Leaderboard

Popular Content

Showing content with the highest reputation on 04/09/21 in all areas

-

Hi all! Restoring a rusted 240z series 1, SCCA vintage race car. Car last raced in 02'. Currently rebuilding to group EP spec's. I figured id start a new thread summarize my plans and progress. Il just add progress photo's to this thread. Thanks for reading! Engine: L24 Block – OEM bore, stroke. OEM materials. Not modified Head – N42 core Modifications: polished bowls. Valve seat de-shrouded. Minor reliefs cut around seats, but within ID spec of gasket. Chambers polished and de-burred. Deck machined to reduce chamber volume to 38.5cc's. Piston-deck clearance is -0.35mm, so with a fel-pro gasket (1-1.25mm), it should net a static CR of 10:1 Intake ports matched and polished within 1” of mounting surface. Same on intake manifold. Valves – OEM intake. Exhaust and seat are custom turned down to 33mm (L24 spec) Valve springs: Custom single bee-hive, with custom machined narrow steel retainer Cam: Exhaust and Intake are symmetric. 320 duration, 234 @ 0.05. 0.500 lift. 109 overlap Carbs: Stock SU's. Will purchase SM needles Exhaust: MSA 6-1 header w/ O2 weld bung, Eastwood header paint, and fiber wrapped. Anticipate using Borla XS straight-through muffler. Will consider adding resonator if I have room. Materials acquired for full 2.75” 304SS exhaust Ignition: Distributor with electronic pick-ups. This came with the car, so not familiar with it. Looking into crank triggered ignitions system for better resolution and tuning. Standard coil, NGK spark plugs and wires. Racing dampener/pulley Stock flywheel. Remote oil filter w/ copper/AL oil cooler mounted in front of radiator 3-row radiator No radiator fan at this time Notes: since class rules allow 12:1, intent is to install domed pistons during the next block rebuild. 10:1 with existing flat-top pistons should currently work for 91 octane. Will use wide-band O2 to log A/F with SM needles to gather data points for needle modification. Transmission – series 2 240z OEM Nissan 4-speed Clutch/Flywheel: Have not pulled transmission since purchase, but presume OEM. OEM driveshaft Differential: 17' Subaru STI helical LSD, 3.545 Half-shafts: Datsun restomod custom CV shafts with integral diff input shafts for STI R180 Have a spare 4.11 R180 but have not ponied up the money to transfer the helical center section. Fuel 12 gallon poly/aluminum fuel cell with steel support bracket. Came with two fuel output ports and one vent. I recently installed a level sending unit so I no longer need to use a dip stick. Dual (redundant) low pressure fuel pumps with outboard check valves, leading to single Y header. 3/8” galv/steel fuel hard-line being installed in tunnel. -6 AN fittings and new nylon/SS braided lines throughout for connection from hard-line to fuel cell and carbs. Generic FPR set to 5psi, feeding SU floats. Currently dead-heading but im looking into the need to install a return line. Brakes Proportioning valve installed in tunnel, protruding into center console for access while driving. OEM rear drums OEM front calipers. Cross-drilled rotors Suspension OEM hubs Struts sectioned with Ground Control coilovers. Eibach springs 350lb/in front, 300 rear Koni 8610 RACE adjustable shocks Ground Control custom bolt-in camber plates Urethane bushings throughout Rear has Apex Engineering control arms (got a good deal on offer-up) Rear sway bar Front is OEM at this time Wheels – Diamond steel racing wheels, 16lbs, 15X7” No tires mounted on racing wheels at this time Chassis Race prepared, lightened, and all trim/accessories removed 8-point “NASCAR” style cage. Door sectioned with only outer surface remaining. Chassis reinforcing Custom rocker reinforcing, utilizing 14 gauge axially and 20- gauge for stiffening ribs rocker to over-fender frame reinforcing (tube) Tube steel reinforcing between roll cage termination on fire wall, through to strut tower. New passenger seat mounting supports. Mounting point 1.5” above floor panel. Custom extension of floor panel stiffening support, through to unibody subframe directly behind floor panels. 2X corbeau 1-piece racing seats Fire suppression E-pull installed, with fire bottle mounted behind passenger seat on floor panel. expired 5-point harness solid/welded rear strut bar. Custom made, removable front strut bar 11lb Braile AGM battery with custom SS battery box, mounted behind passenger seat. Fiberglass rear hatch1 point

