Search the Community

Showing results for tags 'Welding'.

-

Currently upgrading my suspension and brakes. Remove the from tow brackets and found a good amount of rust on bothsides. Located just above the front sway bar location. I searched the forums and didn't find anything showing how this part tackled. I know 12 guage replacement pieces are sold for the sway bar location but haven't found any for the rest of this section. Ill eventually need to address rust on the radiator support. Pointers are appreciated

-

i bought my zx a couple years ago now my goal is partially a restomod but also creating a racecar setup. at the moment im finsihing up with my engine work including intake with pallnet rail and new injectors and the works and a header thats all fine and dandy but my big issue is the body! originally the only rust i found was the spare wheel well but that turned into small patches on all for quarters and passenger floor pan and rails, battery box, to my current discovery the windshield area both on the roof and the wiper cowl. with my lack of experience in body work i cut out the passenger floor and welded in some new steel not have bad for a rookie. i already planned on buying new fibergalss fenders for the front so no need to fix the fenders and i think i can handle the rear quarters but don't know how to work with the windshield trim areas. unlike the s30 the cowl doesn't unbolt so obviously i have to drill out tack welds. and i dont even know what im going to do with roof at the moment but im looking for advice from someone thats had to repair these particular areas before and i know i should have bought a new shell long ago but im in this one deep plus this has been the greatest learning project possible.

-

Hello I have never welded before and was hoping that you all can tell me if I should buy a "mig welder" and attempt to spot weld my entire car myself? If so any ideas of the most inexpensive machine and possible advice on how to learn to do myself?

- 10 replies

-

- entire car

- mig welder

-

(and 3 more)

Tagged with:

-

I have purchased the vintage air 2 for my 70 to 240 Z I was hoping someone knows the specs/measurements for the brackets to install the unit under the dashboard I cannot weld so I’m trying to just put together steel brackets and put them together to fit but I could use some help with how far up and down place it in side to side so I’m not spending an arm and a leg on the brackets. Or if anyone has got extra ones welded I’m willing to purchase them ?😀

- 4 replies

-

- vintage air

- brackets

-

(and 2 more)

Tagged with:

-

Hello everyone on HybridZ! First a quick introduction, as this is my first post here on the forums. About a year ago, I bought a 1971 240Z which I bought from a gentleman Tecumseh, Oklahoma (right outside of Oklahoma City). I don't know much about the car's history aside from the fact that it sat at the gentleman's house since about 2008 because he thought that the engine was blown. Well long story short, the carbs were way out of tune and the distributor was turned about 180 degrees. Now a year or so later I haven't been able to get much work done, however I am in the process of stripping down the whole car, bagging and tagging everything. Being that the car will hopefully be completely stripped of all of its parts soon, I am looking into fixing the rust that exists on the car. The floor pans are long gone as well as the entirety of the passenger footwell all the way up under the cowl, just on the passenger side fortunately. The other hotspots per se are the driver's side a pillar which has a large rust hole, and a few other spots here and there. I am wanting to remove all of the rust that I can in order to ensure that my long-neglected Z doesn't have rust issues in the future. I plan on having it media blasted and epoxy primered (to prevent rust until I can have it painted), I was quoted about $1500 for the media blasting and primer work. I plan on replacing the floor pans, the frame rails, the rust hole on the a pillar, battery tray, etc. Now for my actual question, thank you for staying by the way. My main question is, in what order should I go upon repairing the rust and body flaws? Before or after the media blasting and primer? I've got a lot of work on my hands and I appreciate any advice that you've got. Thanks!

-

Made this turbo back exhaust for this Rb powered 240z, it's made from oval tubing and round tubing. Fully tig welded stainless steel. A HKS Hi-power muffler was used at the back. Rear spare tire well was cut in order to clear the enormous muffler ( customer didn't realize how big the canister was) Cut some sheetmetal and Beadrolled it for strength and style. Came out pretty clean and it sounds awesome! I will try and upload a video here or link to youtube.

