-

Posts

5399 -

Joined

-

Last visited

-

Days Won

58

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by RebekahsZ

-

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

I am on slip plates, btw. I'm considering taking the car to an alignment shop between the 1/2-mile and the mile. But, we always assume that the shop's stuff is more accurate than ours. And that isn't necessarily so. They have calibration issues too. Most of the time there is at least something I have to fix once home from a laser alignment. Last time there were two lock nuts loose. Ive found that just torquing a lock nut can induce as much as 1/8" change. -

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

I'm very open to the possibility that my measurements are crap. Very, and for same reasons you cite and I can't defend them. I'm sure that a set of toe plates and tape measures leaves a lot to be desired in accuracy. I see guys align super fast drag cars with tape measures, so Im not sure how perfect we truly have to be. But I'm doing the best I can. As for wearing out tires-that's what do best! I've been dead-hook, front tire-lifting launching this car for a couple of years. The rear has poly inner bushings and rubber outer bushings with early Modern Motorsport rear LCAs. Steel bushings were just too freakin' loud. I'm betting (and photos suggest) that the tires move forward in the wheel well. I think that any deflection in the bushings on a car driven this way would cause toe-in? So I wasn't surprised that the rear measured with toe-in. I also wouldn't be surprised if these LCAs aren't less rigid than the stock versions. Hoping for a test drive either tonight or in the morning. -

Go to the Suspension FAQs at the top of the forums and look for some basic alignment settings proposed by the late Johnc. Those will get you close enough. Don't get lost in the bushing trap. You should do a coilovers conversion early on with camber plates. That will be required to achieve Johnc's alignment recommendations. Install Koni or Bilstein shocks and mount R-compound 225 series tires. That should do for a while. Then do the Arizona Z Car big disc conversion. If you go to V8 power and big sticky tires you will overwhelm the stock brakes. But if you have an L6 motor or just autocross, stock brakes are fine with Porterfield racing pads/shoes. Good luck! You will get many opinions and you will get picked on with such an open question, but I've given you plenty to work with.

-

If you are in Alabama, I have a standard T56 I can trade you. I need a Magnum for my truck.

-

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

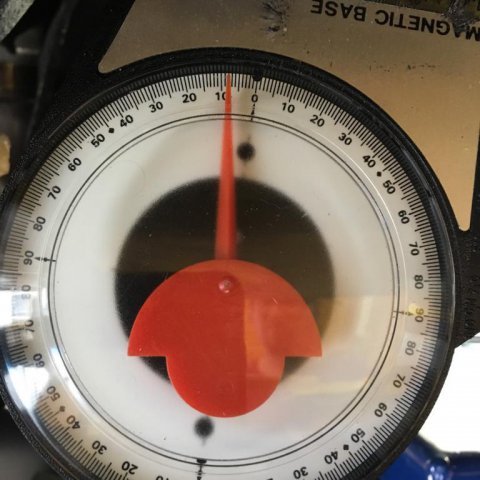

When I raised the static ride height, I lost from a baseline of 4.5 caster down to 2.6 caster. Will be trying to work as much caster back in as fender clearance will allow, then bumpsteering the car again to see how much that messes things up. With a doubling of the spring rate, this thing doesn't move much! Got the rear ride height set, then set rear toe to zero from a baseline of 1/2" toe in. It is funny that with the suspension set 1" higher, the rear toe in was only 1/8", so the rear suspension is a source of bumpsteer too! I know in theory it is not, but in reality it is. -

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

I think it's gonna be bumpsteer spacers that it takes to totally flatten that curve on the chart with x's. That's the final setting I'm gonna run. I will have a report in a month. -

