-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

Rags, How about an electric pump? I believe it was the second gen. MR2's that came with them. They can be pulsewidth modulated for pressure, too.

-

You can't make a race car out of a pig, but you sure can make a damn fast pig.

-

I'll have to see if I can get you a picture of the rear mod they did.

I'd be interested in seeing that too.

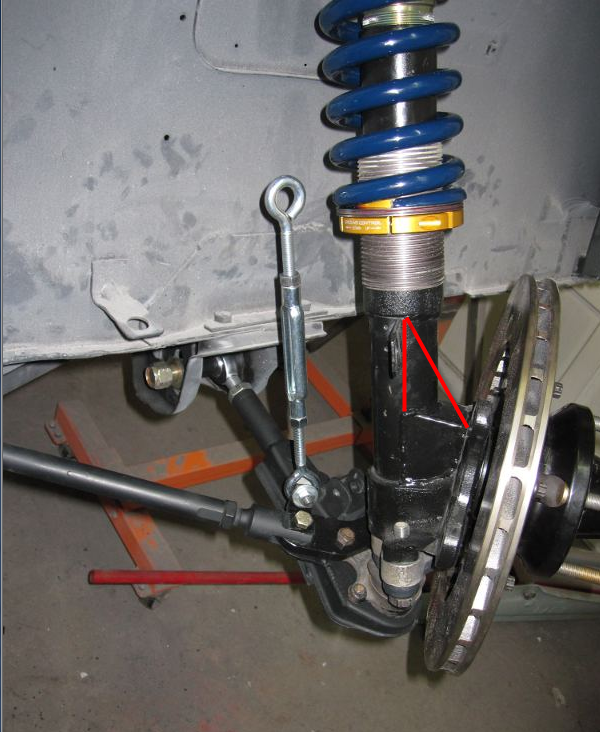

Back to the front bridge... Would there be any benefit in taking it higher up on the strut? Would that help stiffen the strut tube, or would it be dead weight?...

-

I'm not sure you're taking this project serious enough

Congrats on the start up!

-

I've read where people say you shouldn't run the rear sway bar on a autoX car, well even a track car. Supposed to keep both rears planted and reduce understeer...

For my autocrossing, I try to run as little rear bar as possible. Not because it reduces understeer (opposite actually), but because it helps with corner exit bite. S30's are not great at putting power down on corner exit... running a V8 in lower gears exaggerates the problem. For what it's worth, I've been pretty successful in my region running a stock rear bar. Our local courses are typically pretty tight. The only time I've been able to do well with no rear bar is on faster courses.

Are you running stock length struts?

Caster made a big difference in my car.

Ditto that.

-

What follows may or may not be relevant here but it's something that noone in the US seems to do, or at least talk about.

I believe Mortensen has a picture to share with you...

-

Happy days are here!

Congrats. That'll be a hoot!

...along with the Russell push-on EFI AN adapters for the filter and rail...

Be careful of those. A local friend used them and one of the plastic connectors let go and dumped fuel. No one knows for sure if maybe he didn't get it snapped all the way on, but obviously he thought it was.

I used the same part, but threw the plastic in the garbage and machined a cotter pin hole.

-

-

Won't work.

-

Doesn't matter... they are batch fired.

-

The GPS speedo has a built in 0-60 timer. Don't know how accurate it is, but I thought I'd give it a try. I only made one run and botched the launch a little. 4.48 seconds...

I can't make it in 2nd gear, gotta use 3rd for the last few MPH. That never helps.

I think wrapping up the tune and a little better launch, I should be able to get pretty close to 4 seconds flat. Not too shabby for a little NA motor that also makes useful torque @ 1200 RPM.

-

...especially now that Ron is and I might be able to get some help....

I'm not yet committed. Hughdogz gave me a set of half-shafts last weekend, so I'm good for a while. On my wish list is CV's and taller gearing, so I'm just daydreaming right now. But, I'd be happy to lend you a hand with yours.

-

I thought they almost all used the 205mm gear sets.

If I've got my facts straight, the stateside E36 M3 uses a 188mm ring gear, the Euro diff is a 210mm ring.

BRAAP and I went to the JY tonight. I found this 1995 M3 diff (3.15:1)...

I looked at using a BMW diff, but it is wider than the Z diff and looked like a lot of trouble to swap.

Flange to flange is about 11.5"... about 2.5" wider overall than my R180. Yes, it would take some creativity to adapt, but I see nothing scary... yet. The axles would probably be the biggest expense/effort.

...but cost and availablity of higher ratio gears and the amount of mods to fit make this unatractive vs low cost and vailability of R200 options.

In the States, R200 CLSD's cost far more than Bimmer CLSD's. The diff pictured above has 80K miles on it and I can pick it up for $300 (about 1/2 the price of a comparable R200). It's not the large case diff, but I see no need for it in our cars unless you plan on boost and slicks.

