-

Posts

541 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Boy from Oz

-

Here is where the Honda clip fit. While I haven't done this work as yet SpeedRacer has indicated in earlier posts how it's done. I suspect the lock goes through the fibreglass skin and the Datsun skin and then a clip is then inserted.

-

LSx s30 Longtube group buy thread

Boy from Oz replied to 1 tuff z's topic in Gen III & IV Chevy V8Z Tech Board

It is always a challenge to remain focused when working on these cars but if I recall one of the primary goals of this project was to have an off-the-shelf product to suit other off-the-shelf items, e.g. JCI mounts. When you require more changes you may start to lose your customer base and hence the ability to pay less because of the bulk buy. I spent quite a bit of time trying to create a left-side mount similar to the right. This was way before my longtube headers and it was simply because I didn’t like the look of the ‘long’ mount. Like most things it could be done but in my design it required modification to the alternator body and that was defeating a goal on my project to retain as many standard GM components as I can. I don’t want to be stuck miles from anywhere with a broken or damaged specialist component. If you start to relocate the alternator it will cost money and there may be some, like me, who don’t like the look of them mounted up high. Design and manufacture of a new mount will also cost money. If you want to go that way then you might want to consider having your own unique longtubes made(double the price here) but that not only sends you back to square one it actually puts you further behind considering the extra work required… Hang in there guys. -

LSx s30 Longtube group buy thread

Boy from Oz replied to 1 tuff z's topic in Gen III & IV Chevy V8Z Tech Board

As mentioned before, mine was in the exhaust shop for six weeks. I think it's probably best to let the fabricator take his/her time to solve some issues. By now they have realised they are probably not going to make any money on the prototypes at least and they will have plenty of 'remove and replace' jobs waiting in the shop that provide a profit. The more behind they get with the money-making every day jobs the more disenchanted they'll get with this task. I wouldn't put too much pressure on for time but I would keep hammering about the finished job you expect. NB. I've just decided to go to the US for the Monterey Car Week - my first time on the West Coast. -

LS/T56/240z Project Mentor Wanted

Boy from Oz replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

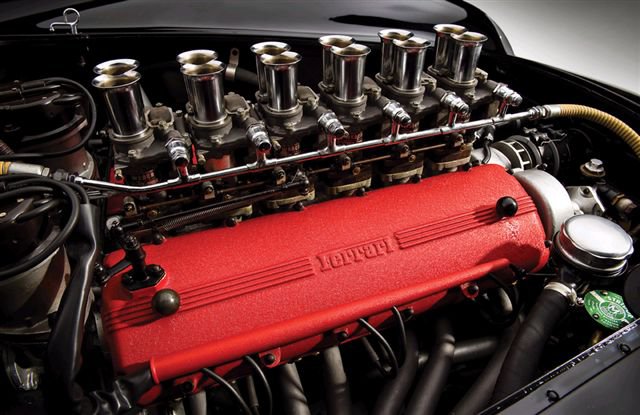

It's back. I was a little anxious that people might think I was a bit pretentious - my project is very much focused of the 250 GTO aspect rather than S30 or LS1. There is a chap down here actually fitting a V12 Ferrari engine to his GTO kit and I'm green with envy. The LSx valve covers were a real find. They are machined out of an aluminum billet and that allowed me to have the Ferrari engraving done. The tubes are just following what Ferrari did 50 years ago. In August I'm actually flying to the US to go to the Monterey Historic races and Pebble Beach just to actually see a GTO - there are none down here. The issue with faux ram tubes is what to do about the throttle body. I am going to make an over-the-radiator cold air intake (type 'OTR' into eBay) and my radiator was made low to facilitate this. I will then cover it with a scoop to look something like the Mustang in the photo. I don't believe there is a sufficient market to mass produce. Send me a PM with your email if you want more photos and a drawing of the brackets. -

LS/T56/240z Project Mentor Wanted

Boy from Oz replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

You're doing some great work there. I'm also running faux ram tube on my 250 GTO build but I've also relocated the coils to complement the look. I thought you might be interested. -

LSx s30 Longtube group buy thread

Boy from Oz replied to 1 tuff z's topic in Gen III & IV Chevy V8Z Tech Board

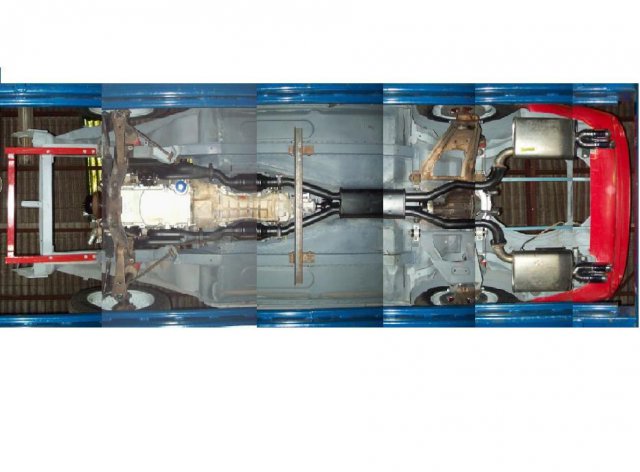

The big rear mufflers are Pontiac G8 and will be swapped once the car is passed our tough registration requirements. The system is tucked up very close to the floor but I'm not so sure I haven't outsmarted myself as I'm now very concerned about the heat transferring to the cabin. -

