-

Posts

1761 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by thehelix112

-

RB20 is a complete waste of time. Why would you drop ~30% of your displacement? Is it going to rev to 9100 vs your 7000 (30% more?) and if it does, is it going to hang together for the same amount of time? I think not. L > RB. Dave

-

Err.. what engine? Dave

-

Which boost reference fuel regulator are you turbo guys using?

thehelix112 replied to gearheadstik's topic in Fuel Delivery

Bosch Adjustable 1.5-5Bar. PN: B 280 500 743 Expensive little sucker. Dave -

The further the injector from the engine the better atomization you get. Autospeed(.com) has an article on it somewhere, was someone's PhD thesis. Also, F1 engines inject into the trumpet. Dave

-

Bastard. Dave

-

I think it all depends on application. On a street car with no ducting, the air may well just spill around the sides instead of flowing nicely through. On a race car with a properly placed ducting entry (high pressure zone) and exit (low pressure zone) the air is PULLED through the core which allows you to run something thicker. How much did you pay for that core? I am envious.

-

7" deep? Jesus. I believe AiResearch is what Garrett was called originally, stand to be corrected on that one though. Garrett cores, like their turbochargers, are pretty decent. 7" deep.. holy hell batman. If i were you and was going to install that, I would be thinking VERY carefully about my entry and exit shrouding. But then, we all should really. Dave

-

Aziza z update. ITs painted candy apple red.

thehelix112 replied to v8260's topic in Body Kits & Paint

Wow. That looks fantastic. Wanna do my paint work when my car gets here? Dave -

Of course there is a substitute. You have lots of options. You could offset grind the std crank, you could get the std crank welded, you could spring for a custom billet crank. Or you could spend the money where it will make the power, in the turbocharger, intercooler and fuel/ignition system. As has been mentioned, a standard bottom end will hold 350hp with a safe tune. Dave

-

Turboing the N/A L28 - Intake manifolds?

thehelix112 replied to JDMFairladyZX's topic in Nissan L6 Forum

Can use either. The turbo intake manifold is better, but you can make do with the L28E one, I am. PS. The search button is over there. *points* Dave -

Definitely a work in non-progress. Dave

-

I'd rather not be a total twat and not have total twat friends. Dave

-

Thanks. I was just about to post the link myself.. Please let me reiterate if anyone has specs they want added, send them to me. Or even better, add them into the system yourself (See those `Add' links?), then press the `Export' button down the bottom and send me what it spits out. Cheers, Dave

-

Autox suspension/slicks discussion - FP

thehelix112 replied to zredbaron's topic in Brakes, Wheels, Suspension and Chassis

zedbaron, To downshift without the clutch, you simply need to match the revs. This involves: 1. Pull the box out of gear. 2. Blip the throttle to get the revs to sweep across the point where they match 3. Apply relatively light pressure to the stick and wait for the revs to match. When they do it will simply pop into gear. I've never done it in anger, so may be wrong. Heel & toe for me. Dave -

Autox suspension/slicks discussion - FP

thehelix112 replied to zredbaron's topic in Brakes, Wheels, Suspension and Chassis

That looks damn nice heavy. Dave -

Autox suspension/slicks discussion - FP

thehelix112 replied to zredbaron's topic in Brakes, Wheels, Suspension and Chassis

http://www.tirerack.com/tires/tires.jsp?tireMake=Kumho&tireModel=VictoRacer+V700 VS http://www.tirerack.com/tires/tires.jsp?tireMake=Kumho&tireModel=ECSTA+V710 I didn't think the V710s lasted that long? Maybe its ok for autox? Dave -

I know which will let you run wider rubber. Those ones. What else matters? Dave

-

Just for peoples FYI, this site is great. http://hyperphysics.phy-astr.gsu.edu/hbase/hframe.html Dave

-

Autox suspension/slicks discussion - FP

thehelix112 replied to zredbaron's topic in Brakes, Wheels, Suspension and Chassis