-

Hell at this point it almost seems cheaper and easier to install an E36 diff.

I've been seriously considering just that. Taller butt gears, very tunable LSD, VSS, CV half-shafts... and no need to machine a diff adapter.

-

So. I guess I need a new tach as well as a new speedo.

If you have a 74-77 tach, there is some chance the BMW ECU will drive it. It won't hurt to give it a try.

...and will mount it on the gear box rear ears to pick up the 3 lobes on the output flange.

I had exactly the same thoughts, early on. I think a Honeywell 1GT101DC Hall Effect would do well, mated to an aftermarket speedo. That was my original plan, since I had intentions of using an aftermarket ECU. However, it may be troublesome with the BMW ECU. In my M3, there are a couple of obvious speed related 'things' going on... speed sensitive stereo, speed sensitive wipers, and gear based rev limiter (which uses info from the VSS). Obviously the first two are irrelevant, but the third item would be affected if the pulse count was off by much. Also, I can only guess at all the EFI related variables BMW may influence with the VSS. It's not something I've researched and it may be nothing to care about, but I would look into it before pushing the ignore button.

-

You're aberrational

-

I have NEVER seen a return line sized larger than the feed line.

Have a look at some small block Chev's. I believe you'll find the LT1, LT4, and L98 run a 5/16" supply and 3/8" return. I'm betting you could find a few more GM vehicles with that scenario.

I forgot to mention that I'm also running their pump speed controller so the pump will be running 1/2 speed at idle and low load situations.

That should allow for a smaller return line.

-

Since the engine runs off individual coils, where do you connect the tach?

The Wolf ECU drives the tach. It's typical for aftermarket tach's to play nice with aftermarket ECU's.

-

Said through squinted eye's and fake accent... "yoo funy maaan".

-

I'd be shocked if RT didn't have an RT diff mount!

Guilty

-

Sorry Pete, I should have been a little more clear. I'm talking specifically about engine vibrations. Car parked, in neutral and rev'd through the range. My stock M3 with it's factory marshmallow mounts still transmits a minor amount of tingle. You really have to look for it to notice. However, with the Z and the poly mounts I was using, it's more noticeable, particularly in the rpm range where I spend the most amount of time with the car (cruise conditions). Wasn't bad, but I wanted better. The rubber did address that specific rev range pretty well (better than expected, actually), both while in neutral and while driving. If I never intended to 'commute' with this car, I would have left the poly, no question.

RE: Exhaust; I'm with you... the low rpm/light load drone is what takes all the enjoyment out of it. The resonator should help you. I got a huge improvement with the homebrew muffler, but I would like even more refinement. Kicking around idea's but I'm nowhere close to acting on any of them.

-

The M50/M52 shares the same architecture as the S52. Should fit the 'same' as my S52.

-

Oddman, The Motorsport motor is nice in NA trim, but not necessarily the holly grail in boosted form. Many FI enthusiasts prefer the non-M motors (M50, M52, etc.) and these are much more affordable. They share the same footprint (so, we know they fit) and a reliable 500HP is almost child's play.

-

Thanks Leon!

My stock headlights were not cutting it. Old wiring, old technology, and about 10K miles a year are driven at night, much of it in unlit rural areas with many critters large enough to turn and old Datsun into scrap. Tony D has been beating the drum for John at H4lights.com, so I gave him a call. Fun guy to talk to, and definitely knows a thing or two about lighting. John steered me to a special he is currently running... Bosch E-Code lenses with NARVA XB3 bulbs, $105.00 shipped, for the pair. Couldn't pass that one up. They are not in the same league as a high-end HID light, but they are more than decent. My daily driver is a '98 M3, and these do a respectable job of competing with the Bimmer. Great budget oriented option.

The shifter throws were too long for my preference and the integral rubber isolator was too... uh... rubbery. I want to feel the engagement of the gearset, not avoid it. I tore the lever apart, off'd the rubber bits, and shortened it. It shifts sooooo much nicer. Very crisp and direct. Enough so, that I will likely do something similar to my M.

The S52 has a slight buzz around 3000 RPM. It's shows up with this conversion and it's faintly there with my stock M3. Unfortunately that correlates directly with highway cruise speed. The poly mounts are not helping with this so I ordered/installed a set of heavy duty rubber mounts from Bimmerworld. I like 'em. They removed a good amount of tingle, but they are still rigid enough to keep the motor from moving around excessively.