LSx s30 Longtube group buy thread

Boy from Oz replied to 1 tuff z's topic in Gen III & IV Chevy V8Z Tech Board

Right side photo as per PM request. There are some big time differences between us so there might be delays in responses. I don't think it's feasible for the fabricator to take into account the brake lines - there just isn't that much area to play with. I personally wouldn't pursue that issue and accept the fact I would have to re-route the lines. Also I couldn't match up the locations of the collector flange faces and I would suggest the fabricator consider building both sides simultaneously. -

LSx s30 Longtube group buy thread

Boy from Oz replied to 1 tuff z's topic in Gen III & IV Chevy V8Z Tech Board

I'm trying to assist here but if you think I'm out of place please let me know. I can't tell for sure but are all the primaries on the engine side of the steering shaft, if so, that might be restricting the ability to get equal lengths. I found it easier to pass the shaft through (two either side - RHD) as there is very little involved in removing the lower section of the steering shaft to fit or remove the headers - let's face it, how many times are you going to do it. I've also included a photo of equal length (approx) headers. I appreciate the LHD and RHD issues but it may assist. I had to fight my guy all the way to ensure I got what I wanted. -

Thank you to the admins and IT folks - looks like it's all systems 'go'. I have made up a papier mache door to try and see if a smaller door would work in proportion with the rest of the bodywork. It seems fine so I might now start work on a real door. 'chelle' - I've taken onboard your suggestion of a higher rocker panel as well as reducing the door height itself. I'm just seeking clarification from the approving engineers down here whether or not they will allow it. On the photo I've painted the rocker black and continued the paint line to the front and rear panels. I think it assist in giving a longer, squatter appearance.

-

LSx s30 Longtube group buy thread

Boy from Oz replied to 1 tuff z's topic in Gen III & IV Chevy V8Z Tech Board

As someone who went through this exercise a few months ago with my RHD I thought I might offer a couple of comments. Fitting ANY longtube headers on an LSx/S30 is a VERY difficult exercise and in all likelihood there will have to be compromises made. There will be minimal clearance and thus the issue of heat transfer to the shell, starter motor, oil filter, etc, will arise (NOTE: make sure the car being fitted with the prototype has the heat shield on the started motor). Make sure the fabricator maximizes ground clearance; this is an area where you should be getting measurements not merely photos. Also make sure equal lenght primaries are being achieved. I dropped into the shop every second day for six weeks to make sure all my concerns were being addressed. Also request that the headers can be removed without the engine having to be moved or worse, removed. You should also have the JCI a/c compresoor mounted on the prototype car to ensure access to spark plug #1 with its heat shield is maintained. I will be amazed if they can be made to suit any other mounts, as well as JCI - there just isn't the sort of space available for such options. I wish you well. Send me a PM if there is anything you think I can assist with. -

It's very disappointing that so many of the photos, illustrations and attachments have recently become unattainable on this thread. I trust the situation can be rectified.

-

The 250 GTO owners hang out on this forum. Post some images of your car. http://forums.hybridz.org/index.php/topic/50042-250-gto-owners-thread/page__st__820 The LS1 installers hang out on this forum. http://forums.hybridz.org/index.php/forum/74-gen-iii-iv-chevy-v8z-tech-board/ The only LS1 mount kits are available here. http://www.brokenkitty.com/zcar/zcar.htm

-

Frame rails with integrated transmission mounts

Boy from Oz replied to Boy from Oz's topic in Fabrication / Welding

Sorry there are no drawings as it was a one-off and I simply made up the components and then tack-welded them in-situ. Having had a little time to reflect on this I now have a few misgivings. As stated earlier I was more interested in the mountings rather than the cross-member design and I had it in mind to replicate the JCI 280Z mount. Somewhat unfortunately my exhaust was made such a close fit to the floor pan that I have to have the cross-member run under the exhaust. Although it is high I am now a little concerned that any accidental contact with a speed hump will create a severe impact on the blunt leading edge rather than just scrapping along it. I'm now going to fit a skid-guard with a raised front edge. I still think the spacers in the rail is a good idea (very easy it install and remove the cross-member) but I think you will have to wait until YOUR exhaust is fitted to design your own cross-member. Regards -

Frame rails with integrated transmission mounts

Boy from Oz replied to Boy from Oz's topic in Fabrication / Welding

It has taken some time to get the shell off the rotisserie, the engine installed and the exhaust fitted (longtubes). So this week I made up the transmission crossmember. Fairly straightforward but the exhaust are tucked up so close to the transmission tunnel that I had to run the cross-member underneath them, but it is still higher than the bellhousing. -

Recommended Location ECM for Daily Driver LS1

Boy from Oz replied to jeff81's topic in Gen III & IV Chevy V8Z Tech Board

I rewired the entire car at the same time. Mine is a RHD but by creating a hole right down on the bellhousing part of the transmission tunnel, rather than the firewall, I had plenty of options to position the ecu, relays and fuses - no problems for a LHD. The other items on the 'electrical board' are a Mongoose immobilizer and the GM cruise control from the donor car. -