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

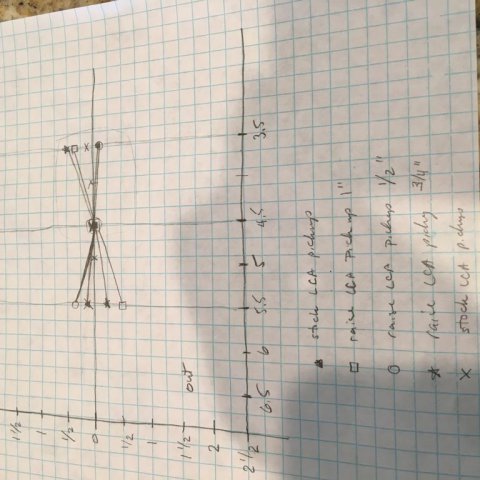

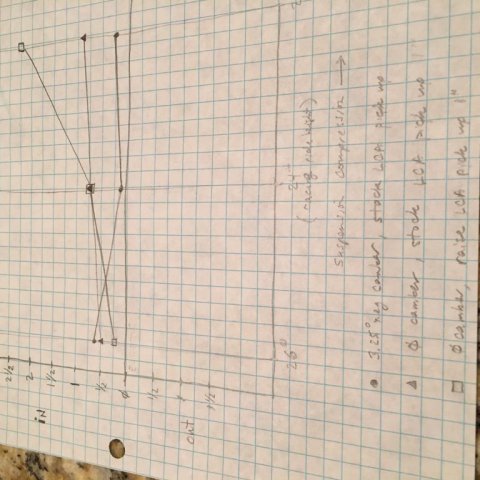

Thanks so much gentlemen. I'm so thankful that a friend came over to help me with the trial and error. I decided that rather than drilling out the stock knuckles, I would try to get the most out of what adjustment I have on the car while waiting for Dave at AZC to get his kit finished up. I see all the issues that come with spacers and wheel clearance issues. Lance, the photo you sent me was priceless-thank you so much. And it is such a privilege to talk to this group of mentors (we are getting scarce on this forum) and it is so nice to be talking about something other than what size wheels and tires will fit a Z! What I found was this: When raising the LCA pick up via a 1" vertical slot, it really steepened the bumpsteer curve very much more than leaving the LCA pick up in the stock location. The flattest curve that I could produce was with the stock pick up point. I do have 1" "bumpsteer spacers at the ball joint end of the TTT LCA. From a day and a half of trial and error, what finally worked the best was to raise the static ride height an inch! If I raised the car more, the curve got steep again. So, I ran thru a toe measurement sequence varying the ride height from 5.5" to 3.5" and here's what I came away with after toe was set to zero at 5" (measured from a bracket on my airdams support structure): 5.5" 1/8" total toe in 5.0" 0 total toe 4.5" 1/16 total in 4.0" 1/16 total in 3.5" 1/8 total in. The track at Ohio has a lot of rise and fall (bumps), so with the 225# springs, the car was getting 2" of compression at the front strut. That equaled 3" of compression at the front of the airdam. I'm sure the relationships are not linear (that would be too easy!), but I'm hoping that with 450# springs I will see approx 1" of compression at the strut rod (I installed an o-ring on the strut rid to act as a tell-tale). I'm going from 250# in back to 400#, so hopefully the rear shouldn't squat (front end lift) as much during the hard-acceleration portion of the 1-mile sprint. I will take my alignment gear to the track and vary static ride height between 5" and 4.5" and see how the car feels. I guess if I can't stand the high airdam, I can always add a little to the bottom! And I sure hope the chute is mounted right at CG so that it doesn't pitch the front end up or down! I will try to go thru this prices again with Dave's bumpsteer kit this winter to try to do better. I will go ahead and get a bumpsteer gauge too. But for now, I have too much else to get ready on the car to chance ruining a steering knuckle, etc. I will let you guys know how it turns out. Time to get the springs on it. -

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

I wish I was too!! I'm looking now at ever immersing with lowering the outer tie rod ends. I have stock knuckles. "Bumpsteer spacers" and about 4.5 degrees caster. How do you guys feel about drilling the steering knuckles for 5/8" bolts to allow me to lower the tie rod end? -

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Ok guys. I did some experiments tonight. I took baseline measurements with -3.25 camber last night. Tonight, I removed the springs and took measures with the stock LCA pick ups, then repeated with the LCA pick ups raised an inch. The super simple graph attached tells the tale. Basically, with my autocross camber setting: from &26" to& 24" (measured from front fender arch to floor) the car toes out 1/2". But from my racing static ride height of 24" to the 22" (when the airdam hits the ground), the car actually toes IN 1/8". When I set the camber to zero, the car toes way in from 1/8" in to 3/4" in at static ride height of 24". When I ran the ride height from 26" to 22", this configuration produced the least change, constantly in the toe-in direction. Very interestingly, raising the LCA pick up an inch made things crazy! From 26" to 24" there was 1/2" toeing in, then from 24" to 22", the car toed in an additional 1-1/2" for a total of 2-1/4"!!! So, perhaps my bumpsteeringbis coming from toe IN rather than toe out? I'm open to suggestions/recommendations. Going to study where the ride height break point is for the LCA angle. The bottom photo does not indicate ride height. To achieve this ride height, the LCAs look like a V! I just dropped it to check tire clearances and snapped the photo cause it looked so cool. I'm actually running at about 6.5" at the rocker pinch weld. -

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Heavy85-care to send me a picture of your configuration and spacer set up as it sits today? Thanks for your advice. Jon-the splitter has been cut off (did it track-side last year) and the front of the trimmed airdam still hit the ground. I think that it hit the ground due to the bumpiness of the course, not so much from down force. I will add a picture tonight that shows the spoiler added to the back of the car. I know lots of folks ignore advice, but I'm trying really hard to comply with you-guys' recommendations. I'm concerned about my safety too!! For both of you, the rear has 1/8" toe in. I bet that increases under acceleration and decreases under braking. I will check that at multiple ride heights. I've installed o-rings on the strut rods to serve as "tell-tales" to let me know just how much actual compression I am getting. I wish I had a way to video the wheel movement and review it in slow-motion. More to follow. And thank you all. -