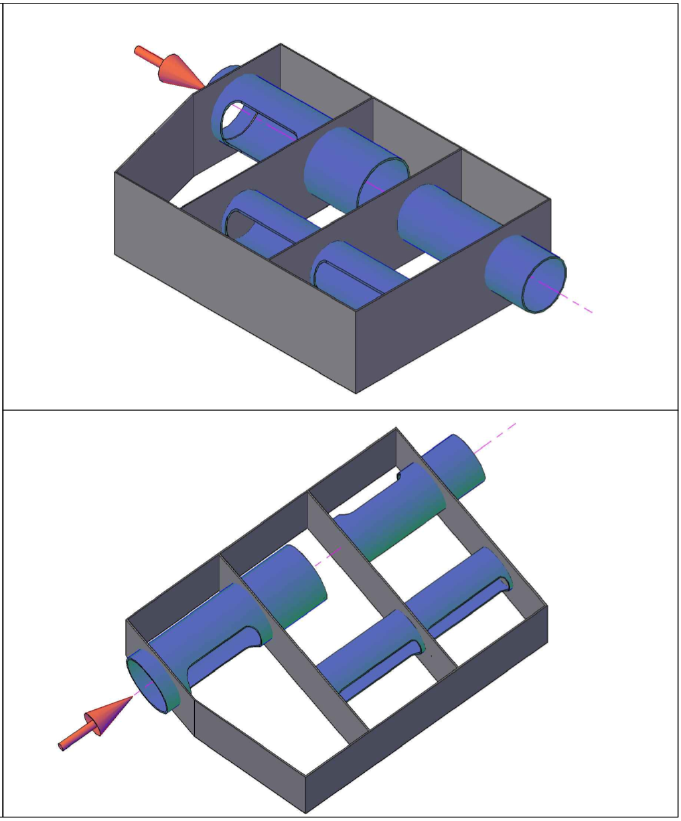

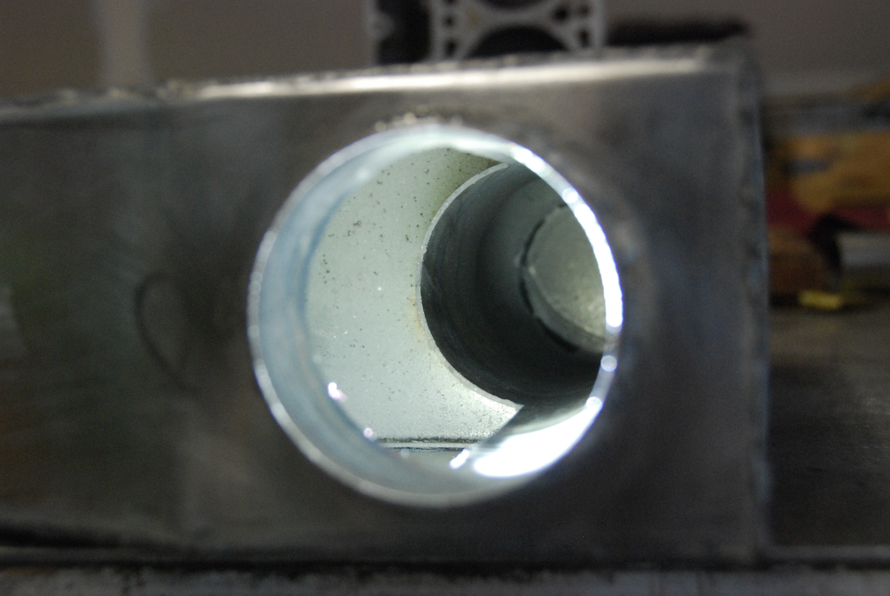

Another effort to help with civility, was an exhaust mod. Three Magnaflow's were not enough. The drone and drumming with ordinary driving was positively obnoxious. Long story short, I built a muffler to replace one of the Magnaflows. It is/was an experiment so I didn't make any effort to take progress pictures. I just wanted it done, ya know? I did model it up prior to fab and it's very close to the final result...

Not a fully inclusive answer but it did make the car significantly more livable. It's still plenty loud, but no longer intolerably so. I'm looking forward to tomorrow's commute, and this is the first time I've felt that way since this conversion.

I've got a failing half-shaft. It's been sniveling for a while now... 'prolly ought to see to it before I regret it.

Bmw M52 into 77 280z

in S30 Series - 240z, 260z, 280z

Posted

Thanks for starting a build thread!

I have a couple concerns about your driveshaft...

1) U-joints, when run at anything other than 0 degrees, accelerate and decelerate as they spin. Typically they are used in pairs and 'timed' to each other to cancel or balance each other out. If you use only one, it may prove tough to get control of vibrations.

2) When driveshaft parts are assembled, such as a trunnion for example, they are pressed in and welded. The press fit contributes GREATLY to the strength of the assembly. If you only 'slip' it together and rely on a simple weld, there's some likelihood of failure.

3) In every shaft I've ever encountered there has always been some method to allow the shaft to run at varying lengths. In other words, the motor and trans are normally allowed to move longitudinally under acceleration and braking, independently of the differential. It looks like your arrangement would bind them together. Not entirely certain of the consequences, but if you haven't given it some thought, you probably should