the lap belts? They look like this: -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Thanks for the tip, nice idea. I do have the Apex crossmember which has bars that brace the TC boxes somewhat. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Finished products: "I'll just do a couple stitch welds around the inside of this strut tower" (Famous last words). Some details of the cage and attachment points. Avoided the stock belt mounting holes so I could use them for my harness lap belt. Not sure if the angle will work out though. Bashed the hump in the transmission tunnel with a hammer to try and get enough seat clearance but it was a lost cause. Went full Flinstones. Filled the bumper holes using some Skillard pieces and warped it pretty bad in the process. Will let the body shop sort that one out. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

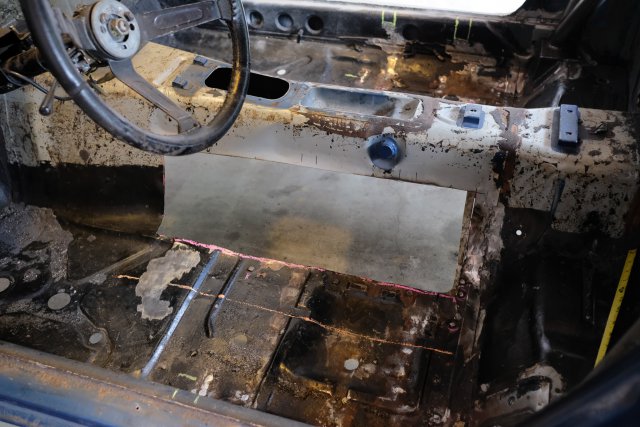

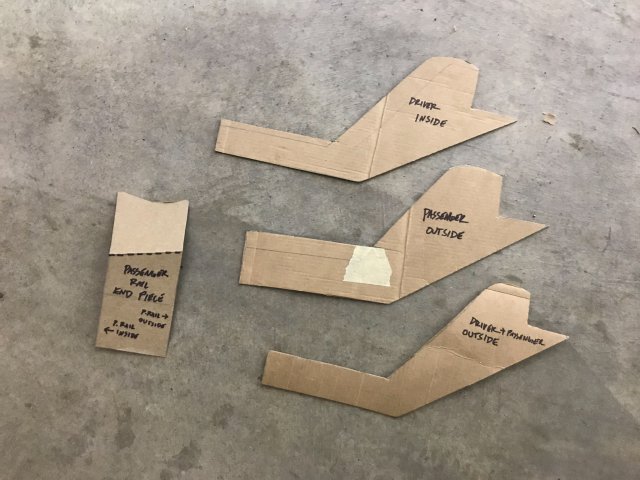

Stripped the rails down to metal in order to test fit some Bad Dog parts, only to discover that mine are unusually asymmetrical. Apparently it was a California car thing? One rail is about an inch taller than the other on one side, and runs flat against the floorpan instead of being contoured like the other side. John from Bad Dog was super helpful and offered to make me custom rails if I sent him templates. If anyone else runs into this problem, drop him a line and see if he can make you a set. Templates made, and subframe connectors mocked up. Had to do these from scratch as they're a totally different shape than on a 240. Determined that the stock seat mounts would have to go unless I wanted my seats to be at a severe angle (and too high). Messy job. Kept ripping holes in the thin floors when trying to remove the spot welds. Sank some tubes through the frame rails and sandwiched 1/8" plates on either side to strengthen the sway bar mounting points. Had a little tube left over from the cage and figured it couldn't hurt to brace the front frame horns. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Thanks! My fabricator friend did it all. We mostly followed the main hoop diagram floating around on here and it fit great. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Signal and reverse lights cleaned up/painted and new lenses added. Will replace all the wiring later. Made some wheels out of swivel casters, 4x4's and U-bolts so I could push the car around. Also had to move garages which was slightly sketchy. In the new space with some major garage upgrades. Finally got the cage in for good. More details to come. Strut towers also cut for weld-in plates. Lining up the T3 weld-in camber plates. IMG_6134.mov Welded on both sides. In retrospect, it would have been prettier if I put them on top of the towers, but it seemed like this would be stronger. They'll be covered by STB brackets anyway. A huge haul of parts show up, as well as seats and belts. Quick test fit: -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Did an illustration of the car (in the future) on an iPad! More at behance: https://www.behance.net/gallery/102683249/Datsun-Tribute-Adobe-Creative-Residency-Commission -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

It is! Just a cheap little test tool off amazon. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

Thanks! Sure, it was pretty simple, just used a plastic polish by McGuires I believe (meant for headlights), along with a cloth buffing wheel attachment on a power drill. Took several passes to get them shiny. You can find similar kits at most auto parts stores. Power tool is a must, unless you want your arm to fall off. Let me know if you have more questions. -

1976 280Z RB30/25 (R.I.P.S.)

artishard116 replied to artishard116's topic in S30 Series - 240z, 260z, 280z

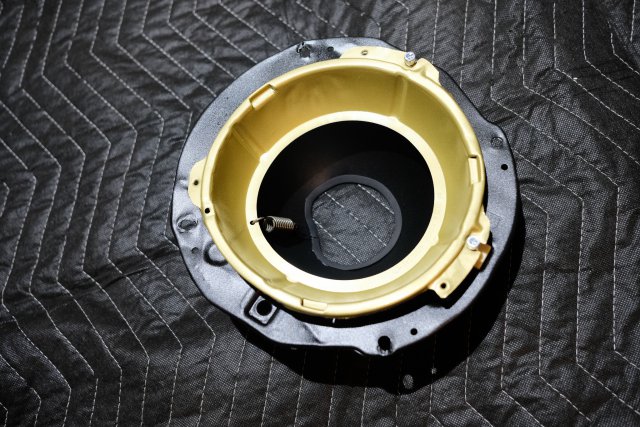

Next I tackled the headlights and installed Dapper led 7's. 40+ years of grime. Cleaned up with a wire wheel. Replaced all the old hardware, trim, and inserts. Used some Camaro parts or something because I couldn't find direct replacements. It required cutting the adjuster holes to squares, but otherwise went smoothly. Painted the buckets. The new lamps require cutting holes in the buckets. Hoping water and dirt won't get in there, but may need to close it off somehow. Lights installed. Actually replacing the glass covers with a more textured version so they look less modern. Testing.