- 3 replies

-

- Rb25 exhaust

- tig

-

(and 5 more)

Tagged with:

-

Ok, so I can see the finish line from a very long journey, that is my 1973 RB 240Z. I have a CLSD from an 1989 Z31T with the CV shafts. I'm trying to get the CV axles bolted into my car but I have been finding out that these adapter options for the CV adapter conversion are PRICEY!!! Especially, when you factor in the price for having to get the 27 spline axles from a 280Z (getting harder to find) and the Modern-Motorsport option. Plus, I don't know why NOBODY developed and adapter for the stock 240Z 25 spline stub axles to just bolt to the Z31T CV axles!!!! People keep saying that it was for strength but I don't buy that. They are not much thicker, and you've only gained just 2 splines. For a stock RB, I'm sure the 25 spline will hold up just fine. I'm just trying to get my CV's under the car. Looking for the welded plate to stock flange option so that I can get my car back on the road. I've seen pictures on Google from what Modern-Motorsports "used" to do, but I need better specs for the plate(steal). I found specs for a plate for the 280ZXT CV's, but I cant figure out why no one has done this for the Z31T CV axles. Maybe I'm looking in the wrong place... Anyone have any answers??? Thanks for any and all help you give.

-

My z is an incomplete project my friend started, since the car is torn down as far as it is I'm going to go a little deeper than he did. My friend dealt with the rust on this car with a wire wheel and Por15, the entire interior floor, engine bay and front wheel wells. I want to cut out and repair a few areas of rust, stitch weld, complete the frame rails to the rear and roll cage. I'm wondering what I can do to get rid of the por15. -soda blasting - looks like eastwood has a 100# blaster, and from what I read the 80/20 mix says it will "The soda media will remove urethane, epoxies, enamels and lacquer top coats along with virtually every primer and filler for automotive and marine use" - media blast - What media is best? How can I keep from warping the metal? -Wire wheel - I don't think I can get into every nook and cranny. -Por15 remover - terrible stuff I hear, can I throw the used chemicals in the trash when I've stripped the por15? Thanks in advance for your help!

-

Hi all, this is my first posting on this site and I've come here in search of some help with my 280z. I bought my 1977 Datsun 280z a few months ago for $2k. I bought it not running, since I'm more of an engine guy I was able to get her started and running in about two weeks after digging through the wiring and figuring out it was a bad ECU. Through further inspection of the chassis of the car, I found some rust. I know rust is typical on Datsun's, but I have a lot of people telling me its a lost cause and the frame repair will be too costly and dangerous to attempt. I've been told to use my 280z as a parts car, and get a rust free chassis to rebuild using the engine and parts from my current car. Here's a few photos of what I'm dealing with Take a look and see what you think. I don't know what I would need to fix severe rust like this. I found front frame rails online for $450, but I'm wary about them because there's no photos. Has anyone here ever used the front frame rail kit from "The Z Store"? If so, what did you have to do to put them in? I'm still considering my options with this, I really don't want to sell the car and I really don't want to have to part it out. However I don't have access to a garage, I don't own a welder (besides a little 90 amp flux core MIG, which I know I can't use for this) and I've really never welded before but it's never too late to learn. What's your opinion?

- 3 replies

-

- frame rails

- welding

-

(and 3 more)

Tagged with:

-

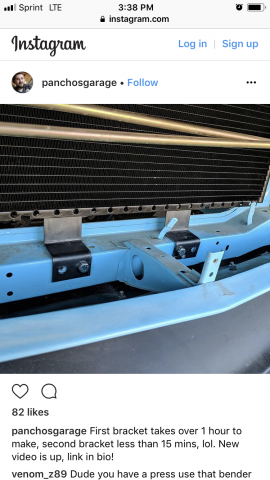

I am in the middle of restoring my 75 280z and have a few questions im hoping you can help me with! I am doing an LM7, or 5.3 v8 build with a Camaro T56 6-speed. Currently, i have scrapped most of the underbody off to clean it up and get to the rust, and all of the rubber coating off of the floor on the inside. Behind the fenders i have noticed, by the door hinges there are a couple of spot welds for the fender/main body piece. I was thinking, that could really be strengthened up with a fresh weld, which got me thinking: Im cutting out the radiator support and welding in tubular, and making custom frame rail and motor, strut tower/firewall braces which should help a lot. I am also going to have a partial/custom cage. What other spots on the car could use some good welds to help strengthen the shell, due to running a 600+hp v8 turbo setup?

- 2 replies

-

- v8

- restoration

-

(and 2 more)

Tagged with: