akeboshi

Members-

Posts

149 -

Joined

-

Last visited

About akeboshi

- Birthday 10/04/1986

Contact Methods

-

MSN

akeboshi11619@gmail.com

-

ICQ

akeboshi11619@gmail.com

-

Yahoo

akeboshi11619@gmail.com

-

Jabber

akeboshi11619@gmail.com

Profile Information

-

Gender

Male

-

Location

San Diego

-

Interests

working on my 77 280z (obviously) playing with my son and wife (family first, D1GP dreams second) and hopefully drifting my Z soon. looking for places in San Diego to learn/practice!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

akeboshi's Achievements

Newbie (1/14)

0

Reputation

-

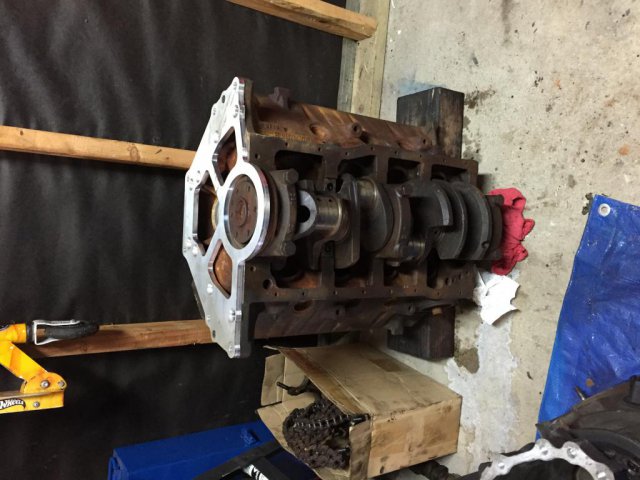

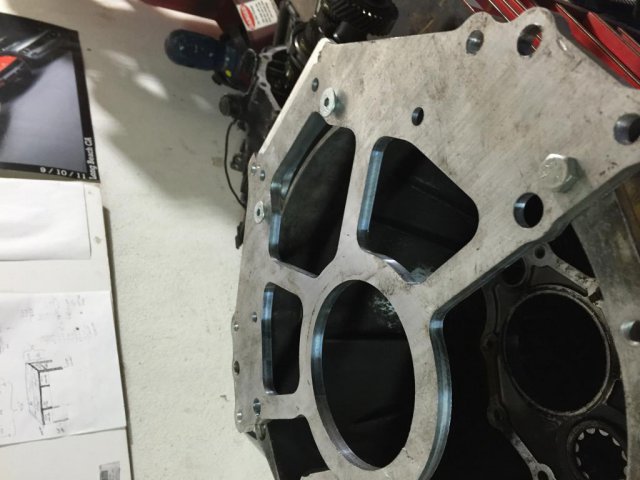

Hello, Its been quite a while since I have posted on the Hybrid Z forum but I thought someone from this forum might find this post interesting or useful. My roots started with Datsuns so I definitely have a soft spot for this place. Anyways, I have been working on what i think to be the first 302/351 to z32 trans adapter. I wasn't able to find any info on it anywhere but I have a feeling it could be popular. I started with an adapter i found on craigslist that allows one to bolt a small block Ford T-5 to a Ford 2.3L which I can only assume is popular with the turbo SVO guys. I believe its from Stinger Performance or a similar company. The reason I chose it was because it already had the right pattern for the block, it was thinner, and of course it was a super cheap craigslist deal. I then made a bushing to center the input shaft to the crank on the lathe. I separated the bell housing to make things easier to handle and placed the adapter on the block. I then tossed the bell and the rest of the trans onto the block making sure the pilot bushing went into the crank, centered the trans and used transfer punches to get the holes started. I have to wait until I get back home to finish it up but my real problem is finding the right flywheel. I can't find any info on the actual diameter of the z32 flywheel. I also saw that there is a 6 hole version as well as an 8 hole version. I might be able to use a Ford 2.3L flywheel because i read that the 2.3L will bolt on to the SBF crank. Maybe if I get lucky the 2.3 will be slightly larger than the z32 flywheel and it will be a matter of turning it down and welding the z32 ring gear on. If anybody can point me in the right direction in this matter it would definitely help.

-

I really wish I could help you with your edis problem but as far as compression goes 115 is not good even for a turbo motor. 150 on the other hand sounds better but like you said, the motor hasn't been broken in yet. What ou really want to look for in this situation more than high compression numbers are consistent numbers. My Na build was at 90 psi after the first 100 miles getting higher eventually to 140. You have your plugs on the right cylinders though.

-

Which f body? Aren't there like 4 generations? I'm very interested in this as it would make my fuel problems easier to deal with.

-

Don't worry fellas, I posted on his video in Japanese. Hopefully he will reply. If he's close to the Tokyo / Yokohama area I might try to go check it out in person. I would LOVE to get ahold of a cnc program for l engine heads. I could probably have a buddy run the program for me!

-

Is that the end for the cam sprocket? If not it should be fine. You should be able to pull the dowel out though.

-

Z32 TT rear Hubs on 240Z rear housing. Can This Be Done?

akeboshi replied to 01vincer6's topic in Drivetrain

Take a pic of the backside of the last pic. -

It would be cheaper (down in socal anyways) to just go to the junkyard and ****** another cam and corresponding lobes (keep them in order this time) shouldnt cost more than 30 bux at a picka and pull.

-

anyone ever used ls exhaust manifolds in a z?

akeboshi replied to _X_'s topic in Gen III & IV Chevy V8Z Tech Board

If they look anything like the VH41 manifolds (what I heard anyways) they should fit great. If you want to be sure ask member fuzzydicerule.He just finished an ls1 swap and for some reason he made his own so maybe not. -

Just wanted to update this thread so that others who may think they have similar problems can use this info. Turns out the head gasket was starting to go out. It was like that from the previous owner. After the new headgasket it was tuned and dynoed in at 199rwhp. Dont know what the torque was though.

-

If you are not using the stock oil gauge you can remove the oil pressure sending unit and thread the new mechanical fitting into that spot. If you have an oil cooler you can go from an unused fitting there as well.

-

If you are not using the stock oil gauge you can remove the oil pressure sending unit and thread the new mechanical fitting into that spot. If you have an oil cooler you can go from an unused fitting there as well.

-

OK, Well it sounds like you know what you want to do despite the input so just do it already. Take some pics too please.

-

Well, its finished. I machined the turbine housing myself and radiused it the best I could on the lathe, but ultimately I had to massage the radius with a dremel as it barely scraped in that area and left a bit of machinist dye in the area of the blades. Spins freely without noise now so it SHOULD work. (Crosses fingers) So a T04E-50 trim turbo with a t04E exhaust wheel in a .63 a/r exhaust housing should be able to break 400 hp with a spoolup by 3000 rpm eh?

-

I have one that was sand blasted. Name a price you want to pay with shipping and its yours. I'm in 91910. Marcus

-

l28et s30 swap bad sputtering

akeboshi replied to 240z72's topic in Trouble Shooting / General Engine

Boost leak dude.