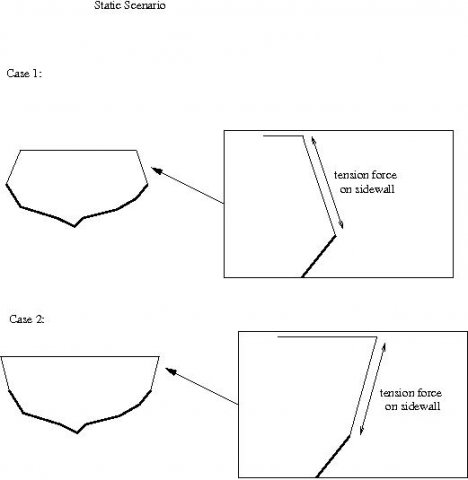

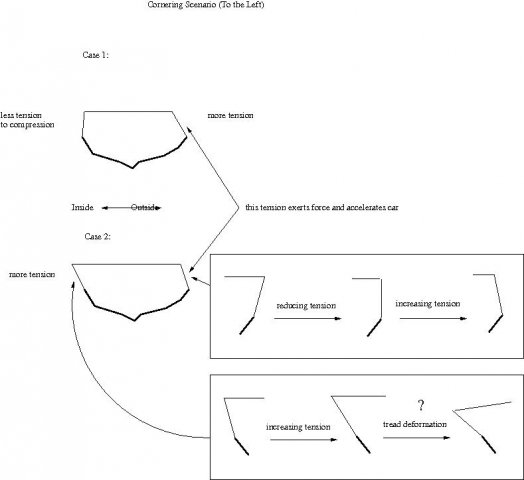

Well, lets think about the construction of a tyre sidewall (something I know very little about, so make of this what you will). A tyre sidewall is essentially rubber. Rubber is quite deformable, and will return to its original shape after compression distortion. For this example, I am supposing that it is much easier to compressively distort a sidewall than it is to do so in tension. That is, its easier to squish, than it is to stretch. I am lead to this conclusion because in compression it can fold on itself. (The deeper question here is whether the multiple tension/compressions that occur at each fold are greater than the overall tension). But anyway, lets assume that this is so. If you have a tyre that is exactly as wide as the rim, at the point that is being support (the bead I believe), then in a simplistic view, each sidewall will make a right angle (inside the tyre) at the join with the tread. If the tyre is wider, you will have an angle less than 90 degrees, if narrower, greater than 90 degrees. (See first attachment). Just to clarify, when a tyre exerts a cornering force on the rim, the following occurs (I think): The outside sidewall goes into tension, the inside sidewall goes into compression. That is, the tyre is moving in the direction it wants the car to go, and moving to this side relative to the rim. Now lets relate this back to our supposition, and consider only two extreme cases: (See second and third attachments) 1. wide rim/skinny tyre. 2. skinny rim/wide tyre. Case 1. The tyre is skinnier than the rim, the inside angle between sidewall/tyre is greater than 90. In this case both the sidewalls are always in tension (its further along the hypotenuse of a triangle than it is along one side - will draw a picture if this isn't clear). As soon as the tread moves to laterally accelerate the car, the tension force on the outside tread increases, whilst the inside tread sees a decrease. This immediate increase accelerates the car with little relative movement between tyre/rim (much movement would simply pull the tyre off the rim, once again, assuming stiff tension elasticity of the sidewall). Case 2. The tyre is wider than the rim, the inside angle between sidewall/tyre is less than 90. In this case both sidewalls are also already in tension. But this tension's horizontal component is in the opposite lateral direction to case 1. When the tread starts to exert a lateral force, the outside sidewall has to go into tension. To get there its current tension force relaxes as the inside angle approaches 90 degrees, then increases as it gets greater than 90 degrees. It is obvious that it takes time for this transition from inwards-facing tension, through no tension, to outwards-facing tension to occur. The only question in my mind is how come the inside sidewall in Case 2, that is, already in tension, doesn't make these two scenarios identical. As I suppose in the third attachment, perhaps the inside sidewall starts to pivot about the tyre/rim attachment which causes tread deformation and a loss of grip. Lots of supposition, lots of writing, no answers. As per usual. Dave PS. This also shows why wider tyres on a skinnier rim can work well for drag applications: Due to the sidewalls already being in tension, any compression of the suspension reduces this tensile load on the sidewall. So in essence, the sidewall is acting as a negative rate spring. That is, it wants to go into compression (as a reaction to the constant tension force). This makes the rear suspenion that much softer. -

That and they have V07 cast on the counterweight at one end (can't remember which). Dave

-

Me too. I stand to be corrected, which happens often. Dave

-

Sparks, That thread you linked to is not proof. And I would need to see some more details to be convinced. I am rather skeptical at heart I suppose. But some questions that arise are: Pressure drop at what flow rate? A usable operating range? I'm sure a 3" pipe and a 1" pipe have almost identical pressure drops at 0.01CFM, but so what? Dave

-

Fair enough. I know very little about the 26, but I understand that almost all of them need attention to the oil supply, though one would have to assume that later versions (R34/N1) would have some factory attempts made to correct the issue. I am not too sure what you mean when you talk about the gearboxes. Unless you are going to be doing a whole heap of work, you won't be running the 26 box, but rather a RB25DET 5-speed. Or are you planning on converting (which car?) to 4wd? Its just my opinion, but it seems to me that every factory engine serves only as a starting point. Or maybe I just have little respect for black-box (at my skill level) factory ECUs. Best of luck, Dave

-

I agree. Those end-tanks are quite nice. I am yet to see side-by-side flow figures for China intercoolers that indicate they are anything other than cheap crap? Have I missed something? They make things as cheaply as possible, do you really think they perform decent quality control (at all, or ) on the core row entries/exits when endtanks get welded over them and you can't really see them? What is that saying: 1. Fast 2. Cheap 3. Not made in China. Pick any two. Dave

-

Please don't add exclamation marks unnecessarily. Please don't neglect commas and capitalization unnecessarily. Dave