Zinpieces

Members-

Posts

101 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zinpieces

-

-

Well I see it's been a year since my last post. There should be a thread for slowest build. Seemed like a good time for an update. Paint is done except for the hood and the glass is in. Might even drive it soon

-

Looking for a fuel filler tube for a '78 280Z

Zinpieces replied to Stevotello's topic in Parts Wanted

-

-

-

They did that for me so I would not mix them up, I have a bunch of parts from 240's and 280.s if you need something I'll try to help

-

I was concerned about exhaust heat affecting my oil cooling and the messy oil changes. This is how I did a remote oil filter on a sb 350

-

-

Sometimes I wonder why it takes me so long to do a car and then I spend two days making one hood latch. The good news is there is only one to go! Just roughed out for today, need to disassemble and paint etc.

-

Not exactly ready for prime time, but at least it's off the floor! Starting to look like it might actually run!

-

Needing a brake line, driveshaft flange, and door handle.

Zinpieces replied to mr_han_solo's topic in Parts Wanted

I have a DAT-110, 50 bucks delivered -

You really really don't want a single axle trailer, 1 flat and you're done. With dual wheels you can change a flat without a jack, just pull up onto a couple of 2X6's and the other wheel comes off the ground. I've trailered cars all over the East Coast and dual axle trailers are much better behaved, not to mention each wheel has a brake so unless you're towing with a dualie you won't get pushed around!

-

TTT coilovers rub on CVs?

Zinpieces replied to socorob's topic in Brakes, Wheels, Suspension and Chassis

I had the same problem. Check the angle of the mounting tab to the base. If its not 90 degrees then there was some warping during welding. Gabriel replaced mine no problem. -

I recently had my 240 shell done by a local "Green Earth" glass slurry. The results were fantastic! The cleanup was a real chore. It took me three days to get the glass out of the car. I don't mean the occasional wisp of powder I mean the five pound clumps. It was worth it, but it was a real chore, a lot of rotating on the rotisserie a lot of tapping, banging, vacuuming, and blowing. If I had done only the exterior the cleanup would have been a breeze. I did everything inside and out. Probably should have just POR 15'd the interior but I am just a little anal when it comes to rust. The job was done on a hot humid day and the skin did start to flash almost immediately. I spent two days with a DA smoothing the body and then shot on epoxy primer sealer inside and out. Painted the shell on my rotisserie which made good coverage a breeze. Plan on sanding the body the glass will leave a rough surface. The inside and the underside got a quick scuff and liberal scrub with wax and grease remover.

-

Never thought it would be so tough to get the shell clean of glass from the media blast. Spent two days blowing, vacuuming, rotating, sanding and wiping. Finally ready we rolled her into the booth and coated her with etch prime. While we were at it we quickie painted the right rear quarter, just enough so my wife can see the color. Now that rust is not an issue I'll start the bodywork

-

Save yourself a lot of time and buy a premade harness from Kwik-Wire, my preference, or Painless, or Ron Francis and adapt it to your Z. It is really easier than you might think!

-

Today I had the guys from Mobile Blast Away over to blast the shell. They use a slurry of powdered glass and water that works incredibly well and will not distort even the thinnest metal. Then I loaded up the shell and took it to a friends body shop. Tomorrow I'll DA the shell and get some etch prime on it

-

I am looking for the most complete, best quality set of moldings, I can find. I need everything from hatch to headlights for my '71 Z. I know some of you guys have done total restorations so someone knows the best deal. Appreciate hearing from you. Tomorrow the body gets media blasted and delivered to the body shop for primer. I'll post some pictures in my build. Thanks!

-

The more I stared at the HE distributor and the firewall the less I liked it. There is no real way to modify the JTR setback plates, but I really wanted the motor a little further forward. I decided to modify the crossmember to allow the motor to move 1.25 in. forward. Basically a new top plate and some boxing. I put the motor and trans back in and feel much better about the spacing. I also have room to install a smooth firewall. Satisfied that the fitment was good and there were no other issues I dropped the motor and trans back out. Gotta put the Z on the back burner now and get ready for Lead East this weekend!

-

Clutch will not disengage: Tried everything

Zinpieces replied to Ben's Z's topic in Trouble Shooting / General Engine

If everything turns freely on a lift or on stands, and you have a problem with the car on the ground I'd look very carefully for some flex in the body. I've seen the geometry of a car change quite a bit because of flex or a frame issue. -

My exhaust system was beginning to show the first signs of rust, so out with it! Then some sanding and some wiping down followed by several coats of high temp aluminum paint. Then I got the sudden desire to start doing some body work. Two hours later I had the rear and front suspension and the diff and mounting out of the car. The trans and motor are unbolted and will be dropped out next. Guess I am committed to doing some body work!

-

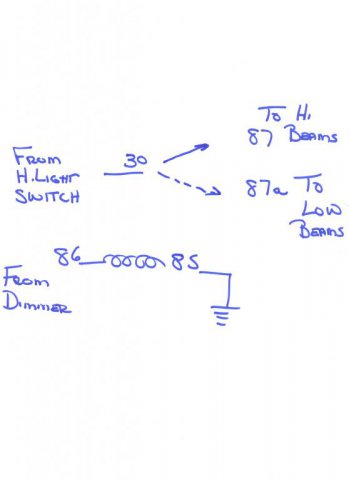

How do I add relays with my EZ Wiring harness?

Zinpieces replied to dpuma8's topic in Ignition and Electrical

You need to power the headlight switch and the dimmer switch separately and you only need the common and one wire from the dimmer switch. It is not being used to switch from hi to lo beam it is being used to energize and de-energize the relay. Relay energized is hi beam and relay de-energized is lo beam. Headlight switch off is dark. If it not clear let me know -

-

Turn Signal Wiring w/ Gm Headlight switch

Zinpieces replied to 240zBoy's topic in Ignition and Electrical

I have developed a method of using the stock turn signal switch with aftermarket harness that works well. The trick is to use a six wire turn signal switch from a 280 rather than a three wire switch from a 240. I can shoot you a diagram if you want