-

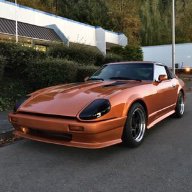

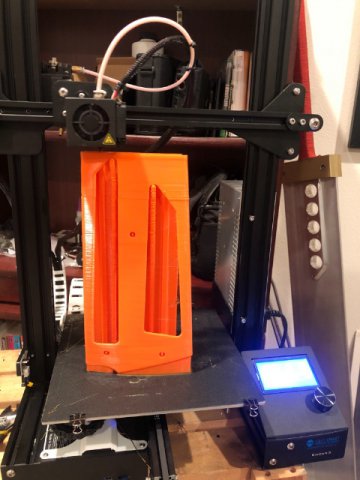

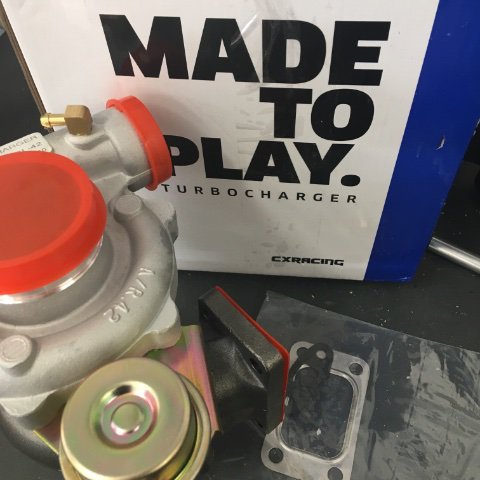

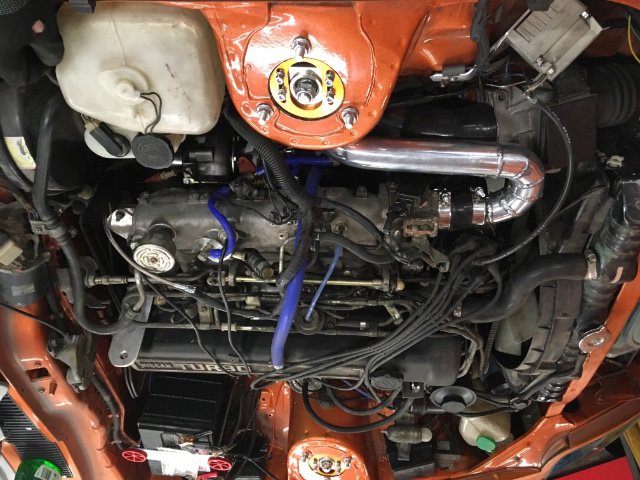

I think this is about the time I sold the grey "parts" car. It was running so nicely that I couldn't bear to strip it for the interior. I did screw around with a funky idea for a gated shifter on the Z. When I was younger, I used to play this arcade game at GameWorks that was a Ferrarri challenge game and it had a gated shifter and it was so cool, I thought I could get it to work on the Z. Turns out the S130 gearbox does not have enough shaft movement at any "reasonable" height for it to have distinct gates. This 3rd prototype did work, but only until I bolted it rigidly to the tunnel. I got rid of it soon after and moved on. A pic of my "peeding" rods. My side panel was cracked and also I do not dig the look. And also I did not appreciate the additional trim piece above it. So I stick it in my "CMM". And by that, I mean my self-converted CNC mill. First test-fit print Third iteration on the car .. measuring clearance note for rev 4 to be printed in ABS. After dragging my temporary exhaust on some speed bumps, I set to tucking it under the car further. I guess I have some explaining about what is to come next. Well, I bought a L28ET motor off craigslist for this car, but it was very bare. It had no turbo, no distributor, no ECU. I set about getting the car running with all the NA gear I had on hand and it ran quite okay with some hacking! I made a custom exhaust with a T3 flange (lol). It was basically a super low-comp NA motor that I was just using to power it while I finished the bodywork. Once I dragged this temporary exhaust on my way out of the grocery store, I hacked it off. As I was planning how I was going to re-weld it, I decided I might as well finally get the turbo so I only have to re-design the exhaust one more time! I had a fancy ball-bearing unit in mind, but then I realized it didn't have an internal wastegate and aint nobody got time for external wastegates. I thought I would give China's finest a try (anyone notice a trend here?) and went with a CX design from the 1980's. I was a Classic Saab 900 Turbo guy for many moons before cash for clunkers and have always had fun with these old-school T3 journal bearing units. I am going to only run a few PSI of boost until I finish my speeduino rig and get bigger injectors (still rocking 185's haha) so I hodge-podged and fabri-cobbled this together.1 point