New Nalle GT!!!! Just bought it half built

Boy from Oz replied to jthom095's topic in Body Kits & Paint

With my 250 GTO kit I installed the diff from a Pontiac GTO but the diffs in the G8 are even better - an all aluminium casing. -

I bought these item back in 2007 and they worked out fine; C6 LS2 oil pan (has shallow rear sump) (kit with bolts/gasket) = 12581810 C6 LS2 oil pick-up screen (same used on LS6) = 12558750 C6 LS2 oil deflector (same as used on LS6/LS1) = 12558189 C6 LS2 dipstick = 12570788 C6 LS2 dipstick tube = 12570787

-

No, sorry, I've not made it as yet. I've been working on the wiring and exhaust. Possibly around May.

-

LS/T56/240z Project Mentor Wanted

Boy from Oz replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

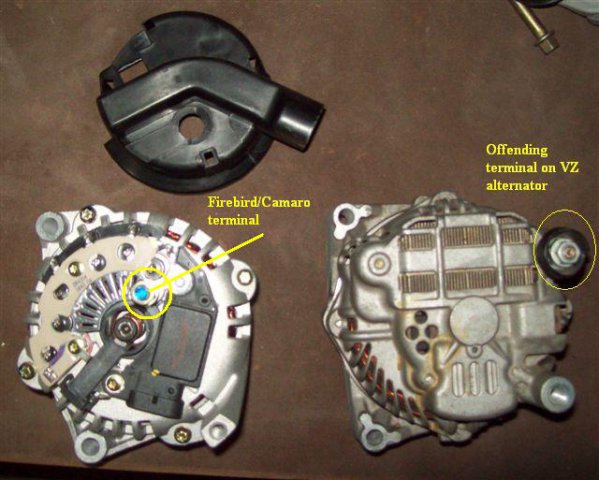

These photos I prepared more for wiring connection reference than overall size but they might help. Basically don't bother even trying to fit an LS2 alternator. There are no F-bodies GMs in this country so I had to buy an alternator from the US - it was one of the best decisions I made on the project. Just to let you know what was involved, I bought the Camaro/Firebird bracket for $15 but it cost $30 in shipping - still worth it. Go straight for a Camaro/Firebird alternator - remember the engine will move on the mounts so you need good clearance. No problem with the amps unless you are running power windows, central locking, etc. NOTE: There are two types of plastic cowls and the one in the photo is the wrong one... D'oh! There is one without the scoop but with ventilation slots - thats the one you want. -

Thinking about buying this donor.

Boy from Oz replied to EvilC's topic in Gen III & IV Chevy V8Z Tech Board

I write purely from an Australian perspective but I honestly don't think it's that good a prospect. In my experience most of the salvage recoup comes from items forward of the engine and I don't see any on that car. You could possibly sell the doors and boot lid to a repair shop and there might be a bigger market for the seats, airbags and tail-lights. There is generally no interest in the suspension. The engine should be okay as it doesn't look like a heavy impact (airbags not deployed) but I would check to see if the a/c compressor was torn from the block and if so, were the lugs on the block damaged. There are plenty of LSx/t56 combinations down here so I would wait for one of those, but I don't know what the availability is like in the US. Either way, good luck. -

Relocated ignition coils on LSx - any ideas?

Boy from Oz replied to Boy from Oz's topic in Gen III & IV Chevy V8Z Tech Board

It would depend on the valve covers you use. If you are just using the standard covers minus the coils then you could use a couple of clamps on two of the post on the covers, (see photo). -

What is this V8 donor worth?

Boy from Oz replied to EvilC's topic in Gen III & IV Chevy V8Z Tech Board

No they don't...too wide. In 2008 paid $5200 for this 2005 GTO pick-up and got an amazing $2500 back from unwanted parts on eBay. I kept items like the dbw throttle pedal and even the diff which I have installed in my S30. Every item forward of the engine is soughtafter. -

Ls1 - t56 master cyl options

Boy from Oz replied to aziza z's topic in Brakes, Wheels, Suspension and Chassis

I'm installing the booster and m/c from the LS1 donor car, however it does mean reworking the clutch m/s position - not running as yet. (RHD vehicle) -

Here is where I'm mounting mine. In the second photo a final rotational alignment still needs to be done before mounting to the panel. In the third photo they are resting on the guard and need to be raised 50mm or so. I've also revised the bracket design from this first attempt. I trust you get the idea. (This is a RHD vehicle)

-

There is a big thread about Riverside on those forums and another about 'lost' circuits. Also, only 100 cars were required for 'Omologato' and it is strange that while there were never 100 Aston Martin DB4 GT Zagatos, nor Lightweight E-types produced nothing is ever said about them being allowed homologation Back to the present - I've copied the nostril dimensions and I don't consider, in my case, there is enough variation to warrant altering the positions. I have to compromise from time to time because if I chased every detail I would never get the car finished. I will however be reshaping the interior of the intakes and making covers. Thanks for the advice.