-

Posts

296 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by KAZU

-

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

I saw the video below and decided to remove my front ZG flares upward quite a bit. Previous position. removed all but a rear end rivet and rotate the flare upward. After cutting the metal fender, wheel can be relocated out by extending the LCA. Gap at the front end was filled with pieces of flare. Pic clearly tells why I had to cut metal fender. The 17" tire is as high as the stock fender edge. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

No problem. It was easier to make than I thought. I went to drive it. Finally it runs under full boost. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

I made critical mistakes on this engine. Exhaust cam was dialed completely wrong timing and tried to start it until the engine oil was saturated with gas, 30-minuntes-idling without the water pump pulley belt, oil filter plumping was the reversal direction, etc. I am very lucky man because just only a problem, oil leak from oil pump or the oil gallery plug on front side of the block. BTW, a temporary grill cover was made from aluminium sheet. I'll test this if cooling capacity is efficient. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

Front under panel, made by 1/2" plywood. Engine oil keeps leaking from the oil pump. My car is usually as slow as stock 260z because I rarely find the positive boost in the pressure gauge. Finally I found something hidden in the inlet side of intercooler. A plastic bag. I put it in the piping during maintenance. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

Fortunately only engine hood was damaged and repaired with sliding hammer, body filler and rattle can paint. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

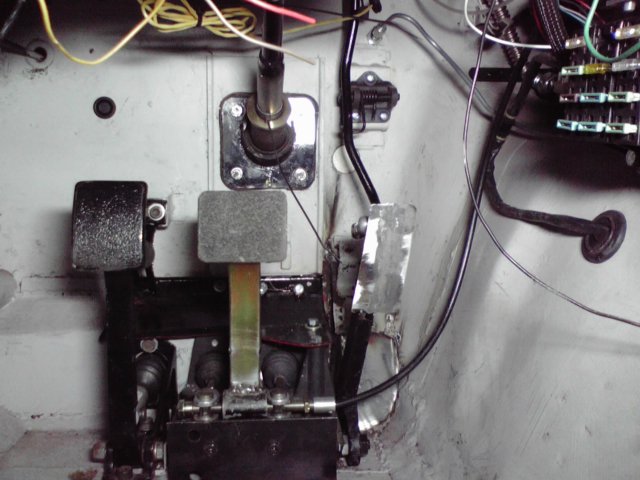

High caster adapters, tension/compression rods and LCAs were fitted. Mustang Bullitt wheels are replaced by a set of polished R33GT-R wheels. A taxi got tail ended by me:p I pressed both brake and gas pedals. So pedal plate of the gas was relocated by an inch toward the right. Two good news. MXL dash logger finally shows the engine parameters again. I figured out a wiring mistake in RS232C TX /RX connection between MXL and Link G4 ECU. Also I found current bridge in vehicle speed pulse wiring. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

For what other than noise? -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

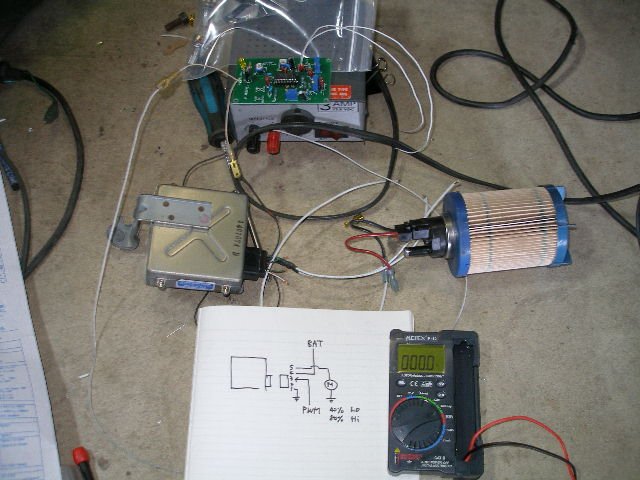

The car is running! I replaced an old DTA P8Pro ECU with a Link G4 Xtreme. It took a month to figure out the correct ignition/trigger sensors setting. Now engine runs fine with a genuine Nissan crank sensor. Test drive has done. Priority is chassis modification not the engine. I felt some difficulty in clutch pedal control because of Tilton clutch and lightweight flywheel. Next, the brake pedal w/o booster feels like pressing the floor. I am realized that I do not necessary to feel the brake pedal stroke during braking, it is better to try to press the seatback with my hip. Then wide-opened the throttle several times. Boost was lost because the silicone hose popped out. I liked the rear multilink with the GT-R LSD diff. Exterior is sleeper but the fuel pumps are too loud to be sleeper. I am already hacked the Toyota fuel pump controller pinouts. Link ECU has several flexible PWM AUX outputs so it can send the signal to the controllers. Isolating the fuel plumping with cabin is also required in highway use in Japan. If not, the car does not pass the inspection. Metal work has finished. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

-

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

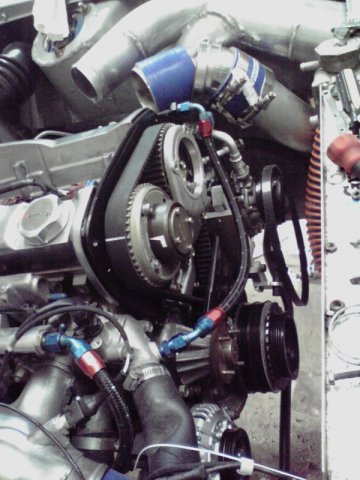

I didn't measure the dimension. At least two inches in each side may be added. Update. There was difficulty in dialing the NVCS cam timing teeth wheel because the fixing screws are put from the backside. I was planning to modify it but I found a better solution. Trust Greddy cam wheel for RB25NVCS. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

