-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

Each search engine has its own idiosyncrasies. For example, I use Google's Alerts to track news for my work, and I've found that I need to create alerts using both the singular and plural forms. For example, "biometric" and "biometrics" return different results. Given Google's search engine, which many would argue is one of the best, treats them differently, I'm not surprised that this search engine treats a dash differently from no dash.

-

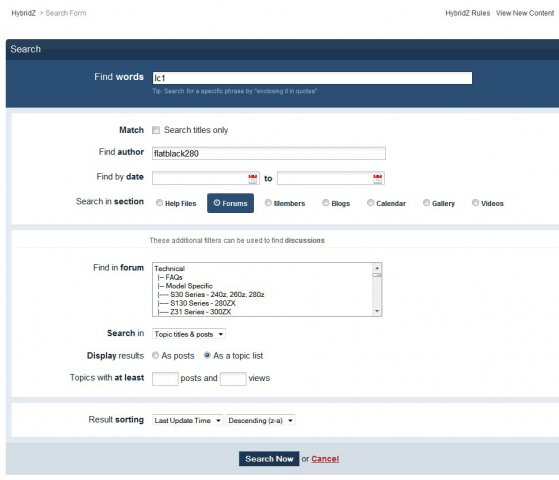

flatblack280z, do me a favor and try searching again. Just to be sure you and I are doing the same thing, click the gear on the upper right corner next to the search box. Then use "LC1" (without quotes) in the find words field, and your name in the author field. Then make sure to click the forums button (mine continually defaults to help) AND make sure none of the forums are selected in the box below. Screenshot attached. When I do that, I find 2 threads of yours with LC1 in them.

-

Jon, I think you are saying the same thing as Flatblack280z: that the non-vented toyota 4x4 calipers can use the same hoses as the stock calipers. My first comment probably caused the confusion when I assumed (mistakenly) that the non-vented calipers used the same fittings as the vented. My mistake, and again, sorry for the confusion.

-

http://www.tweakit.net/shop/product_info.php?cPath=57_40_29&products_id=126&osCsid=3s8sovcm89a1iao8ulo0v8ec40 I know you said you wanted to buy in the US, but I couldn't find one either so bought this from Australia. I had it week after I placed the order online. Double check the nipples will be big enough for your next build - my power goals are more modest than yours I'm still running an airtex low pressure pump to fill it. It was rated 2-3 psi from when I ran triple webers. I'm sure you could go with something in the 3-6 psi range if it was easier to source.

-

He is saying that those two wires go to the loop on the back of the tach. Normally the loop is in series (spliced into the circuit) that controls current through the coil. The MSD box takes over supplying power to the coil so something has to replace that function in order to get the tach to work. The MSD tach adapter is doing that, hence the need to connect it to the wires that used to be attached to the coil. BTW, there's no need for the resistor on the fender any more. Simplest thing is to just use some #16 wire and the appropriate connectors to create a jumper across it.

-

This was not my post so take what I'm suggesting with a grain of salt, but I think this section below is referring to the wires near the coil under the hood on the driver side fender: I don't think you want to be doing anything with the coil on the back of the tach. It's been years since my car's ignition was stock, but I'm pretty sure the black/white and green/white wires were originally connected to the two terminals of the coil. You probably removed them when you installed the MSD ignition box?

-

The inductive loop is the white wire that is looped on the right side in these pictures. There should be a screw/clamp holding the looped part to the back of the tach IIRC.

-

The tach's inductive loop is on the back of the tach. The loop's wires both go into the 4 pin connector. Post a picture and I can help you pick them out.

-

I think you'll get a lot of people recommending a Walbro GSL392. It's rated 255 l/h which I think will get you to 400 whp or so. (I'm going from memory so you might want to go to one of the power calculator websites and see how much fuel is required to get to that level.) I've run up to 18 psi with it and it had no trouble keeping up. It's as little as $110 or so online. Do get it with the installation kit which includes a foam rubber sleeve and 2 straps to keep the noise out of the cabin. I bought mine with the kit from http://www.injectedperformance.com/ for $107 shipped.

