-

Posts

541 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Boy from Oz

-

To engage the right indicators on my S30 requires and extra 'tug' on the arm of the switch. I've pulled it apart - but unfortunately didn't take photos - and it appears the contact points are worn. They are similar in appearance to distributor contact points. I'm wondering if anyone has suggestions how I could either build up the worn/pitted contacts, e.g. silver solder(?) or, modify the mechanism to gain more movement, e.g bigger ball, stretch spring? Thanks (edit) There are some images here but it is of an earlier 4 contact switch whereas mine is the later 2 contact version. http://www.classiczcars.com/topic/50735-turn-signal-switch-spring-ball/

-

If you don't have an a/c to start with why not install a Vintage Air unit. There are several threads here, and YouTube clips, to show how it is done.

-

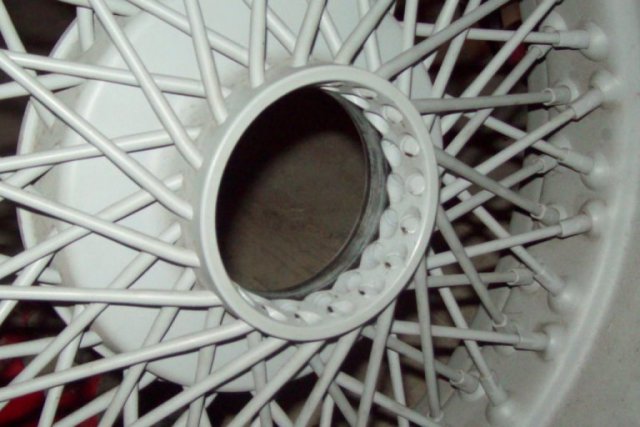

The bad thing about Dayton Wheels is that they have (had?) appalling quality control. I purchased my Daytons some years ago as I believe wheels are critical to getting the right 'look'. I built the fender shapes and the suspension around the wheels. When I finally got to run the car I had a bad knocking sound in the rear which I eventually traced to the Willwoods - but that's another story. In the process of researching the knock I discovered the spoke heads which attached to the Dayton centre hub were too big, or the centre was not drilled deep enough for the spoke heads. Either way the heads protruded above the taper seating surface. As a result the caps only engaged on a small area of the spoke head rather than the broader taper surface, further, this resulted in a deep groove being gouged in the caps when the caps were tightened. I had to use a die grinder to trim down the excess material. Compare the 1st and last photos to see different seating. When I raised this with Dayton they simply said the wheels were out of warranty, although they were hardy used.

-

Give some thought to modifying other alloy covers which are available. I had planned to build up a centre strip by running a series of welds the length of the cover and then engraving the Ferrari name and ribs. I discovered the covers I purchased (for an LS1) were 6mm thick so there was no need to add weld material.

-

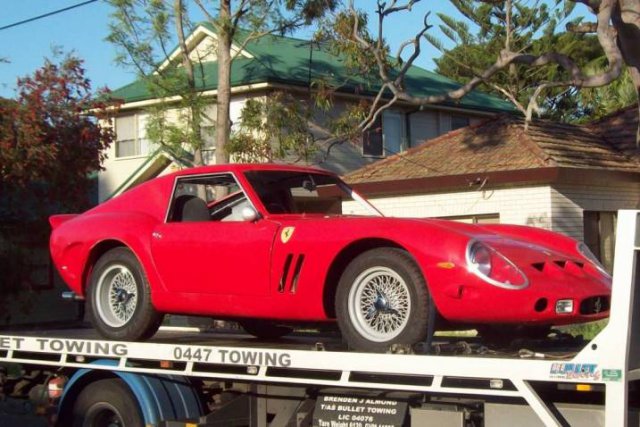

Probably the most worked Datsun-based replica in Australia is for sale. Sudden, very serious, ill-health has forced Alex (non-member) to offer for sale his pride and joy. I could go on and on about the work on this car but you need to be a serious GTO enthusiast to understand all the nuances associated with the modifications. The car is fitted with a BMW V12 engine and is registered in Qld. For any Aussies interested, the car is located in South-East Qld and Alex can give further details to, and arrange an inspection for, interested potential buyers. PM me for Alex's details, but please, seriously interested buyers only.

-

LS / T56 Clutch Master Cylinder & Slave Connector

Boy from Oz replied to Kenji's topic in Drivetrain

For the master cylinder I used the one from the donor car = GTO For the bleed line I used bundy tube (approx, 100mm - 60o bend - 100mm) then flexible hose. I ran the hose up the firewall for easy access. My car is RHD and I retained the original bundy tubing across the top of the transmission, however, getting access to the bundy/flex hose junction was a PITA and I'll swap it for a full flex hose similar to the bleed line when I next drop the transmission. This may not be an issue for a LHD car. -

Totally agree. NewZed. I can't add 'likes' so I'll say "thanks".