Engine compartment wiring has done. Essentially no stock loom remained. The car has only 3 filament bulbs, two H4 headlights and a battery charge lamp. New thicker Griffin Scirocco radiator. I got a new A/F sensor of LC-1 but still no voltage. Ordered a new set. Even if with the new LC-1, I'm tired of tuning with an old DTA ecu. I'll replace it with dependable Link G4Xtreme (red) with KnockBlock. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

The funny thing is that I am not a good buyer of S30's. I found my car when I was located in NY. -

I'm going to order one with a knock box. Any other new purchase? A Link G4 Xtreme ECU, which is essentially identical to a Vi-PEC v88, can be obtained from here for $1,560.00.

-

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

Making the bulkhead to isolate the fuel system. Side panels are steel and top/front part will be aluminium. PC display is too small for my half-century-old eyeballs. So I decided to fabricate a display enclosure to be hung anywhere I can read the small font. HVAC control will be relocated top of the center panel and an audio unit will be loaded in the lower opening. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

I am located in the second city to be subject to nuclear attack. And you? -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

I bought used ThinkPad X61 for ECU setting and configuring the dash logger but I couldn't make connection with logger. So I dug an old mini PC which I bought for in-car use and have been using at office until the VGA connector dislocated from the M/B. Soldering such fine pattern was quite challengeable for me but succeeded. Display panel is 7.1" real XGA (1024 x 768). Good news is the battery voltage can directly be supplied to both PC and Display. Bad news is no room for audio. I will put some switches and I/O of PC between the display and HVAC panel. This setup enables me to type keyboard on my lap. Note PC cannot be used in such way. Mercedes louvers cannot be there because the 240z interior is narrower. There will be round shaped louvers instead. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

You might miss where I am located now. I got them from auctions.yahoo.co.jp. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

Nothing special. I just cut the front end of the flares. Car is on jackstands. The tire is at fully extended position. AC plumbing. It's no fun. Control panel wiring has done. I didn't do any ducting yet but cool air comes from the HVAC box. AC system components are from several models of Suzuki. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

Exhaust cam dialed correctly and the engine ran. Soon after that, unusual rattle noise came from the cam sprockets. Intake sprocket is from ECR33 RB25NVCS and the cam is from ER34 RB25NEO. One of the four fixing bolts was dropped off and the others were loose. Fixed. I'm realized that Innovate LC-1 didn't make any voltage. I dig an old DIY-WB board and replaced with LC-1. It worked just fine. Engine idles a little bit high and the A/F shows rich. Unreliable genuine Nissan ignition transistor was gutted. DTA-fast ECU has internal ignition amplifiers. Finalizing the body work. The S14 silvia air dam was trimmed to fit the stock 240z bumper. Front overhung is short in 240z than S14 silvia. Minor work should be needed at the wheel arch. -

75/10-76/7 : A-S30 76/8-78 : C-S31 Both equipped with L20 and fuel injection.

-

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

I couldn't find enough space for twin exhaust. Pipe diameter after merge is less than 3". A A/F sensor (Innovate LC-1) is located vertically. I've been trying to start the engine for a while and finally figured out the exhaust cam (it actually is RB26 intake cam) dialed completely wrong. I remove the cam almost 180 degree at the cam sprocket. ECU is DTA P8Pro, sequential injection with direct coil firing, and switched intake cam timing. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

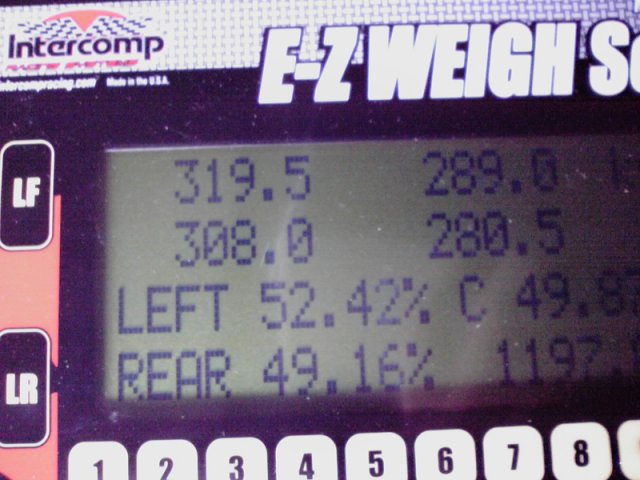

Rattle can paint job. Corner weight measurement with driver (me): Today Left 52.42% Cross 49.87% Rear 49.16 1197 kg (2642 lbs) Dec.29, 2009, with L28 ITB Left 52.17% Cross 50.59% Rear 50.72 1138.5kg (2512 lbs) -

Nissan genuine airdam for GB export?

-

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

I got a set of 3" full dual exhaust pipes and only one pipe may be enough for my RB26. Turbine outlet was cut and welded. Hose band and welding rod method worked well to be fixed the pieces for welding. Floor toe board was also cut and welded. My car does not accept any airdam for 240z because the intercooler is located below the bumper. Front air dam I've gotten is for S14 sylvia. Upper bumper part was cut out and narrowed at the center. -

240z with RB26DETT, multilink, EPS, etc

KAZU replied to KAZU's topic in S30 Series - 240z, 260z, 280z

There is no room for box air filter container. I fabricate a aluminium duct. Time consuming job has done.