-

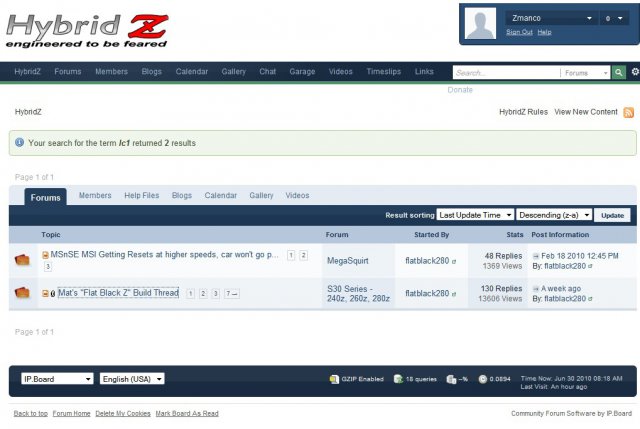

Hmmm, when I tried it, I found 2 threads with the term "lc1" by "flatblack280". Check out the screenshot I attached.

-

An EDIS coil pack for our L6 actually has 3 coils in it. Each coil fires 2 plugs which are matched to the pairs of pistons that move in sync. Stony is correct that each pair is fired at the same time for simplicity, but only one cylinder will have any air/fuel and hence make power. The other is wasted. To the OP, I would double and triple check that you have the plug wires attached correctly. From what you describe, that's most likely culprit.

-

Try using advanced search (click the gear to the right of the magnifying glass upper right). Enter the user's name and search terms. Make sure to select "Forums" as mine was defaulting to "Help". I found 2 threads searching "LC1" authored by you.

-

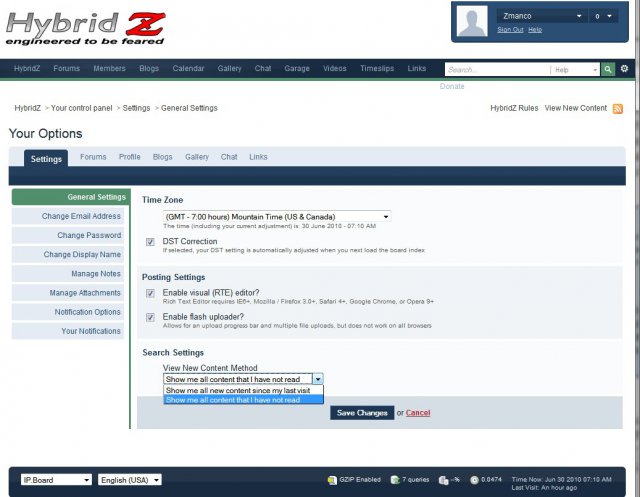

It used to be that when I clicked the "view new content" link at the top right that I would see all the new posts I hadn't yet read. A while ago it changed and I now only see what's new since the last time I was on the site. The problem is that if I come to the site to check something and then leave, it effectively marks EVERYTHING as "not new" and unless I go through each forum separately, I never see those posts as "new". I've gone through the settings and this screenshot suggests that maybe the "View New Content Method" is broken? I've tried both settings but nothing changes.

-

Short answer: without knowing what you're planning, the answer is "no" there isn't a checklist. Longer answer: there are probably an infinite number of permutations for putting a turbo motor into a 240z. At one extreme you start with a 280zx turbo donor car and literally just take parts off of it and put them into the 240. At the other extreme you can build up a full custom L28 (or bigger) that doesn't use anything from the factory turbo. In my case all I used was the block with the crank and pistons, intake manifold, drive shaft and half shafts. Everything else was from something else. So it's probably impossible to create a checklist that could address all these combinations. I will suggest that you do 2 things: 1) decide what your build plan will be. What block/head/cam/pistons/intake manifold/turbo/intercooler/radiator/oil pump+cooler/exhaust/transmission/driveshaft/halfshafts/differential/LSD do you plan to use? 2) decide which ECU/injectors/fuel rail/fuel pump/gas tank/surge tank (if necessary)/fuel lines you plan to use. There are quite a few build threads on this site that should give you some good ideas of how to plan it for your specific goals. I didn't measure it, but I'll bet I spent at least 100 hours reading on this site before I picked up the first tool to start my swap. It's not rocket science if you do your homework. BTW, in case you didn't pick up on it, there's your checklist Anyone else have something to add?

