-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

What can I eliminate from my engine bay?

A lot... potentially.

This car still has A/C and power steering...

Every part/piece on your car serves a purpose. Before you start ripping and tearing, I would recommend trying to understand what it is you're trying to remove, relocate, or replace.

-

I'll second Jon's post. I've done it quite a bit for both personal projects and in industry.

As far as heat, the 140 should do fine with a S.S. 16ga. butt weld. My 130 struggles a little on fully lapped 16ga. S.S., though.

-

Ross, I've been using a 110v Millermatic 130 for about 15 years. It's been a great machine. It welds the heck out of .0625. It'll do a pretty decent job on very light gauge metals with .023 wire. For corner welds it does a fine job up through 10ga, providing you keep the duty cycle down around 50%. But, it won't do a proper structural weld on lapped 10ga. For that type of work a 220v machine is needed.

-

Ron, do you mean an aluminum driveshaft makes it better or worse? A Z driveshaft is so short the weight difference would be minimal, unlike my SX one.

Better. Much better. It's not about the weight.

-

1) The diff is offset laterally.

2) The angles that matter are the U-joint angles. They need to be equal to each other, and minimal.

3) Knowing the stock angles is not going to help you.

I've fought this very thing with V8 conversions. An aluminum driveshaft can make a tremendous difference.

-

-

Peej,

You were right, pulling the numbers from a fully assembled car is a little challenging.

I took the measurement as follows:

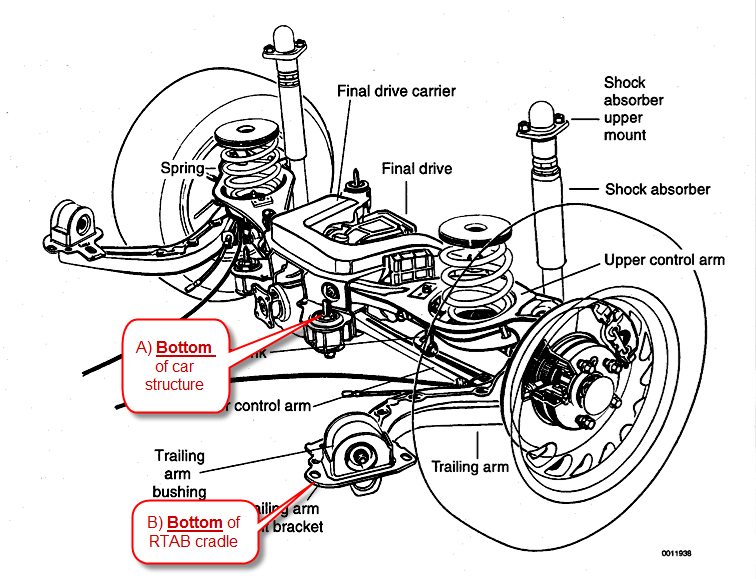

Point A... At the front mount of the sub-frame at the bottom of the cars structure.

Point B... At the bottom side of the RTAB cradle. There are too many layers of metal to get a good measurement at the mounting surface of the cradle without taking things apart. Aside from the bolt heads, the bottom is flat and ‘clean’.

The result is: Point B is 15/16†lower than point A, +/- 1/8â€

-

peej, I've got a '98 M3. Let me know specifically what measurements you're looking for and I'll try to round them up for you.

-

I merged your two build threads.

Thanks for the update. Keep them coming!

-

-

ratsun.net has a few listed in their classifieds.

-

Last set of motor mounts have been sold.

Thanks guy's.

-

zentech,

If you're going to cruise other members wanted ad's, take your correspondence off line.

-

FOR SALE

I finished up all four sets. Three are spoken for and shipped. I have one set left...

First $150 in my Paypal account takes them. Shipping is included in the US. If outside the US, PM me and I'll get you a quote.

P.S. The black paint is a very light coating just to protect them until you're ready to install. It will remove quite easily.

-

Looks like you got the 6bolt CV flange on the diff flange. Most 95 M3s had the black sheep diff with the CV joint at the rear of the driveshaft. Any other year of the e36M3 will have the same case, but with a 4 bolt flange.

As you mentioned, the '95 M3 diff I have came with a CV. It was a manual coupe. My '98 M3 coupe w/manual trans came with a U-joint. BRAAP's '97 M3 sedan w/manual came with a CV. Another friends '98 M3 w/automatic has a U-joint. To be honest I haven't figured out the pattern, but I can't say I've tried, either. If you have the magic decoder ring, don't be bashful

Are you going to keep producing those mounts?

I don't have any plans to keep making them.

If so how much are you selling them for?See next post.

I've always thought a boosted s52 would be an awesome swap.You and I think alike

-

I apologize for sounding d**k-ish, but I don't find those links very convincing. I have a little more faith in something like this...

-

...and weight a bit more than 1/2 what the L28 does, doe to the alluminum alloys.

Please don't do that. Just because it's aluminum doesn't automatically mean it's 'weightless'. If you want to post claims of this nature, we ask you to provide some back-up for the statement.

-

4G63 and I'm moving the battey and cooling system to the rear of the car

If you wouldn't mind terribly, I'd like to know the overall height of that motor. From the bottom of the pan to the top of the timing gear, please?

-

The "book" is this forum. Help yourself to the search engine or start reading the FAQ's and Members Projects subforum. It'll keep you busy for a LONG time.

-

It isn't hard. LT1 w/T56, driver in the seat and half tank of fuel, winds up at about 51% rear.

-

Glad I could help.

-

I've built another set of mounts for one of our members...

I have 3 more sets laser cut and formed. Just need to weld them up. 1 set is for another HZ member. The other two will go up for sale here.

-

Jeep.

-

Must... buy... Miata...

...And hybridize it. Don't settle for hauling it home... when you can haul it home fast

What can I eliminate from my engine bay?

in Nissan L6 Forum

Posted

Gold star for you. Yes, there is life beyond the internet. People have been doing this stuff long before forums were readily available. We bought books and read them. A used FSM will cost less than a tank of fuel and be an invaluable source of information for as long as you own your Z.

It depends on your skills/experience. For some people here it’s a walk in the park. For others, not so easy. I’d say, if you’ve never done anything like it or much EFI work, it will probably be a bit of a challenge. Pretty much all modern aftermarket EFI packages are capable of a multi-coil system and they’re all just a little different. Find a local EMS dealer and see what system he recommends and talk to him about your ignition choices. A good dealer will be happy to help you understand what ‘his’ system will require.