-

Firstly let me offer my genuine thanks to all who have contributed to this thread, some really useful input. Constructive criticism never hurt anyone. I think I really need to film the front of the diff to try and establish a fuller picture before making changes, if any. A bit more information: 1. The inner bushes on the LCA are OEM rubber - some may have missed that earlier. (See point 4) 2. The outer ends are 'bushed rod ends', replacing the metal spherical rod ends. (See point 4) 3. Despite the LS1 the car is for touring and not for performance use - driver is too old, too slow, and too stupid! 4. My major initial concern was related to metal fatigue. I'm happier to see energy dissipated in bushings, and accept the associated suspension geometry change, rather that through the S30 shell and OEM or fabricated mounts, etc. Sorry if I'm reinventing the wheel here but I haven't followed too closely other non-standard diff installs. Again, my thanks for the input.

-

I probably didn't make it clear in post #6 but the moustache bar bushes are poly. The inner LCA are rubber.

-

I'll see if we can film the nose area. The original filming was undertaken merely to identify a knocking sound - which turned out to be a brake pad (we think) - so this issue is a bit of a surprise.

-

Set up detailed here: http://forums.hybrid...s-like-a-glove/ http://www.viczcar.c...tted-to-a-240z/

-

I originally thought it was flex in the bar but the more I watch it the more I think it's 90% in the end mounts. The mount bushes are polyurethane. The mount is the same as used by Arizona Z with their aluminium moustache bar The suspension is not attached, although the bushes are new OEM rubber and not polyurethane. I can't recall the wall thickness of the 25 x 50 mm bar but it wasn't thin. I'd be interested to see if anyone else has filmed this with 350 or more hp.

-

This is with a standard LS1. Has anyone had failures in this area or designed anything to address this apparent excess movement?

-

I believe the rear suspension sits in a cradle. Do you mean the whole suspension or just the diff? The 2004 GTO diff I used preceded the all alloy G8 diff but offered a choice of 5 or 6 ratios from 2.89 to 4.11. Off the top of my head I think they are 2.89, 3.08. 3.46. 3.8x? and 4.11 http://forums.hybridz.org/topic/69682-gm-lsd-irs-diff-in-s30-fits-like-a-glove/ http://www.viczcar.com/forum/topic/12048-tutorial-holden-diff-fitted-to-a-240z/ Here is a photo of the cradle from my donor car.

-

-

Unless you are a retiree looking for a hobby I honestly wouldn't recommend this project. There is an unbelievable amount of devil in the detail. During the course of my build I met two owner/builders who told me they spent 6-8 months of 8 hour days, six days a week. just fitting a standard kit. It seems it's very difficult not to wander to other aspects of the car, e.g. engine, suspension, etc. to complement the bodywork I have come away from my experience with a total respect for design engineers. Some of the modification I undertook seemed so straightforward in concept but turned out to be very difficult and very time consuming to execute. If you really want one of these cars I would suggest (based on the info you provided) you sell what you have - and you may be lucky to recoup half your expenditure - then buy a completed car and modify it to your own taste and pocket. There is a lifetime of work in that alone.

-

You are probably better off trying to chase down the ScorpionZ rear mould which was sold to Oliver Graham Meulbrouck (Google and see also British phonebook) around 2006 and marketed under OM Sportscars. They went under fairly quickly but the moulds may only have changed hands in 2013; http://zclub.net/forum/showthread.php?t=8071&page=2 I'm not sure what Michelle has done but I had to create a recess in the roof for about 150mm to position a standard 240Z perspex rear window.

-

I used all the Puckett except the roof and door skins. Puckett owners, RR in New York and EF in Toronto, were very helpful. I'm not sure if I told you in emails but the kit was a basket case. Someone had cut up a berlinetta kit to make a spyder. I had to realign all the bits to rejoin them and make up those parts which were missing. Unfortunately when I layered up the joins the whole kit distorted as there was no support, as would be normally provided by a mould. I had to cut it up again, create braces and once more reattach all the sections. I think this may be already somewhere on this thread. To add insult to injury there was no gelcoat so we had to painstakingly hand fill all the pores. I made my own wider doors (also 50mm lower at the top and 50 cut off the bottom) and wider/higher sills (rockers) to suit, and modified the front guards (fenders) to add 50mm to their width and align with the new sills. I still have to make aluminium door cards - and a million other details! Again I think I might be going over information already on this thread.

-

There is another car here in Oz that is just sensational and puts mine to shame, I'll see if I can get the owner/builder to come on here. For all the fabulous advice you've given you can drive mine any time you want. I'll make you a set and bring them over next year when I come over for the Indy 500.

-

Great to see there is so much interest. Wes, I'm not sure exactly what you want. I must have thousands of photos but they are mainly of the details of components or construction. The idea was for any future owner/s to see how it all went together. Here are a few general shots of the build. PS. I've learnt how to spell oil in Italian 'Olio'... D'oh!

-

I haven't been on this site much over the past few years but now that I've finally got my car on the road I thought I'd post a THANK YOU to the members for their ideas and suggestions during the long long build. In the early years members on this site provided a tremendous amount of information and inspiration. It was sad at times to see some enthusiastic starters fail to get to the finish line but those that have I now share your sense of satisfaction. I have made wonderful friends with fellow kit owner/builders around the world and personally met a few in my travels, and their travels to Oz. There appears to be a general lack of interest in these cars now the 240Z is moving into the 'classic' phase with few wanting to modify them with GTO kits. Once again, my thanks to you all. Peter Here are a few images: I particularly like this arty photo a friend of mine took.

-

John was known and admired around the world. His passing has been noted with great sadness here in Australia, the UK and France.

-

-

-