New project-reducing bumpsteer

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Over the winter, I slotted my front crossmember. I am waiting on AZC steering knuckles to allow spacing on the tie-rod side of things as well, but the last batch he had made did not pass QC, so that modification will be delayed until after the race. So, my only real options that I see are: adjust LCA pick up height, reduce camber to as close to zero as possible, maximize caster, and stiffen up the spring rate to reduce ride height changes. So, tomorrow I hope to reduce camber and start playing with the LCA pick up height. I did install a chute over the winter, so that may help with getting the car slowed a good bit before applying the brakes, IF the chute mount is well placed relative to the car's CG (if not, that could alter my attitude too). -

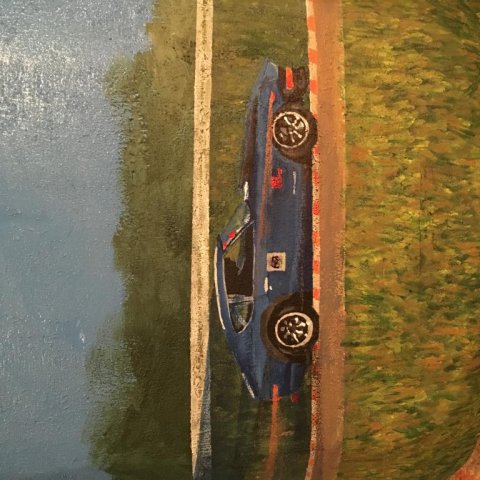

My car wanted to steer off the track on braking above 170mph at the Ohio Mile last year. It was a white knuckle experience for me. The direction that it went seemed to alternate with each application of the brakes, so I'm blaming it on bumpsteer rather than a problem with my brakes. So, it is time to try to reduce bumpsteer. With the same set up that I ran (my autocross alignment-lol: 3.25 negative camber, 4.5 caster, 1/8" toe in, 225# coilovers, stock LCA pick ups), I got some baseline toe change measurements as a starting point by using toe plates and an air-powered bridge jack to lift the car from the point where the front tires were just touching the floor to the point where the airdam was on the floor (by running the coilovers seats all the way down). I am running 1st generation TTT LCAs, which I think are longer than stock LCAs. Ride height was measured from the top of the fender arch to the floor. Alignment plates were used. When coming down from a ride height of 26" to 24", the total toe in goes from 3/4" toe in to 1/8" toe in (in this range, the car toes OUT as expected). Then from 24" (my racing ride height) to 22" (low enough for the airdam to scrape the ground-which it does on the standing mile), the toe in goes from 1/8" to 3/8" toe in (in this range of travel, the car toes IN)! This was a big surprise-I expected toe out to continue as the nose dropped.

-

ST front sway bar clearance question

RebekahsZ replied to madkaw's topic in Brakes, Wheels, Suspension and Chassis

I don't know you well enough to say you are dumb-I'm not mean like that. -

ST front sway bar clearance question

RebekahsZ replied to madkaw's topic in Brakes, Wheels, Suspension and Chassis

Just space the bar down from the frame. -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

I may have gotten mine from DatsunPartsLtd. -

shops that do turnkey ls 240z swap?

RebekahsZ replied to alphalonewolfxiong's topic in Gen III & IV Chevy V8Z Tech Board