-

Megasquirt fan control using the fast idle relay on relay board

Zmanco replied to jacob80's topic in MegaSquirt

jabob80, I'm afraid I don't have time to look all this up to check it out. I rarely remember pin numbers, rather I follow the wiring on the schematics to see what pins on the MS board lead to the DB connectors and relay board. Use these two schematics I'm attaching (I saved them from the MS site) to trace the wires and I'm sure you'll be able to answer the question yourself. megasquirt_ShemV3.00.pdf mspower_ShemV1.2.pdf -

I'll add that including shipping and resurfacing a set of rockers, the entire Delta Cams upgrade was around $150 IIRC. If you choose a grind that keeps the lift near stock (less than .450" IIRC) then you can keep the stock springs and valve seals too. I can't think of an upgrade with more bang for the buck than that. Just remembered you said you need the car as a daily driver so I imagine you couldn't send your main cam to them. Perhaps they have one you can swap with yours as a core, or you can pick one up on hybridz cheap? I'd call them before you get too far along keeping it stock.

-

If the real issue is weeping out the side of the HG, then maybe you should try a different gasket. I had this issue consistently with 2 different heads on an N42 block. The block was checked for flatness before I rebuilt it. And at various times both heads were checked and shaved .0005" IIRC as a clean up. Yet it still wept on the passenger side during track days. I've always run Felpro HG and some say that's just the way those are. If the factory HG was easier/cheaper to get, I'd try that. BTW, I have a P90 that I shaved and I'll suggest something in the middle that picks up on some of what both Tony and Jon say. The cost to shave and shim the head was in hind sight, not worth it. But it's rather cheap and easy to put a reground cam in while you have the head off. I used a Delta Cams regrind of a stock L28 cam (don't remember which one) that makes great power from 3500 to 6500 and still idles great. Plus, with the lower compression you can be sure to run full advance without detonation, something that's iffy with a CR in the 10:1 range, especially on hot days. Put your money and time into cleaning up the P79, add a reground (Delta or Isky), and slap that on and I think you'll find yourself with a potent and reliable motor Try a factory HG while you're at it as they seem to be less susceptible to weep with a straight head and block.

-

Just to clear things up, I have two sets of three injectors. Each set of injectors is wired in parallel. If 6 ohms is the proper resistance for each injector by itself, then when all three are wired in parallel, the proper resistance is 2 ohms. Unfortunately I was not able to find 2 ohm resistors with enough power dissipation, hence I created one by wiring three 6 ohm resistors in parallel. Hope that helps. Indeed, there are better approaches. I've been watching the development of MS3 and will probably at some point just swap to it. But for now, it's getting hard just from a packaging point of view, to add any more boards/modules as I'm running out of space on the mounting board under the passenger seat. I didn't see how far this project was going to go, so didn't make the best use of space. For example, I just ordered a KnockSense knock sensor module which I need to install as well. Plus, right now at least, I don't have any problems with idle quality even with these 440cc injectors. In other words, at least right now, it ain't broken I ran out of time last weekend and won't be back home until this weekend. If things go really well I'll get it up and running on Saturday morning and have some time to tune and shake it down before a track day on Sunday. That would let me confirm that the intermittent problem is indeed solved. Unfortunately I am not able to recreate it on the street.

-

You're correct, my mistake, I forgot that the FPR is AFTER the injectors on the Z.

-

I can't see how the filter would cause the pressure to be too high, but nonetheless, I wouldn't want a low pressure filter in a FI car. leaking fuel = bad things happening If the other FPR doesn't solve it, you might want to temporarily install the pressure gauge before the FPR to see what the outlet pressure of the walbro is.

-

Strange, I'm running with the stock FPR and a walbro 255 and the FPR doesn't have any problem maintaining pressure. Have you double checked that the vacuum line to the regulator is still intact? I don't know what the max input pressure is for the FPR, but it's hard to imagine that the walbro is exceeding that, unless the FPR is defective. Do you have a spare FPR you can swap in?

-

If the idle is jumping between 800 and 1500 I wonder if you have something else wrong - perhaps a vacuum leak? That doesn't sound like something due to MS given you're not letting it control an IAC. Also, what do you mean by " and when i hit the gas it acts like it hits a rev limiter"? If you haven't already done this, try out TunerStudio for tuning instead of megatune. It has an autotune feature called VE Analyze that really works well. Of course, you need to get your timing and AFR tables squared away. Then just drive. It's not perfect, but it's the best I've seen so far for MS. My setup is different enough from yours that I don't think my msq would do you any good, especially since I'm running MS2/Extra.