I stopped counting at about $15k back in the early 1990s. If you enjoy it, it is worth it. -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Crushed brake line replaced and brakes bled. Tomorrow night we swap axles and tires. The goal for this week is to get the springs off the car and get some baseline bumpsteer measurements. -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Chute mount painted. Chute release mechanism (parking brake handle) painted and reinstalled. Passenger seat reinstalled. Fuel tank reinstalled, filled with 93 octane. License plate and tail light surround modified for chute and reinstalled. Went to local cruise-in last night and tried the line-lock out when leaving. Don't know if the street rodders liked all that rubber smoke or not. I did it just up wind of where all the old-timers and their wives were sitting in lawn chairs, but away from any cars with shiny paint jobs. Got lots more attention than ever before (it helps to show up without a hood). Burned rust off the rotors that had built up since April autocross (last time car was driven). car fired right up as soon as fuel pressure gauge hit 50 psi (I love EFI!). Car is back on lift to replace a front brake line that got crushed at ZCON 2015 in an off-track excision. It still flows but probably won't pass ECTA tech if spotted. Got the framework for the LSR airdam installed too. Was assisted all day and 'til 11pm by Thomas a new member of hybridZ who lives 2 hours away. His '71 Z came from Austin, TX and is incredible as a stocker-81,000 original miles. I encouraged him retain the A/C and to keep it stock. We got it on the lift and found 4 leaking struts and 2 bad inner tie rods. A test drive only revealed the need to perfect the clutch pedal adjustment and the need for inner tie rods and to have the rotors turned or replaced. otherwise car drove great. Was leaking oil from cam cover and oil pan. We found all the bolts finger tight and torqued them all evenly to 84 inch-lbs / 7 ft-lbs. His car drove like a dream-even had original exhaust pipe, was very torque-y and quiet. He has tuned it well. We hope to replace those few wear items before spring when Z Atrack will hopefully be held again (it has been 3 years) at Nissan HQ in Franklin, TN in April. I hope Thomas will enter as a stock (repainted) car and will likely place in top 3, and I will enter in some crazy ultra modified class and will likely win the T-shirt I bought at registration, if past history proves itself. Maybe we will get an Ansa style muffler for Thomas after that just to sexy up the car. But I bet a muffler alone would put him in Modified class, and his car deserves a trophy as it sits. So hopefully he will leave it alone for a bit and not catch my disease. It was great having a buddy over to the shop, and he was a good co-worker. Brought great home-made chocolate chip cookies as a peace offering and I ate nearly the whole bag! Well done, Thomas! Kudos to Charith in LA/SD for helping Thomas find such a great car. -

shops that do turnkey ls 240z swap?

RebekahsZ replied to alphalonewolfxiong's topic in Gen III & IV Chevy V8Z Tech Board

They ARE out to make a living, so I don't hate 'em. It kinda is what it is. He wasn't dishonest, he was....profitable. Which is what all businesses seek to be. When it comes to your engine: inspect it. Take it down to the long block and look at the valve train and the bottom end. Look for signs of abuse or an episode of oil pressure loss. Cut open and inspect the oil filter. The engines consume oil the I the PCV system so a lot of them get driven with low oil level. The donor engine for my truck was known to have bad bearings. He just never went to the effort to find out why. If he had just spent a little profit to have the engine spec'd out at a machine shop, instead of just slapping new bearings in it 3 times before he scratched his head a little, I'd be telling a very different story. -

shops that do turnkey ls 240z swap?

RebekahsZ replied to alphalonewolfxiong's topic in Gen III & IV Chevy V8Z Tech Board

And no, I won't tell you who did my truck because even after all that, I still like him and want to be able to list him among my friends. He fell off the pedestal I had him on, but I still think he is worth knowing and that he has a lot to offer as a person and as a tuner. I will use him for tuning, but I won't bring him a big start-to-finish project again. I'm willing to consider the possibility that I might be hard to please. -

shops that do turnkey ls 240z swap?

RebekahsZ replied to alphalonewolfxiong's topic in Gen III & IV Chevy V8Z Tech Board

A lot is going to depend on your expectations. I did my swap in my Z over a 2 year period and I did it to my standards. I paid a guy 13k total (parts and labor) to do the swap into my truck because I thought it would be faster, and I am intimidated by airconditioning, guages, and cruise control. He did it to his standards. Specifically, it took 6 months, I had to take it back 3 times for bearings because his standard for a rebuild didn't include have the block checked by a machinist to be sure it wasn't warped. His standards included kinked air conditioner lines, old coils and old plug wires rubbing on the steering shaft, headers that rub the suspension, $900 headers that don't fit when you can have custom headers built for that price, a tune that is set for best numbers at WOT when it is a street truck so now it runs rich, stinks and gets bad mileage, no oil in the transmission, re-used valve cover gaskets that leak, a 13 year old engine harness that throws knock sendor codes all the time, Airconditioning that holds a charge for 2 days then goes inop, etc, etc. At least the cruise control works. If you do it yourself, you will get what you pay for. If you pay somebody, you will get less than you pay for. I guess that is what it takes for mechanics to make money and maybe I should feel bad for them. Be as specific as you can with your expectations when you get your estimate. Then, expect the mechanic to never look at your list again. Have 2X the money set aside as the estimate. BTW-my 4000 pound truck does 14.1 and 100mph in the quarter, spinning thru first and second gears on street tires. But I can't run both the headlights and the airconditioning at the same time, the clutch hydraulic line spits out of the slave about every 6 months, I sometimes have to hold it in second gear with my hand (thanks to the no oil in the tranny-not discovered until it started failing), and I have to clear some recurrent engine codes about every 3 days. Other than that the truck is fine, and I'm driving it daily. Oops-I forgot-it uses a lot of oil. On the flip side: I've had ZERO reliability issues from my Z. -

It's dead.

-

Delete the rear bar. If you just bought it, return it. A rear bar actually hurts the Z. So you are killing yourself to add weight to the car that works against you in corners. Costs you traction exiting corners. Even if you have an LSD.